Bolton Tools BT1324 User manual

OWNER’S MANUAL

MODEL:BT1324&BT1330

PRECISION METAL LATHE

ASSEMBLY AND OPERATING INFORMATION

2

INDEX

General Safety Instructions Page 2

Features Specifications Page 3

Illustrated Features Page 4

Lifting Installation Page 5 6

Lubrication Positions Page 7 8

Operating Controls Page 9

Threading Chart Page 10

Grounding Instructions Page 11

Parts Diagram- Lathe Head Page 12

Parts Listing- Lathe HEAD

Parts Diagram-Tailstock

Parts Listing-Tailstock

Parts Diagram-Lathe Bed

Parts Listing-Lathe Bed

Parts Diagram-Lathe Trestle

Parts Diagram- Apron Parts

Parts Diagram-Compound Box

Warranty

3

GENERAL SAFETY INSTRUCTIONS

EXTREME CAUTION SHOULD BE USED IN OPEATION ALL POWER

TOOLS.KNOW YOUR POWER TOOL, BE FAMILIAR WITH ITS OPEARTION.READ

THE OWNER’S MANUAL AND PRACTICE SAFE USAGE PROCEDURES AT ALL

TIMES.

CONNECT your machine ONLY to the matched and specified power

source.

WEAR SAFETY G LASSES, RESPIRATORS, HEARING PROTECTION and

SAFFTY SHOES when operating heavy machinery. Always wear safety

glasses.

DO NOT wear loose clothing or jewellery when operating machinery.

A Safe Environment is important. Keep the area free of dust, dirt and other

debris in the immediate vicinity of the machine.

BE ALERT! Do Not Use prescription or other drugs that may affect your

ability or judgement to safely use this machine.

DISCONNECT the power source when changing tool bits and or any

equipment.

NEVER leave an operating tool unattended.

ALWAYS keep blades, knives or bits sharp and properly aligned.

ALWAYS keep all safety guards in place and ensure their proper function.

4

ALWAYS make sure that any tools used for adjustments are removed before

operating the machine.

ALWAYS secure your work with the appropriate clamps or vises.

ALWAYS keep bystanders safely away while operating machinery.

THINK SAFELY.WORK SAFELY. Never attempt a procedure if it dose not

feel safe or comfortable.

BT1324&BT1330 METAL LATHE

As part of the growing line of metalworking equipment, we are

proud to offer the CT089 Metal Lathe. The name guarantees Craft

Excellence. By following the instructions and procedures laid out in

this owner’s manual, you will receive years of excellent service and

satisfaction. The BT1324&BT1330 is a professional tool and like all

power tools, proper care and safety procedures should be adhered

to.

Features and Specifications

Max. Swing over bed 13'

Max. Length of work piece 24' /30'

Max. Swing diameter over tool post 220mm

Spindle Bore 1.5'

5

Spindle Taper MT.5#

Max Lateral Stroke over tool post 160mm

Max Longitudinal stroke over tool post 4'

Metric Thread kinds on processing 17

Inch Thread kinds on processing 20

Metric thread pitch on processing 0.5~4 mm

Inch thread pitch on processing 9-40 1/N”

Longitudinal–feed on spindle tool post 0.135~1.80mm/r

Max. stroke of tail stock sleeve 70mm

Tail stock sleeve taper MT.3#

Spindle speeds available 12

Spindle speeds range 75~1950

Electromotor 1100w/220v/60HZ

Net weight 330kg

Full size 130cm*74cm*60cm

150cm*74cm*63cm

Outer packing size 133cm*77cm*75cm

155cm/77cm*75cm

Standard Accessories(only for BT1330)

Working lamp

Cooling pump

6

Steady Rest

Follow Rest

Face Plate

3 Jaw Chuck

Stands with oil tray

Splash Guard

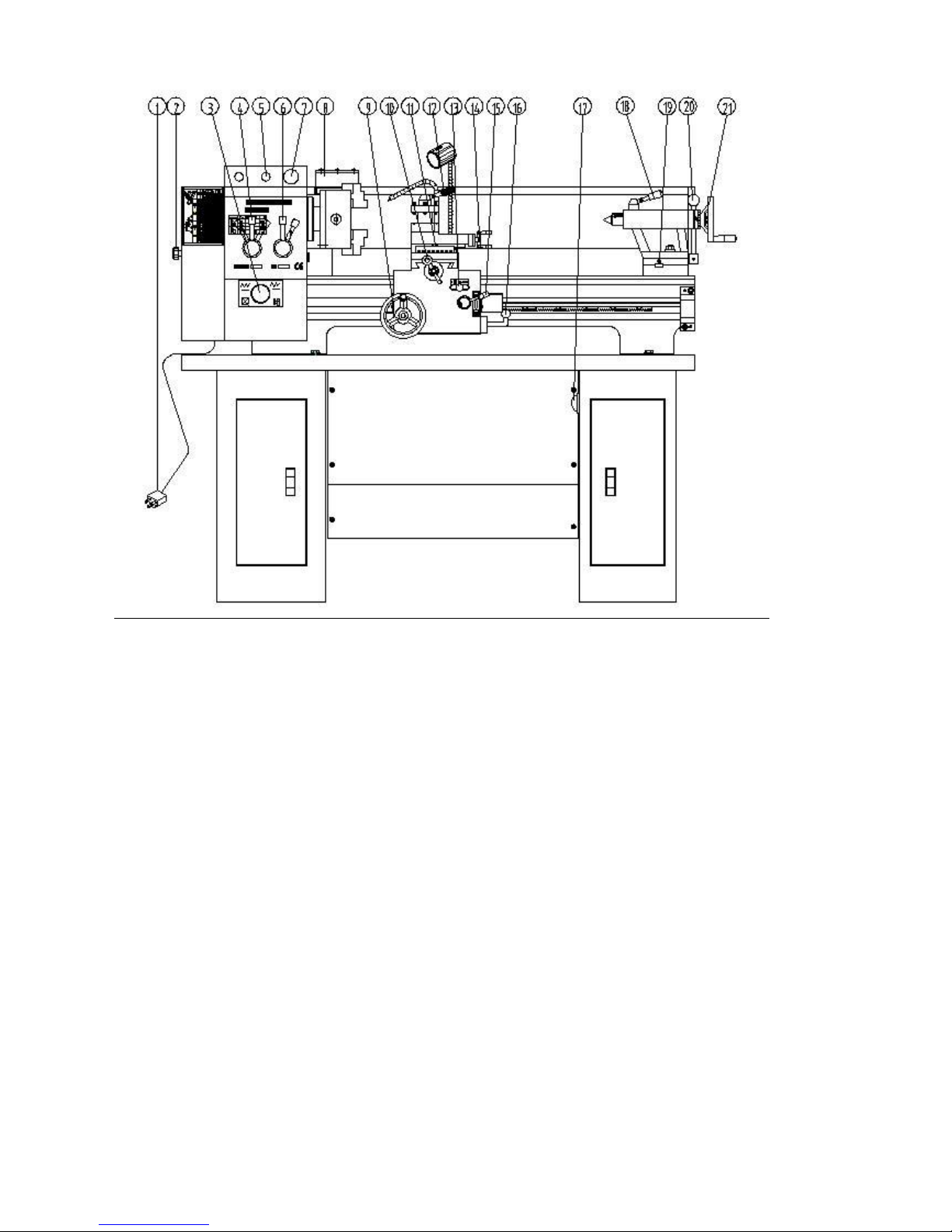

Illustrated Features

Fig 1.Driving system drawing

1. Input Pulley

2. Gear Change

7

3. Gear Change

4. Gear Change

5. Gear Change

6. Gear

7. Gear

8. Gear

9. Gear

10. Gear

11. Spindle Gear

12. Gear

13. Tool Post Lead Screw

14. Tool Post Nut

15. Tail Stock Lead Screw

16. Tool Post Nut

17. Longitudinal Screw

18. Longitudinal Nut

19. Cross Nut

20. Cross Lead Screw

21. Gear

22. Gear

23. Gear

24. Worm Gear

25. Worm

8

26. Gear

27. Gear

28. Gear

29. Gear

30. Gear

31. Gear

32. Gear

33. Gear

34. Gear

35. Motor Pulley

36. Gear

37. Gear

38. Gear

39. Gear

Lifting&Installation

It is recommended that this machine is lifted by the use of a crane

or hoisting mechanism as it is very heavy.

9

Fig 2. Lifting drawing

Lifting&Installation cont

Please refer to figure 3 when installing this machine. As this lathe is

for the most part pre-assembled at the factory, there is not a great

deal of assembly for the end user.

Line up the four bolt holes with the stand and carefully place the

lathe on the stand.

10

Fig 3. Installation drawing.

After installation, be sure to clean the antiseptic coat (used to

preserve and protect during shipping) off the guide carriage, tail

stock, change gear and pulley with a clean cloth and non-corrosive

cleaner.

Lubrication Positions

11

Fig 4. Lubrication positions drawing.

Please refer to the Lubrication chart on the following page in order

to properly lubricate and maintain your Lathe. Proper lubrication of

any tools, especially Metal Lathes should not be ignored.

12

Lubrication Positions Cont.

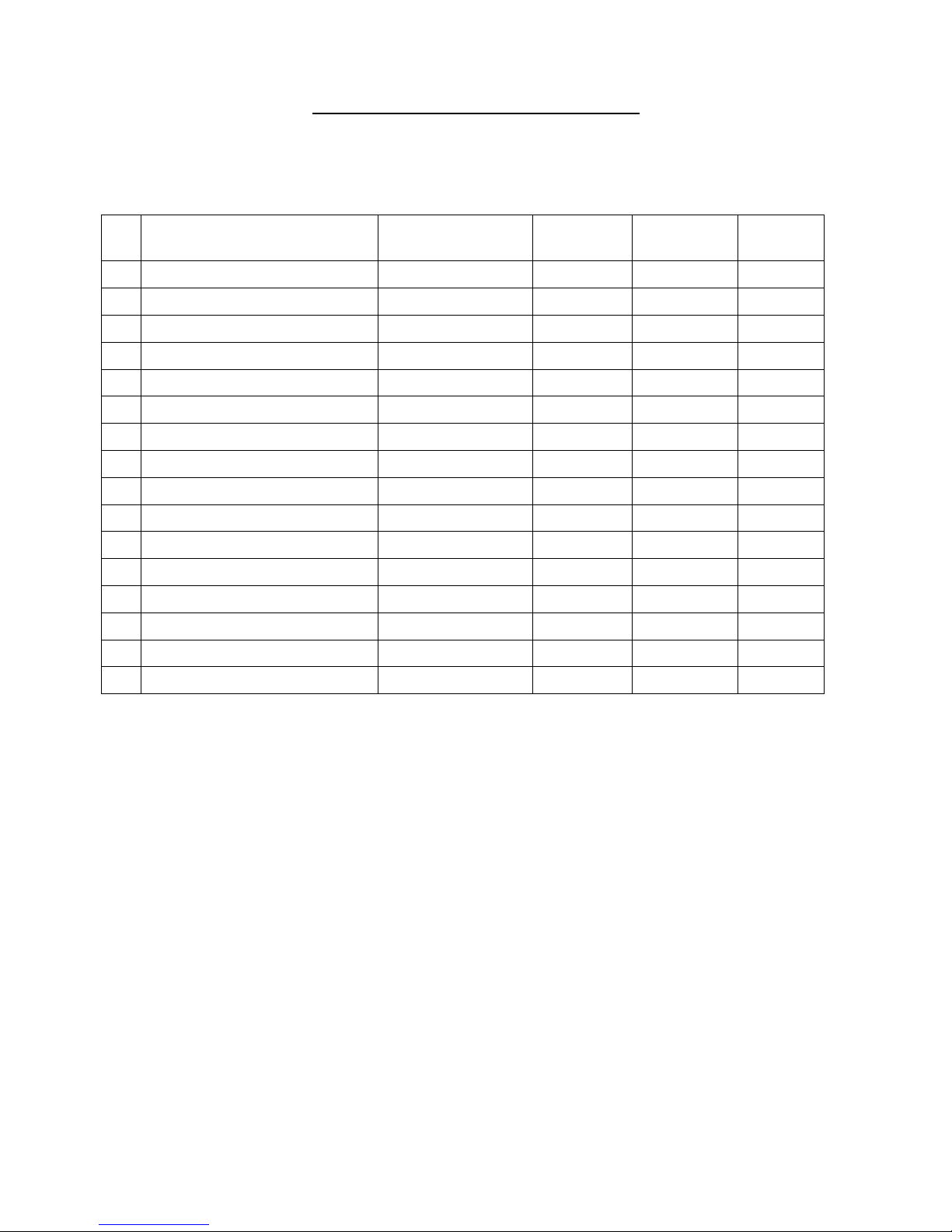

Attached List 1: Lubrication Positions Li

Attached List 1;Lubrication Positions Li

Item

No.

Lubrication Position

Located part

Located part

Methods

Lubrication Oil

Lubrication

Period

1

Gears. bush bearing

Left trestle

Gun oiling

Machine oil

0ne year

2

Spindle bearing

Lathe head

Greasing

Grease

1/year

3

Thrust bull bearing

Left trestle

Greasing

Grease

1/year

4

Slide way, lead screw, guide surface

Apron parts

Gun oiling

Machine oil

2/days

5

Gears, racks

Apron parts

Greasing

Grease

One month

6

Tool post lead screw, guide surface

Tool carriage

Gun oiling

Machine oil

2/days

7

Longitudinal lead screw

Lead screw

Gun oiling

Machine oil

2/days

8

Lathe bed guide

Lathe bed

Gun oiling

Machine oil

2/days

9

Tail stock sleeve

Tailstock

Gun oiling

Machine oil

2/days

10

Tailstock lead screw bush bearing

Tailstock

Gun oiling

Machine oil

2/days

11

Bearing pedestal

Lathe bed

Gun oiling

Machine oil

2/days

12

Cross nut lead screw

Small carriage

Gun oiling

Machine oil

2/days

13

Bearing bush

Small carriage

Gun oiling

Machine oil

2/days

14

Thrust bearing

Lead screw pedestal

Greasing

Grease

6/s year

15

Change gear shaft

Compound box

Gun oiling

Machine oil

2/s year

16

Bearing

Input pulley

Greasing

Grease

6/s year

Notes: 1. Recommend to use 3#Ca grease

2. Recommend to use 3#Ca grease 20# machine oil

3. The parts lubricated by grease should be cleaned and the

machine oil in feed box be changed and renewed up to the

center line of the oil indicator regularly

13

Fig5.Llectrical System Drawing

Operating Controls

REFER TO THE DIAGRAM BELOW FOR THE BT1324&BT1330

operation controls.

14

Fig 6.Operation Parts Fig.

1. Power source-plug

2. Transmission Box Cover

3. Forward/Reverse Switch for lead screw-Middle position is

Neutral

4. Shift Knob-Gear change

5.

6. Shift Knob-Gear change

7. Stop button

8. Chuck

9. Longitudinal-Feed hand wheel

10. Small Carriage Cross Feed hand wheel

15

11. Tool Post Swivel Nut

12. Tool Post feed hand wheel

13. Auto Feed for Tool Post-Left, Right, Neutral

14. Tool Carriage hand wheel

15. Carriage Auto-Feed Switch

16. START Forward/Reverse Switch

17. Pump Switch

18. Handle Lock for tailstock center

19. Offset Screw

20. Lever to lock Tailstock

21. Tailstock hand wheel

Threading Chart

Please see the following diagram for reference to cutting

threads

16

Threading

Cutting threads can be performed by the manual use of the

change gears and handle 4&5(refer to Operating Controls)

Grounding Instructions

In the event of a malfunction or breakdown, grounding provides

the path of least resistance for electrical current and reduces the risk

of electrical shock. This tool is equipped with an electrical cord that

has an equipment grounding conductor and a grounding plug. The

plug MUST be plugged into a matching outlet that has been properly

installed and grounded in accordance with ALL local codes and

ordinances.

DO NOT MODIFY THE PLUG PROVIDED. If the provided plug will

17

not fit the electrical outlet, have the proper outlet installed by a

qualified licensed electrician.

IMPROPER CONNECTION of the equipment grounding

conductor can result in risk of electrical shock. The conductor wire

with the green insulation (with or without yellow stripes) is the

equipment-grounding conductor. If repair or replacement of the

electrical cord or cord or plug is required, DO NOT connect the

equipment grounding conductor to a live terminal.

If in doubt about these instructions consult a qualified,

licensed electrician.

USE ONLY A THREE-WIRE EXTENSION CORD with a 3-prong

grounding plug and three-hole receptacles that accept the tool’s

plugs as shown.

18

Parts Listing-Lathe Head

No.

SPINDLE BOX

1

V710 GB/T1171-1986

V-belt type 680

皮带

2

M16*1.5 GB/T812-1988

Spanner nut

圆螺母

3

16 GB/T858-1988

Lock washer for circular nut

止动垫圈

4

BT1324&BT1330-02-031

Spindle pulley

皮带轮

5

30 GB/T894.1-1986

Circlips for shaft-type A

轴用挡圈

6

6206/P6 GB/T276-1994

Taper roller oearing

深沟球轴承

7

M5*16 GB/T77-1985

Hexagon socket head screw

内六角螺栓

8

BT1324&BT1330-02-030

Pulley seat

皮带轮支承座

9

35.5*2.65 GB/T3452.1-1992

O-seal ring

O型密封圈

10

FB016030 GB/T13871-1992

Felt coller

骨架橡胶密封圈

11

M6*8 GB/T818-1985

Crossrecessed pan head screws

十字盘头螺钉

12

6 GB/T97.1-1985

Plain washers

平垫圈

13

BT1324&BT1330-02-005

Lathe head

主轴箱

14

BT1324&BT1330-02-021

Nut

螺母

15

BT1324&BT1330-02-022

Felt coller

密封圈

16

BT1324&BT1330-02-020

Oil Screw

排油螺栓

17

BT1324&BT1330-02-058

Washer

橡胶垫圈

19

18

6 GB/T7940.4-1995

Oil cup

油杯

19

11 GB/T894.1-1986

Circlips for shaft-type A

轴用挡圈

20

BT1324&BT1330-02-040

coller

挡圈

21

BT1324&BT1330-02-039

Change Gear

挂轮 C

22

BT1324&BT1330-02-042

Sleeve spacer

隔套 D

23

A5*36 GB/T1096-1994

Plain parallel key

平键

24

BT1324&BT1330-02-041

Sleeve

衬套 B

25

BT1324&BT1330-02-038

Change Gear

挂轮 B

26

BT1324&BT1330-02-043

Shaft

芯轴

27

9*1.8 GB/T3452.1-1992

O-seal ring

O型密封圈

28

M5*8 GB/T71-1985

Screw

开槽锥端紧定螺钉

29

BT1324&BT1330-02-052

Block

拨块 A

30

M8*20 GB/T77-1985

Hexagon socket head screw

内六角螺栓

31

A6*30 GB/T117-1986

Taper pins

圆锥销

32

BT1324&BT1330-02-019

Adjust block

调整压板

33

M8*25 GB/T77-1985

Hexagon socket head screw

内六角螺栓

34

M8*10 GB/T77-1985

Set screws with cone point

内六角平端紧定螺

钉

35

0.8*5*20 GB/T2089

Spring

压缩弹簧

36

6 GB/T308-1989

Steel ball

钢球

37

BT1324&BT1330-02-004

Handle seat

手柄座

38

GB/T117-1986

Taper pins

圆锥销

39

M5*16 GB/T819-1985

Screw

十字槽沉头螺钉

40

BT1324&BT1330-02-009

Localing sleeve

转向座

41

BT1324&BT1330-02-057

Washer

垫圈

42

11.2*2.65 GB/T3452.1-1992

O-seal ring

O型密封圈

43

BT1324&BT1330-02-055

External snap ring

拨块 B

44

A10 JB/T9741.2

Oil Sight

油标

45

M10*30 GB/T77-1985

Hexagon socket head screw

内六角螺栓

46

BT1324&BT1330-02-003

Handle lever

手柄杆

47

AM8*40 JB/T7271.3-1994

Knob

手柄套

48

BT1324&BT1330-02-050

Sleeve

压盖 E

49

BT1324&BT1330-02-018

Washer

垫圈

50

12 GB/T894.1-1986

Circlips for shaft-type A

轴用挡圈

51

BT1324&BT1330-02-053

Shifting fork shaft

导向滑杆

52

BT1324&BT1330-02-055

Right shifting fork

拨叉 B

53

BT1324&BT1330-02-010

Sleeve

压盖 A

54

M10 GB/T41-1986

Nut

螺母

55

10 GB/T97.1-1985

Plain washers

平垫圈

56

BT1324&BT1330-02-033

Gear change

挂轮 A

57

FB016030 GB/T13871-1992

Felt coller

骨架橡胶密封圈

58

BT1324&BT1330-02-034

Sleeve

压盖 D

59

BT1324&BT1330-02-018

Washer

垫圈

60

6203/P6 GB/T276-1994

Taper roller oearing

深沟球轴承

61

A4*10 GB/T1096-1994

Plain parallel key

平键

20

62

BT1324&BT1330-02-044

Output shaft

输出轴

63

A5*60 GB/T1096-1994

Plain parallel key

平键

64

BT1324&BT1330-02-045

Gear

齿轮

65

BT1324&BT1330-02-046

Gear

齿轮

66

BT1324&BT1330-02-048

Gear

齿轮

67

BT1324&BT1330-02-049

Sleeve spacer

隔套 E

68

BT1324&BT1330-02-023

Sleeve

压盖 B

69

BT1324&BT1330-02-032

Sleeve

压盖 C

70

BT1324&BT1330-02-011

Sleeve spacer

隔套 A

71

A5*22 GB/T1096-1994

Plain parallel key

平键

72

BT1324&BT1330-02-017

Gear

齿轮

73

BT1324&BT1330-02-016

Gear

齿轮

74

BT1324&BT1330-02-015

Gear

齿轮

75

42 GB/T894.1-1986

Circlips for shaft-type A

轴用挡圈

76

22 GB/T894.1-1986

Circlips for shaft-type A

轴用挡圈

77

BT1324&BT1330-02-014

Middle shaft

滑移轴

78

6*4*10 GB/T1566-1990

Thin flat key

薄形平键

79

BT1324&BT1330-02-012

Gear

齿轮

80

BT1324&BT1330-02-013

Gear

齿轮

81

M50*1.5 GB/T812-1988

Spanner nut

圆螺母

82

50 GB/T858-1988

Lock washer for circular nut

圆螺母用止动垫圈

83

M5*20 GB/T77-1985

Hexagon socket head screw

内六角螺栓

84

BT1324&BT1330-02-036

Sleeve

后端盖

85

BT1324&BT1330-02-037

Pressurize washer

后端盖垫圈

86

BT1324&BT1330-02-035

Sleeve spacer

衬套 A

87

32010/P6X GB/T276-1994

Taper roller oearing

圆锥滚子轴承

88

55 GB/T894.1-1986

Circlips for shaft-type A

轴用挡圈

89

BT1324&BT1330-02-047

Gear

齿轮

90

32012/P5 GB/T276-1994

Taper roller oearing

圆锥滚子轴承

91

BT1324&BT1330-02-007

Pressurize washer

前端盖垫圈

92

BT1324&BT1330-02-006

Mainshaft bearing oil seal

前端盖

93

BT1324&BT1330-02-008

Lathe spindle

主轴

94

A8*16 GB/T1096-1994

Plain parallel key

平键

95

BT1324&BT1330-02-029

Sleeve spacer

隔套 C

96

BT1324&BT1330-02-028

Gear

齿轮

97

BT1324&BT1330-02-026

Sleeve spacer

隔套 B

98

BT1324&BT1330-02-027

Gear

齿轮

99

BT1324&BT1330-02-025

Gear

齿轮

100

A5*10 GB/T1096-1994

Plain parallel key

平键

101

A5*70 GB/T1096-1994

Plain parallel key

平键

102

BT1324&BT1330-02-024

Spingle shaft

输入轴

103

M8*30 GB/T77-1985

Hexagon socket head screw

内六角螺栓

104

BT1324&BT1330-02-002

Oil port plug

螺钉

105

BT1324&BT1330-02-001

Transmission cover

箱盖

106

28 GB/T894.1-1986

Circlips for shaft-type A

轴用挡圈

This manual suits for next models

1

Table of contents

Other Bolton Tools Lathe manuals