Body Flex Sports BRM2170 User manual

BRM2170/

BRM2180

OWNER’S MANUAL

*This item is for consumer use only and it is not meant for commercial use.

OWNER’S MANUAL

*This item is for consumer use only and it is not meant for commercial use.

For use under U.S. Patent numbers 6159132, D459773, D438264

BRM2170/2180 Page 1

General Information

Warranty

Body Flex Sports warrants your product for

a period of 1 year for the frame and 90 days

on all parts if the item is used for the intended

purpose, properly maintained and not used

commercially. Any alterations or incorrect

assembly of the product will void this warranty.

Proof of purchase must be presented for any

warranty validation (no exceptions). This

warranty applies to the original purchaser only

and is not transferable.

This warranty does not cover abuse or defects

caused during use, storage or assembly.

During the warranty period, Body Flex Sports

reserves the right to:

a). provide replacement parts to the

purchaser in an effort to repair the item.

b). repair the product returned to our

warehouse (at the purchaser’s cost).

c). replace the product if neither of the two

previously mentioned actions effect repair.

This warranty does not cover normal wear and

tear on upholstery.

Questions

If you have any questions concerning the

assembly of your item or if any parts are

missing, please DO NOT RETURN THE

ITEM TO THE STORE OR CONTACT THE

RETAILER. Our dedicated customer service

staff can help you with any questions you may

have regarding the assembly of this unit and

can also mail you replacement parts.

Customer Support

Customer Support is open 9:00 a.m. to 5:00

p.m. (Pacific Time) Monday through Friday.

Please contact us by any of the following

means.

Body Flex Sports, Inc.

21717 Ferrero Parkway, Walnut, CA 91789

Telephone: (888) 266 - 6789

Fax: (909) 598 - 6707

Email: info@bodyflexsports.com

Safety

Before you undertake any exercise program,

please be sure to consult with your doctor.

Frequent strenuous exercise should be

approved by your doctor and proper use

of your product is essential. Excessive or incorrect

training may result to health injuries. Please read

this manual carefully before commencing the

assembly of your product or starting to exercise.

• Please keep all children away from this item

when in use. Do not allow children to climb or

play on them when they are not in use.

• Supervise teenagers while they use this unit.

• For your own safety, always ensure that there

is at least 3 feet of free space in all directions

around your product while you are exercising.

• Regularly check to see that all nuts, bolts and

fittings are securely tightened. Periodically

check all moving parts for obvious signs of

wear or damage.

• Clean only with a damp cloth, do not use

solvent cleaners. If you are in any doubt, do

not use your product; contact CUSTOMER

SUPPORT.

• Before use, always ensure that your product

is positioned on a solid, flat surface. If

necessary, use a rubber mat underneath to

reduce the possibility of slipping.

• Always wear appropriate clothing and

footwear such as training shoes when

exercising. Do not wear loose clothing that

could become caught in moving parts during

exercise.

• Do not use this unit if it is not functioning

properly or if it is not fully assembled.

• Do not use this unit for commercial purposes.

This unit is for home use only.

Storage and Use

Your product is intended for use in clean

dry conditions. You should avoid storage in

excessively cold or damp places as this may

lead to corrosion and other related problems.

Weight Limit

Your product is suitable for users weighing:

250 pounds or less.

• Before use, you must read and understand all

instructions & warnings stated in this Owner’s

Manual as well as posted on the equipment.

• It is the facility owner’s responsibility to properly

instruct users on the proper operation of the

equipment and to warn them of the potential

hazards.

• If at any time during exercise you feel faint, dizzy

or experience pain, stop and consult your

physician.

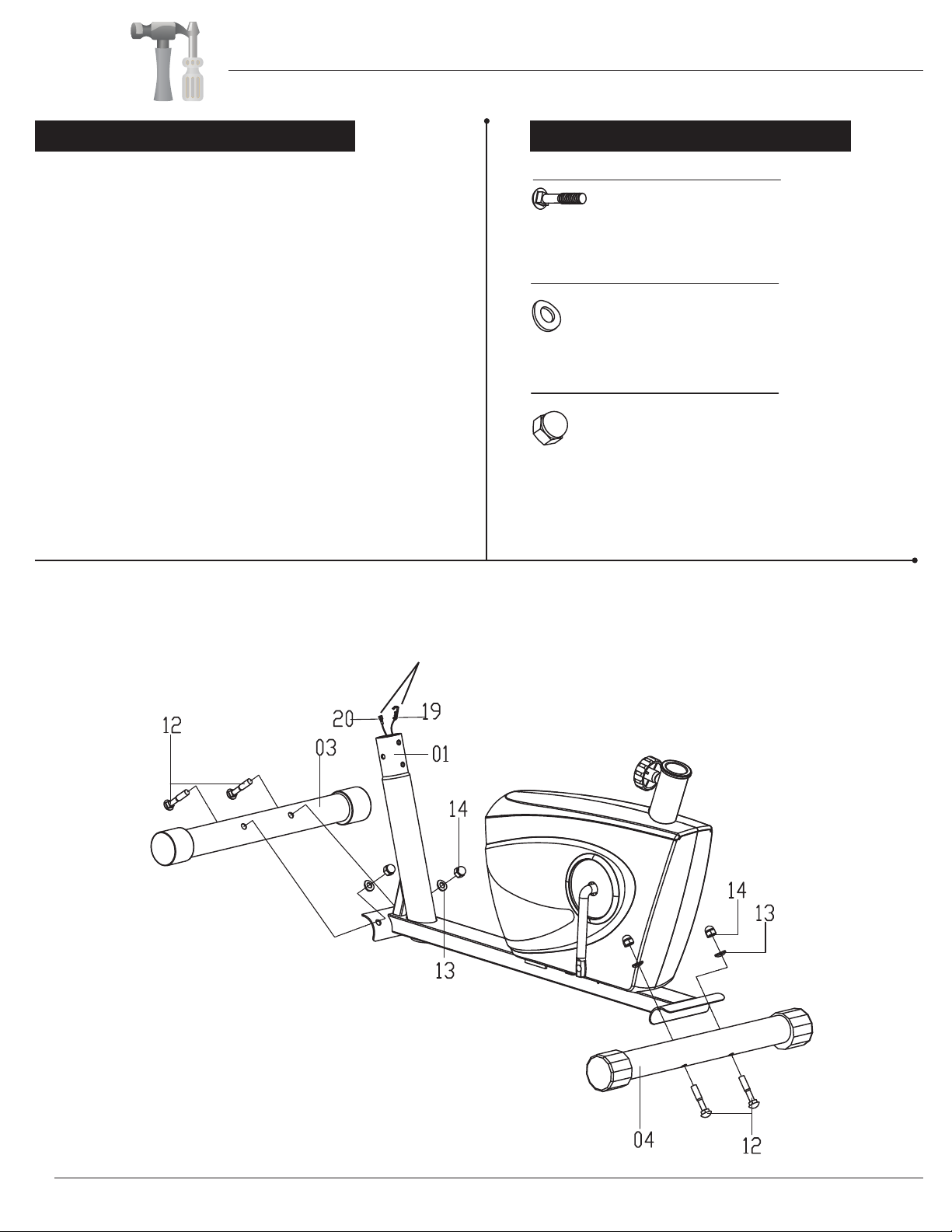

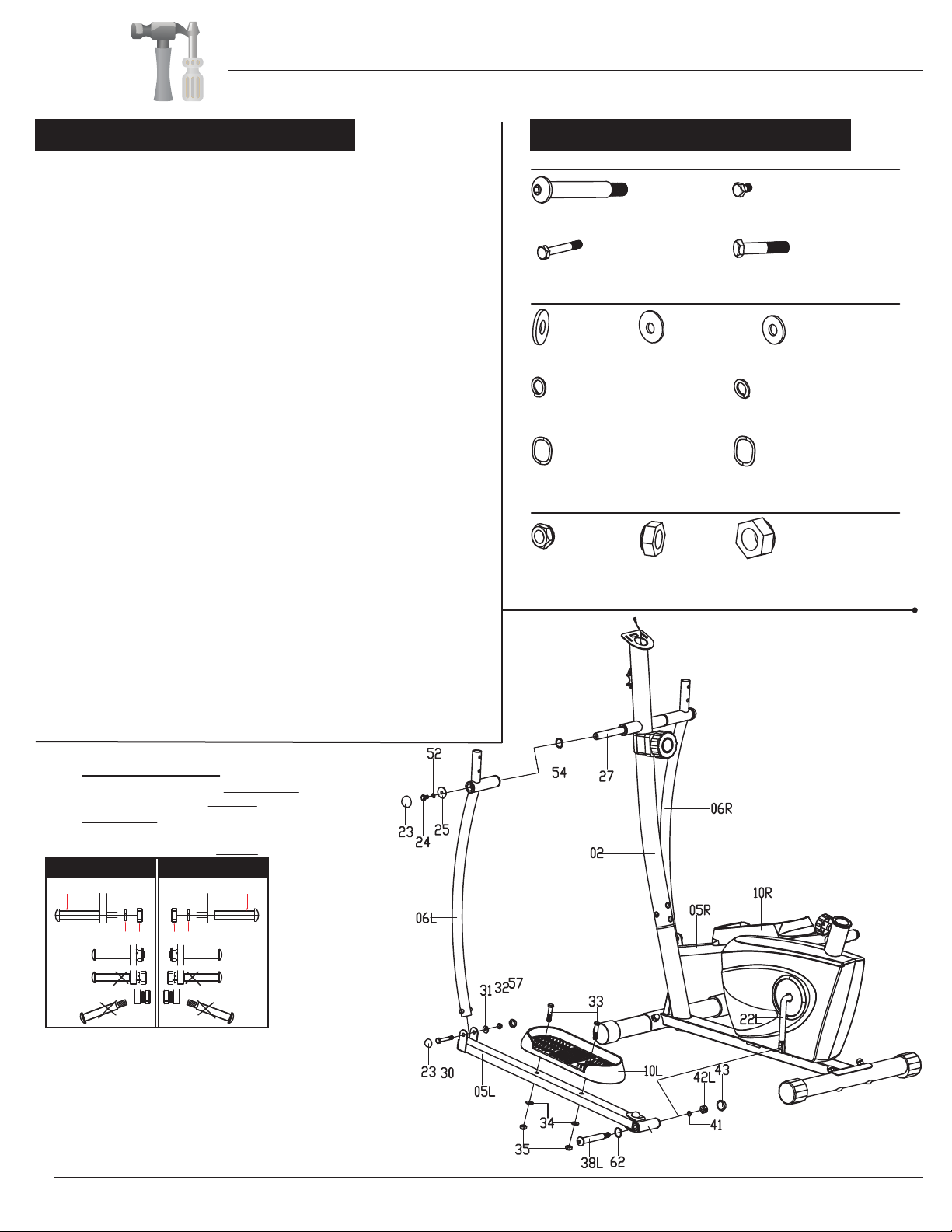

Assembling Tools

- Ruler with both metric and English measurements

- 2 x Adjustable Wrenches

- 1 x Philips (”Crosshead”) Screw Driver

•

Any adjustment devices that could interfere with

the user's movement on this unit should not be

left projecting.

Hardware & Tool List

The following hardware is used to assemble your unit. Please take a moment to familiarize yourself with these items.

PLEASE NOTE: some of these parts may have already been pre-assembled on your unit.

Page 2

#12. Carriage Bolt

(M10×57 mm)

[4 Pieces]

#38L. Left Pedal Hinge Bolt

#38R. Right Pedal Hinge Bolt

#13. Arc Washer (M10)

[4 Pieces]

#30. Hex Bolt

(M8×55 mm)

[2 Pieces]

#33. Hex Bolt

(M10×45 mm)

[4 Pieces]

#45. Carriage Bolt

(M8×40 mm)

[4 Pieces]

#51. Bolt

(M8×30 mm)

[2 Pieces]

Pre-assembled

#55. Screw

(M4X12 mm)

[2 Pieces]

Pre-assembled

#16. Bolt

(M8×16 mm)

[4 Pieces]

Pre-assembled

#24. Hex Bolt

(M8×15 mm)

[2 Pieces]

Pre-assembled

#41. Spring Washer (Φ13×B2)

[2 Pieces]

#31. Washer

(M8, t1.5)

[2 Pieces] #34. Washer (M10)

[4 Pieces]

#25. Washer

(M8, t2.0)

[2 Pieces]

#52. Spring Washer (M8)

[4 Pieces]

Pre-assembled

#56. Arc Washer (M8,R25)

[4 Pieces]

Pre-assembled

#44. Arc Washer (M8, R16)

[4 Pieces]

#62. Special Washer (D17×0.3)

[2 Pieces]

)Φ20#54. Special Washer (

[2 Pieces]

Pre-assembled

#14. Cap Nut (M10)

[4 Pieces]

#32. Nylon Nut (M8)

[2 Pieces]

#35. Nylon Nut

(M10)

[4 Pieces]

#42L. Left Nylon Nut

#42R. Right Nylon Nut

#58. Nut

(M8)

[4 Pieces]

S8 [1Piece] S6 [1Piece]

S13-14 [1Piece] S17-19 [1Piece]

S10-13-14-15-17 [1Piece]

Pre-assembled

Bolts

Washers

Nuts

Others

[1 Piece of each]

[1 Piece of each]

#70. Washer

(M8)

[3 Pieces]

Pre-assembled

#74. Washer (M10)

[1 Piece]

#78. Nylon Nut

(M8)

[3 Pieces]

Pre-assembled

#68. Knob Bolt (M12)

[1 Piece]

#75. Knob (M10)

[1 Piece]

BRM2170/2180

Page 3

BRM 3670 Stride Cycle Page ?

Parts Listing

The following parts list describes all of the parts illustrated on the

exploded diagram on the following page. Please note, most of

these parts are already pre-assembled on your unit.

End Cap (口40×25×1.5 )

01 Main Frame 42L/42R Left/Right Nylon Nut

02 Front Post 43 Bolt Cap (S19)

03 Front Stabilizer 44 Arc Washer (M8, R16)

04 Rear Stabilizer 45 Carriage Bolt (M8×40 mm)

05L/05R Left/Right Pedal Arm 46 End Cap

06L/06R Left/Right Coupler Bar 47 Foam of Handlebar

07L/07R Left/Right Handlebar 48 Foam of Pulse Handlebar

08 Pulse Handlebar 49 End Cap (Φ25×1.5)

09 Monitor 50 Handle Pulse Wire (Lower)

10L/10R Left/Righ Pedal 51 Bolt (M8×30 mm)

11 End Cap for Front Stabilizer 52 Spring Washer (M8)

12 Carriage Bolt (M10×57 mm) 53 Handlebar Cover

13 Arc Washer (M10) 54 Special Washer (Φ20)

14 Cap Nut (M10) 55 Screw (M4X12 mm)

15 End Cap for Rear Stabilizer 56 Arc Washer (M8,R25)

16 Bolt (M8×16 mm) 57 Bolt Cap (S13 )

17 Tension Controller 58 Nut (M8)

18a/18b Main Sensor Wire (Middle) 59 Washer (M5)

19 Tension Wire 60 Tension Controller Cover

20 Main Sensor Wire (Lower) 61 Bushing (Φ14*10*Φ10.1 )

21 Screw (M5X45 mm) 62 Special Washer (D17×0.3)

22L/22R Crank 63 Screw (ST3×10 mm)

23 Bolt Cap (S14 ) 64 Right Shroud Cover

24 Hex Bolt (M8×15 mm) 65 Left Shroud Cover

25 Washer (M8, t2.0) 66 Main Sensor Wire (Upper)

26 Bushing (Φ 32×28) 67 Handle Pulse Wire (Upper)

27 Front Post Axle 68 Knob Bolt (M12)

28 End Cap (Φ28×1.5) 69 Seat

29

BRM2170/2180

70 Washer (M8)

30 Hex Bolt (M8×55 mm) 71 Horizontal Seat Bar

31 Washer (M8,t1.5) 72 U Bracket

32 Nylon Nut (M8) 73 End Cap

33 Hex Bolt (M10×45 mm) 74 Washer (M10)

34 Washer (M10) 75 Knob (M10)

35 Nylon Nut (M10) 76 Seat Post

36 Bolt Cap (S16 ) 77 Seat Post Sleeve

37 Hex Bolt (M10×50 mm) 78 Nylon Nut (M8)

38L/38R Left/Right Pedal Hinge Bolt

39 Bushing (Ф24×20×Ф16.1 )

40L/40R Pedal Connection Joint

41 Spring Washer (Φ13×B2)

# Description # Description

Page 4

Exploded Diagram

The following diagram is provided to help you familiarize yourself with the parts and

hardware that will be used during the assembly process. Please note that not all of the

parts and hardware you see here will be used while you are assembling the machine

because some of these items are already pre-installed. Please continue to the next

page to begin the assembly process and use this page only as a reference guide for

parts and hardware.

BRM2170/2180

Page 5

Hardware Required

#12. Carriage Bolt

(M10×57 mm)

[4 Pieces]

#13. Arc Washer (M10)

[4 Pieces]

[4 Pieces]

Bolts

Washers

Nuts

A s s e m b l y S t e p 1

#14. Cap Nut

(M10)

Make sure these two wires are visible and hang out before

proceeding to the next step. If they have fallen

inside the tube, use a bent wire to “fish” them out.

Spinning

End Caps

Height Adjustable

End Caps

With the help of an assistant, attach the Front Stabilizer (#03)

to the front of the Main Frame (#01). Insert two Carriage Bolts

(#12) through the Front Stabilizer (#03) followed by the front

of the Main Frame (#01). Secure them together using two Arc

Washers (#13) and two Cap Nuts (#14).

Now attach the Rear Stabilizer (#04) to the rear of the Main

Frame (#01). Insert two Carriage Bolts (#12) through the

Rear Stabilizer (#04) followed by the rear of the Main Frame

(#01). Secure them together using two Arc Washers (#13)

and two Cap Nuts (#14).

Please note: The Front Stabilizer (#03) has end caps that

spin for ease of relocating the unit and the Rear Stabilizer

(#04) has height adjustable end caps for leveling of the unit.

Assembly Instructions

FRONT OF UNIT

REAR OF UNIT

BRM2170/2180

Page 6

Hardware Required

Make sure this wire is

hanging out before

assembling the Front

Post (#02).

#16. Bolt

(M8×16 mm)

[4 Pieces]

#56. Arc Washer (M8,R25)

[4 Pieces]

Bolts

Washers

A s s e m b l y S t e p 2

Remove the four Bolts (#16) and four Arc Washers (#56) that were

pre-assembled on the Main Frame (#01) and set them aside as they

will be used later in this step.

Connect the Main sensor Wire (Middle) (#18b) to the Main Sensor

Wire (Lower) (#20) and then follow the instructions in the diagram

below to connect the Tension Wire (#19). After connecting the Tension

Wire (#19) to the Tension Controller (#17) slide the Front Post (#02)

onto the Main Frame (#01) making sure not to pinch the wires and secure

using the fourBolts (#16) and four Arc Washers (#56) that were

TENSION WIRE ASSEMBLY

Insert the tip of the Tension

Controller (17)wire into the Tension

Wire (19) head at an angle. Tilt the

Tension controller (17) wire into the

crevice and then pull upward.

Assembly Instructions

previously removed.

BRM2170/2180

Assembly Instructions

Hardware Required

Bolts

Washers

Nuts

[1 Piece of each]

Hardware Required

Please refer to the diagram below and pay special attention to corresponding

left & right side parts. Misplacing parts during assembly will lead to incorrect

assembly and may result in serious injury.

#38L/R. Left/Right Pedal Hinge Bolt

[1 Piece of each]

#30. Hex Bolt

(M8×55 mm)

[2 Pieces]

#33. Hex Bolt

(M10×45 mm)

[4 Pieces]

#24. Hex Bolt (M8×15 mm)

[2 Pieces]

#41. Spring Washer (Φ13×B2)

[2 Pieces]

#31. Washer

(M8,t1.5)

[2 Pieces]

#34. Washer (M10)

[4 Pieces]

#25. Washer

(M8, t2.0)

[2 Pieces]

#52. Spring Washer (M8)

[2 Pieces]

#62. Special Washer

(D17×0.3)

[2 Pieces]

#54. Special Washer

(Φ20)

[2 Pieces]

#32. Nylon Nut

(M8)

[2 Pieces]

#35. Nylon Nut

(M10)

[4 Pieces]

#42L. Left Nylon Nut

#42R. Right Nylon Nut

Pedal Hinge Bolt (#38L) and CLOCKWISE to tighten

Left Nylon Nut (#42L) with BLACK inner nylon ring.

A s s e m b l y S t e p 3A s s e m b l y S t e p 3

LEFT SIDE RIGHT SIDE

38L 38R

41 42L 42R41

40L

Note:

Keep the Left/Right Pedal Hinge Bolt

(#38L/38R) perfectly

straight as they go

through the Left/Right Pedal Connection

Joint (#40L/R)

and the Crank (#22L/R).

If the Left/Right Pedal Hinge Bolt (#38L/38R)

are connected to the

Crank (#22L/22R)

incorrectly,

damage to the

Left/Right Pedal Hinge Bolt

(#38L/38R) and Crank (#22L/22R)

will occur.

PLEASE NOTE:

b):Turn CLOCKWISE to tighten the Right Pedal Hinge

Bolt (#38R) and COUNTERCLOCKWISE to tighten

Right Nylon Nut (#42R) with WHITE inner nylon ring.

Remove two Hex Bolts (#24), two Spring Washers (#52), two

Washers (#25) and two Special Washers (#54) that are

pre-assembled on the Front Post Axle (#27) and set them aside

as they will be used in a later process.

Insert the Front Post Axle (#27) through the Front Post (#02).

Make sure the Front Post Axle (#27) is centered. If you encounter

too much friction, try using WD40 or Vaseline asa lubricant.

Slide one Special Washer (#54) onto the left side of the Front Post

Axle (#27) then followed by Left Coupler Bar (#06L). Secure them

together by hand tighten one Hex Bolt (#24), one Spring Washer

(#52) and one Washer (#25) that were previously removed.

Align and attach the left Pedal Connection Joint (#40L) on the

Left Pedal Arm (#05L) to the left Crank (#22L). Insert Left Pedal

Hinge Bolt (#38L) through a Special Washer (#62) followed by

left Pedal Connection Joint (#40L) and left Crank (#22L). Screw

the Left Pedal Hinge Bolt (#38L) tightly into the left Crank (#22L)

by turning COUNTERCLOCKWISE and then secure it by hand tighten

one

Spring

Washer

(#41) and one Left Nylon Nut (#42L) by turning it

CLOCKWISE.

Align and attach the Left Coupler Bar (#06L) to the Left Pedal

Arm (#05L). Hand Tighten them together using a Hex Bolt (#30),

a Washer (#31) and a Nylon Nut (#32).

At this point secure the Hex Bolts (#24), Hex Bolt (#30) and Left

Nylon Nut (#42L) that were hand tightened previously.

Attach Bolt Cap (#23) to the end of Hex Bolt (#24) and Hex Bolt

(#30). Attach Bolt Cap (#43) to the end of Left Nylon Nut (#42L).

Attach Bolt Cap (#57) to the end of Nylon Nut (#32).

Attach the Left Pedal (#10L) to the Left Pedal Arm (#05L) and

secure them together using two Hex Bolts (#33), two Washers

(#34) and two Nylon Nuts (#35).

Repeat this process on the other side.

a):Turn COUNTERCLOCKWISE to tighten the Left

Page 7

BRM2170/2180

Page 8

Assembly Instructions

Hardware Required

#45. Carriage Bolt

(M8×40 mm)

[4 Pieces]

#51. Bolt

(M8×30 mm)

[2 Pieces]

#52. Spring Washer

(M8)

[2 Pieces]

#44. Arc Washer.

(M8, R16)

[4 Pieces]

#58. Nut (M8)

[4 Pieces]

Bolts

Washers

Nuts

A s s e m b l y S t e p 4

Insert the Left/Right Handlebars (#07L/07R) onto

the open ends of the two Coupler Bars

(#06L/06R).

Secure the

Left/Right Handlebars (#07L/07R) using

two

Carriage Bolts (#45), two Arc Washers (#44) and

Nuts (#58) as illustrated below.

Install the Pulse Handle Bar (#08) onto the front side

of the Front Post (#02) using the two Bolts (#51) and

two Spring Washers (#52)

previously removed.

Slide the Handlebar Cover (#53) over the Pulse

Handlebar (#08).

Feed the Handle Pulse Wire (Lower) (#50) through

the neck of the Front Post (#02) until the wires stick out

of the opening as shown in circle close up diagram below.

You will need to connect the Monitor (#09) in a later step.

Remove the

two

Bolts (#51) and two Spring Washers

(#52) that were pre-assembled on the Front Post

(#02) and set them aside as they will be used later

in this step.

two

Feed the Handle Pulse Wire

(Lower) (#50) through the

neck of the Front Post (#02)

until they are sticking out of

the opening.

BRM2170/2180

Page 9

Assembly Instructions

A s s e m b l y S t e p 5

The assembly process is complete; however, please read all safety

instructions in this manual as well as any safety/warning labels on

the unit before use.

Please ensure all nuts, bolts and knobs are securely tightened before using the unit.

A.) Remove the two Screws (#55) that are pre-assembled on the back of the Monitor

(#09)

and set them aside as they will be used later in this step.

Connect the Handle Pulse Wire (Lower) (#50) to the Handle Pulse Wire (Upper)

(#67)

and connect the Main Sensor Wire (Middle) (#18a) to the Main Sensor Wire

(Upper) (#66).

Secure the Monitor (#09) to the bracket on the Front Post (#02) using the two Screws (#55)

that were previously removed.

B.)

Remove the Washers and Nuts that are pre-assembled on the back of the Seat

(#69),

then remove the Knob Bolt (#68) that is pre-assembled on the Main Frame (#01) and set

them aside as they will be used later in this step.

Slide the Seat (#69) onto the Horizontal Seat Bar (#71) , ensuring that it is positioned a

s

shown in the illustration below, then tighten with the three Washers (#70) and

Nylon Nuts

(#78) that were previously removed. Assemble the Horizontal Seat Bar

(#71) onto the Seat

Post (#76) by inserting the end of the Horizontal Seat Bar (#71) through Seat Post (#76) as

illustrated below and secure with one Washer (#74) and one Knob (#75). This knob can be

loosened to adjust the distance of the seat from the handle bars. Make sure to tighten the

knob after making an adjustments. Insert the Seat Post (#76) into the mouth of the post

protruding from the Main Frame (#01) down a minimum of 4 inches to engage the lowest

hole. Please ensure that the hole on the Seat Post (#76) facing the same side as the Knob

Bolt (#68) so it can be aligned and fully engage through the lowest corresponding hold on

the Main Frame (#01). Screw in the Knob Bolt (#68) through the Main Frame (#01) post

and fully through (at minimum) the lowest hole located on the Seat Post (#36). Please refer

to illustration. You may adjust the Seat Post (#76) to the height most comfortable for you

after complete assembly. Please always check to ensure a hole has been fully engaged

when you secure and tighten the Knob Bolt (#68).

Hardware Required

After complete assembly: If the computer

is not picking up your hand pulse signal

(or you are getting inaccurate readings),

Please refer to our “Troubleshooting”

section on Page 12 for other troubleshoot

issues.

HAND PULSE SIGNAL

Troubleshooting

#55. Screw (M4x12 mm) [2 Pieces]

Bolts

Washers

Nuts

Others

#70. Washer

(M8)

[3 Pieces]

#74. Washer

(M10) [1 Piece]

#78. Nylon Nut

(M8) [3 Pieces]

#68. Knob Bolt (M12)

[1 Piece]

#75. Knob (M10)

[1 Piece]

BRM2170/2180

FRONT

OF UNIT

Computer Operation

Page 10

FUNCTION MARK:

1. Lift off the battery cover and place two SIZE-AAA batteries into the

battery housing on back of monitor with the +/- sides installed correctly.

2. Please ensure batteries are correctly positioned and battery springs are in proper

contact with batteries.

3. Replace battery cover and ensure it is tightly closed.

4. Battery life is approx. 1 year under normal usage.

5. If the display is illegible or only partial segments appear, remove batteries and wait

15 seconds before reinstalling.

6. Removing the batteries will erase the computer memory.

*NOTE: Please refer to our “TROUBLESHOOTING” page in this manual if you have

any trouble with the LCD Computer Monitor or Pulse/Recovery Functions.

FUNCTIONS AND OPERATIONS:

Mode or function: Explanation:

Auto On/Off & Auto As long as the machine is in motion, the monitor will

Start/Stop remain on. If the machine is not in use and/or not in

motion for over 4 minutes, the monitor will turn off and

reset all function values to zero.

Auto Scan

monitor will rotate through all 5 functions: Speed, Distance,

Time, Odometer & Calories. Each function will display for 6

seconds.

Speed Press the button until the ARROW points to “S” to display

the current speed.

Trip Distance Press the button until the ARROW points to “D” to display

the trip distance you are traveling.

Elapsed Time Press the button until the ARROW points to “T” to display

the elapsed time.

Total Distance Press the button until the ARROW points to “O” to

(Odometer) display the total accumulated distance.

Press the button until the ARROW points to “A”, the

A: Auto Scan O: Odometer (Total Distance)

S: Current Speed C: Calories Burned

D: Distance Traveled : Pulse Rate

T: Elapsed Time

BATTERY INSTALLATION/REPLACEMENT:

0:00

TIME

ODOMETER

CALORIES

PULSE

DISTANCE

SPEED

SCAN

BRM2170/2180

Computer Operation

Page 11

BRM2170/2180

Current Speed The maximum signal that can be detected is 1200

RPH

Trip Distance 0.1-999.9 Miles

Elapsed Time 0:00-99:59( Minute : Second )

Odometer 0.1-999.9 Miles

Calorie 0.1-999.9 K.cal

Pulse Rate 40-240 beats per minute

Controller 4 bit single chip microprocessor

Sensor No-contact magnetic type

Battery type 2 PCS of SIZE-AAA

Operating temperature 0℃ - +40℃ ( 32℉ - 104℉ )

Storage temperature -10℃ - +60℃ ( 14℉ - 140℉ )

Calories Press the button until the ARROW points to “C” to display

the calorie consumption/calories burned.

Pulse Rate Press the button until “” appears to show your heart rate

(Pulse) in beats per minute. Place the palms of your hands

and grip lightly on both the contact pads and the monitor will

display your heartbeat rate in beats per minute (BPM) on

the LCD display.

*Please be aware that the pulse sensors are not medical devices; the pulse sensors

should not be used or applied for medical reasons.

Reset Holding the button for 3 or more seconds will reset all

functional values to zero (except Odometer). The Odometer

will reset anytime the batteries are removed & replaced.

SPECIFICATIONS:

FUNCTION

Auto Scan Every 6 seconds

Troubleshooting

If the computer is not picking up your hand pulse signal (or you are getting

inaccurate readings), please adjust the following:

1. Slightly moisten/dampen the palms with water so the sensors can detect a

pulse signal.

2. Do not grip the sensors too tightly. Only moderate pressure need be applied.

Gripping the sensors too tightly restricts and seizes detection of your pulse.

3. Remove any rings or jewelry to prevent interference.

4. Check to ensure all pulse sensor wires are properly connected and are

not damaged.

You may need to refer to installation/assembly directions for the pulse sensor

wires in this manual.

If the computer is not displaying the CALORIES/DISTANCE/TIME/(ETC.) functions

(or you are getting inaccurate readings), please adjust the following:

1. Check to ensure all computer sensor wires are properly connected and are

not damaged.

You may need to refer to installation/assembly directions for the sensor wires

in this manual.

If the computer display is blank & not displaying any data (or does not appear to

power on), please adjust the following:

1. Check to ensure all sensor wires are all properly connected and are

not damaged.

2. Check to ensure the AC Adapter* or Batteries* are properly plugged in or

fully charged.

Troubleshoot Area

HAND PULSE SIGNAL

CALORIES/DISTANCE/

TIME/(ETC.)

COMPUTER Display

(AFTER COMPLETE ASSEMBLY)

Solution

*Please check your product manual to determine if your model uses either

1. an AC Adapter, or 2. Batteries to power your unit.

For your safety, please do not discard this Troubleshooting sheet or the Owner’s Manual,

and keep them in a place where you can easily access/refer to them at any time.

If you are still having any troubleshooting issues, please contact our Customer Support

for further assistance.

Page 12

BRM2170/2180

Before use, you must read and understand all instructions & warning stated in this Owner's Manual as well as

posted on the equipment.

Warm-Up Instructions

Groin Stretch

1. Sit with your knees flexed

and soles of feet together.

2. Hold your ankles and bend

at your hips (keep your

back straight) as you press

your knees toward the

floor with your elbows.

Hamstring Stretch

1. Sit with your left leg extended and bend your right

leg at the knee as you place the sole of your right foot

against the inner thigh of your extended leg.

2. Flex the foot of your extended leg (toes pointed

toward ceiling) and gently bend forward from your

hips; keep your back straight.

3. Reach your hands on your extended leg as far as pos-

sible and then switch legs and repeat.

Trunk Twister

1. Sit with your leg extended and

bend your right knee as you cross

your right leg over your left leg.

Your right foot should be flat on the

floor alongside your left knee.

2. Place your left arm on the outside

of your right leg and pull against

that leg while twisting your trunk

as far as possible to the right. Place

your right hand on the floor behind

your buttocks. Reverse leg posi-

tions and repeat.

Hip Stretch

1. Lie on your back and raise your right leg as you clasp both hands

under the back of the knee. Keep your left leg straight.

2. Gently pull your right leg toward your trunk without raising your

upper body. Switch leg positions and repeat.

The following flexibility exercises are provided to you as a means to prevent injury while you are exercising. A

proper warm-up routine decreases the chance of injuring your muscles while you are exercising. Please take the

time to do these flexibility exercises before and after each time you exercise.

Quadriceps Stretch

1. Stand on your left leg and hold onto

a support with your left hand.

2. Flex your right leg behind you, grasp

your ankle or foot with your right

hand and pull your foot toward your

buttocks. Keep your back straight

and right knee pointed down. Repeat

on the other leg.

Page 13

BRM2170/2180

Trunk Flexion, Prone

1. Assume the depicted position on your hands and knees. Stretch your hands out in front of you and then slowly start to pull

them back in toward your body as you tuck your chin and arch your back upward.

2. Return to the starting position slowly.

Shoulder Stretch

1. Bring your right hand over

your right shoulder to the

upper back and bring your

left hand under your left

shoulder to the upper back.

2. Try to reach your finger-

tips. If you are not able to

reach your fingertips, use

a towel as an extension of

your hands and gently pull

one hand toward the other.

Reverse arm positions and

repeat.

Calf Stretch

1. Place both hands against

a wall to aid your balance.

Press the ball of your left foot

against the wall and keep the

heel of the same foot rested

on the floor (make sure your

left knee is bent).

2. Slowly start to straighten your

left knee and you will feel

the muscles in your left calf

stretch. Switch leg positions

and repeat.

Warm-Up Instructions

Page 14

BRM2170/2180

Proof of purchase

Model Number BRM2170/2180

version: 09-04-2012

This manual suits for next models

1

Table of contents

Other Body Flex Sports Elliptical Trainer manuals

Popular Elliptical Trainer manuals by other brands

NordicTrack

NordicTrack AudioStrider 990 PRO NTEL09811.2 user manual

Weslo

Weslo Momentum 4.0 Elliptical Manuale d'istruzioni

Progear Fitness

Progear Fitness Air elliptical pro 1307 owner's manual

Torque Fitness

Torque Fitness XPLLP owner's manual

Octane Fitness

Octane Fitness PRO3700C Operation manual

Xterra

Xterra FS5.8e owner's manual