Issue J Jun 03

PAGE

2

E2M28 and E2M30 Rotary Vacuum Pumps

INTRODUCTION

2

• When flammable or pyrophoric materials are

present within the equipment you must:

• Not allow air to enter the equipment.

• Ensure that the system is leak tight.

• Use an inert gas purge (for example, a

nitrogen purge) to dilute any flammable gases

or vapours entering the pump inlet, and/or

use an inert gas purge to reduce the

concentration of flammable gases or vapours

in the pump and in the exhaust pipeline to less

than one quarter of the gases' published lower

explosive limits (LEL).

• For further information, please contact BOC

Edwards: refer to the Addresses page at the end

of this manual for details of your nearest BOC

Edwards company.

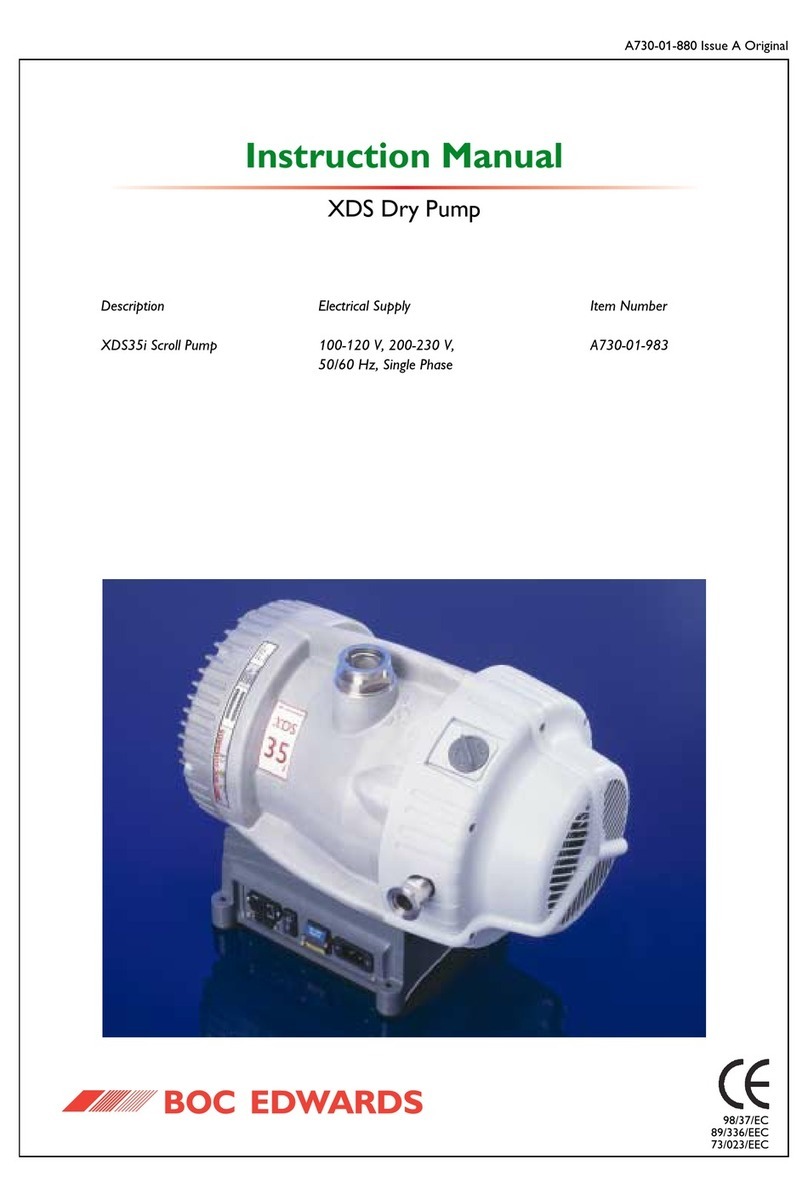

1.3 Description

The BOC Edwards E2M28 and E2M30 pumps are

shown in Figure 1. Refer to Figure 1 for item

numbers in brackets in the following descriptions.

The E2M28 and E2M30 pumps are two-stage, direct

drive, sliding vane pumps. The pump is oil-sealed and

designed for reliable, long-term operation in both

laboratory and industrial environments. The pump is

a free-standing unit. The drive is provided through a

flexible coupling by a single-phase or three-phase

(four pole) motor.

The motors are totally enclosed and are cooled by

the motor-cooling fan which directs air along the

motor fins.

The single-phase motors have a thermal overload

device. When the motor is too hot, the thermal

overload device switches off the pump. The thermal

overload device has an automatic reset; when the

motor cools down, the device resets and the motor

will restart. The single phase motors have an on/off

switch.

An oil pressure system lubricates the pump shaft

bearing surfaces and rotor sealing faces. The pump

has an oil distribution valve which prevents

discharge of oil to the pump interior (suckback)

after the pump stops. The pumping chambers are

air-tight, so this arrangement prevents air suckback

unless the gas-ballast valve is open. For protection in

this case, refer to Section 1.4.

You can inspect the level and condition of oil in the

oil box reservoir through the oil sight-glass (12). An

oil filler-plug (1) is fitted to the top of the oil box.

The pump has an oil drain-plug (11) to allow gravity

oil drain.

The pump has an inlet-port (6), outlet nozzle (2) and

gas-ballast control (3). The pump is mounted on an

aluminium alloy baseplate (10) on rubber pads.

Details of suitable vibration isolators and other

recommended accessories are given in Section 7.3.

1.4 Gas-ballast

To pump high vapour loads, gas-ballast is delivered

into the pump to prevent condensation of the

vapour carried by the pumped gases.

Air (or another gas) can be introduced into the low

vacuum stage through the gas-ballast control. The

gas-ballast control is a multi-turn valve which you

can adjust, as required, between closed and fully

open.