Booth & Co AXBRIDGE BC-AXB-149/RRK-CP User manual

AXBRIDGE

BC-AXB-149/RRK-CP

BC-AXB-149/RRK-BN

INSTALLATION GUIDE

This instruction booklet covers model:

BC-AXB-149/RRK-CP

BC-AXB-149/RRK-BN

Version 1, 1-5-19

VADO

Wedmore Road, Cheddar,

Somerset, England BS27 3EB

tel 01934 744466

fax 01934 744345

www.vado.com

sales@vado.com

23

Please read these instructions carefully before starting installation and keep for

future reference.

Remove all packaging and check the product for missing parts or damage before

starting installation.

Any alterations made to this product and fittings may infringe water regulations and

will invalidate the guarantee.

The installation must comply with all Local/National Water Supply Authority

Regulations/Byelaws and Building and Plumbing Regulations.

To be installed in accordance with BS EN806.

We strongly recommend that you use a qualified and registered plumber.

General installation

Important - please read

This fitting is a mixing device and therefore water supplies should be reasonably

balanced.

When installed, the fitting must comply with the requirements of the Water Supply

(Water Fittings) Regulations 1999 and Scottish Byelaws 2004.

For further information, contact the Water Regulations department of your local water

supplier (see the WRAS website www.wras.co.uk for details) or the Water Regulations

Advisory Scheme by email (info@wras.co.uk) or telephone: 01495848454.

Before making any inlet pipe connections, all supply pipes MUST be thoroughly flushed

to remove debris. Failure to do so could result in damage or low flow from the mixer

unit. Water Supply (Water Fittings) Regulations 1999 Schedule 2 Section 13.

The fitting of isolating valves to the inlet feeds is advised for ease of maintenance.

Please take great care when installing this mixer not to damage its surface.

Please note if installing in an enclosed environment, access should be left for servicing

and maintenance. No costs relating to inadequate access can be accepted.

Operating Specifications

Operating Pressure

Minimum operating pressure 1 bar

Maximum operating pressure 5 bar

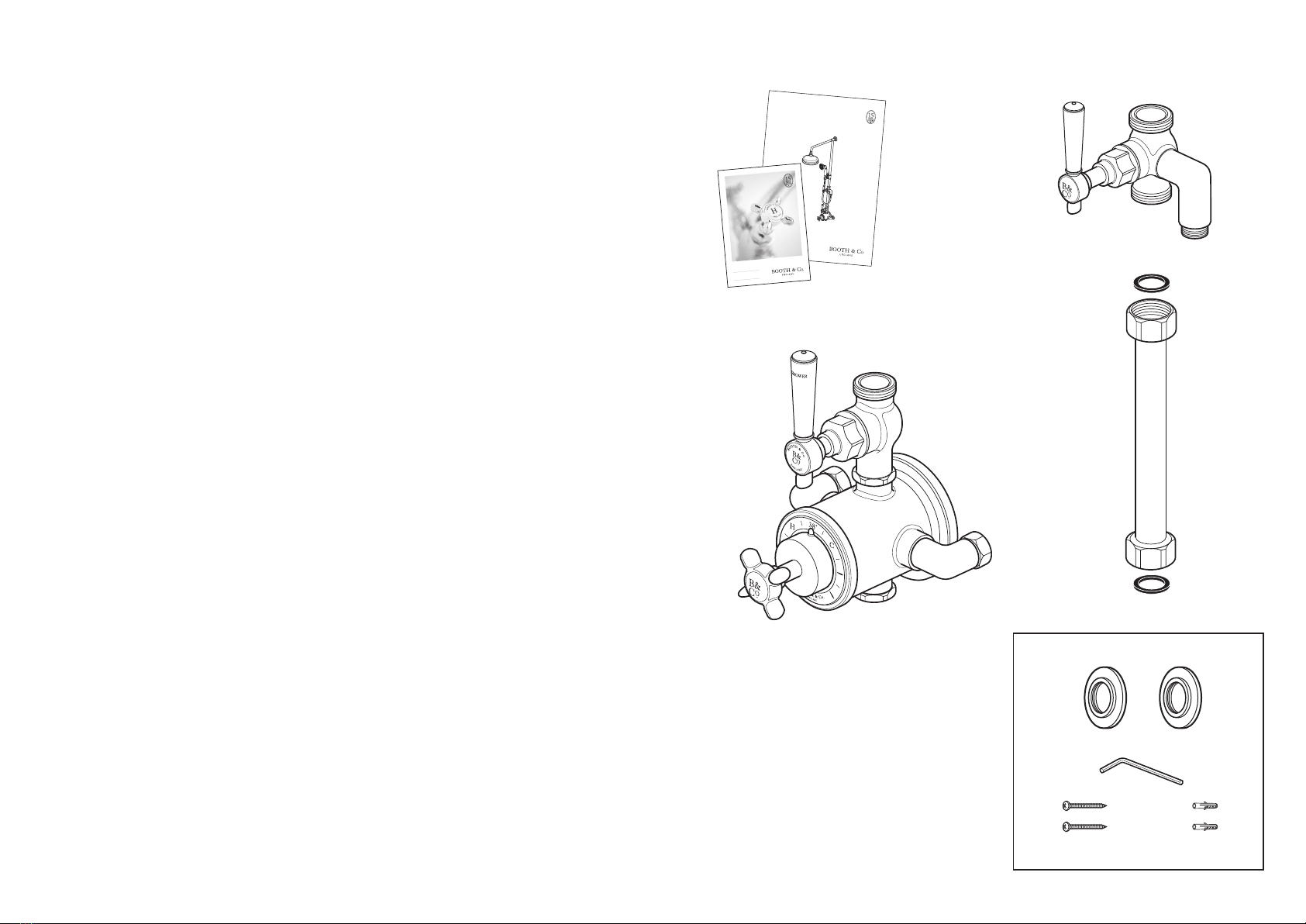

Contents of Packaging

Installation guide &

User manual

Covers

AX BR ID GE

BC- A XB -14 9- CP

BC- A XB -14 9- BN

INS TA LL A TI ON G UI DE

SH OWER V ALVE W ITH RI SER

US ER GUID E

KE EP FOR

FU TU R E R E FE R E N C E

AX B RI DG E

Accessory box 1

Diverter

Screws x 2 Wall plugs x 2

Hex key

Short riser with 2 washers

Valve body

4 5

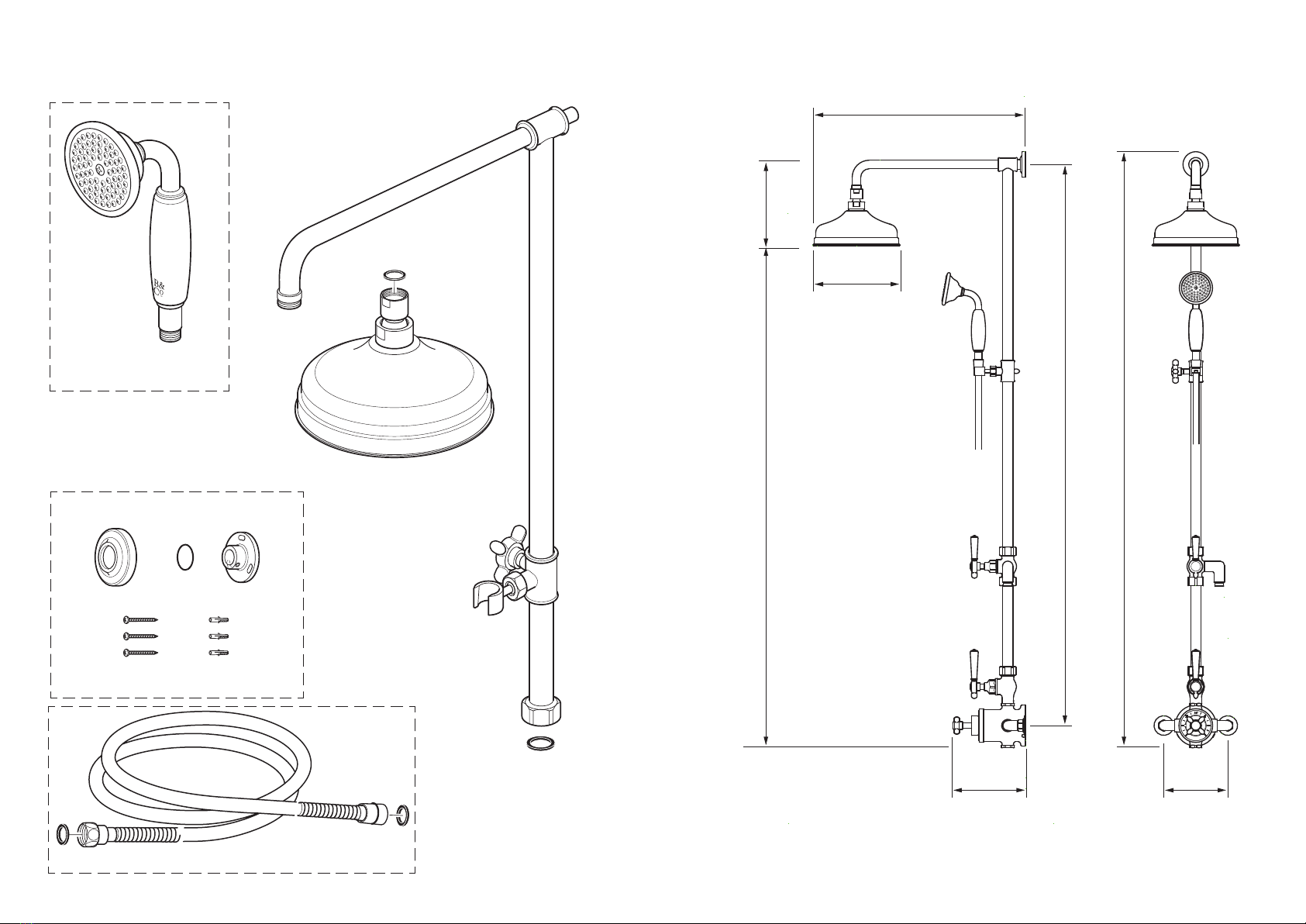

Contents of Packaging

Handset

Riser with washer

Shower hose with 2 washers

Shower head with washer

Cover O-ring Bracket

Accessory box 2

Screws

x 2

Wall plugs

x 2

Dimensions

495mm

205mm

170mm 150mm

921mm 202mm

1070mm

1143mm

6 7

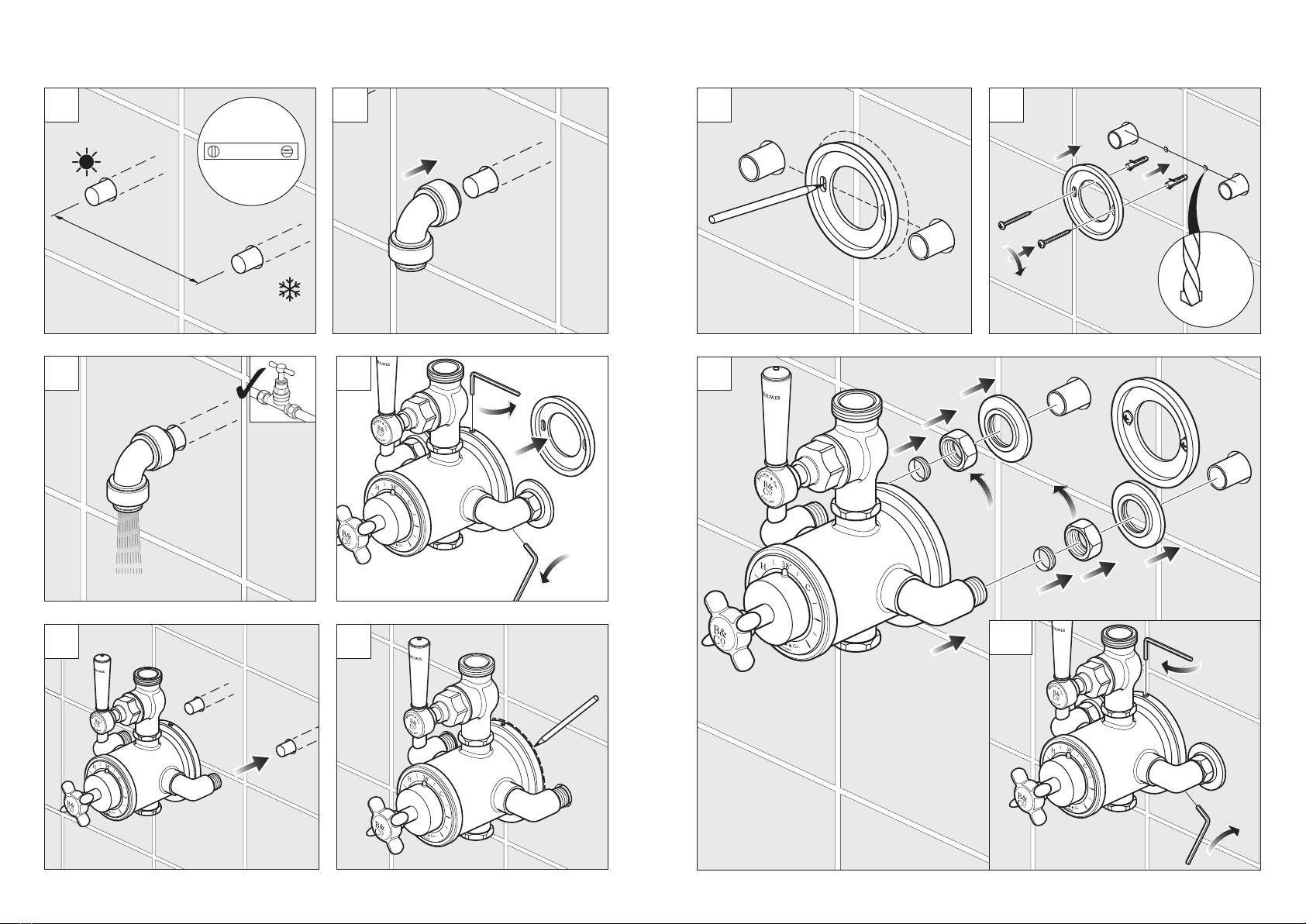

Installation - Quick guide

2

3

1

4

5 6

1

2 3

4

0 5

1

2 3

4

0 5

1

2 3

4

0 5

1

2 3

4

0 5

147-153mm

x 3

Installation - Quick guide

9

10

8

6mm

1

2

3

5

1

2

3

5

4

7

8 9

Installation - Quick guide

11 12

1413

Installation - Quick guide

15 16

19 20

1817

10 11

Installation - Quick guide

21 22

23 24

Installation

Prepare the wall with 2 copper pipes

at 147-153mm centres. Make sure the

pipes are level.

Connect the water supply to the

inlet pipes. The hot water should be

connected to the left hand pipe .

Before installing your new mixer, flush

through the pipe work to ensure removal

of debris, turn off the water supply.

(Do not allow dirt, metal particles or

shavings to block the filters fitted on

inlets).

147-153mm

Mounting plate

Inlet pipe

20-25mm hole

Remove the mounting plate from the

back of the valve by releasing the three

grub screws and pulling out the plate.

Place the mounting plate in the centre

of the marked position and mark the two

fixing holes.

Temporarily place the valve over the

copper pipes and mark the back of the

body against the wall.

There is a small amount of adjustment

on the inlet pipes to allow fitting onto the

copper pipes. Screw each side in or out

as required, ensuring that both sides are

screwed in equally.

Remove the valve.

12 13

Installation

Fig. 1

Cover

Cold

Hot

During and after installation protect the outer parts of the valve to avoid damage to

plated surfaces.

Place the covers over the copper pipes, followed by the nuts and the olives.

Push the valve onto the copper pipes and the mounting plate, tighten both the nuts on

the inlets being careful not to damage the plated surface.

Drill the marked holes to a suitable

depth for the wall plugs and secure with

supplied screws.

If you are fitting the valve to a partition

wall or a wall of particularly soft

substrate you will need specialist fixings.

Mounting plate

Screws

Wall plugs

Nut

Olive

Inlet pipe

Installation

Secure the valve into position by

tightening the three grubs crews, one

at 12 o'clock and the other two at 4 and

eight o'clock

Hex key

Place the washer into the nut and screw

the short riser to the diverter and tighten

being careful not to damage the chrome

surface.

Grub screw

Short

riser

Washer

Diverter

Hose

connection

Hex key

14 15

Installation - riser rail

Place the washer into the nut and screw

the top riser to the diverter and tighten

being careful not to damage the chrome

surface.

Slide the wall bracket onto the riser and

place against the wall.

Wall bracket

Riser

Valve

Washer

Short

riser

Riser

Washer

Diverter

Short riser

Place the washer into the nut on the

bottom of the short riser and screw onto

the valve.

Do not over tighten.

Installation

Warning! Please check for any

hidden cables and pipes before drilling

holes in the wall.

Drill the marked holes to a suitable

depth for the wall plugs and secure with

supplied screws.

Slide on the cover.

Replace the riser onto the valve.

Slide the riser into the wall bracket.

Make sure that the riser is vertical and

secure in position using the grub screw

on the side of the wall bracket.

Finally tighten the nut to secure the riser

to the valve.

Make sure that the riser is vertical and

mark the 3 fixing holes in the wall bracket

with a pencil.

Wall bracket

Wall bracket

Screws

Wall plugs

Cover

Wall bracket

Riser

Hex key

16 17

Washer

Hose

Diverter

Handset

Installation - Shower hose

Washer

Hose

Shower head

Washer

Riser arm

Shower head

Make sure there is a rubber washer in

place in the shower head and screw onto

the riser arm.

Handset

Place one of the rubber washer into the

cone end of the hose and screw to the

handset.

Valve

Place the second rubber washer into the

nut end of the hose and attach it to the

diverter outlet.

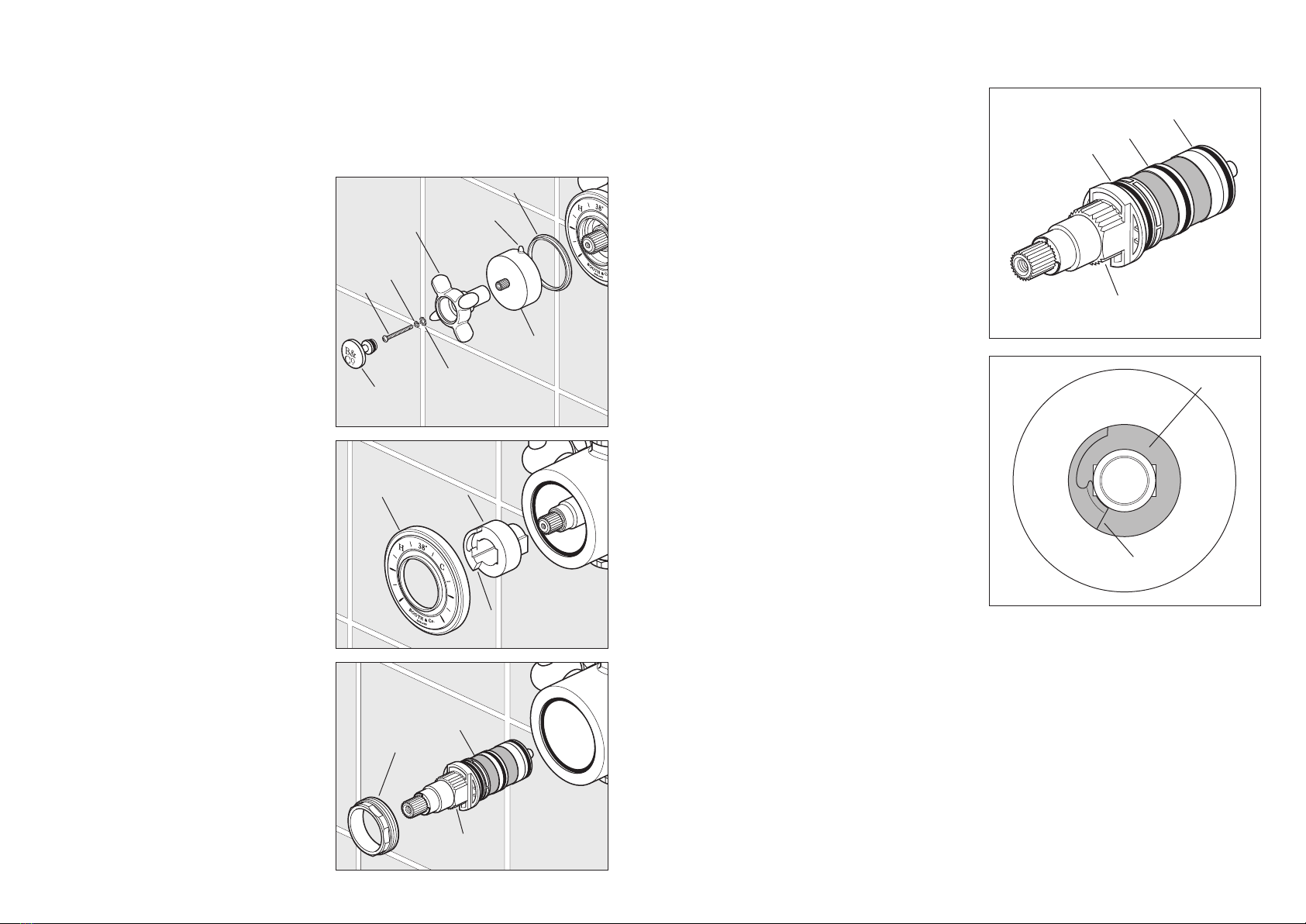

Commissioning

The valve has been factory set under

balanced pressures and hot supply at 65°C.

When your specific operating conditions are

significantly different from the above, the

temperature of the delivered water may vary

from the setting.

When the difference is too great, you can

adjust the calibration of the valve to suit

individual requirements of the installation.

Note: mixed water temperature at the

terminal fitting should not exceed 46°C.

With the temperature handle fitted and the

temperature indicator located at

12 o'clock, check the temperature of the

water being delivered from the outlet with a

thermometer.

Note: temperature readings should be

taken at normal flow rate after allowing the

system to stabilise.

If the temperature is not 38°C proceed to

commission the valve as follows.

Carefully prise out the ceramic screw cover

with a suitable flat tool, remove the screw

and washers and pull off the handle, shroud

and spacer ring (g 1).

Ensure the step on the stop ring is as

pictured (g 2).

Rotate the spline of the thermostatic

cartridge clockwise to decrease and anti-

clockwise to increase the temperature until

38°C is achieved at the outlet (g 3).

Note: the sensing part of the thermometer

probe must be fully submerged in the water

that is to be tested.

Carefully replace the spacer ring, shroud

and temperature handle with the

temperature indicator located at 12

o'clock without turning the spline of the

thermostatic cartridge.

Screw the temperature handle in place

using the washers and screw, replace the

screw cover.

Ensure the water temperature does not

exceed 46°C when turned entirely

anti-clockwise.

Fig. 2

Fig. 3

Stop ring

Spline

Handle

Screw

cover

Lock

washer

Screw

Spring

washer

Shroud

Spacer ring

Indicator

Fig. 1

Step

18 19

Maintenance

We advise that the below is carried out annually as failure to do so may result in

invalidation of warranty.

Shut off the water supply to both hot and cold inlets, before commencing any

maintenance work below.

Fig. 1

Fig. 2

Fig. 3

Handle

Screw

cover

Lock

washer

Screw

Spring

washer

Shroud

Temperature

ring

Securing nut

Stop ring

Cartridge

Step

Locating slot

Spacer ring

Indicator

Thermostatic cartridge

To clean the filters, you must first remove

the cartridge from the housing.

Removing the Cartridge

1. Shut off the water supply to both inlets.

Ensure the thermostatic valve has been

successfully isolated.

2. Using a suitably flat tool remove the

screw cover, unscrew and remove the

temperature handle and pull off the shroud

and spacer ring (g 1). Remove the ceramic/

chrome temperature ring allowing access to

the valve (g 2).

3. Using pliers if required gently remove

temperature stop ring (essential) (g 2).

4. Turn shower on to check isolation, please

ensure that your body/hands are not under

the flow of water as there is a potential for

delivery of hot water.

5. Using a 32mm box spanner unscrew and

remove the valve securing nut then carefully

pull out the thermostatic cartridge (g 3).

Note: Ensure care is taken as a small

amount of residual water may escape when

removing the cartridge.

Fig. 5

Fig. 4

Maintenance

6. Clean the cartridge filters by rinsing

them under running water to remove any

debris.

7. If there is limescale deposits then it is

recommended to immerse the cartridge

for a few minutes in 50% white vinegar

+ 50% hot water, brush the filters gently

and then rinse under running water to

clean all particles. If this is not effective, a

replacement cartridge should be fitted.

8. Before reassembling the cartridge,

clean its housing with a wet cloth and

grease the O-rings using a suitable

silicone grease. Insert the thermostatic

cartridge into the body aligning the slot in

the body with the grub screw (g 4).

9. Screw the securing nut on and tighten

using a box spanner, careful not to

overtighten.

10. Replace the temperature stop ring on

the cartridge with the cold step located at

7 o’clock (g 5).

11. Turn the water supply on.

12. Check the water temperature to

ensure correct commissioning. See

previous section.

13. Replace the ceramic/chrome

temperature ring, spacer ring and shroud

with the temperature indicator located at

12 o'clock without turning the spline of

the thermostatic cartridge.

Screw the temperature handle in place

using the washers and screw, replace the

screw cover.

O-ring

Locating slot

O-ring

O-ring

Stop ring

Step

This manual suits for next models

1

Table of contents

Other Booth & Co Bathroom Fixture manuals

Popular Bathroom Fixture manuals by other brands

Glacier bay

Glacier bay 67778-0001 Installation and care guide

VINNOVA

VINNOVA 703472 manual

Hans Grohe

Hans Grohe AXOR Starck 10925000 Instructions for use/assembly instructions

noken

noken SKY Installation and Maintenance

Hans Grohe

Hans Grohe Fixfit Square 26455000 Assembly instructions

Signature Hardware

Signature Hardware Contemporary 949170 quick start guide

Orbital Systems

Orbital Systems R3 OS8733-E manual

KEUCO

KEUCO Axess 35006 010801 Mounting instruction

Hans Grohe

Hans Grohe MySelect S Vario 26637400 Assembly instructions

Relax

Relax Smart 0801-A Assembly instructions

Kinedo

Kinedo Eden installation instructions

Blanke

Blanke BAY-BOX S Installation instruction