Jul 05 Issue H

XDS Dry Pump

INTRODUCTION

3

PAGE

3

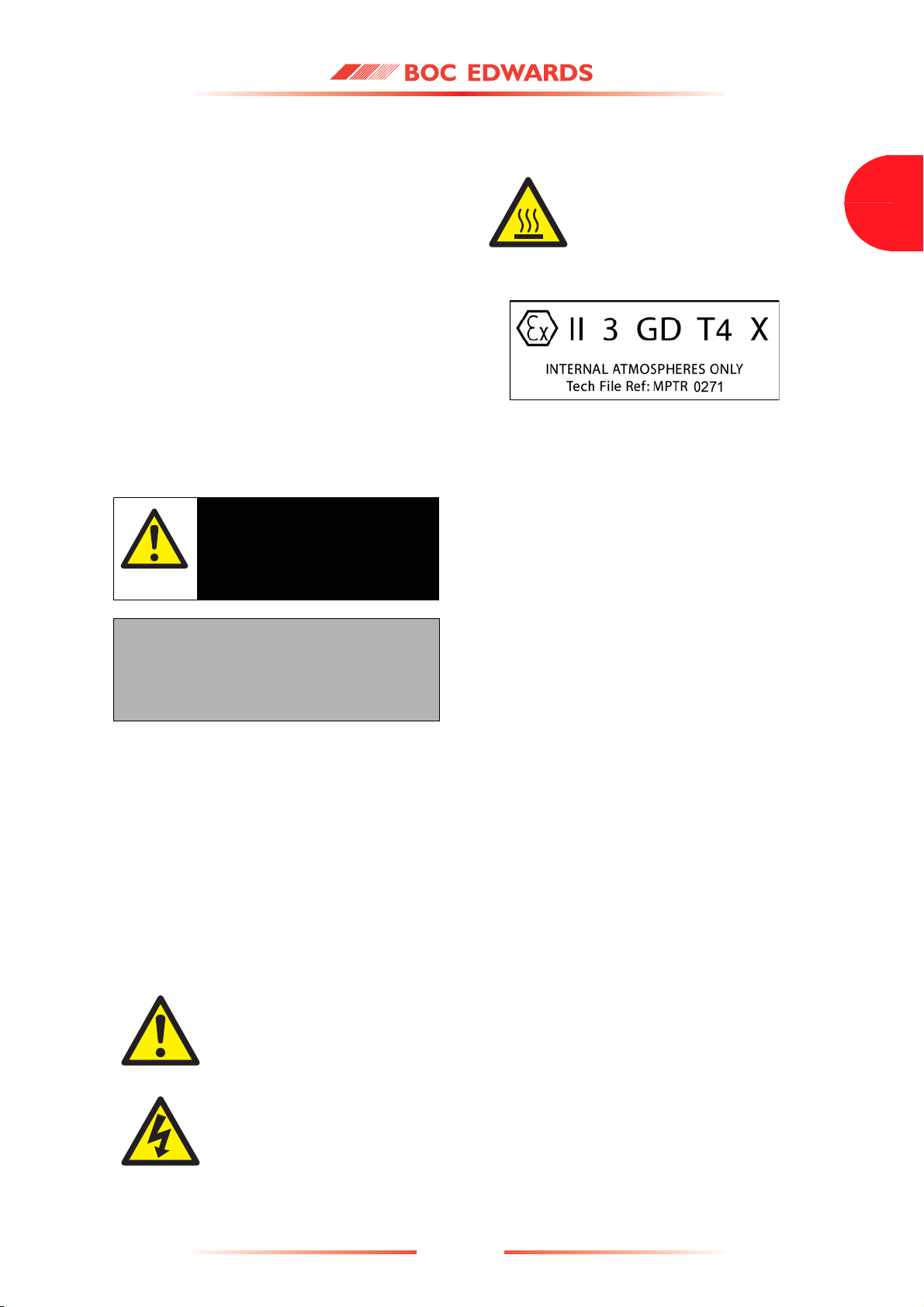

• When flammable or pyrophoric materials are

present within the equipment you must:

• Not allow air to enter the equipment.

• Ensure the system is leak tight.

• Use an inert gas purge (for example, a

nitrogen purge) to dilute any flammable

gases or vapours entering the pump inlet,

and/or use an inert gas purge to reduce the

concentration of flammable gases or

vapours in the pump and in the exhaust

pipeline to less than one quarter of the

gases' published Lower Explosive Limits

(LEL).

For further information, please refer to the back

page of this instruction manual for the contact de-

tails of your nearest BOC Edwards.

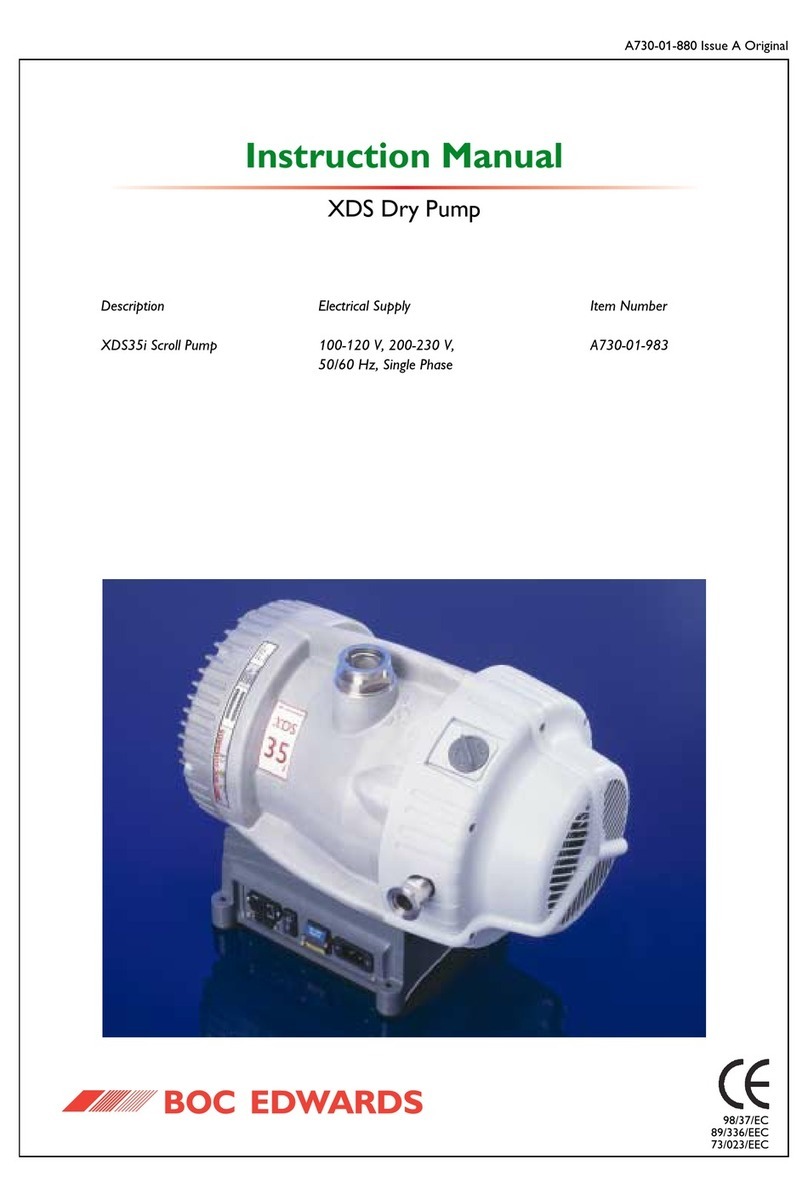

1.3 Description

The XDS pump is shown in Figure 1. Refer to

Figure 1 for item numbers in brackets in the

following descriptions.

The XDS pump is a compact, reliable vacuum pump

which is suitable for use on vapour handling

processes. The XDS pump may be used for some

pumping applications involving corrosive substances

and particulates; for information

on pumping flammable gases, please

refer to Section 4.5 and contact BOC Edwards for

any further assistance.

The body of the pump includes a fixed scroll and an

orbiting scroll. The orbiting scroll is driven by the

electric motor through an eccentric cam on the

motor drive shaft. The movement of the orbiting

scroll, meshed with the fixed scroll, forms

successive crescent shaped volumes in the pump.

Gas which enters the pump through the inlet is

compressed by the movement of the orbiting scroll

and swept towards the centre of the fixed scroll.

The compressed gas enters the exhaust port near

the centre of the stationary scroll and is exhausted

from the pump through the outlet.

The XDS pump is a dry vacuum pump, as all the

bearings, with their hydrocarbon lubricant, are

isolated from the vacuum space.

The inlet of the pump is fitted with a removable inlet

strainer which prevents the entry of debris into the

pump.

The pump mechanism is driven directly by a single-

phase or three-phase electric motor. Single-phase

motors are fitted with an on/off switch (7) and a

thermal overload device. When the motor is too

hot, the thermal overload device switches off the

pump. The thermal overload device has an

automatic reset; when the motor cools down, the

device resets and (unless you have incorporated

suitable control equipment which must be manually

reset), the motor will restart.

The pump is air-cooled by a fan mounted at the

opposite end to the motor.

The pump is mounted on a baseplate on rubber feet.

Details of suitable vibration isolators and other

accessories are provided in Section 7.

1.4 Gas-ballast control

To pump high vapour loads, gas-ballast is delivered

into the pump to prevent condensation of the

vapour carried by the pumped gases.

Air can be introduced to the low vacuum stages

through the gas-ballast valve. Alternatively, an inert

gas such as nitrogen can be supplied through a

suitable external valve.

The gas-ballast control has three-positions:

• Closed (position '0')

• Low flow (position 'I')

• High flow (position 'II')