Bodine Quality IN Motion 0810 User guide

Type FPM 0810, 0830, and 0850

Permanent Magnet DC Motor Controls

(with driver board only, or with F-B-R board)

Model 0810 up to 1/17 HP

Model 0830 up to 1/6 HP

Model 0850 up to 1/3 HP

SPECIFICATIONS

Input Voltage: ...................115 VAC±10%; 50/60 Hz, single phase

Input Current:

Model 0810........................................ 2.9 Amps AC

Model 0830........................................ 4.2 Amps AC

Model 0850........................................ 9.0 Amps AC

Armature Voltage (nominal) ............................. 0-130 VDC

Armature Current (max. continuous)

Model 0810..........................................0.50 Amps

Model 0830.......................................... 1.25 Amps

Model 0850..........................................2.30 Amps

07400156.i

www.bodine-electric.com

Instructions for Installation and Operation

2

© 2023 Bodine Electric Company.

All rights Reserved. All data subject to change without notice. Printed in U.S.A.

BODINE LIMITED WARRANTY

The Bodine Electric Company warrants all products it manufactures to be free

of defects in workmanship and materials when applied in accordance with

nameplate specifications. Bodine motors and gearmotors purchased with

and used only with appropriately applied Bodine controls are covered by this

warranty for a period of 24 months from the date of purchase or 30 months from

date of manufacture, whichever comes first. Bodine motors and gearmotors

used with non-Bodine controls and Bodine controls used with non-Bodine

motors and gearmotors are covered by a 12 month warranty period. The Bodine

Electric Company will repair, replace, or refund at its option, any of its products

which has been found to be defective and within the warranty period, provided

that the product is shipped freight prepaid, with previous authorization, to

Bodine or to a Bodine Authorized Service Center. Bodine is not responsible

for removal, installation, or any other incidental expenses incurred in shipping

the products to or from Bodine. This warranty is in lieu of any other expressed

or implied warranty – including, but not limited to, any implied warranties of

merchantability and/or fitness for a particular use. Bodine’s liability under this

warranty shall be limited to repair or replacement of the Bodine product and

Bodine shall not be liable, under any circumstances, for any consequential,

incidental or indirect damages or expenses associated with the warranted

products. Proof of purchase of motor or gearmotor and matching control as a

system must be provided with any claim.

Control Type ____________Serial No._________________

Date of Purchase ________ Place of Purchase__________

3

4

IMPORTANT

Read this manual completely and carefully. Pay special attention to all

warnings, cautions, and safety rules. Failure to follow the instructions could

produce safety hazards which could injure personnel or damage the control,

motor, or other equipment. If you have any doubts about how to connect

the control or motor, refer to the detailed sections of this manual.

5

SPECIFICATIONS

INPUT VOLTAGE1...............................115VAC ± 10% 50/60 Hz SINGLE PHASE

INPUT CURRENT

Models 0810 through 0818 ..................................................... 2.9 Amps AC

Models 0830 through 0838 ..................................................... 4.2 Amps AC

Models 0850 through 0858 ..................................................... 9.0 Amps AC

ARMATURE VOLTAGE (Nominal) .................................................... 0-130 VDC

ARMATURE CURRENT (Max. Continuous)

Models 0810 through 0818 ................................................... 0.50 Amps AC

Models 0830 through 0838 .................................................... 1.25 Amps AC

Models 0850 through 0858 ................................................... 2.30 Amps AC

AMBIENT TEMPERATURE (Max.)

Chassis ............................................................................................ 0 to 50°C

Encased ........................................................................................... 0 to 40°C

SPEED REGULATION (Typical) ...................................................................... 2%

SPEED RANGE (Typical) .................................................................... up to 42:1

LINE VOLTAGE COMPENSATION .............................................................. 1.5%

ELECTRONIC F-B-R BOARD ............................ 10 reversals per minute MAX. 2

ACCELERATION TIME ....................................... 0.5 to 10 seconds (adjustable)

Notes:

1 For 220/240VAC single-phase operation, a 2:1 step-down isolation transformer may be used. Signal Transformer

Type DU-1 (1 KVA) is recommended for models 0850 to 0858 and Type DU-1/2(.5 KVA) for models 0810 to 0838.

2 The number of reversals are limited to 4 max. with model 0858 when using motor Type 42D7, unless brake

resistor is mounted outside the enclosure.

Standard Features Include:

• Industrial quality enclosure (Encased Models 0815-8, 0835-8, 0855-8)

• Terminal Block for easy electrical connections

• L-Bracket/Heat Sink for simplified mounting

• Inhibit Function standard on Models 0810, 0830, and 0850

• Adjustable Acceleration

• Temperature Compensation

• line and Armature Fuses

• Tight Speed Regulation

• Line Voltage Compensation

• Optical Isolation with Interface Boards

• On-board Torque (Current) Limiting, Speed Regulation,

and Min/Max speed adjustments

• Wall Mounting Provisions for encased controls

Optional Features Include:

• Mechanical F-B-R Kits for chassis controls only

• Electronic F-B-R Kit (for chassis controls and encased Models 0815, 0835,

and 0855)

• Local/Remote Control Kit (standard on encased Models 0816, 0836, 0856)

6

SAFETY PRECAUTIONS

The following safety precautions must be observed during all phases of

operation, service, and repair of this electronic drive/motor product. Failure

to comply with these precautions or with specific warnings elsewhere in

this manual violates safety standards of design, manufacture and intended

use of the products. Bodine Electric Company assumes no liability for the

customer’s failure to comply with safety requirements and practices.

Warnings, such as the example below, highlight potentially dangerous proce-

dures throughout this manual. Instructions contained in the warnings must

be followed.

WARNING AVERTISSEMENT

Dangerous voltages may be

present in the electronic speed

control, gearmotor or motor.

These voltages could cause

serious injury or death. Use

extreme caution during handling,

testing, and adjusting. Properly

guard the electronic control

and motor to prevent accidental

contact by all persons.

The chance of explosions, fires,

or electric shocks can be reduced

with thermal and over-current

protection, proper grounding,

enclosure selection, and good

maintenance. The following safety

considerations are not intended

to be all-inclusive. Specific

references throughout this manual

should also be consulted.

Des tensions dangereuses

peuvent être présentes dans le

régulateur électronique de vitesse,

le motoréducteur ou le moteur.

Ces tensions peuvent entraîner

des blessures graves ou la mort.

Soyez extrêmement prudent lors

de la manipulation, des tests et des

réglages. Protégez correctement

la commande électronique et le

moteur pour éviter tout contact

accidentel par toutes les personnes.

Le risque d’explosions,

d’incendies ou de chocs

électriques peut être réduit grâce

à une protection thermique et

contre les surintensités, une mise

à la terre appropriée, une sélection

de boîtier et un bon entretien.

Les considérations de sécurité

suivantes ne sont pas destinées à

être exhaustives. Les références

spécifiques tout au long de ce

manuel doivent également être

consultées.

“The use of electric motors and generators, like that of all other utilization of

concentrated power, is potentially hazardous. The degree of hazard can be

greatly reduced by proper design, selection, installation, and use, but hazards

cannot be completely eliminated. The reduction of hazard is the joint responsi-

7

bility of the user, the manufacturer of the driven or driving equipment,

and the manufacturer of the control or motor or generator.”*

Bodine products are designed and manufactured to comply to applicable

safety standards and in particular to those issued by ANSI (American

National Standards Institute}, NEMA (National Electrical Manufacturers

Association), U.L. (Underwriters Laboratories, Inc.}, and CSA (Canadian

Standards Association}.

* Standards Publication No. ANSI CS.1/NEMA MG-2. “Safety Standard

for Construction and Guide for Selection, Installation and Use of

Electric Motors and Generators.”

Available from: www.nema.org

Most Bodine products are “third party approved” with respect to

construction. Type-FPM chassis controls “recognized by U.L., Inc.” are

designated by having a “ “symbol in the upper right corner of their

nameplates. In addition, most products are CSA certified, identified by

a “ “ symbol. If you need specific information regarding the ‘’third

party approval” status of Bodine products, contact the nearest Bodine

representative, or the home oce.

However, since even well-built apparatus can be installed or operated in a

hazardous manner, it is important that safety considerations be observed

by the user. With respect to the load and environment, the user must

properly select, install, and use the apparatus-for guidance on all three

aspects see safety standards publication No. ANSI C5.1/NEMA MG-2

(footnoted above).

GROUNDING

Both electronic controls and motors must be securely mounted and

adequately grounded. Failure to ground properly may cause serious

injury to personnel.

FUSING

Both the control input and output are fused. If fuses must be replaced,

they must always conform to the values and ratings specified on the

control’s nameplate.

LIVE CIRCUITRY

Open-type electronics should be properly guarded or enclosed to

prevent accidental human contact with live circuitry. No work should

be performed on or close to the control or motor (including brush

examination or replacement) while the control is connected to the AC

line. If an AC line switch is used, it should be a Double Pole Single Throw

(DPST), so that both sides of the AC line can be disconnected.

8

9

10

WARNING AVERTISSEMENT

This speed control should

only be installed by a qualified

technician, electrician or electrical

maintenance person familiar

with its operation and associated

hazards. The National Electrical

Code (NEC), local electrical and

safety codes, and when applicable,

the Occupational Safety and

Health Act (OSHA) should be

observed to reduce hazards to

personnel and properly.

Ce régulateur de vitesse ne

doit être installé que par un

technicien qualifié, un électricien

ou une personne de maintenance

électrique familiarisé avec son

fonctionnement et les risques

associés. Le National Electrical

Code (NEC), les codes électriques

et de sécurité locaux et, le cas

échéant, la loi sur la sécurité et la

santé au travail (OSHA) doivent être

respectés afin de réduire les risques

pour le personnel et de manière

appropriée.

MOUNTING THE CONTROL PROPERLY

The mounting template (provided in the shipping box) can be used to

facilitate mounting the control. The control may be mounted in any position.

Please refer to the mounting template packed with your particular control for

instructions.

WARNING AVERTISSEMENT

The user must provide a proper

enclosure for chassis type

controls. Circuitry is not at ground

potential. Do not perform work

on or near the control while it is

connected to the AC line.

L’utilisateur doit fournir un boîtier

approprié pour les commandes de

type châssis. Le circuit n’est pas

au potentiel de la terre. N’eectuez

pas de travaux sur ou à proximité

de la commande lorsqu’elle est

connectée à la ligne CA.

CONNECTING THE DRIVER BOARD

WARNING AVERTISSEMENT

Always disconnect the 115VAC

power to the speed control before

making any electrical connections,

or when replacing motor brushes.

Connecting the 115VAC power

source should be the very last

connection made. Please follow

the instructions carefully.

Débranchez toujours l’alimentation

115 VCA du régulateur de

vitesse avant d’eectuer des

connexions électriques ou lors

du remplacement des balais du

moteur. La connexion de la source

d’alimentation 115 VCA doit être la

toute dernière connexion eectuée.

Veuillez suivre attentivement les

instructions.

11

Figure 1:

Top view of FPM driver board

When pin11 is pulled low

(connected to pin 7—the signal

common) the SCRs will be

disabled and the motor will

coast to a stop.

NOTE: Any exposed circun boards should be handled in a static-protected

area. The feature boards use CMOS circuitry. Static discharge into the

feature boards must be avoided.

All encased controls accept 1/2-inch liquid tight conduit fittings. For wire

sizes and electrical connections refer to the National Electrical Code (NEC)–

Article 430–”Motors, Motor Circuits, and Controllers” and/or applicable

local area codes. If extension cords are used, they should be kept short

for minimum voltage drop and optimum performance. Only copper wire

with 60°C rated insulation is recommended. The terminal block will accept

leads up to 14 gauge (18 gauge is the smallest recommended size). Please

also review the safety notes on pages 6, 7, 8, and 10. The barrier terminal

block (TB1) screws should be tightened to 6 lb-in.

12

NOTE: This control does not provide motor over temperature protection. The user is

responsible for providing this protection in the equipment where this control is used

REMARQUE: La détection de la surchaue du moteur n’est pas assurée par cette control.

13

Figure 2:

FPM driver board – Fuse selection and DIP switch settings.

Application note: select 42A5-FX (90/130V) models may exceed type FPM

current limit. Consult Bodine technical support for more information.

E-mail: [email protected].

Control

Model

Number

Motor/

Gearmotor

Product Type

Motor

Speed

@ 130

VDC

Rated

Motor

Amps

Motor/

Gearmotor

Power [HP]

DIP

Switches

in “On”

Position

Armature

Fuse (FA)

Line Fuse

(FL)

0810

through

0818

24A0BEPM 2500 0.22 1/50 2,4,5,6,7 239.2001

235.0051

24A2BEPM 2500 0.3 1/29 1,2,3,5,8 239.3001

24A4BEPM 2500 0.48 1/17 1,2,3,4 239.5001

0830

through

0838

24A4BEPM 2500 0.56 |

0.81 1/23 | 1/11 1,2,3,7

MDA

1.252ABC 62

33A3BEPM 2500 0.78 |

1. 0 1/16 | 1/8 1,2,7

33A3BEPM 2000 0.71 1/12 1,2,5,6

33A3BEPM 2500 0.71 1/12 1,2,7

33A5BEPM 2500 0.91 1/8 1,2,5

42A3BEPM 2500 1 1/8 1,2,5

42A4BEPM 2000 1. 3 1/6 1,2,4

0850

through

0858

24A4BEPM 11,500 1. 1 1/7 1,2,3,4,5 MDA 22

ABC 122

33A3BEPM 2500 0.78 |

1. 0 1/16 | 1/8 3,4,5 MDA

1.252

33A5BEPM 2000 1. 4 1/6 3,4 MDA 1.52

33A5BEPM 2500 1.4 | 1.8 1/8 | 1/4 2,3,4,5,8 MDA 22

33A5BEPM

[WX] 2500 1.3 | 1.7 1/8 | 1/4 2,3,4,5,8 MDA 22

33A7BEPM 2500 1.8 | 2.4 1/6 | 1/3 1,2,4 MDA 2.52

42A5BEPM

[5N] 2500 1.9 | 1.8 3/16 | 1/4 1,4 MDA 22

42A5BEPM 2500 1. 8 1/4 1,4 MDA 22

42A5BEPM

[FX] 2500 2.1 | 2.8 3/16 | 3/8 1,4 MDA 2.52

42A7BEPM 2500 2.3 1/3 1,2,8 MDA 2.52

1 Littelfuse 2 Bussmann

14

5. Referring to Fig. 1, identify the barrier terminal block (TB1) on your control’s

driver board. Connect the ground wire and motor armature wires to the

terminal block. Finally, attach the 115VAC power line to the terminal block.

DO NOT connect the 115VAC power line to an external power source at this

time. (This should always be the very last connection you make.)

* In Fig. 1, the armature is connected for clockwise (CW) rotation. For counter-

clockwise rotation (CCW), simply reverse the connections at A1 and A2. The

connections at A1 and A2 can be reversed with the Electronic F-B-R Board

or mechanical F-B-R switches.

Speed Regulation is adversely aected by the length of the leads from

terminals A1 and A2 to the motor. Lead lengths of 25 feet or more can produce

measurable degradation, especially at lower armature speeds. Shorter leads

and heavier gauge wire will improve speed regulation.

WARNING AVERTISSEMENT

The DC speed control and

PMDC gearmotor or motor

must be securely and

adequately grounded, as

shown in Fig.1. Failure to

ground the system properly

may result in serious injury.

La commande de vitesse CC

et le motoréducteur ou le

moteur PMDC doivent être

solidement et adéquatement

mis à la terre, comme indiqué

à la Fig.1. Une mise à la terre

incorrecte du système peut

entraîner des blessures graves.

Terminal Descriptions:

L............ Hot side of 115VAC line

N........... Neutral side of 115 VAC line

A1......... Negative* motor armature supply voltage

A2......... Positive* motor armature supply voltage

......... Earth ground for control and motor

15

16

WARNING AVERTISSEMENT

Disconnect all power to the speed

control before changing the F-B-R

board’s braking resistor or when

installing the F-B-R kit.

Débranchez toute alimentation

du régulateur de vitesse avant de

changer la résistance de freinage

de la carte F-B-R ou lors de

l’installation du kit F-B-R.

CONNECTING AN F-B-R KIT

If you have purchased a separate electronic Forward-Brake-Reverse Kit

(Model 0890) read the installation instructions provided with the Kit and

install the Kit before proceeding.

CONNECTING THE ELECTRONIC F-B-R BOARD

If you are not using an F-B-R Board, proceed to “Operating the Control”on

page 20.

The electronic Forward-Brake-Reverse (F-B-R) Board (Fig. 4) controls the

motor’s direction of rotation. When the direction signal is changed, the motor

will decelerate, approach zero speed, reverse direction, and then accelerate

to the selected speed. This protects the motor, gearing, and other drive

components from damage from high reversing torques.

Figure 4

Electronic Forward-Brake-Reverse Board, Showing Connections to Speed

Potentiometer and F-B-R Switch (also refer to Fig. 3B, p.15).

17

Figure 5

Description of Pins on J7 of the F-B-R Board.

Pin Description

Corresponding

Wire Color

4 Input—Brake Signal Violet

5 OUTPUT — +12VDC White

7 OUTPUT— 0VDC Gray

8 Speed Pot Regulation Blue

10 INPUT — Speed Signal Orange

12 Speed Pot Connection Yellow

16 INTPUT — Direction Signal Brown

*Non-isolated common for driver board

All connections described in these instructions are made to socket J7 (on

the F-B-R Board) using the color-coded wires from the pre-wired connector

provided with your control or F-B-R Kit. Fig. 5 describes the functions of the

pins on J7, and matches each pin to a corresponding colored wire from the

prewired connector.

Connect wires securely, keep them short, and bundle the power and control

leads separately to minimize noise pickup. Long or unterminated leads may

pick up extraneous signals that could aect the performance of the motor

and control.

A. Manual (Mechanical)

Control

The electronic F-B-R Board can

be operated manually. Encased

models 0818, 0838, and 0858 are

wired at the factory for manual

control. If you have the Model

0890 F-B-R Kit, you must supply

your own speed pot and switches

for manual control. Fig. 8 shows

how “Forward/Reverse” and “Run/

Brake” switches may be added to

the F-B-R Board.

B. Electronic Control

CAUTION AVERTISSEMENT

The control board signal common

is not at ground potential, any

external signal or equipment

connected to the control must be

electrically isolated from ground

(e.g., relay or optically isolated).

Non-isolated signals will damage

the control and/or associated

external equipment.

Le signal commun de la carte

de commande n’est pas au

potentiel de la terre, tout signal

ou équipement externe connecté

à la commande doit être isolé

électriquement de la terre (par

exemple, relais ou isolation

optique). Des signaux non isolés

endommageront la commande et/

ou l’équipement externe associé.

Optional Analog and Digital Interface Boards are available to conveniently

interface FPM controls’ driver boards to externally generated electronic

signals for control of motor speed, direction of rotation, and braking. The

Interface Boards provide optical isolation between the input signal and the

control’s circuitry, and are recommended for applications requiring electronic

control. However, if the user is certain that isolated inputs are available, they

may be used without an interface board.

18

19

20

OPERATING THE CONTROL

WARNING AVERTISSEMENT

Risk of explosions, fires, or

electric shock hazards can be

reduced through thermal and

over-current protection, good

maintenance, proper grounding,

and enclosure selection. Review

safety considerations outlined

in “Safety Precautions” and

“Installing the Control.”

Les risques d’explosion, d’incendie

ou de choc électrique peuvent

être réduits grâce à une protection

thermique et contre les surintensités,

un bon entretien, une mise à la

terre appropriée et la sélection

du boîtier. Passez en revue les

considérations de sécurité décrites

dans «Précautions de sécurité» et

«Installation de la commande».

This manual suits for next models

2

Table of contents

Other Bodine Controllers manuals

Popular Controllers manuals by other brands

Penn

Penn MR5 Series Technical bulletin

Fuji Electric

Fuji Electric FRENIC-HVAC series instruction manual

Roth

Roth Touchline SL Installation

LinMot

LinMot CC-Link IE Field Basic C1250-CC Series manual

Bryant

Bryant Evolution Connex SYSTXBBECC01- installation instructions

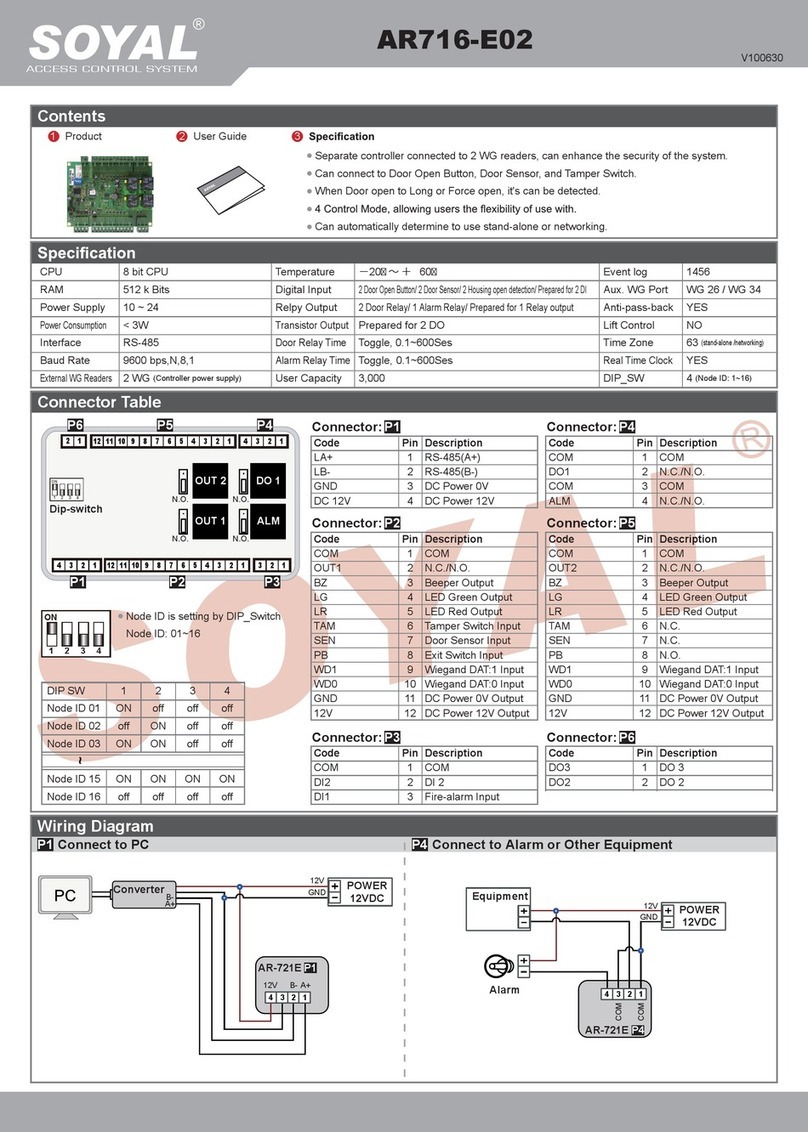

Soyal

Soyal AR716-E02 quick start guide

HBM

HBM eDAQ EXRCPU quick start guide

Orno

Orno OR-GB-447 Operating and installation instruction

Lippert Components

Lippert Components OneControl Tank Monitor V1 installation manual

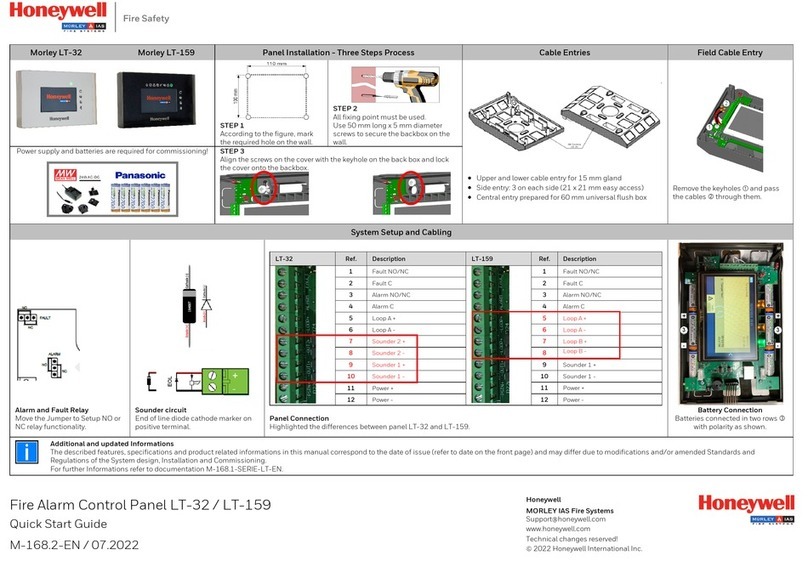

Honeywell

Honeywell LT-32 quick start guide

Digital Watchdog

Digital Watchdog KB-100 user manual

Det-Tronics

Det-Tronics R8471A instructions