bohm Stirling HB6 Planning guide

Popular Engine manuals by other brands

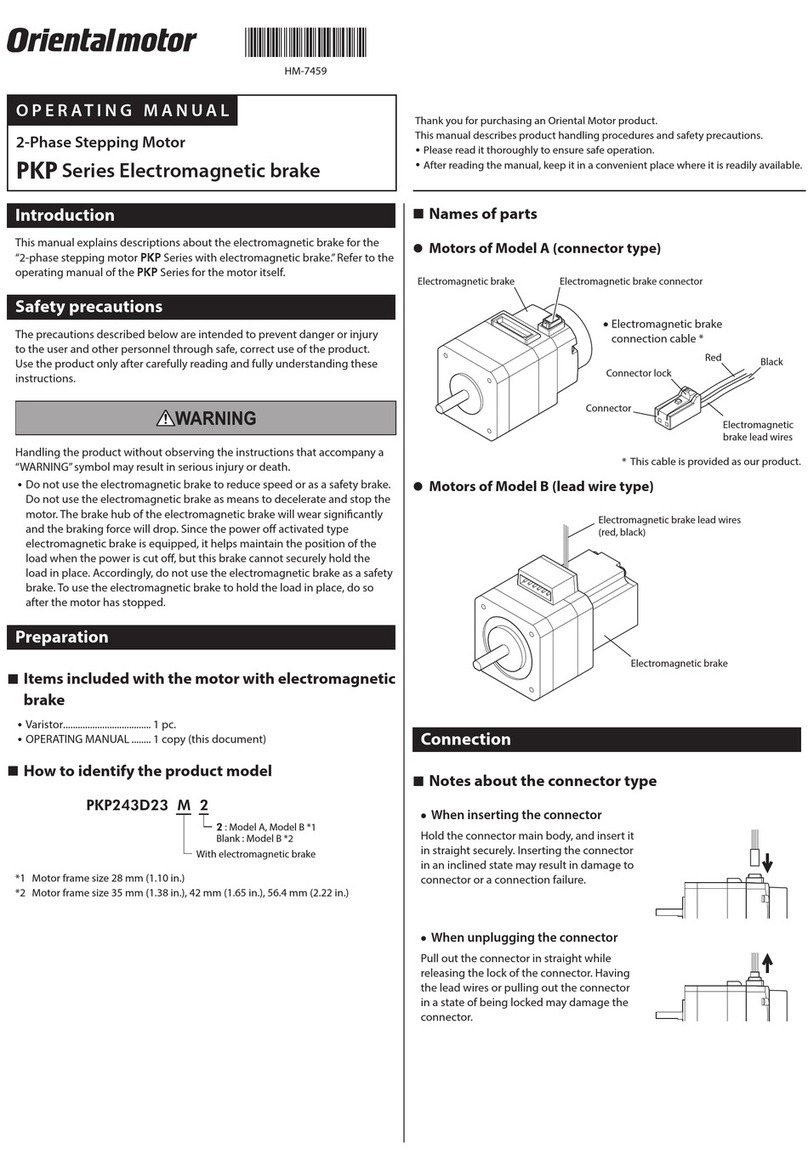

Oriental motor

Oriental motor PKP Series operating manual

CRRCpro

CRRCpro GP22R manual

Oriental motor

Oriental motor World K Series operating manual

GiBiDi

GiBiDi RUNNER REB35 6/28 Instructions for installation

woodmizer

woodmizer E10 Safety, Operation, Maintenance & Parts Manual

Oriental motor

Oriental motor BMU Series quick start guide

Oriental motor

Oriental motor US Series operating manual

Oriental motor

Oriental motor BMU Series operating manual

Oriental motor

Oriental motor RK Series operating manual

Oriental motor

Oriental motor BLE Series operating manual

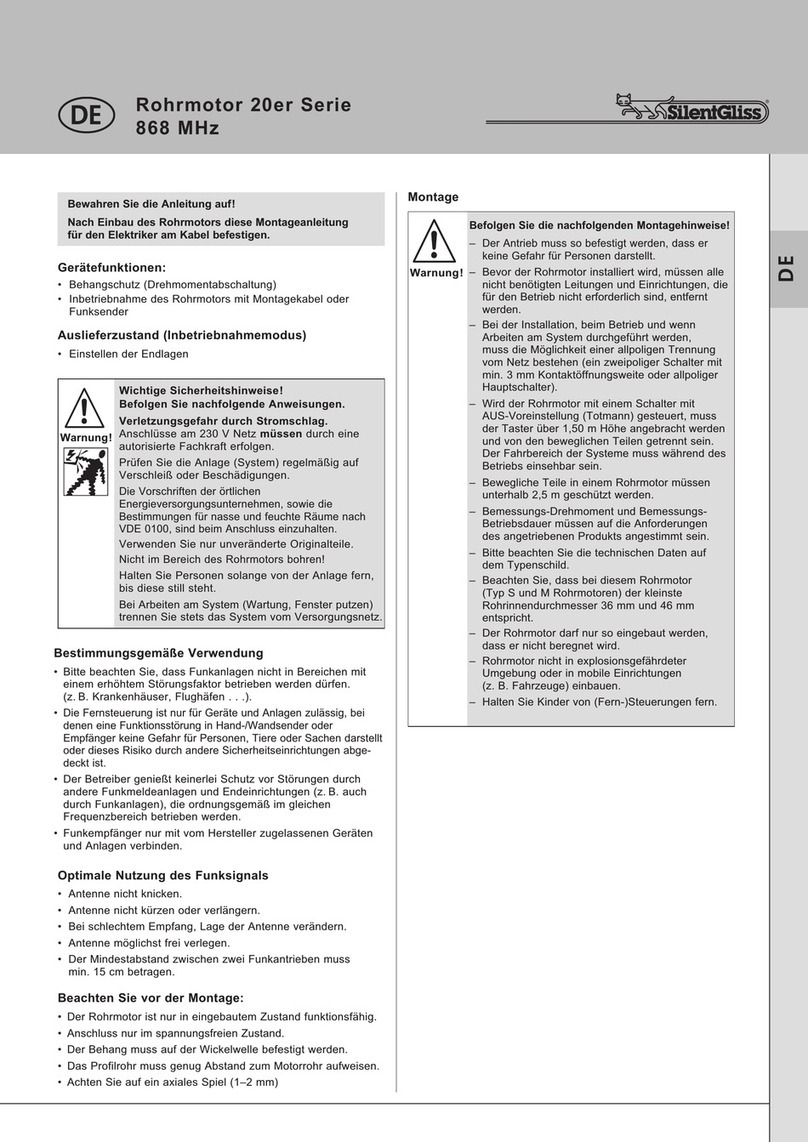

Silent Gliss

Silent Gliss 20 Series instructions

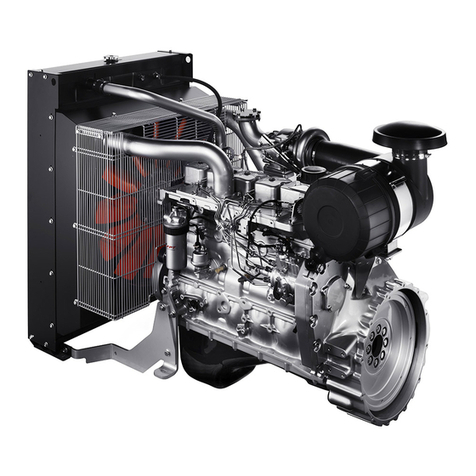

ST. SpA

ST. SpA TRE 352 Operator's manual