Bodine 0790 User guide

201 Northfield Road | Northfield Illinois, 60093, U.S.A. | Phone 773.478.3515 | www.bodine-electric.com | [email protected] 07400213 Rev.C

5.25 REF.

7.12 REF.

1.00 TYP.

.38 TYP.

.38 TYP.

1.00 TYP.

.28 I.D.

HOLE TYP.

.12 R.

TYP.

72” REF.

3.08 REF.

6.35 REF.

.109

MIN.

3.63 REF.

3.92 REF.

SPEED

0

ON

O

F

100

POWER

R

BODINE

ELECTRIC

COMPANY

wp

w

m

C

motor s

p

eed contr

o

D

C

l

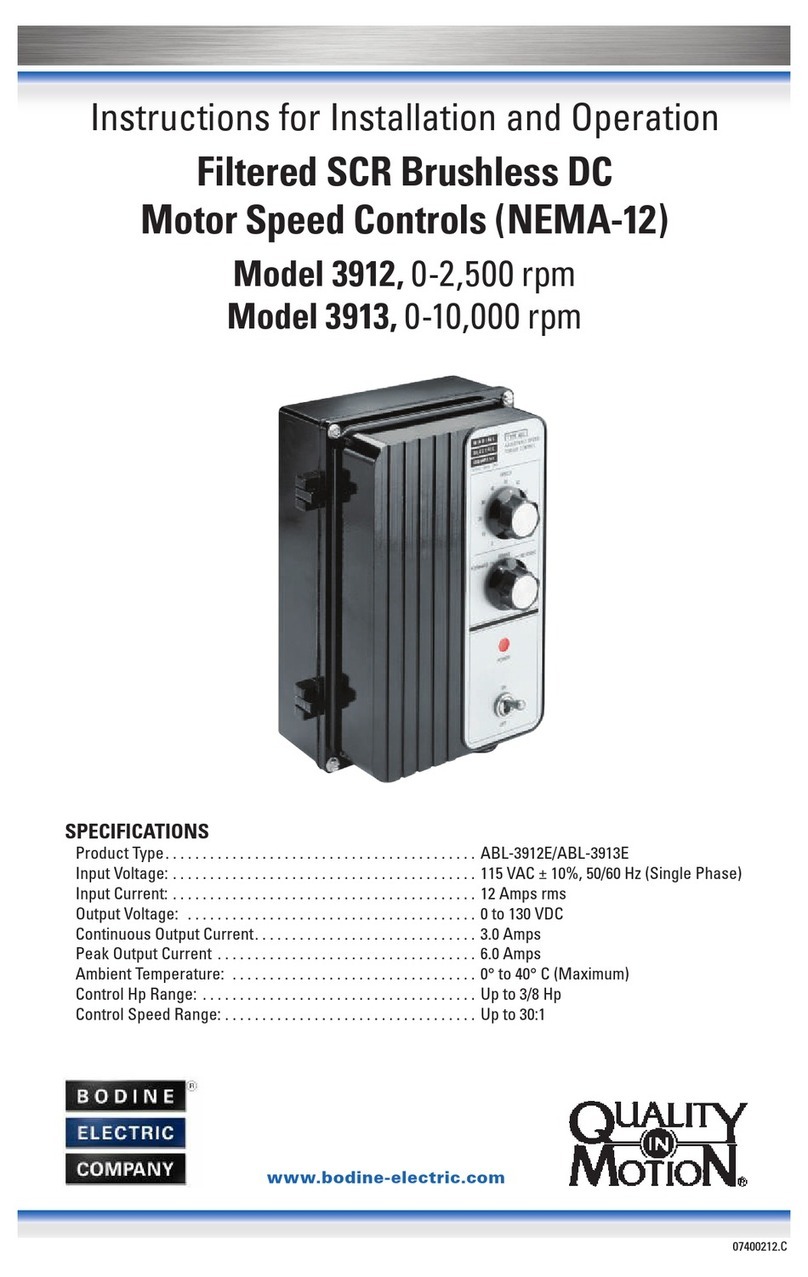

SPECIFICATIONS

Input Voltage 115 VAC ±10%, 50/60 Hz, single phase

Maximum Input Current, Continuous

Model 0790 2.5 Amps RMS

Model 0791 5.7 Amps RMS

Output Voltage 0-130 VDC

Ambient Temperature 0-40° C.

Maximum Output Current, Continuous

Model 0790 2.00 Amps DC*

Model 0791 3.20 Amps DC

Maximum Output Current, Peak

Model 0790 2.20 Amps DC

Model 0791 5.00 Amps DC

Speed Regulation 1% of rated speed

obtainable with most motors

Acceleration/Deceleration Time Adjustable, 0.1-15 seconds

Means for Speed Adjustment 10K Ohm potentiometer

Means for Drive Inhibit switch closure

Diagnostics green power LED, red current limit LED

* Thermal rating only. Actual max. continuous output current is 1.25 Amps.

INSTALLATION

WARNING: This control should only be installed by a qualified person familiar with

its operation and associated hazards. The National Electrical Code (NEC), local

electrical and safety codes, and when applicable, the Occupational Safety and

Health Act (OSHA) should be observed to reduce hazards to personnel and property.

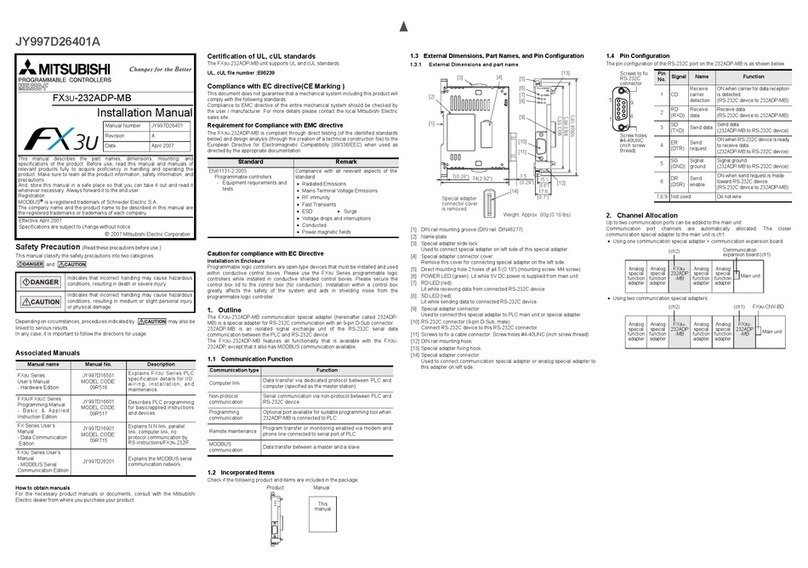

FIGURE 1–Control mounting dimensions

Instructions for Installation and Operation

Type WPM Filtered PWM Speed Controls for Permanent Magnet DC Brush Motors

• Models 0790 & 0791, NEMA 1 enclosure

Step 1: Mounting the Control

The control may be mounted using any two or all four mounting holes. The mounting

holes have clearance for 1/4-20 or M6 screws.

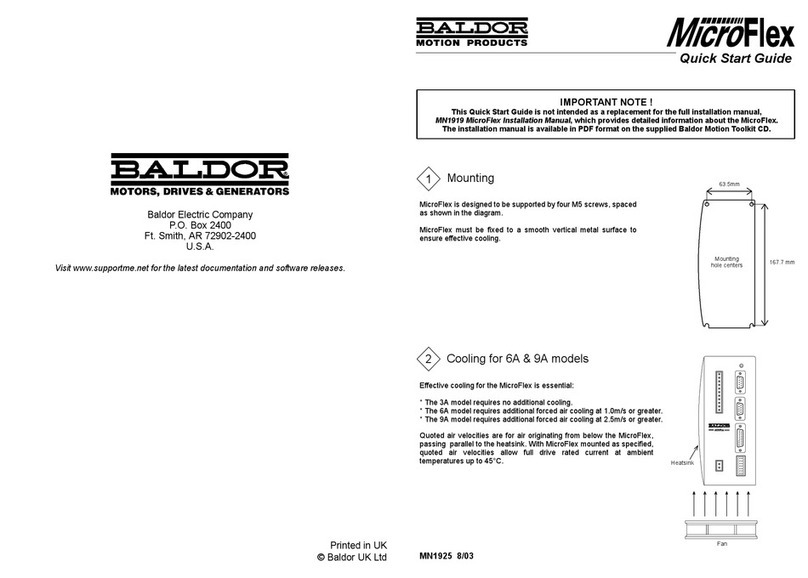

Step 2: Preliminary Setup

HORSEPOWER & ACCELERATION SELECTOR SWITCHES–Control models 0790 and

0791 are packaged with the enclosure cover unattached. Remove the cover to set

the horsepower and acceleration selector switches. Figure 4 shows the location of

a bank of 8 dip switches. Set switches 1 through 6 to match the type, speed, and

current ratings on the Bodine motor nameplate per Figure 2 (consult Bodine on

settings for non-Bodine motors). Set switches 7 and 8 to select the acceleration/

deceleration time range per Figure 3.

Step 3: Electrical Connections

The enclosure cover must be removed as shown in Figure 4 to make the electrical

connections.

WARNING–All parts of the circuit operate at voltages capable of causing

serious injury or death.

WARNING–The AC power line to the control should be the last connection made.

CAUTION–The control board signal common is not at ground potential. Any

external signal or equipment connected to the control must be electrically

isolated from ground.

INHIBIT SWITCH (OPTIONAL)–A mechanical switch or relay with contacts rated

for low voltage may be connected to terminals “H1” and “H2”. With the switch

open, the motor will run. With the switch closed, the motor will coast to a stop.

WARNING–The inhibit switch should not be used to disable motor or control

when servicing these or driven equipment. Disconnect the AC power instead.

FIGFIGURE 2–Setup of Dip Switches 1 through 6

Control

Motor Ratings Control Setup

Motor

Type

Armature

RPM@

130V1

Motor Rated

Amps2Motor HP

Dip

Switches

On

Peak

Output

Amps3

Continuous

Input

Current4

Model

0790

24A0 2500 0.22 1/50 Consult Bodine Factory

24A2 2500 0.3 1/29 1,2 0.6 0.8

24A4 2500 0.48 1/17 1,2,3 1.0 1.1

24A4 2500 .56 | .81 1/23 | 1/11 3,5,6 1.2 1.4

33A3 2500 .78 | 1.0 1/16 | 1/8 2,4,5,6 2.1 1.9

33A3 2500 0.74 1/12 3,5,6 1.2 1.4

33A3 2000 0.71 1/12 3,5,6 1.2 1.2

33A5 2500 0.91 1/8 2,4,5,6 2.1 1.9

42A3 2500 1 1/8 2,4,5,6 2.0 2.0

42A4 2000 1.3 1/6 1,2,4,5,6 2.2 2.5

Model

0791

24A4 11500 1.1 1/7 351.7 1.9

33A3 2500 0.74 1/12 1 1 1.4

33A3 2500 .78 | 1.0 1/16 | 1/8 3 1.7 1.9

33A3 2000 0.71 1/12 1 1 1.4

33A5 2500 1.4(1.3) | 1.8(1.7) 1/8 | 1/4 2,3 2.0 2.5

33A5 2000 1.4 1/6 3 1.7 1.9

33A5 2500 0.91 1/8 3 1.7 1.9

33A7 2500 1.8 | 2.4 1/6 | 1/3 3,5 4.1 3.6 | 4.8

42A3 2500 1 1/8 1,3 1.9 2

42A4 2000 1.3 1/6 2,3 2 2.5

42A5 2500 1.9 | 1.8 3/16 | 1/4 3 1.7 1.9

42A5 2500 1.8 1/4 3,5 4.1 3.6

42A5 2500 2.7 1/3 3,5 4.1 4.8

42A7 2500 2.3 1/3 2,3,5 4.9 4.0

42A7 2500 3.4 1/2 2,3,5 5.0 5.7

42A7 2500 3.3 7/16 2,3,5 5.0 5.7

FIGURE 3–Setup of dip switches 7 and 8

Switches Acceleration/Deceleration Time Range (seconds)6

7 8 ACC pot fully CCW (factory setting) ACC pot fully CW

Off Off .1 .3

Off On .5 2.0

On Off 3.5 12.0

On On 4.0 15.0

1. For armature speed of a geared motor, multiply the output speed at the driveshaft by the

gear ratio.

2. If the user desires to install their own armature fuse on the control output to protect the motor

from continuous overloads, base fuse ratings on the motor rating in this column.

3. Peak current available with TORQ pot in fully CW position (factory setting). This current exceeds

the continuous rating of the motor and is for intermittent overload conditions only.

4. Use this column for sizing a line fuse on the control input.

5. The REG potentiometer must be turned fully CCW (off) for high-speed type 24ABEPM motor.

6. Time for voltage across A1 and A2 to ramp up to 130 V when speed pot is turned from 0 to 100;

or to ramp down to 0 V when it is turned from 100 to 0. The time for a motor to accelerate from 0

to 2500 rpm or decelerate from 2500 to 0 rpm is dependent on motor size and loading conditions.

RoHS

COMPLIANT

201 Northfield Road | Northfield Illinois, 60093, U.S.A. | Phone 773.478.3515 | www.bodine-electric.com | [email protected] 07400213 Rev.C

INSTALLATION, continued

OPERATION

Step 4: Preliminary Checks Before Starting

1. Before starting the control, check all fuses, connections, and adjustments such

as horsepower switch settings.

2. Check all rotating members. Be sure keys, pulleys, etc. are securely fastened and

safety guards are in place.

3. Check for proper mounting and alignment of products, and verify safe loading on

shafts and gears.

4. Check that motor is securely mounted.

5. Test the motor unloaded first to verify proper connections.

Step 5: Operating the Control

1. With AC power switch OFF, set the speed pot to ZERO (fully counterclockwise).

2. Turn the AC power switch ON.

3. Turn the speed pot until motor rotates at desired speed. Note that “SCR rated”

motors, or motors rated 90 VDC, will run faster with a filtered control because of

the 130 VDC max. output voltage.

4. If the motor does not start promptly and run smoothly, turn the AC power switch

OFF, unplug the control, and refer to “TROUBLESHOOTING,” below.

Step 6: Internal Adjustments

Most users will find the factory calibration of the control to be acceptable for

their application. For those who want to fine-tune the control, five trim pots are

accessible on the PC board. First, remove the enclosure cover. Figure 4 shows the

locations of the internal adjustment potentiometers.

WARNING–Use a non-metallic or insulated adjustment tool for internal

adjustments. Circuit components are at high potential and accidental short-

circuiting and shock hazard may occur with conductive tools.

TROUBLESHOOTING

WARNING–Disconnect the control from the AC power source before working on

the control, motor, or driven equipment.

If the motor does not operate, disconnect the AC power and double check all

connections and fuses. Make sure the TORQ pot is not turned fully counterclockwise.

If a fuse is blown and the motor is not locked (stalled) or overloaded, do not replace

the fuse. The control may be damaged. If the motor is overloaded, reduce the load

and replace the blown fuses with new ones of the proper type and rating. If the

problem persists, contact your source of purchase or a Bodine Authorized Service

Center and describe the problem in detail. Include all nameplate data for both motor

and control.

MOTOR CONNECTIONS–Feed the motor cable through the opening in the bottom of

the enclosure. For clockwise armature rotation, connect the “+” motor wire (white

wire on Bodine motors) to terminal “A2” and the “–” motor wire (black wire on

Bodine motors) to terminal “A1”. For counterclockwise rotation, reverse the motor

connections. Reinstall enclosure cover.

LINE FUSE–Models 0790 and 0791 are equipped with a fuseholder on the front

panel that is accessible to users for field replacement of the fuse. A four amp

fuse is factory installed in model 0790 and an eight amp fuse is factory installed

in model 0791.

AC POWER CONNECTIONS–Models 0790 and 0791 are equipped with a six foot long

cable having a standard connector for 115 VAC outlet. When all other connections

are made, plug it in.

OFF

ON

8 7 6 5 4 3 2 1

S1 (BLUE)

DIP SWITCHES

MAX

TORQ MIN

S2 (ORANGE)

S3 (YELLOW)

L2 (WHITE-GRAY)

L1 (GRAY)

A2 (+)

Factory-wired

to speed pot on

front panel

Factory-wired to

on/off power switch

}

}

}

A1 (–) User connects motor

here. CW connection

shown.

ACC

H2

H1 User can connect an optional

inhibit switch here

}

REG

LIMIT LED

POWER LED

To Motor

To 115 VAC Line

FIGURE 4–Electrical connections and internal adjustments

BODINE LIMITED WARRANTY

The Bodine Electric Company warrants all products it manufactures to be free

of defects in workmanship and materials when applied in accordance with

nameplate specifications. Bodine motors and gearmotors purchased with

and used only with appropriately applied Bodine controls are covered by this

warranty for a period of 24 months from the date of purchase or 30 months from

date of manufacture, whichever comes first. Bodine motors and gearmotors

used with non-Bodine controls and Bodine controls used with non-Bodine

motors and gearmotors are covered by a 12 month warranty period. The Bodine

Electric Company will repair, replace, or refund at its option, any of its products

which has been found to be defective and within the warranty period, provided

that the product is shipped freight prepaid, with previous authorization, to Bodine

or to a Bodine Authorized Service Center. Bodine is not responsible for removal,

installation, or any other incidental expenses incurred in shipping the products

to or from Bodine. This warranty is in lieu of any other expressed or implied

warranty–including, but not limited to, any implied warranties of merchantability

and/or fitness for a particular use. Bodine’s liability under this warranty shall

be limited to repair or replacement of the Bodine product and Bodine shall

not be liable, under any circumstances, for any consequential, incidental or

indirect damages or expenses associated with the warranted products. Proof

of purchase of motor or gearmotor and matching control as a system must be

provided with any claim.

MINIMUM SPEED LIMIT–Turn the MIN pot clockwise to make the motor run faster

than 0 rpm when the speed pot is set at “0”. With the MIN pot fully clockwise

and the speed pot set at “0” output voltage will be about 50 VDC. Increasing the

minimum speed will also increase the maximum speed, so the MAX pot may need

to be adjusted.

MAXIMUM SPEED LIMIT–Turn the MAX pot counterclockwise to make the motor

run slower than full speed when the speed pot is set at “100”. With the MAX pot

fully counterclockwise and the speed pot set at “100” the motor will run at about

60% of full speed.

TORQUE LIMIT–Turn the TORQ pot counterclockwise to reduce the peak torque

capability of the motor. Most Bodine motors will produce about 200% of rated

torque with the horsepower switches set per Figure 2 and the TORQ pot turned

fully clockwise. The motor must be properly sized for the application so that

it only produces this peak torque intermittently. Turning the TORQ pot fully

counterclockwise will produce 0% torque (stall).

ACCELERATION/DECELERATION TIME–Turn the ACC pot to simultaneously adjust

the acceleration and deceleration time within the range selected by dip switches

7 and 8. Refer to Figure 3. Clockwise rotation of ACC pot increases acceleration or

deceleration time.

SPEED REGULATION–The REG pot sets the gain of the IR compensation. It is factory-

set so that the speed of most Bodine motors varies no more than 2% from no load to

full load at full speed when the horsepower switches are set per Figure 2. The REG

pot normally requires no adjustment by the user unless better speed regulation is

needed or no speed regulation is needed. Turn the REG pot clockwise to increase IR

compensation. Turning it too much will make the system unstable. If this happens,

turn the REG pot counterclockwise to reduce the IR compensation. When using the

WPM control in a closed-loop system with another control device, turn the REG pot

fully counterclockwise to eliminate IR compensation.

© Copyright 2011 Bodine Electric Company. Data subject to change without notice.

This manual suits for next models

1

Other Bodine Controllers manuals