JET has the most extensive selection of turning machines available and offers

a full range of lathes and accessories. All models are available in a range of sizes.

We offer packages that include taper attachments, collet closers, and digital

readouts to meet the needs of any operation.

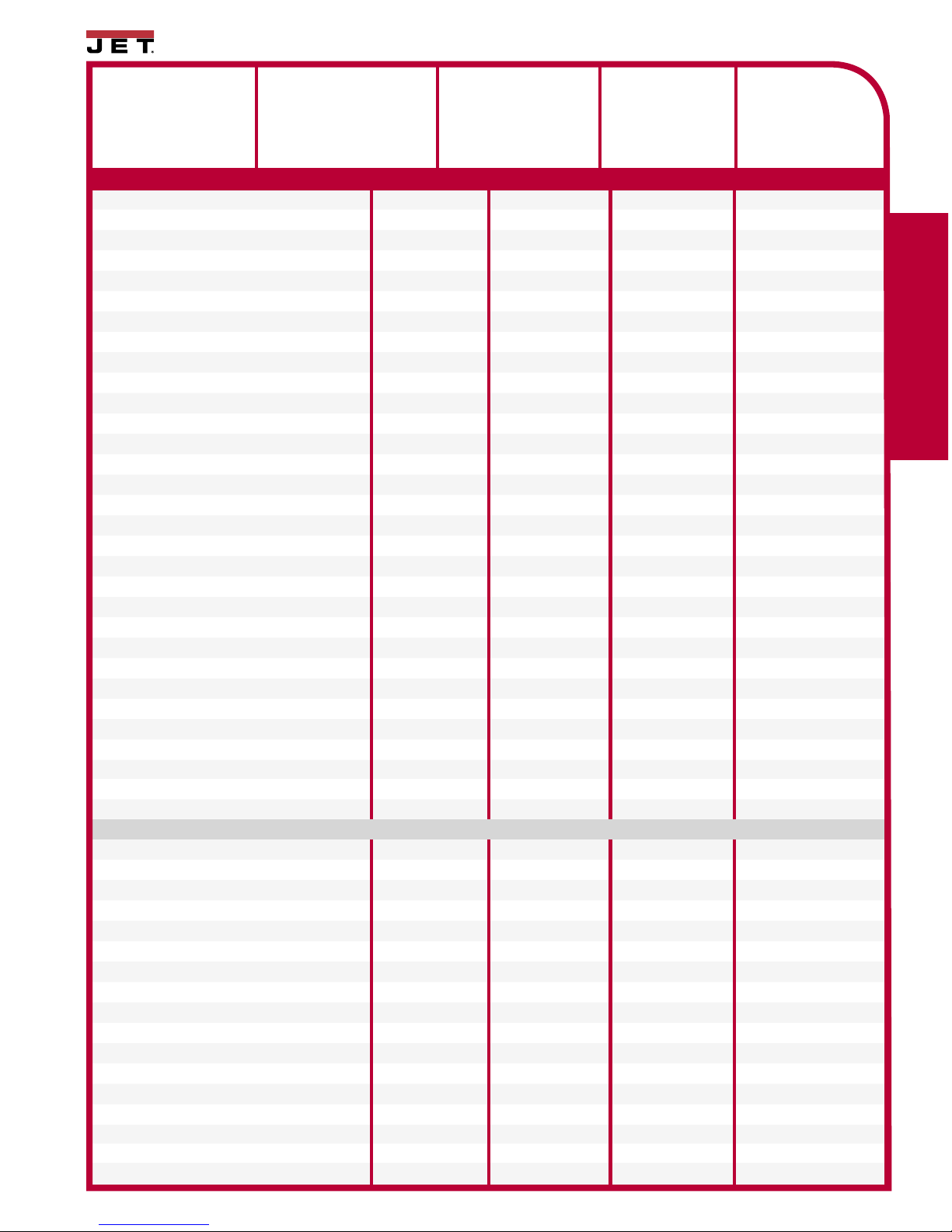

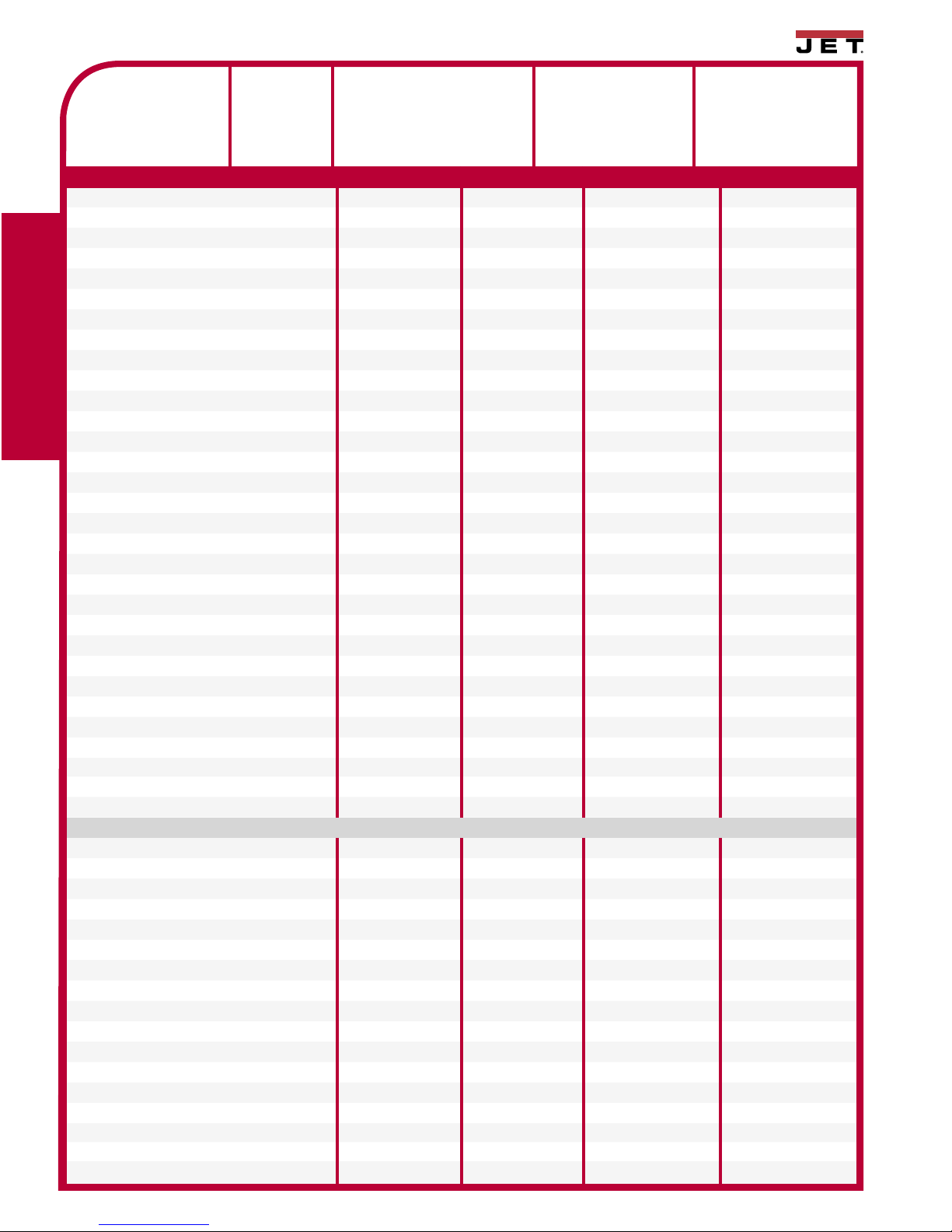

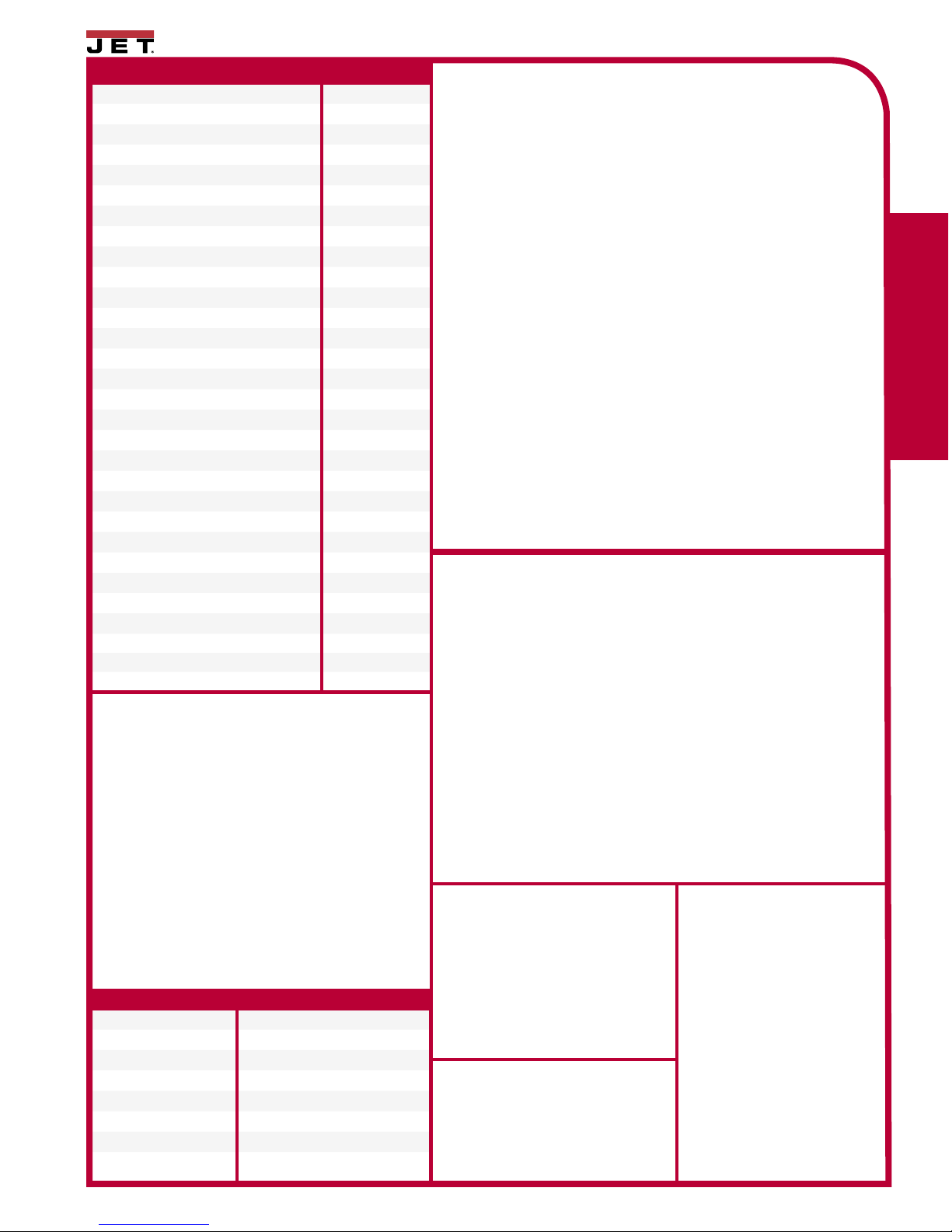

TURNING PACKAGES

STOCK NUMBER 321360A 321357A 321810 321820 321830

Model Number BDB-1340A GHB-1340A GH-1340W-1 GH-1340W-3 GH-1440W-1

Swing Over Bed (in.) 13 13 13 13 14

Swing Over Cross Slide (in.) 7-25/32 7-25/32 7-1/2 7-1/2 8-1/2

Swing Through Gap (in.) 18-3/4 18-3/4 19 19 20

Length of Gap (in.) 8 8

Distance Between Centers (in.) 40 40 40 40 40

Spindle Bore (in.) 1-3/8 1-3/8 1-1/2 1-1/2 1-1/2

Spindle Mount D1-4 D1-4 D1-4 D1-4 D1-4

Spindle Taper (with sleeve) MT-5 (MT-3) MT-5 (MT-3) MT-5 (MT-3) MT-5 (MT-3) MT-5 (MT-3)

Number of Spindle Speeds 12 8 12 12 12

Range of Spindle Speeds (RPM) 60-1,240 70 - 2,000 40 - 1,800 40 - 1,800 40 - 1,800

Number of Longitudinal and Cross Feeds 40 40 40 40 40

Range of Longitudinal Feeds (in./rev.) .0036 – 0.1005 0.0036 – 0.1005 0.0012 – 0.0294 0.0012 – 0.0294 0.0012 – 0.0294

Range of Cross Feeds (in./rev.) .0012 – .0345 0.0012 – 0.0345 0.0003 – 0.0103 0.0003 – 0.0103 0.0003 – 0.0103

Number of Inch Threads 40 40 40 40 40

Range of Inch Threads (TPI) 4-112 4 - 112 4 - 112 4 - 112 4 - 112

Number of Metric Threads 27 27 22 22 22

Range of Metric Threads (mm) 0.2-6 0.2-6 0.45-7.5 0.45 -7.5 0.45-7.5

Tool Size (max./in.) 5/8 x 5/8 5/8 x 5/8 5/8 x 5/8 5/8 x 5/8 5 5/8 x 5/8

Compound Slide Travel (max./in.) 2-11/16 2-11/16 3-1/2 3-1/2 3-1/2

Cross Slide Travel (max./in.) 6-5/16 6-5/16 6-3/8 6-3/8 6-3/8

Carriage Travel (in.) 35 35 37-1/2 37-1/2 37-1/2

Tailstock Spindle Travel (in.) 3-3/4 3-3/4 4-3/4 4-3/4 4-3/4

Tailstock Taper MT-3 MT-3 MT-3 MT-3 MT-3

Steady Rest Capacity (in.) 2-5/8 2-5/8 3-3/4 3-3/4 3-3/4

Follow Rest Capacity (in.) 2-3/4 2-3/4 2-3/4 2-3/4 2-3/4

Width of Bed (in.) 7-3/8 7-3/8 10-1/2 10-1/2 10-1/2

Overall Dimensions (in./L x W x H) 71 x 32 x 45 71 x 32 x 47 73-3/4 x 29-1/2 x 46-3/4 73-3/4 x29-1/2 x 47-1/2 73-3/4 x29-1/2 x 47-1/2

Motor 2 HP, 1Ph, 230V 2 HP, 1Ph, 230V 3HP, 1Ph, 230V 3HP, 3Ph, 230 /460V 3HP,1Ph, 230V

Prewired 230V

Net Weight (lbs.) 954 1,015 2081 2081 2191

LATHE INCLUDED IN ALL PACKAGE NUMBERS LISTED BELOW

Taper Attachment 321120 321119 321521 321516 321517

Collet Closer 321555 321518

Taper Attachment & Collet Closer

Acu-Rite 100S DRO

Acu-Rite 200S DRO 321121 321122 321532 321459 321549

Acu-Rite 200S 3-Axis DRO

Acu-Rite 200S DRO & Taper Attachment 321123 321550

Acu-Rite 200S DRO & Collet Closer 321526 321548

Acu-Rite 200S DRO, Taper Attachment & Collet Closer 321538 321546

Anilam 311 DRO 321545

Anilam 311 DRO & Collet Closer

Anilam 550 DRO

Anilam 550 DRO, Taper Attachment & Collet Closer

Newall C80 DRO 321130 321131 321132 321133 321134

Newall C80 DRO & Taper Attachment 321143

Newall C80 DRO & Collet Closer 321581 321536

Newall C80 DRO, Taper Attachment & Collet Closer