Bochem Instrumente Lift 240 User manual

@LABORBEDA

BOCHEN®

LAB SUPPLY

Operating manual

Lift 240

®

Save for future use!

LAB SUPPLY

Revision

Date Version Chapter Reason Responsible

06.08.2011 00.01 All New version M. Schreieck

Operating manual

Lift 240

(Serial number) Page 2 of 27

Index

Operating manual (Serial number) Page 3 of 27

Lift 240

Content

1General information.................................................................5

1.1 Delivery scope and responsibilities..........................................5

2Safety........................................................................................6

2.1 Intended Use............................................................................6

2.2 Safety signs..............................................................................6

2.2.1 Structure of safety information.................................................6

2.2.2 Safety signs and their importance............................................7

2.2.3 Icons used in the document.....................................................7

2.3 Safety instructions....................................................................8

2.4 Safety concept .......................................................................10

2.4.1 General information................................................................10

2.5 Residual risks.........................................................................10

2.6 Staff requirements, due diligence...........................................10

2.6.1 General information................................................................10

2.6.2 Due diligence .........................................................................11

2.6.3 Training..................................................................................11

2.7 In an emergency ....................................................................11

3Specifications.........................................................................12

4Machine description ..............................................................13

4.1 Function description...............................................................14

5Transport ................................................................................15

6Installation and startup .........................................................16

6.1 Assembly................................................................................16

6.1.1 Safety instructions for the installation.....................................16

6.1.2 Procedure...............................................................................16

6.2 Startup....................................................................................17

6.3 Coordination for the radio frequency......................................17

6.4 Setting the end stop...............................................................18

7Operation................................................................................19

7.1 Safety instructions for the operation.......................................19

7.2 Switching on and off...............................................................20

8Fault diagnosis.......................................................................21

9Maintenance ...........................................................................22

9.1 Safety instructions for maintenance and repair......................22

9.2 Battery replacement...............................................................23

Index

Operating manual (Serial number) Page 4 of 27

Lift 240

10 Dismantling and disposal .....................................................24

10.1 Removal.................................................................................24

10.2 Storage...................................................................................24

10.3 Disposal .................................................................................24

11 Annex......................................................................................26

11.1 Applicable documents............................................................26

12 Warranty deed........................................................................27

Figures

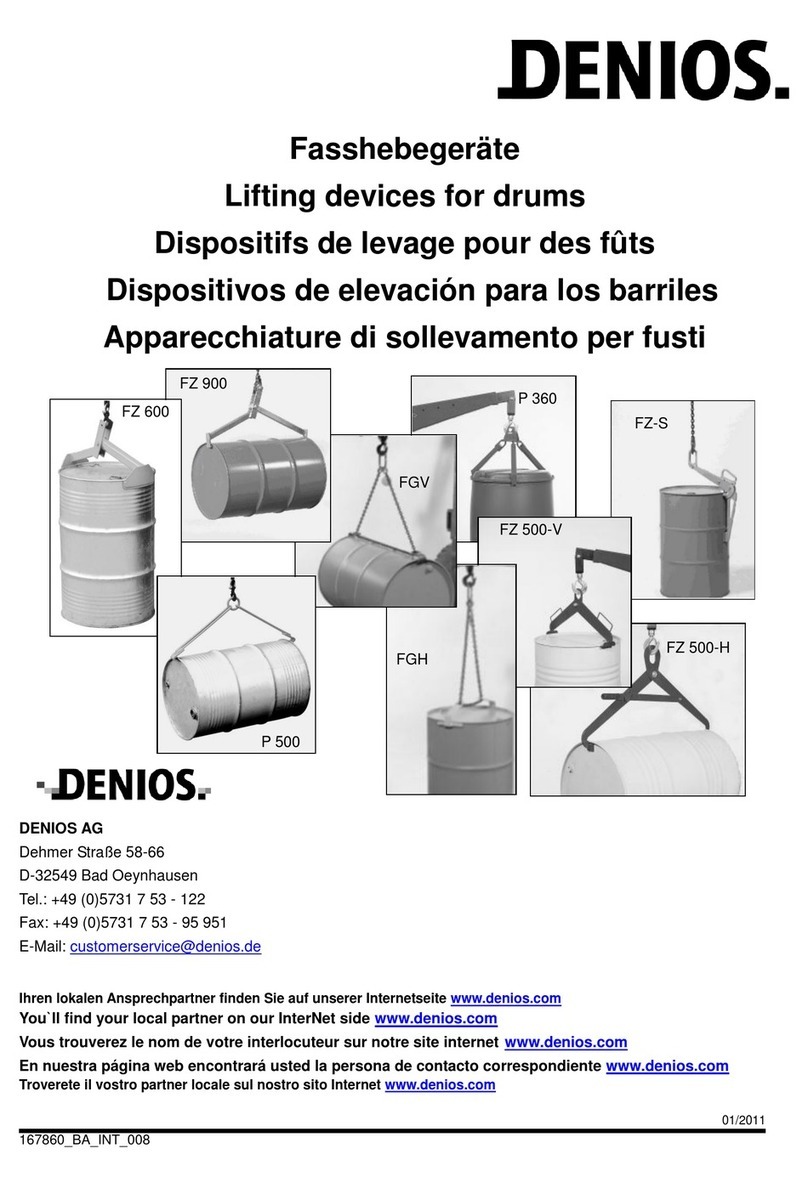

Figure. 1 Delivery scope...................................................................5

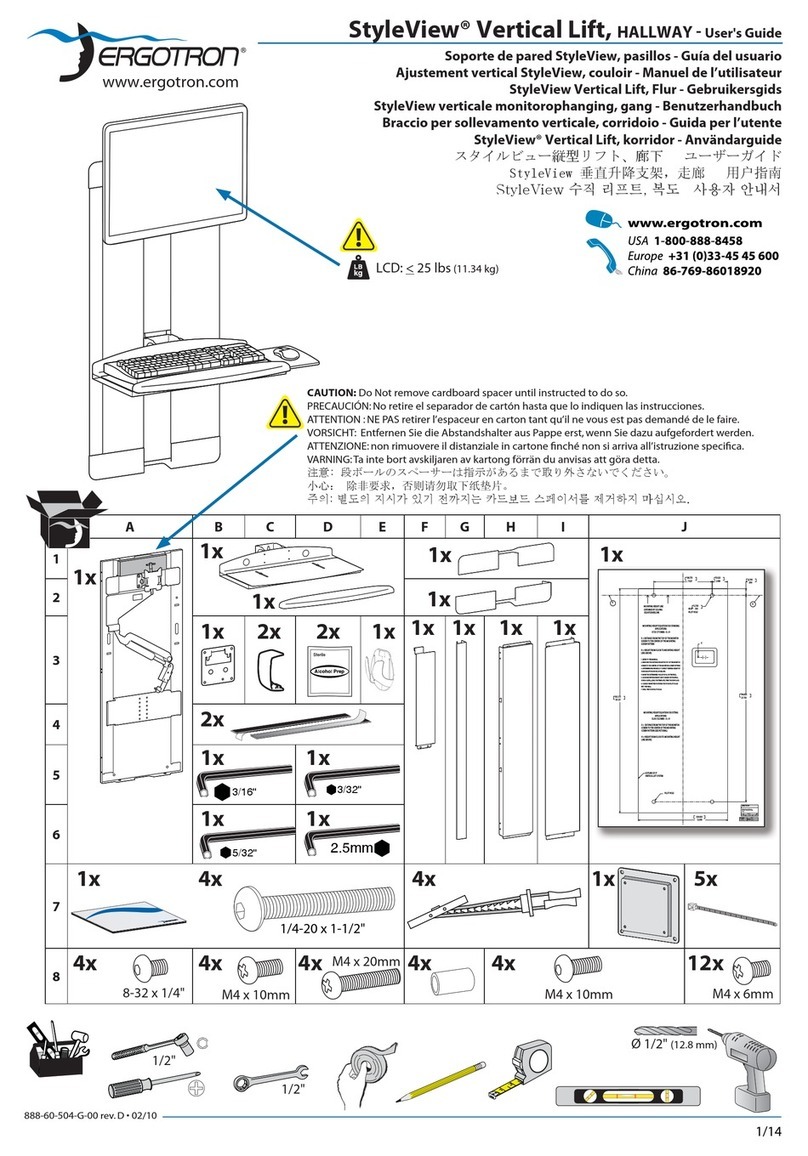

Figure. 2 View ................................................................................13

Figure. 3 Setting the end stop........................................................18

General information

Operating manual (Serial number) Page 5 of 27

Lift 240

1 General information

1.1 Delivery scope and responsibilities

The electric hoist "Lift 240" was developed and built by Bochem

Instrumente GmbH.

Technical changes based on new research and technologies are

made without prior notice.

Subsequent changes by the operator are not the responsibility of the

manufacturer.

Warranty

The warranty is governed by the laws of the Federal Republic of

Germany.

The delivery scope includes:

Figure. 1 Delivery scope

•Electric hoist "Lift 240"

•Wireless remote control

•Power supply

•Operating manual

•Replacement battery

Safety

Operating manual (Serial number) Page 6 of 27

Lift 240

2 Safety

2.1 Intended Use

The wireless-controlled electric scissor lift table Lift 240 is used to lift

laboratory equipment and devices.

The application range of the lift table is the area of industry and

research within buildings.

The lifting table is movable, i.e. not intended for a permanent

installation.

It is intended for the connection to a public power supply network.

Improper use is the lifting of objects that exceed the maximum

allowable weight.

The device must not be used in hazardous areas!

2.2 Safety signs

2.2.1 Structure of safety information

The following signal words are used in this document in conjunction

with safety signs to illustrate possible dangers.

Danger!

Death or serious bodily injuries will occur, if the respective

precautionary measures are not taken.

Warning!

Death or serious bodily injuries can occur, if the respective

precautionary measures are not taken.

Caution!

Minor bodily injuries can occur, if the appropriate precautionary

measures are not taken.

Attention!

Property damages can occur, if the appropriate precautionary

measures are not taken.

Information

Here you receive information and instructions to perform the

following tasks effectively and safely.

Safety

Operating manual (Serial number) Page 7 of 27

Lift 240

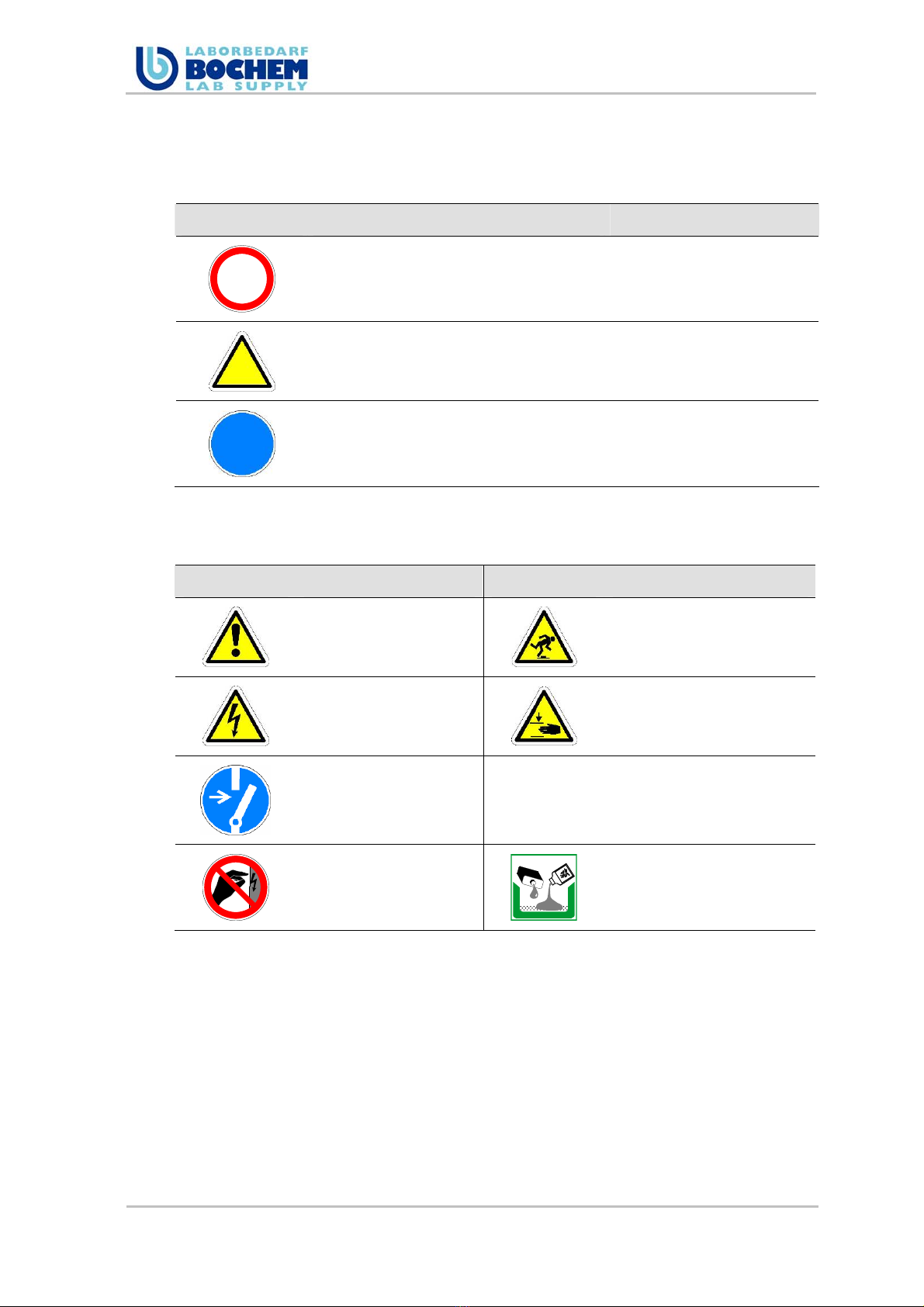

2.2.2 Safety signs and their importance

The importance of safety signs is indicated by shapes and colors.

Shape Color Importance

Safety color red

Contrast color white Prohibition

Safety color yellow

Contrast color black Warning

Safety color blue

Contrast color white Order

2.2.3 Icons used in the document

Icon Importance Icon Importance

Warning of a hazardous

area or situation Warning against a tripping

risk

Warning against

dangerous electrical

voltage

Warning against hand

injuries

Disconnect prior to

performing work

Do not touch, live parts Information for disposing of

substances

Safety

Operating manual (Serial number) Page 8 of 27

Lift 240

2.3 Safety instructions

Prerequisite for the safe use and trouble-free operation of the lift table

is the knowledge of the basic safety instructions and occupational

safety regulations.

This operating manual contains all the necessary information to

operate the machine safely.

The internal health and safety regulations must be observed.

Warning!

Ignoring the operating instructions can cause personal injuries and

equipment failures.

>The operating manual, especially the safety instructions must be

read and applied by every person who works with the lift table.

>Only change parameters and settings after carefully reading the

operating manual.

Danger!

Danger to life by touching live parts.

•Work on the electrical equipment must only be carried out by

authorized trained personnel.

•Faulty connections or settings can result in damages.

•The device may only be operated with the supplied cables and

wires.

•Do not perform work on energized parts.

•Replace damaged cables immediately. Attach loose connections.

Carry out work only after disconnecting the power supply (pulling

the plug).

•Cables may not be pinched or crimped. Cables must be routed

so that they will not form tripping hazards or can be damaged. Do

not place anything on the cables and connections.

Risk of explosions

•The lift table cannot be used in areas at risk of explosions!

Warning!

Risk of injuries by smashing laboratory equipment and released

chemicals, material and functional damage!

•Observe the correct adjustment of the height limit

•Keep the lift table in view during the process

Safety

Operating manual (Serial number) Page 9 of 27

Lift 240

Warning!

Risk of crushing the hands between the lift table scissors!

•Do not operate the lift table without bellows

•replace defective bellows

(contact the manufacturer)

Warning!

Risk of tripping!

>Make sure that no loose cables or objects are located on the floor

in the work area.

>Place the device and the connections so that no one steps on it,

or drives or stumbles over it.

Attention!

Material and functional damage!

•The device may not be doused with liquids, sprayed with water or

be exposed to rain!

•Verify the stability when transporting and at the initial startup.

Safety

Operating manual (Serial number) Page 10 of 27

Lift 240

2.4 Safety concept

2.4.1 General information

Protection is the objective:

•of the operator against injuries,

•the lift table against damages and standstills,

•the environment against dangers.

The following protective measures were applied in reference to a risk

analysis:

•12 V power supply for the drive unit to protect against electrical

shock.

•Bellows over scissor rods and drive unit

•mechanical height limitation

•Battery-powered wireless remote control

•Flare signals as a status indicator,

•Safety instructions on the device and in the operating instructions.

2.5 Residual risks

The rated loads of max. 25 kg may not be exceeded.

Note

Observe all

•warnings and safety instructions,

•other markings, such as transportation devices attached o the

device.

2.6 Staff requirements, due diligence

2.6.1 General information

Never allow personnel under the influence of response-reducing

substances or is incapable of operating the machine based on health

reason to operate the device.

Note

The operating instructions must always be available at the location of

the device. The location must be known to employees.

Safety

Operating manual (Serial number) Page 11 of 27

Lift 240

2.6.2 Due diligence

Personnel must:

•have read and understood the operating instructions

•be trained in the operation of the equipment

•know how to perform individual jobs

•be medically able to use the device

2.6.3 Training

Work on the machine may be performed by reliable and trained

personnel.

Maintenance work may be performed by professionals who due to

their specialized training, knowledge, experience and knowledge of

the relevant provisions assess the work assigned to them, identify

potential hazards and can take necessary measures to reduce

accident hazards.

2.7 In an emergency

Note the following points:

•Locations of first aid stations must be known.

•Personnel must be informed of their response in an emergency.

•The proper response should be checked regularly and recorded

accordingly.

Specifications

Operating manual (Serial number) Page 12 of 27

Lift 240

3 Specifications

Measurements

Dimensions

(retracted) L x W x H 240 x 240 x 120 mm

Footprint: 260 x 260 mm

Max. height 300 mm

Work area (space requirement) 240 x 240 mm

Weight 6 kg

Performance data

Traversing speed 480 mm/min

Min to max 320 mm/min

Traversing distance of scissors

max. 180 mm

Load capacity max. 25 kg

Motor data

Rated torque 5 Nm

Idle speed 70 rpm

Tightening torque 56 Nm

Transmission ratio 69:1

Protection type IP 24

Energy supply

Power consumption 12,000 mA

Supply voltage of transformer 100 - 240 VAC, 50/60 Hz

Power output 24 V

Battery remote control 3 V, lithium cell CR2430

Environmental conditions

Approved ambient temperature 5 °C to 45 °C

Noise emissions < 40 dB (A)

Material

Work area 18/10 steel

Housing 18/10 steel

Bellows PTFE

Machine description

Operating manual (Serial number) Page 13 of 27

Lift 240

4 Machine description

Figure. 2 View

Item Designation

1 Lift platform

2 Bellows (covers electric motor and lift mechanics)

3 Base

4 ON / OFF switch

5 LED ready, UP / DOWN

6 Knurled nut, adjustable end stop

7 AC adapter connector on the back

8 Power supply

9 Remote control

4

1

5

2

3

6

8

9

7

Machine description

Operating manual (Serial number) Page 14 of 27

Lift 240

4.1 Function description

The lift table Lift 240 is used for leveling laboratory equipment (e.g.

glasses, flasks, Bunsen burners, etc.) when conducting scientific

procedures such as in a chemistry lab.

The scissor lift of the table device is powered by a 24V electric motor

with worm gear.

A laboratory unit placed on the lifting platform can be continuously

lifted by remote control or lowered.

The maximum lifting height may be limited by an adjusting wheel

fixation (see Section 0).

The remote control allows the of operating multiple lift tables via a

display selection. Each lift table must first be taught to its control

frequency (see Section 0).

The remote control has a power saving mode and is activated by

pressing the red button.

Transport

Operating manual (Serial number) Page 15 of 27

Lift 240

5 Transport

The lift table is secured in its packaging against damages during

transport.

Do not lift the lift table during transport by the lifting platform or

bellows. The bellows could be damaged. Hold the lift table by the

base during transport.

Attention!

Material damage and risk of injuries!

•Work carefully - hands and feet can be crushed

•When transporting the lift table, secure it against falling and

crashing.

•Secure loose equipment parts before transporting against falling.

Installation and startup

Operating manual (Serial number) Page 16 of 27

Lift 240

6 Installation and startup

6.1 Assembly

6.1.1 Safety instructions for the installation

Attention!

Damage to the machine!

•Maintain a safe location for the device.

•Select a dry, level and slip-proof location.

•Watch for good ergonomics

•Make sure that no cables are pinched.

Warning!

Risk of tripping!

•Make sure that no loose cables or objects are located on the floor

in the work area.

•Place the device and the connections so that no one steps on it,

or drives or stumbles over it.

6.1.2 Procedure

•Select a suitable location

Power supply:

•Connect the power supply with the lift table (1) - Connection

pos (2).

•Plug the power cable (3) into the power supply. Plug the power

cable into a grounded socket.

1

2

3

Installation and startup

Operating manual (Serial number) Page 17 of 27

Lift 240

6.2 Startup

Switch the device on with the red toggle switch. The blue and red

LED flash very quickly.

Now press the bottom or top button of the remote control for about

3 seconds until the blue LED on the top or the red LED on the bottom

flashes more slowly.

Now you can traverse the lift platform by pressing the remote control

with the top button for up (UP) and with the lower knob for down

(DOWN).

6.3 Coordination for the radio frequency

Are each lift table must be adjusted for the signal detection of the

radio frequency of the remote control.

•For teaching, the upper or the lower button of the remote control

must be pressed sequentially for 3 seconds when the lift table is

switched on.

The blue (1) or red (2) LED at the base of the lift table flashes during

the teach-in in quick succession.

If the motor controller has detected the appropriate signal, the blue

and red LED flash more slowly. The unit is operational.

•Lift and lower the lift table for a trial without a load.

The lift table moves until the upper or lower button of the remote

control is pressed or until the maximum or minimum position is

reached. A brief, inadvertent contact with the control buttons has no

effect.

Note

When operating several lift tables, it is recommended to number

the individual lift tables, for example, with labels to prevent any

mix-ups and therefore accidents.

1

2

Installation and startup

Operating manual (Serial number) Page 18 of 27

Lift 240

6.4 Setting the end stop

Figure. 3 Setting the end stop

In order to adjust the end stop of the lift platform, the lateral surface

knurled nut (1) must be loosened. The slide can now be adjusted in

direction "- " or "+".

The slide is now locked in place by tightening the knurled nut.

When adjusting the slide to the stop in direction "+", the maximum

height of the lift platform is reached. Shifting in direction "-" limits the

height.

You need a measuring tape or yardstick to determine the upper

endpoint.

Raise the loaded lift platform by pressing the blue button on the

remote control until the desired height is reached.

Is the desired height is reached, shift the slide until it audibly snaps

into place. Now tighten the thumbscrew. The end stop is now

adjusted.

Based on the design, the lift platform can be lowered somewhat

further when reaching of minimum height by pushing the lift platform

manually down.

1

Operation

Operating manual (Serial number) Page 19 of 27

Lift 240

7 Operation

7.1 Safety instructions for the operation

Warning!

Ignoring the operating instructions can cause personal injuries and

equipment failures.

>The operating manual, especially the safety instructions must be

read and applied by every person who works with Lift 240.

>Only change parameters and settings after carefully reading the

operating manual.

Risk of explosions

•The lift table cannot be used in areas at risk of explosions!

Warning!

Risk of injuries by smashing laboratory equipment and released

chemicals, material and functional damage!

•Observe the correct adjustment of the height limit

•Keep the lift table in view during the process

Warning!

Risk of crushing and shearing the hands between the lift table

scissors!

•Do not operate the lift table without bellows

•replace defective bellows

(contact the manufacturer)

Caution!

Material and functional damage, bearing damage!

•Please note the maximum load capacity.

•Carefully load the lift platform. Set the rated load centered on the

floor area of the lifting platform.

Operation

Operating manual (Serial number) Page 20 of 27

Lift 240

7.2 Switching on and off

•The lift table is switched on by

using the rocker switch (1). The

red and blue LEDs on the unit

now flash very quickly.

•Continue to press the button for

up (UP) or down (DOWN) for

about 3 seconds, the unit is then

ready.

•Raising the lift table, continue to

press the button for up, labeled

UP on the remote control, as long

as you keep pressing, the lift

table moves upward and the LED

on the unit flashes blue.

•Lowering the lift table, continue to

press the button for down,

labeled DOWN on the remote

control, as long as you keep

pressing, the lift table moves

downward and the LED on the

unit flashes red.

1

Table of contents

Popular Lifting System manuals by other brands

Powermate

Powermate LiftGate LV-TL Series Installation & operation manual

Lippert Components

Lippert Components Level-Up owner's manual

Effemme

Effemme WIZARD UP 30 M operating instructions

Pro-Lift

Pro-Lift T-3101 Operating instructions & parts manual

AMF-BRUNS

AMF-BRUNS HUBMATIK K90 operating instructions

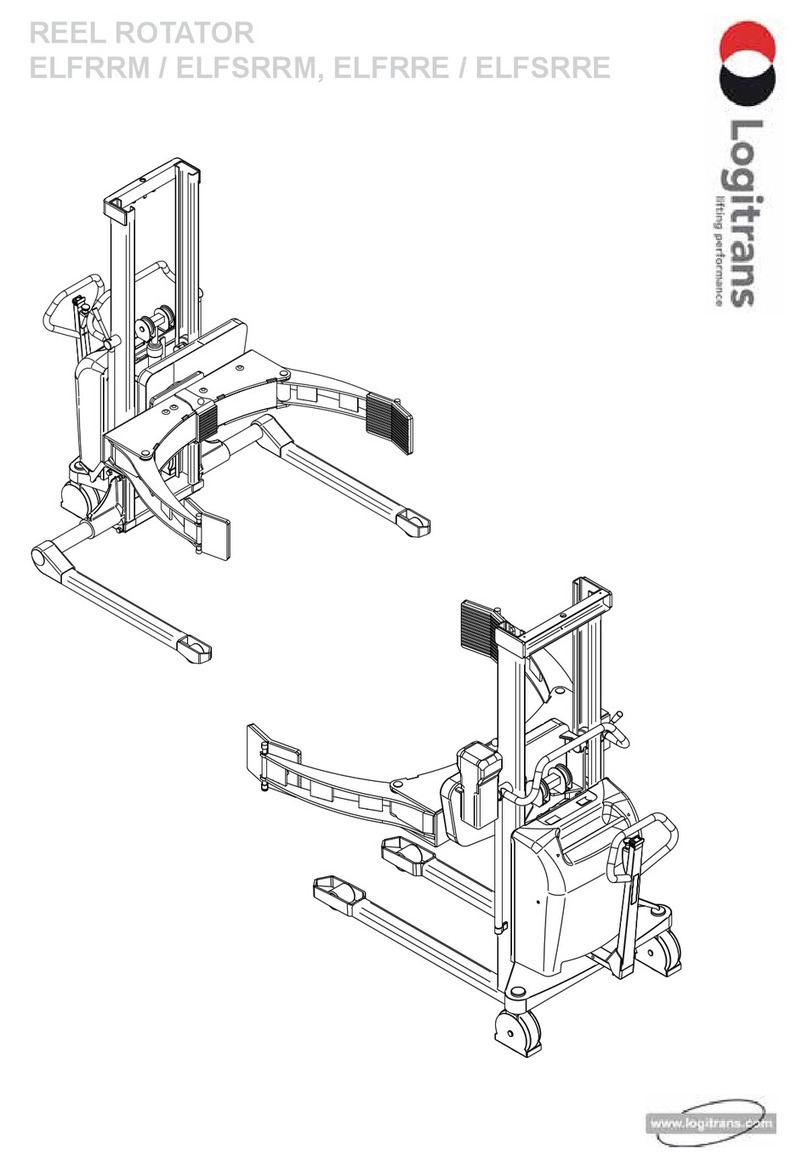

logitrans

logitrans ELFRRM manual