BOCK combiflex.fc Installation and operating instructions

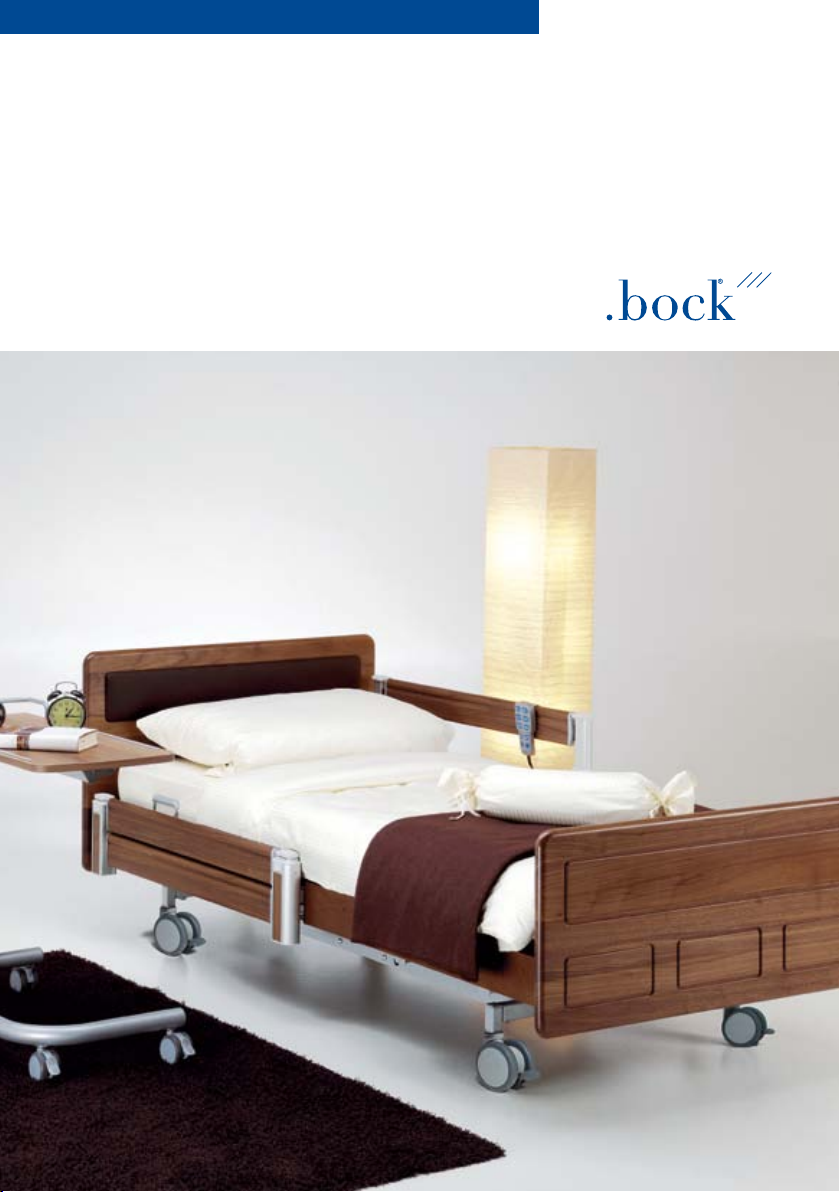

Modell fc 200, Buche massiv, Walnuss gebeizt, Kopfteil mit

Lederbesatz dunkel

Assembly and operation manual

combiflex fc

Dear Customer,

In deciding to buy our comfort sleep system combiflex fc you

have opted for a first class product in functionality and reliability.

This product has been manufactured and tested in accordance

with the current valid standards for medical used beds.

Sleep is individual- and so is combiflex fc. The combiflex fc

grows with your requirements; even later adjustments are pos-

sible without a problem. Equip the comfort system individually

with the combiflex fc wooden frame, optionally with the prac-

tical, telescopic side rails. Decide on the ripolux® lying surface

system. What counts with this system are your needs and an

absolutely convincing comfort.

Yours faithfully,

Klaus Bock

3

Content

1. General notes

1.1 The first impression – Visual inspection

1.2 Security advice

2. Cleaning, care and disinfection

2.1 Cleaning and care

2.2 Disinfection

2.3 Avoid hazards

3. General description of function

3.1. Constructive design and function

3.2 How to carry out the quick and easy assembly:

3.3 Caution: Personal injuries

4. The ICS Sytem

4.1 What is ICS?

4.2 The drive and the handset

4.3. Analysis function of the handset

4.4 Caution: Electrical operation

4.5. The mains isolation

5. Accessories

5.1 Acessories

5.2 Mattresses

5.3 Special mattress ripocare

6. Setting up and operating

6.1 General notes

6.2 Special features

6.3 Scope of delivery

6.4 Technical Data

6.5 Assembly of the combiflex fc bed-in-bed system

6.6 Changing of the bed-in-bed system to a comfort bed

6.7. The assembly of the telescopic splitted side rails and side

paneling of the frame

6.8 Disposal

6.9 Troubleshooting

4

6

9

16

21

23

4

1. General notes

The various bed systems that are made by Hermann Bock GmbH

meet the special requirements for use in rehabilitation and the-

rapy establishments as well as for care at home. Their reliable

functioning and long service life mean that all our beds are of a

particularly high quality. Our beds need little maintenance when

used and inspected properly. No bed leaves the Hermann Bock

production plant until it has passed final quality inspections and

has been tested by a technical inspectorate in Germany named

TÜV. Every health bed thus meets the requirements of directive

93/42/EEC for medical products.

The beds are tested and manufactured on the basis of the cur-

rently applicable European standards for electrically operated

hospital beds. The electric components of our beds conform

with safety standard EN 60601-1 for medical devices.

All nursing beds are subjected to a thorough functionality test

carried out on site by our qualified delivery staff. This is accom-

panied by an extensive instruction of the person being autho-

rized to operate the bed in order to familiarize the operating

person with the bed‘s functionality and its safe handling.

For further information and support, please read this manual for

assembly and use and the contained safety Guidelines.

1.1 The first impression – Visual inspection

Please conduct a thorough visual inspection of the bed to check

for external damages and completeness prior to the assembly

and initial operation. Please note that the bed has to be consi-

dered by you to be in a sound and faultless state before continu-

ing with the next step that informs you about the intended use

of the individual bed elements set out in the following functio-

nal description.

1.2 Security advice

Please consider the following:

– Because of careless grapping into the adaptation mecha-

nism underneath the lying surface, or between the lying

surface and the electrical adjustable components, while

adjusting the bed can lead to bruises on the extremity.

– Do not leave your children play unattended with the bed

or accessories of the bed!

– When leaving the bed, the head and foot part of the

lying surface should be lowered in its lowest position.

– All adaptation mechanisms and motors have to have the

space to work without restrictions.

* Warning note from Bock

The user of this product is

highly recommended to

thoroughly read this assem-

bly- and operation manual

in order to prevent poten-

tial damages and malfunc-

tions from occurring at the

assembly and initial ope-

ration

5

– Do never open the box or the plug of the motor! Due

to unauthorised opening and inappropriate repairs the

warranty claim expires. Furthermore, risks for the user

might occur.

– Repairs can only be carried out by specialized person-

nel!

– Handset, plug and motors are only supposed to be used

as in the manual specified purpose!

– Please check regularly if the cable or box is damaged. If

this should be the case do not use the bed. Exchange

the parts after consulting your dealer.

– Never let liquids infiltrate inside the motors or plug; it

might lead to electrical blows or short circuits.

– When you install the electrical cables please mind that

no sharp edges or kinks occur. The cables are not allo-

wed to go through the adaptation mechanism

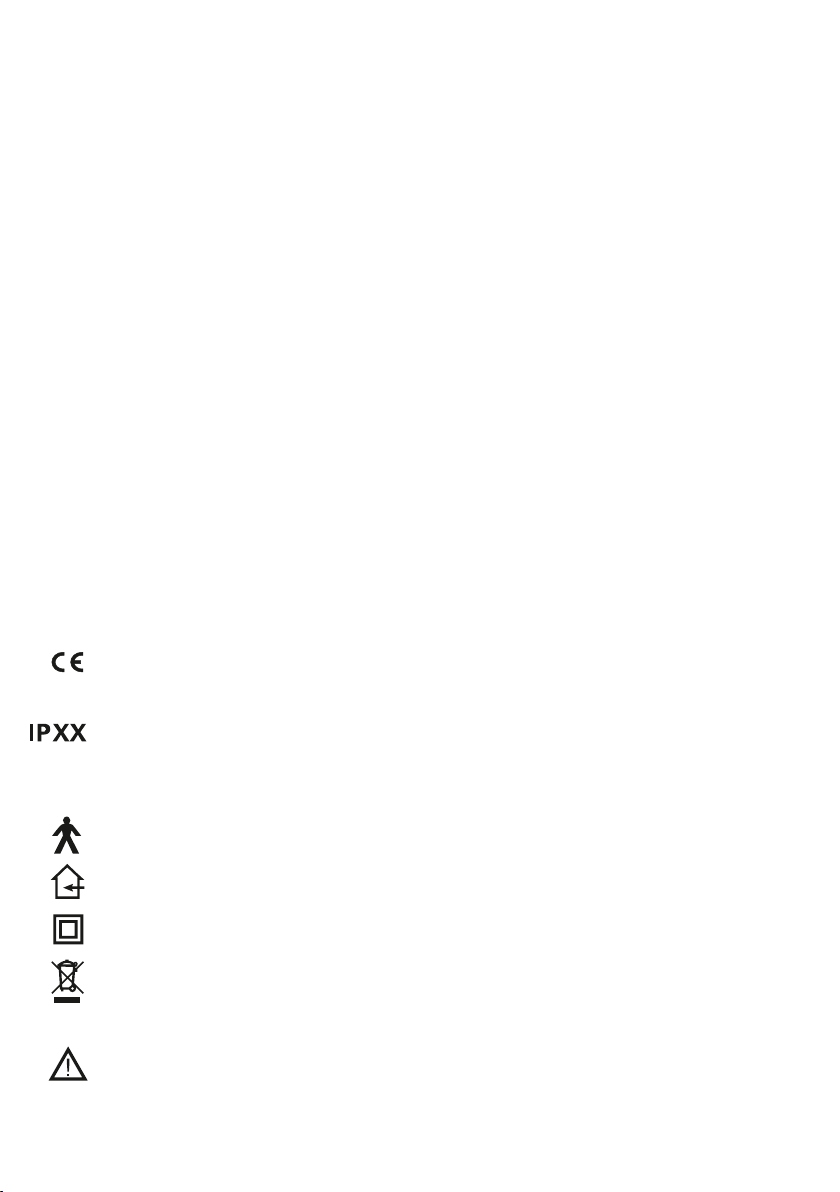

Explanation of symbols used on name plate:

Mark of conformity according to guidelines for medical

products

The first digit indicates the protection class for shock-hazards

and penetration by solid objects

The second digit indicates the protection class for

penetration by water

„Medical equipment part, type B“

„Only to be used in dry environment“

Protection class II (duoble Iinsulation, protective insulation)

This product must be disposed to a selected waste disposal

within the european union. This product may not be disposed

together with unsorted domestic waste.

Take note of the accompanying documents

Thermal cut-out in the transformer

Doubly insulated transformer

6

2. Cleaning, care and disinfection

The individual bed elements are made up of high-quality mate-

rials. The surfaces are covered with a permanent polyester-coa-

ting.

All wooden components have an environmentally-compatible

surface-seal. The patented support-system ripolux consists of

high-quality synthetics. All bed elements are easy to clean and

cared for using wipe- and spray disinfection means according to

the applicable sanitary requirements with respect to the various

fields of application. Observing the following care instructions

will retain the usability and visual appearance of your nursing

bed for a long time.

2.1 Cleaning and care

Steel pipes and varnished metal components:

Please use a wet wiper and a customary, mild household deter-

gent for the cleaning and care of these surfaces.

Wooden-, decorative- and plastic elements:

All customary furniture cleaners and cleaning detergents can be

used. The cleaning of the plastic elements using a wet wiper

without detergent additives should generally be sufficient. For

the care of the plastic surfaces, you should use a product, which

is specifically suitable for plastics.

Drive:

In order to prevent the intrusion of moisture, the drive housing

should only be wiped with a slightly moist cloth.

> Bock top advice

Scrapes and varnish chip-

pings that go through

the entire varnish coating

should be preventively

sealed with appropriate

repair means against the

infiltration of moisture.

7

The ripolux support system:

To clean the plastic carrier and spring elements as well as the

base use a slightly moistened cloth without adding any cleaner,

or add a product that has been designed specifically for plastics.

If the support system needs particularly intensive cleaning, pull

off the spring elements and the carrier elements off the lying

surface frame. The plastic elements that you have removed in

this way can be cleaned or sprayed with hot flowing water. The

plastic elements can be sprayed with a suitable plastic cleaning

agent for disinfection. Most of the moisture can be removed

from the surface of the plastic by a gentle shaking, the remain-

der will dry within a short time. After drying thoroughly with no

residue, re-assemble the parts.

Alternatively the individual lying surface elements can be com-

pletely removed from the frame and cleaned.

2.2 Disinfection

All means in accordance to the standard EN 12720 can be used

for the wipe disinfection. However, you should apply only mild

and gentle means so as to retain the material resistance of the

plastic elements such as the drive housing, decorative elements,

ripolux and ripolan. Concentrated acids, aromatic and chlorinated

hydrocarbons, as well as detergents containing highly concen-

trated alcohol, ether, ester and ketone may damage the material

and should therefore be avoided.

8

2.3 Avoid hazards

Please make sure to consider the following guidelines with

respect to the electrical component parts of your nursing beds

as this crucial to avoiding hazards related to the cleaning and dis-

infection. The non-observance of these guidelines may result in

considerable damages of the electrical lines and the drive.

1. Disconnect the mains supply and position it in such a

way that contact with excessive amounts of water or

detergents can be excluded.

2. Check of all plug-connections for correct position accor-

ding to the instructions.

3. Check of the wires and electrical component parts for

damages. Should you detect any damages, do not per-

form any cleaning operations, but first have the defects

repaired by the manufacturer or authorized personnel.

4. Check the mains supply for residual moisture before

starting the operation and dry or blow out the device, as

the case may be.

5. On suspicion of the intrusion of moisture into the elec-

trical components, disconnect the mains supply imme-

diately resp. do not reestablish the connection. Put the

bed out of operation immediately, attach an appropriate

visible labeling and get in contact with the manufacturer.

* Warning note from Bock

It is absolutely not recom-

mended to use abrasive

cleansers resp. detergents

containing grinding parti-

cles, cleaning pads or stain-

less steel cleaners for the

cleaning. Do neither use

organic solvents such as

alkyl/aromatic halids and

ketones nor detergents con-

taining acid or alkaline.

Never clean the bed using a

water hose or high-pressure

cleaner, as this might lead

to the intrusion of fluid into

the electrical components

which causes malfunctions

and hazards.

9

3. General description of function

3.1. Constructive design and function

The lying surface

Besides a robust slatted frame, the lying surface of the Bock

health bed can be optionally equipped with two further lying

surface variants.

The combi-lying surface

The combi-lying surface is a steel lying surface with removable

ripolux® springs.

The patented anti-decubitus-system ripolux

The patented supporting-system ripolux is available for eve-

ry lying surface. ripolux consists of a wide lying surface frame

made of steel pipe and featuring four functional fields: back rest,

stationary seat part, upper and lower thigh rest. The four ripolux-

supporting elements made of high-quality plastic with all in all

51 individual spiroplex®-spring elements are fitted on the lying

surface frame. The electronic adjustment of ripolux takes place

without any restrictions and the same function as described

dependent on the bed model.

Back support Upper leg support

fixed seat section Lower leg support

Combi-lying surface

10

The scope of delivery for the ripolux includes:

4 Supporting elements made of plastic

51 Spiral springs

51 Rubber plugs

3.2 How to carry out the quick and easy assembly

The functional areas of all three versions are identical and are

spread over four areas: Back support, fixed seat section, upper leg

support and lower leg support.The frame for the lying surface is

made of welded steel tubing that has been covered with a PE powder

coating. The height of the lying surface is continuously adjustable

by means of 24 V direct current motors that are operated via the

easy-to-use hand control. The back support is electrically ad-

justable from 0 to 70 degrees.

The leg section consists of a two-part foot unit. Each individual

position can be continuously adjusted by pressing a button on

the hand control. The electronic hand control can also be used

for an automatic tri-function to raise the occupant‘s legs to a

stretched position and to make a bend in the area between the

heart and knees. The lower leg support automatically moves par-

allel to the lying surface in proportion to the upper leg support.

The leg section can be lowered with the aid of a 9-volt battery in

the event of a power failure.

The lifter

The height adjustment of the comfort bed combiflex fc is

carried out by a double lifter technique. The double lifter can be

height adjusted by two integrated single motors. The surface of

the steel tube construction has a PE powder coating.

11

The splitted telescopic side rails

As an option the comfort bed combiflex fc can be equipped with

splitted side rails. The side rails serve as a protection against fal-

ling out and makes the getting in and out of the bed easy.

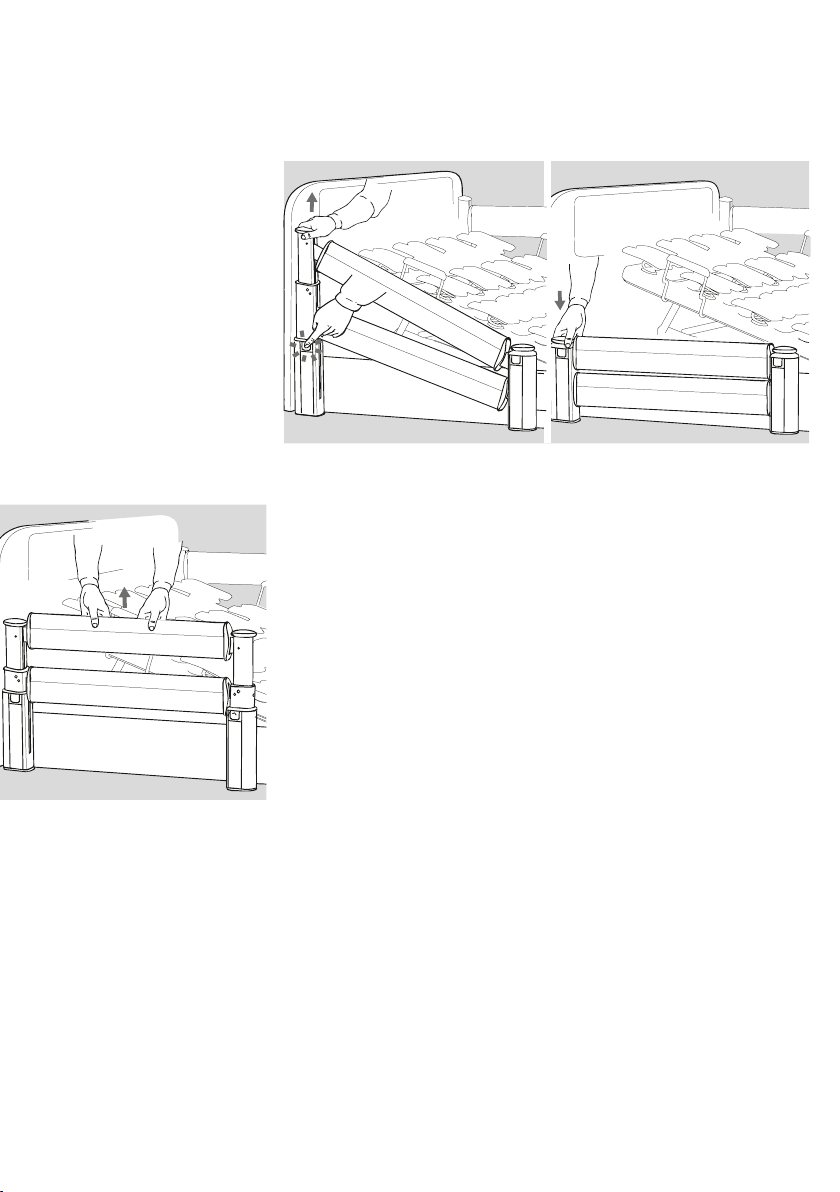

Usage of the splitted telescopic side rails

Each side rail can be adjusted individually. The trip lever for the

adjustment can be found on the telescopic bar.

In order to lower the side rail please grab with one hand the

upper knop on the telescopic bar, lift it a little bit and with the

other hand please push the button of the trip lever on the tele-

scopic bar (Fig. 2). The side rail can now be lowered easily. Now

the stands in the diagonal position (fig. 3).

Left: Fig. 2, right Fig.3

> Bock top advice

Should the side rail form

the diagonal position

(Fig.3) not be lowered but

raised, please grab the

knop of the telescopic bar

and raise it until the side

rail locks in.

12

In order to lower the other part of the side rail, please grab the

side rail on the part of the end panel. Push the locking device on

the end panel (Fig.4) and lower it slowly. Now the side rail is in

the lowered position (Fig. 5).

Left: Fig. 4, Fig.5

If one side rail element should be raised for the usage as a pro-

tection against falling out, please grab the upper side rail with

both hands and pull it to the top until you hear that it has locked

in. The side rail is now in the upper position (Fig.6).

Fig. 6

13

3.3 Caution: Personal injuries

The intended use of all moveable component parts is likewise

crucial for the prevention of hazards to the person in need of

care as for the safety of the relatives and/or nursing staff. This

requires of course the correct assembly and operation of the

bed. Avoid hazards due to unintentional adjustments related to

the drive and wrong operations occurring by using the locking

device.

These recommendations apply in particular,

> when, due to certain disabilities, the care recipient is

unable to operate the hand switch on its own.

> when the care recipient may be endangered due to

unwanted adjustments.

> when the side railings are in pulled up position and

there is a danger of bruises and contusions,

> when children are being left unattended in the room

with the bed.

Always make sure that the hand switch is, when not in use, put

into the suspension hook at the bed and cannot drop down.

The operation of the bed should generally only be performed

by instructed nursing staff resp. relatives or in the presence of

instructed persons. When adjusting the lying surface, it has to

be checked that the care recipient‘s extremities are not resting

between the side railings of the adjustment area.

Before making any electronic adjustments, it‘s of utmost im-

portance to check whether any part of the care recipient‘s ex-

tremities are resting in the adjustment area between the base

frame and head or foot rest, or if they are persons in the area

between the floor and the lifted lying surface. These are the

areas bearing a particularly high risk for bruises.

* Bock-Gefahren-Hinweis

During the electrical

adjustment of the lying

surface you have to take

care that the person does

not have a contact to the

side rails or that no extre-

mities are between the

side rails. This has also to

be considered when you

move the side rails, fur-

thermore the person has

to lay in the correct posi-

tion.

14

The distances between the side railings have to be less or equal

12 cm. Note that the side railings must not remain in diagonal

position, when these are being used.

Dimensions of a side railing in one piece

Dimensions of a partitioned side railing

> Bock top advice

When using different mat-

tress thicknesses, the mini-

mal height of 22 cm minus

the compression, mea-

sured from the upper edge

of the side railing above

the mattress, must not be

undershot. The use of hig-

her mattresses requires an

additional plug-in railing

which is available as equip-

ment.

15

Extract of the TÜV PS 51036 Inspection program, dimensions of

the side railings according to EN 60601-2-38

* Warning note from

Bock

– Do only use original side

railings from Bock which

are available as equip-

ment for every nursing

bed.

– Do only use technically

sound and undamaged

side railings that have

the permissible clea-

rances.

– Make sure that the side

railings click into place

– Check all mechanical

parts on the bed fra-

me and side railings

required for the fixing

of the latter for possible

damages before moun-

ting and every new

application.

– The control of the side

railings should always

take place with high dili-

gence, as it may easily

come to bruises of the

fingers due to the longi-

tudinal spars.

16

4. The ICS System

4.1 What is ICS?

The ICS is an entirely new solution for manufacturers of medi-

cal, healthcare, and wellness/ therapy beds. Intelligent control

systems (ICS) are able to control and monitor components and

parameters of a medical product in the most dependable man-

ner. Through an individual adaptation of more than 100 parame-

ters this micro-processor control system can be perfectly adju-

sted to medical applications.

Product Details:

− Micro-processor controls

− Soft Control

− Synchronization

− Memory function

− Special functions and processes, for example the main-

tenance position or parallel adjustment of all 4 motors,

for example comfort sitting position

− Easily programmable, approx. 100 parameters (pre-)

adjustable

− Safe disconnecting and end position, for example

collision protection

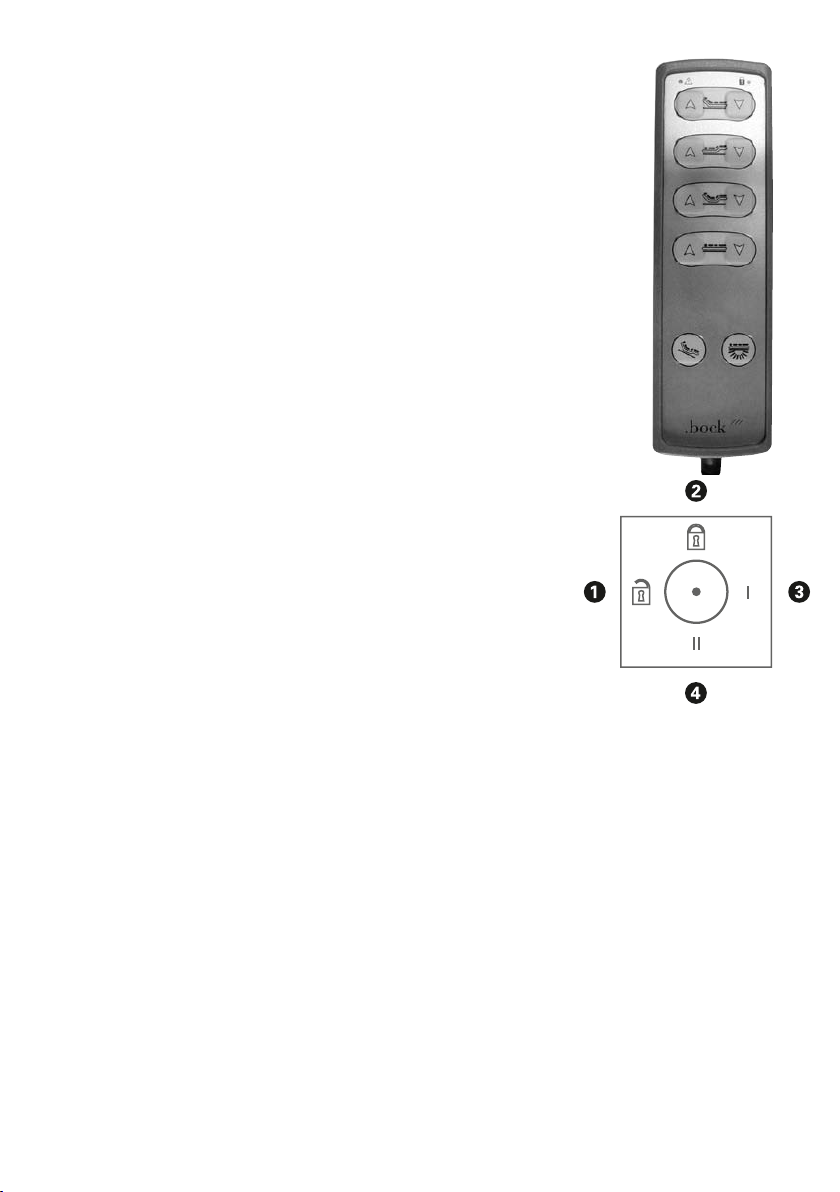

4.2 The drive with the hand set

By an ergonomic designed hand set the base functions are

assessable. The large buttons ensure a safe use.

The single buttons are labeled with the corresponding symbols.

The motors do work as longs as the button is pushed. A spiraled

cable offers the needed free space.

17

The hand set of the combiflex fc

The following function can be controlled by pushing the buttons:

Function button 1 Back rest up

Function button 2 Back rest down

Function button 3 Lower leg part up

Function button 4 Lower leg part down

Function button 5 Auto shape up

Function button 6 Auto shape down

Function button 7 Lying surface up

Function button 8 Lying surface down

Function button 9 Comfort sitting position

Function button 10 Light underneath the lying surface

5 and 6 Buttons pressed simultaneously :Reset function

By pressing the button no. 9 the comfort sitting position goes

only up. All positions have to be lowered individually.

The hand control also has an integrated disabling function that

can be activated or deactivated by the key (Fig 1). To disable the

entire electrical function, insert the key into the lock located on

the backside and activate or deactivate the disabling function

with a corresponding twist of the key.

Deactivation position of the handset 1:

Comfort-sitting position (button 9) is locked,

all other functions are enabled.

Deactivation position of the handset 2:

All functions of the handsets are locked.

Deactivation position of the handset 3:

All functions of the handset are enabled.

Deactivation position of the handset 4:

Without function.

1

3

5

7

9

2

4

6

8

10

Fig. 1

18

4.3 Analysis function of the handset

Red LED is flashing twice (2x)

Actuator is overloaded (Power cut-off). This failure mode is

due to

• Bed load is higher than the safety load parameters

• Bed collides with something (pinching protection)

Red LED is flashing four times (4x)

Hall impulses are missing. This failure mode is due to:

• Defective actuator (Operate every single actuator to

check which one is defective)

• Defective control unit

Red LED is flashing five times (5x)

The 9V-battery is empty. This failure mode is due to

• The battery hasn’t been changed after using the

emergency lowering function

• An unintentional operation without power has been

performed

No function

This failure mode is due to:

• The hand set is locked

• The plug of the handset is not connected properly

• Mains Isolation connector is defect

If none of this true, then the fault lies in the control.

Red and green LED are flashing

If this error occurs the applied hand set is not suitable for this

specific ICS system. The red LED is flashing a few times follo-

wed by the greed LED flashing one time.

19

The system works on its own

If the systems works on its own, for example it goes to early

into the inclination position, a loss of a position is on hand. This

might happen due to changing the motor. In order to repair this

fault a initialization has to be carried out. The initialization is car-

ried out by a key combination, the third button pair from above

(autocontur) is to be used. Both buttons are pressed until the

complete initialization. After the pressing of both button the red

LED lamp start to flash. After 5 seconds all drives go down at

a low rate of velocity. Due to the low rate of velocity it is possi-

ble to notice possible collision in time and to react accordingly.

4.4 Attention: Electronic drive

Hermann Bock calls its electrically operated nursing and therapy

beds health beds, because they considerably facilitate the care

recipient‘s recovery process in both physical and mental aspects

while relieving pain at the same time thanks to their versatile

functions. When applied as medical product, electrically opera-

ted beds require particular consideration with respect to the con-

tinuous safety inspections. These include the safe and professi-

onal handling of the bed, the daily check of the electrical equip-

ment, and the proper maintenance and cleaning.

In order to avoid damages of the cables, the cable installation

should take place outside the potential damage areas. Also avoid

skin contact with edge parts. All potential risks of too high

contact voltages should be excluded, as this helps to prevent

injuries caused by an electrical shock. Too high contact voltages

may especially occur when the mains

connecting lead has been damaged, the discharge currents are

incorrect or too high, or the drive housing has been penetrated

by liquids, which might have happened due to improper cleaning

procedures. These damages may lead to malfunctions of the

control and hence to unwanted movements of the individual bed

elements, that bear an increased risk of injuries for the person in

need of care and the operator.

> Bock top advice

Owning to the mains dis-

connection, the bed is

entirely free from electric

smog and requires small

amounts of energy, as

energy is only consumed

with the performance of

adjustments.

* Warning note from

Bock

The high safety standard

of Hermann Bock´s beds

doesn´t mean a guaran-

tee of the exclusion of

any risks. It is actually the

strict observance of the

manufacturer’s data and

the specifications of the

intended use that fulfill the

purpose of the safety mea-

sures and apply as precau-

tionary and active preven-

tion of any risk.

20

4.5 Mains isolation

The mains isolation facility that is integrated in the mains plug

provides other practical advantages in addition to guaranteeing

a high level of safety. Activation of mains isolation prevents

magnetic and electric alternating fields from being generated in

the bed. The mains isolation facility operates independently and

does not require an additional transformer for its standby mode.

When the drive unit has been disconnected from the mains, no

electricity is used and a switching noise in the relay indicates

correct operation. Of course, mains isolation is compatible with

higher-level mains isolation options.

The isolation facility in the mains plug is activated by pressing a

button on the hand control. A capacitor charged with direct cur-

rent in the drive unit supplies electricity to the twopole relay in

the mains isolation facility, and turns on the transformer in the

drive. The capacitor is recharged, and is ready for the next actu-

ation. Whenever the button on the hand control is released, the

relay in the mains isolation facility turns off the mains network

(two poles). A switching noise indicates that this function is

being executed. The 9-volt battery that is installed in the control

as standard for emergency movements will, if necessary, back

up the mains isolation capacitor if the latter has not been used

for some time and has therefore lost its voltage. If the capaci-

tor and the 9-volt battery have been exhausted, it is sufficient to

press the green button to get the mains isolation facility working

again. When taking the bed out of service, the contact to the 9

Volt battery should be released by pulling out the plug.

Mains disconnection in closed and opened view

* Warning note from Bock

The simultaneous use of

electrical devices may cau-

se, particularly in the direct

environment of the service-

able bed, low electromagne-

tic interactions with these

electrical devices, such as

radio noise. When such rare

cases occure, you should

extent the distance of the

devices and not use the

same plug or switch off the

noisy device for the time

being.

If the bed is operated not

in line with its purpose,

thus simultaneously with

electrical, medical devices,

you should deactivate the

functions of the bed for

the duration of applica-

tion using the integrateted

locking function provided in

the hand set

9- Volt battery for the emer-

gency lowering

Table of contents

Other BOCK Indoor Furnishing manuals

Popular Indoor Furnishing manuals by other brands

Westwood Design

Westwood Design ECHO Assembly instruction

VIPACK

VIPACK AMORI AMKB9014 Assembly instructions

Forte

Forte OWKM03-0001 Assembling Instruction

HOMCOM

HOMCOM 713-080V91 Assembly instruction

Poliman

Poliman CLARA KIT Assembly instructions

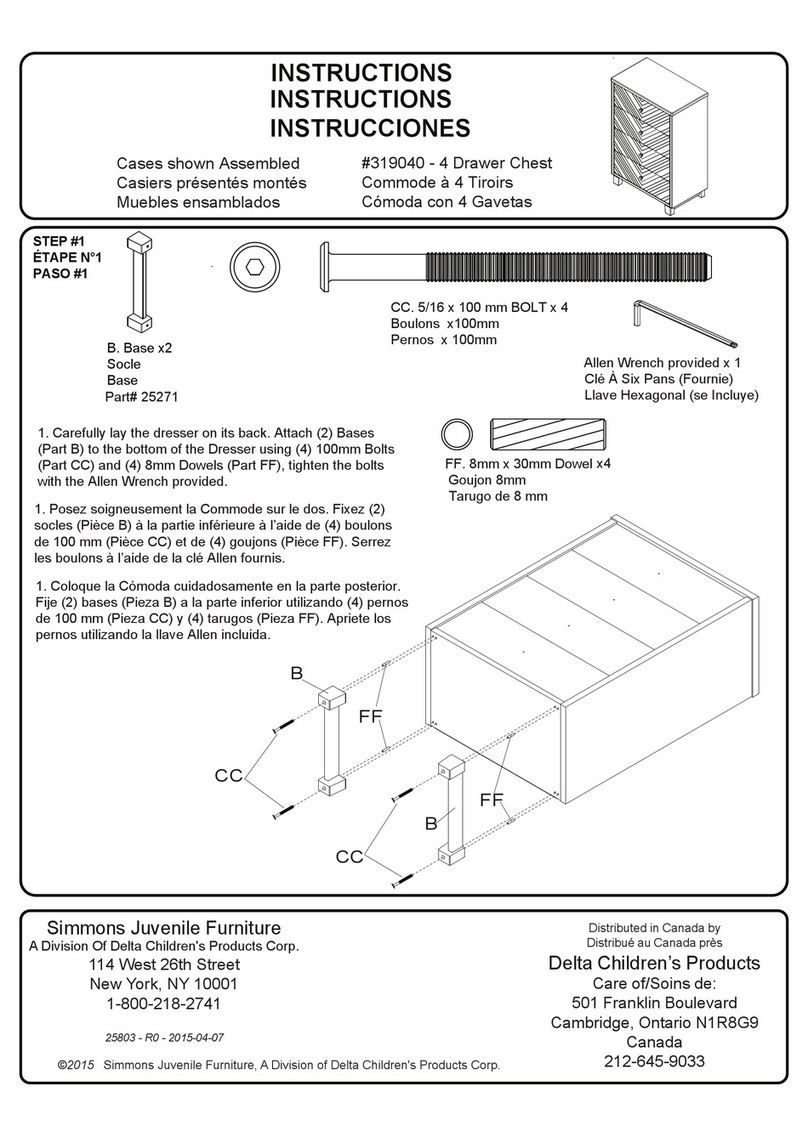

Simmons Juvenile Furniture

Simmons Juvenile Furniture 319040 Instructions for use