C-PRO MEGA RACK & C-PRO GIGA RACK APPLICATION MANUAL

Page

3

Table of contents

1

GENERAL INFORMATION......................................................................................................5

1.1

Description ............................................................................................................................5

2

APPLICATIONS.........................................................................................................................8

2.1

Application 1: use of the C-PRO MEGA RACK (single circuit control unit)......................9

2.2

Application 2: use of the C-PRO GIGA RACK (dual circuit control unit with separate

condensation).................................................................................................................................10

2.3

Application 3: use of the C-PRO MEGA RACK with the C-PRO EXP MEGA I/O

expansion unit (dual circuit control unit with separate condensation)...........................................11

2.4

Application 4: use of the C-PRO GIGA RACK with the C-PRO EXP GIGA I/O expansion

unit (dual circuit control unit with separate condensation)............................................................12

2.5

Controller electrical connections.........................................................................................13

2.5.1

C-PRO MEGA RACK electrical connections .............................................................13

2.5.2

C-PRO GIGA RACK electrical connections...............................................................14

2.5.3

Input and output identification tables...........................................................................15

2.6

Preset configurations...........................................................................................................19

2.6.1

C-PRO MEGA RACK preset configurations (single circuit compressor packs) ........19

2.6.2

C-PRO GIGA RACK preset configurations (dual circuit compressor packs).............20

2.7

I/O expansion unit electrical connections ...........................................................................21

2.7.1

C-PRO EXP MEGA electrical connections.................................................................21

2.7.2

C-PRO EXP GIGA electrical connections...................................................................22

2.7.3

Input and output identification tables...........................................................................23

3

COMPONENT NETWORK AND ACCESSORIES ................................................................26

3.1

Example for the C-PRO MEGA RACK and C-PRO GIGA RACK built-in versions........26

3.2

Example for the C-PRO MEGA RACK and C-PRO GIGA RACK case versions Errore. Il

segnalibro non è definito.

4

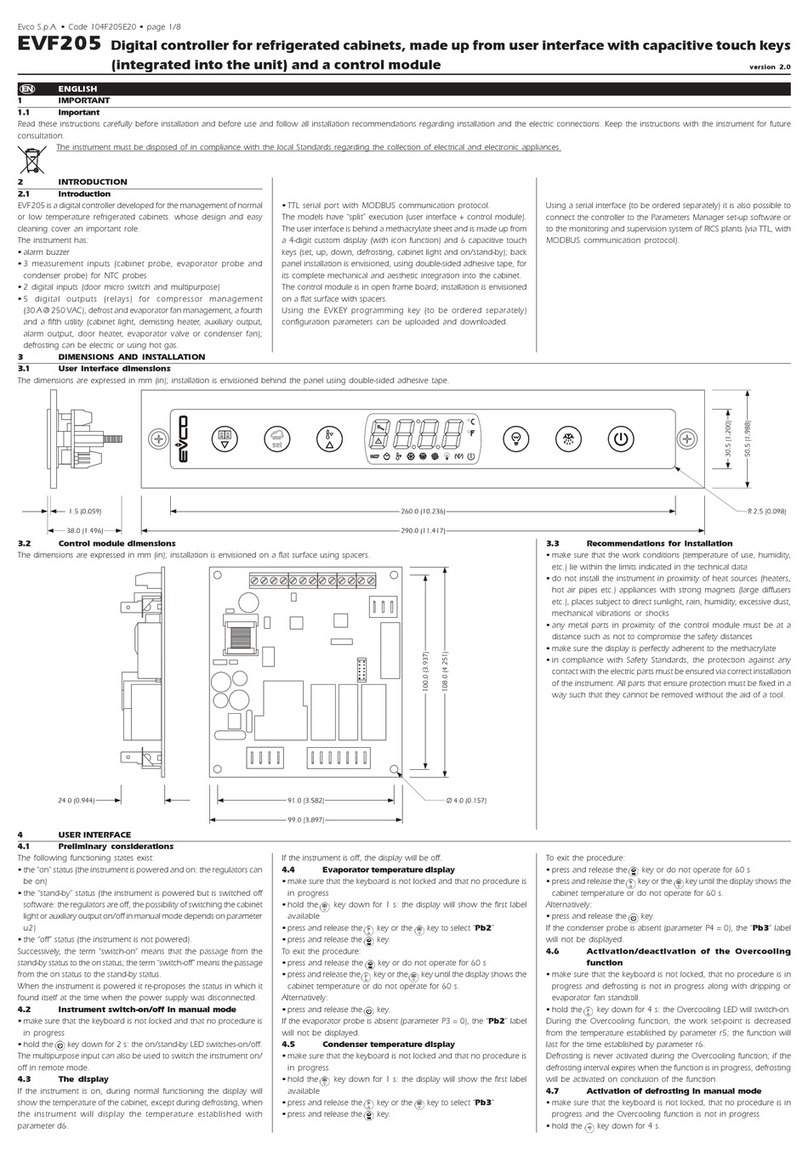

USER INTERFACE ..................................................................................................................27

4.1

Display and keypad.............................................................................................................27

4.1.1

Built-in interface ................................................. Errore. Il segnalibro non è definito.

4.1.2

V- View user terminal......................................... Errore. Il segnalibro non è definito.

4.2

Page list ...............................................................................................................................28

4.3

Conditioned visibility..........................................................................................................34

5

CONFIGURATION PARAMETERS .......................................................................................35

6

REGULATIONS........................................................................................................................68

6.1

Machine configuration ........................................................................................................68

6.2

Machine and individual circuit status..................................................................................69

6.3

Compressor regulation ........................................................................................................71

6.3.1

Side band regulation.....................................................................................................71

6.3.2

Neutral zone regulation................................................................................................72

6.3.3

Side band regulation with inverter...............................................................................73

6.3.4

Neutral zone regulation with inverter ..........................................................................74

6.4

Compressor management ....................................................................................................75

6.4.1

Compressors per circuit ...............................................................................................76

6.4.2

Compressor status........................................................................................................76

6.4.3

Compressor rotation.....................................................................................................77

6.4.4

Increment management................................................................................................78

6.4.5

Protective device timings.............................................................................................80

6.4.6

Startup delay from reset...............................................................................................81

6.4.7

Safety device inputs .....................................................................................................81