bokar XTRACTOR XF-300 Series User manual

INSTRUCTION MANUAL

XF-300 Series

High Volume

Fume Extraction Systems

P/N X-DOC154

20-Oct-10

Rev. B

650 Scranton Pocono Hwy.,

Covington Twp., PA 18444, USA

Tel: (570) 842-2812 Fax: (570) 842-4290

E-Mail: [email protected]

www.bokar.com & www.SMT-tool.com

XF-300 Series High Volume Fume extraction systems

Bokar International www.bokar.com, www.No-Stat.com, www.ZeroCharge.net Page 2 of 11

XF-300 Series High Volume Fume extraction systems

TABLE OF CONTENTS

PAGE

I. INTRODUCTION 2

II. SAFETY 4

III. PACKAGING 7

IV. UNPACKING 7

V. SET-UP AND INSTALLATION 7

VI. SYSTEM DESCRIPTION and APPLICATION 8

VII. TECHNICAL SPECIFICATIONS 9

VIII. OPTIONAL EQUIPMENT 10

I. INTRODUCTION

A cost effective unit capable of extracting fumes, with optimal flow rates, for up to two soldering stations

using any of the following attachments:

•Maximum number of 50mm Arms, Cowls or Down Draft Trays - 2

•Maximum number of 75mm Arms, Cowls or Down Draft Trays - 2

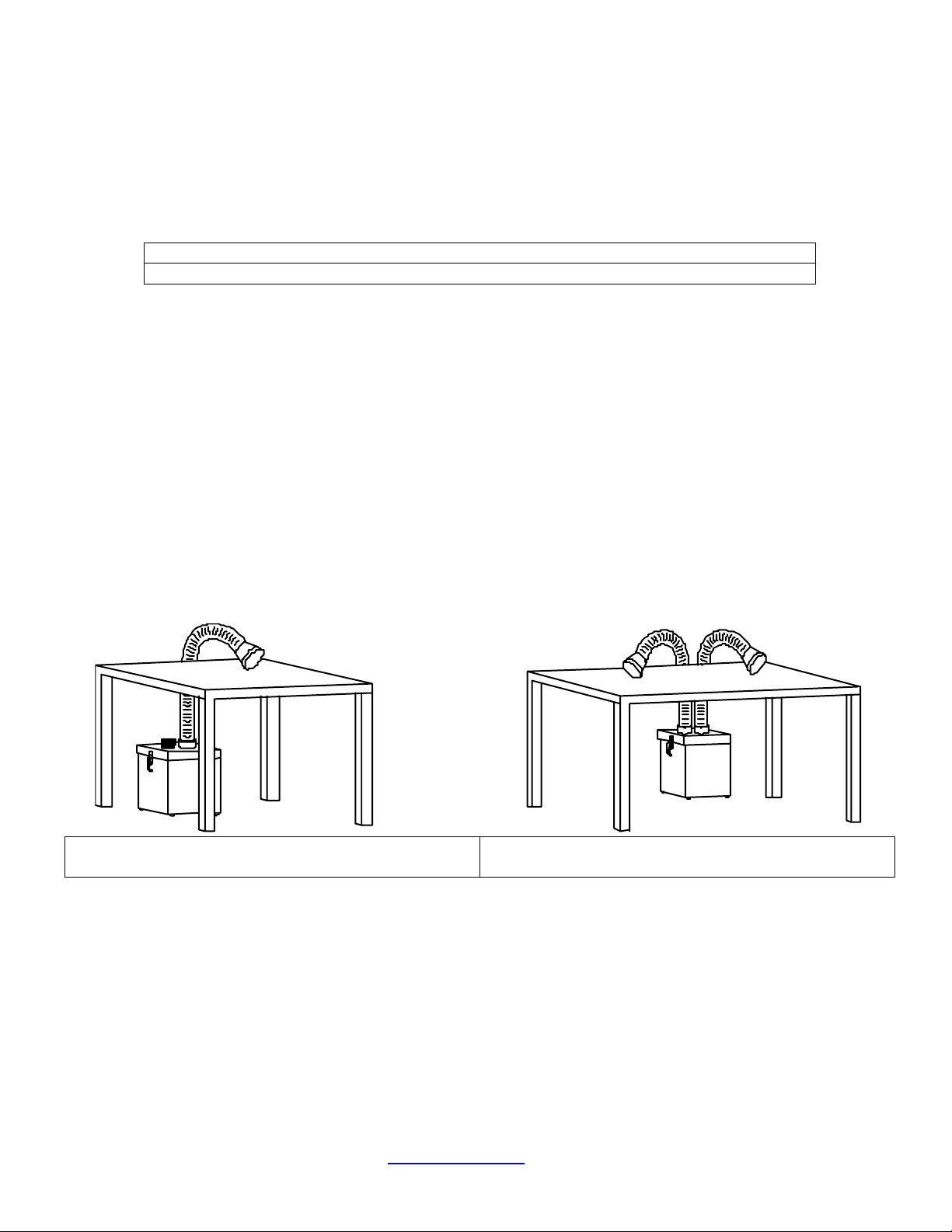

XF-301 XTRACTOR

XF-302 XTRACTOR

FIG 1. VIEW OF THE SYSTEM

XF-300 Series High Volume Fume extraction systems

Bokar International www.bokar.com, www.No-Stat.com, www.ZeroCharge.net Page 4 of 11

II. SAFETY

The purpose of this "SAFETY" section is to inform the users of the heading guidelines used in this manual to

indicate special Notes, Cautions, Warnings or Dangers. Also included are precautions, which must be

observed when operating or servicing this product.

These "NOTES", "CAUTIONS", "WARNINGS" and "DANGERS" are inserted in this manual whenever

deemed necessary. They appear in a blocked off form with outline and a shaded background to highlight the

information as shown below.

NOTE

xxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxx

NOTE

Used to indicate a statement of company recommendation or policy. The message may relate directly or

indirectly to the safety of personnel or protection of property. NOTE is not associated directly with a hazard

or hazardous situation and is not used in place of "CAUTION", "WARNING" or "DANGER".

CAUTION

Used to indicate a hazardous situation, which may result in minor or moderate injury. May also be used to

alert personnel to conditions, procedures and practices which, if not observed, could result in damage to or

destruction of the product or other equipment.

WARNING

Used to define additional information, that if not closely followed may result in serious damage to equipment

and represent a potential for serious personnel injury.

DANGER

Defines additional information, that if not closely followed may result in severe personnel injury or death.

Danger is not used for property damage unless personal injury risk is present.

PRECAUTIONS

The following are general safety precautions, which personnel must understand and follow when using or

servicing this product. These precautions may or may not be included elsewhere in this manual.

XTRACTOR Fume Extraction systems are designed to reduce the level of harmful contaminants from the

work environment and to assist in the achievement of recommended health and safety requirements for

local exhaust ventilation and contaminant removal. Be sure to follow all Application and Maintenance

guidelines contained herein and precautions contained in other relevant product safety literature (i.e.,

Material Safety Data Sheets) provided with the substances and equipment producing the fumes to be

extracted.

DISCLAIMER

Bokar International hereby disclaims all responsibility for any personal injury, property damage, fine, citation

or penalty imposed by any government or private entity which results from any use, misuse or mis-

application of this product, failure of the user to regularly maintain the product according to the

recommended guidelines, or failure to adequately monitor fume extraction exhaust air and the ambient

workplace air for the presence of harmful levels of gases, fumes and particulates.

Compliance with all applicable environmental and personnel safety regulations is the sole responsibility of

the user and adequate self-monitoring of exhaust air released into the atmosphere or the workplace as well

as monitoring of the ambient workplace air is strongly recommended.

XF-300 Series High Volume Fume extraction systems

Bokar International www.bokar.com, www.No-Stat.com, www.ZeroCharge.net Page 5 of 11

WARNING

FAILURE TO COMPLY WITH THE APPLICATION AND MAINTENANCE GUIDELINES, FILTER

REPLACEMENT SCHEDULES, MONITORING RECOMMENDATIONS AND SAFETY

GUIDELINES CONTAINED HEREIN AND

IN OTHER RELEVANT PRODUCT SAFETY

LITERATURE (I.E., MATERIAL SAFETY DATA SHEETS) PROVIDED WITH THE

SUBSTANCES AND EQUIPMENT PRODUCING THE FUMES TO BE EXTRACTED COULD

RESULT IN RISK OF SERIOUS INJURY, FIRE OR EXPLOSION.

To insure continued effective performance, the following guidelines must be followed.

General Purpose Filter Cartridge

The XF-300 Series is equipped with the General Purpose Filter Cartridge which has been designed to

capture particulates and noxious gases and odors that are present in the air being filtered. Over time, the

HEPA filter will gradually become clogged, impeding air flow through the system, and the capacity of the gas

filter will be reached, reducing its ability to continue to neutralize and adsorb noxious gases and odors.

General Purpose Filter Cartridges must be replaced at regular intervals to ensure that the fume extraction

system is operating effectively. These intervals will vary depending on the type of work being performed, the

level of use, and the amount and composition of airborne contaminants produced.

CAUTION

To ensure the highest level of performance, use only XTRACTOR replacement filters in your XF-

300 Series Fume Extractors Systems.

The exhaust air stream from the central filtration unit as well as the ambient air in the workplace should be

monitored with appropriate and adequate measuring/detection devices to assure compliance with all

applicable Health and Safety regulations.

Flammable vapors and gases (i.e. Isopropyl Alcohol) are removed by and accumulate in the gas portion of

the General Purpose Filter Cartridge presenting a potential fire hazard. Therefore, the user must exercise

appropriate precautions when extracting such fumes or when handling and disposing of filters containing

such flammable substances. Follow all fire safety and personnel protection guidelines contained in the

Material Safety Data Sheet (MSDS) for the substance(s) producing the extracted vapors and gases (fumes).

DANGER

XTRACTOR FUME EXTRACTORS ARE NOT INTENDED TO BE USED AS A SUBSTITUTE

FOR DEVICES SUCH AS PERSONAL PROTECTIVE RESPIRATORS THAT ARE DESIGNED

TO REMOVE POORLY ADSORBED SUBSTANCES INCLUDING CARBON MONOXIDE,

METHANE, HYDROGEN, ACETYLENE AND OTHER GASES. RISK OF SERIOUS INJURY OR

DEATH, FIRE OR EXPLOSION MAY RESULT FROM IMPR

OPER USE. IF IN DOUBT,

CONSULT WITH YOUR INDUSTRIAL HYGIENIST.

When disposing of used filters, extreme care must be taken to comply with all applicable environmental

regulations. Carefully consult the MSDS supplied with the material(s) producing the fume. If in doubt, check

with your local Environmental Authority.

Extreme care must be exercised when disposing of a used General Purpose Filter Cartridge containing

potentially hazardous substances. When disposing of filters, appropriate and adequate personal protective

equipment (i.e. gloves, respirators, plastic containment bags, etc.) must be used when hazardous

substances such as asbestos, lead, radioactive or biohazard materials may be present. Consult the Material

Safety Data Sheet (MSDS) of the materials generating the extracted fume.

XF-300 Series High Volume Fume extraction systems

Bokar International www.bokar.com, www.No-Stat.com, www.ZeroCharge.net Page 6 of 11

DANGER

NEVER USE XTRACTOR FUME EXTRACTION SYSTEMS TO EXTRACT FUMES FROM

HIGHLY FLAMMABLE LIQUIDS AND GASES SUCH AS ETHER, GASOLINE (PETROL) AND

OTHERS. RISK OF SERIOUS INJURY, DEATH, FIRE OR EXPLOSION MAY RESULT.

CERTAIN

AIRBORNE CONTAMINANTS SUCH AS METHYL ETHYL KETONE,

CYCLOHEXONE, OZONE AND OTHERS, WHEN CONTACTED WITH ACTIVATED CARBON,

CAN UNDERGO OXIDATION, DECOMPOSITION OR POLYMERIZATION RESULTING IN

EXOTHERMIC REACTIONS OR HEAT GENERATION. PACE FUME EXTRACTION SYSTEMS

MUST NOT BE USED TO EXTRACT FUMES FROM THESE SUBSTANCES.

WARNING

Use with inappropriate chemicals or substances, failure to provide regular maintenance or other

misuse of your Fume Extraction System may result in contaminated air being re-circulated into

the work environment.

CAUTIONS

Utilize all standard electrical safety precautions when using this or any other electrical equipment.

DANGER

POTENTIAL SHOCK HAZARD – All repairs made on this product should be performed by qualified service

personnel only. Line voltage parts will be exposed when equipment is disassembled. Service personnel

must avoid contact with these parts when troubleshooting.

NOTES

To insure continued peak performance, use genuine XTRACTOR replacement parts.

XF-300 Series High Volume Fume extraction systems

Bokar International www.bokar.com, www.No-Stat.com, www.ZeroCharge.net Page 7 of 11

III. PACKAGING

There are two boxes. One contains the system and the second one, one or two arms.

XF-301

XF-302

Box #1

1. XF-300 – Base with XF-300-CF combined

filter, pre-filter

2. Power cord

3. Manual

4. Guarantee card

Box #2

1. XF-A75ESD – 75 mm ESD Arm with Funnel

Box #1

1. XF-300 – Base with XF-300 CF combined

filter, pre-filter

2. Power cord

3. Manual

4. Guarantee card

Box #2

1. Two XF-A75ESD – 75 mm ESD Arm with

Funnel

XF-301H

XF-302H

Box #1

1. XF-300 – Base with XF-300-HF HEPA/Gas

filter, pre-filter

2. Power cord

3. Manual

4. Guarantee card

Box #2

1. XF-A75ESD – 75 mm ESD Arm with Funnel

Box #1

1. XF-300 – Base with XF-300-HF HEPA/Gas

filter, pre-filter

2. Power cord

3. Manual

4. Guarantee card

Box #2

1. Two XF-A75ESD – 75 mm ESD Arm with

Funnel

IV. UNPACKING

Prior to use of the system, please check if the system is complete. Should you notice that any items

are missing, please notify us, giving the details of model number, voltage, date of purchase, where

purchased and what is missing. Missing items must be reported within 7 days from the date of purchase.

WARNING

When unpacking, please be careful and read the manual prior to turning the system

“ON”. Please check that the voltage of the System corresponds with the voltage of

your available supply. Connection to incorrect voltage supply may cause damage to

the System!

V. SET-UP AND INSTALLATION

PLACEMENT

Three major considerations need to be addressed for proper placement of the central filtration unit.

•Exhaust Port: The exhaust port is located on the bottom of the filtration unit, next to the on/off switch.

When positioning the unit, make sure that the exhaust port is not blocked or that airflow from the

exhaust port is not restricted in any way. Additionally, the on/off switch (located on the back of the

filtration unit) must be readily accessible.

•Unit Location: The filtration unit should be located so that it will not block aisleways or impede normal

operating traffic or material handling pathways. It is important to position the unit in such a way that

allows for proper clearance to remove the filter access cover and replace the filter as needed.

XF-300 Series High Volume Fume extraction systems

Bokar International www.bokar.com, www.No-Stat.com, www.ZeroCharge.net Page 8 of 11

•Proximity to the work area: The filtration unit should be placed as close to the work area as possible.

If using a flex hose, it is advantageous to keep the length of flex hose as short as possible. Do not

kink or create any sharp bends in the flex hose, as this will reduce airflow.

POWER

The XF-300 Series will plug into a standard 110 volt or 230 volt electrical outlet, depending on the model

you purchased. Be sure the unit you have is rated for the intended power supply.

WARNING

Failure to supply the correct voltage to the unit will result in damage to the motor.

FILTERS

Before operating the unit, make sure the filter is correctly positioned. The pre-filter is always on top and the

blue side of the prefilter should be facing upward. The direction of airflow is clearly marked on the filter

cartridge. Airflow is always in a downward direction for the XF-300.

INLET CAPS

If an inlet port is not connected to a collection device, it must be covered with the inlet cap provided.

VI. SYSTEM DESCRIPTION and APPLICATION

Connecting One or Two XF-75A-ESD Arms with Funnel

1. Slide the narrow end of the XF-A75-ESD Arm over one inlet port on the XF-300 Base.

2) Secure the Arm to the inlet of the XF-300 with the Arm clamp (provided).

3) Position the Arm for maximum extraction performance.

4) If using one Arm, make sure the inlet cap covers the unused inlet.

5) Repeat steps 1 through 3 to attach second Arm.

XF-301 XTRACTOR – XF-300 Base one

XF-A75ESD Arm with Funnel

XF-302 XTRACTOR – XF-300 Base two XF-A75ESD

Arm with Funnel

NOTE: XF-300 Base can be placed on the bench top or located under a workbench, depending on operator

preference.

XF-300 Series High Volume Fume extraction systems

Bokar International www.bokar.com, www.No-Stat.com, www.ZeroCharge.net Page 9 of 11

VII. TECHNICAL SPECIFICATIONS

Unit specification:

Dimensions

(mm) HxDxW

Weight

Air Flow

(with filters)

Power

Unit

Voltage

V AC

Noise Level

dBA

Filter

Type

Filter

Efficiency

450x300x300 55 lbs

(25 kg)

200 cfm

(340m3/h)

Radial

Blower 115 or 230 52

Hi Efficiency

95%

0.3 micron

HEPA/GAS

99.997%

0.3 microns

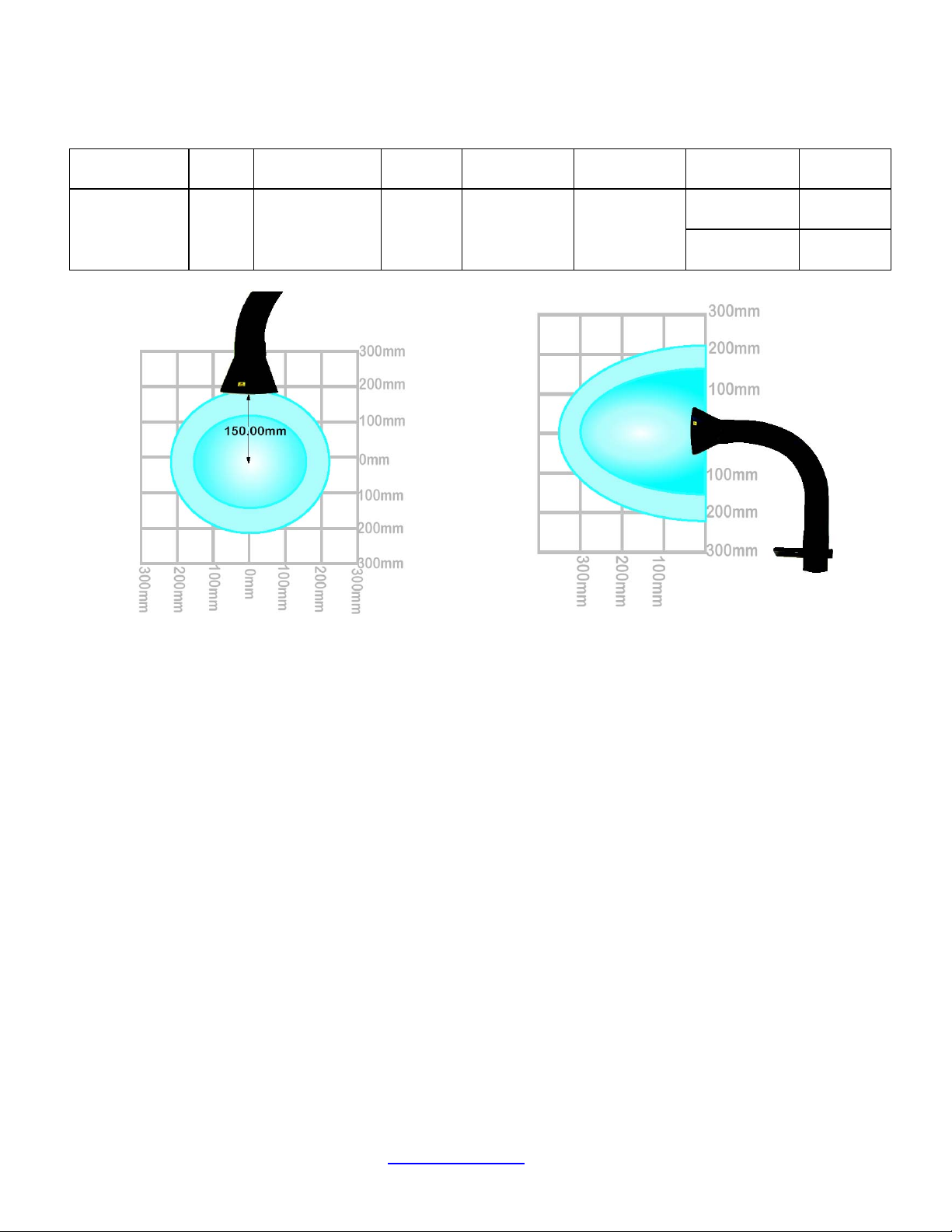

XF-A75ESD – 75 mm Arm with funnel 950 mm in

length, funnel 160 mm in diameter.

The measurements were taken with the arm

situated above the working area.

XF-A75ESD – 75 mm Arm with funnel 950 mm in

length, funnel 160 mm in diameter.

The measurements were taken with the arm situated

sideways at the working area.

Diagrams above highlight the capture area of the arm with extracting at a flow rate of 120 cfm (200 m3/hr).

XF-300 Series High Volume Fume extraction systems

Bokar International www.bokar.com, www.No-Stat.com, www.ZeroCharge.net Page 10 of 11

VIII. OPTIONAL EQUIPMENT

•XF-A75ESD - 75 mm ESD Arm with Funnel

•XF-B75ESD - 75 mm ESD Arm with Bench Bracket and Funnel

•XF-C75ESD - 75 mm ESD Cowl

•XF-D75ESD - 75 mm ESD Down Draft Tray

XF-C75ESD

XF-B75ESD

XF-A75ESD

XF-D75ESD

•Variable speed/flow control available

FILTERS

All Extraction Systems incorporate a progressive series of filters designed specifically to maximize life for

both particulate and gas capture.

Pre Filter

The pre filter is designed solely to protect the life of the micro filter.

For the majority of units, X-KAR use a pleated synthetic media

with a separation of typically 95% of particulate down to 0.8

microns. In cases where larger amounts of sub micron particulate

are generated, a higher efficiency filter can be fitted or stand alone

Bag filter can be installed to give greater life to the pre filter and

ensure adequate protection to the main filter.

Micro Filter

The Micro Filters incorporate a series of bonded webbing between the pleats. This feature not only ensures

even spacing between each pleat, but also alleviates the possibility of airflow vibration or collapse through

pressure build up during gradual filter saturation. Each Micro filter is designed to withstand up to 6 times the

maximum operating pressure for its designated unit. With filter efficiency of 99.997% down to 0.3 microns

and 95% as small as 0.01 microns.

XF-300 Series High Volume Fume extraction systems

Bokar International www.bokar.com, www.No-Stat.com, www.ZeroCharge.net Page 11 of 11

Gas Filter

The standard gas filter is made up of a 50/50 mix of Activated Aluminum Potassium Permanganate and

Activated Carbon. The media neutralizes a broad base of chemical and VOC (Volatile Organic Compound)

pollutants. A comprehensive range of specialized filters together with electronic gas sensing is available for

more demanding or diverse applications.

All filters are produced in accordance with ISO9002 with micron filtration complying with BS3928. A

certificate of conformity for each filter is available upon request.

Available filters:

Part Number

Description

XF-300-FS

Filter Pack (Pre & Foam Filter) for 300 System (95% eff)

XF-300-HF (CF)

Combined HEPA/Gas filter for 300 System 99.997%DOP

XF-300-PF

Prefilter for use with HEPA filter (pack of 5)

BOKAR International

650 Scranton Pocono Hwy.,

Covington Twp., PA 18444, USA

Tel: (570) 842-2812 Fax: (570) 842-4290

E-mail: bokar@bomir.com

www.bokar.com, www.FumeXtraction.com US Master Distributor: www.bomir.com

This manual suits for next models

2

Table of contents

Popular Scrubber manuals by other brands

Ghibli & Wirbel

Ghibli & Wirbel O 143 S10 Use and maintenance

Monster

Monster Electric 4 Frame instruction manual

Advance acoustic

Advance acoustic Micromatic 13E Instructions for use

Prochem

Prochem Comanche CM1 operating instructions

COMAC

COMAC ULTRA 120 B-G Use and maintenance manual

Cleaning Machines

Cleaning Machines KF 50B manual