BOQU pHG-2091 User manual

SHANGHAI BOQU INSTRUMENT COMPANY WWW.BOQUINSTRUMENT.COM

pHG-2091

Online pH / ORP Meter

User manual

SHANGHAI BOQU INSTRUMENT CO.,LTD

Address:No. 118 Xiuyan Road,Pudong New Area,Shanghai,zip code:201315,China

www.boquinstrument.com|email:michael@shboqu.com|mob:86-15000087545

SHANGHAI BOQU INSTRUMENT COMPANY WWW.BOQUINSTRUMENT.COM

Content

Foreword................................................................................................................................1

User notice.............................................................................................................................4

Chapter 1 Production introduction...............................................................................5

1.1 Features.......................................................................................................................5

1.2 Technical indexes........................................................................................................5

Chapter 2 Installation........................................................................................................6

2.1 Meter installation.........................................................................................................6

2.2 Electrode installation...................................................................................................7

2.3 Meter wiring................................................................................................................7

Chapter 3 Button operation.............................................................................................9

Chapter 4 Meter display and operation.......................................................................9

Chapter 5 Settings..............................................................................................................11

5.1 System Setting............................................................................................................11

5.2 Signal Setting.............................................................................................................12

5.3 Online Calibration......................................................................................................12

5.4 Remote Setting...........................................................................................................13

5.5 Alarm Setting..............................................................................................................13

5.6 Information Inquiry.....................................................................................................13

Chapter 6 Communication protocol.............................................................................14

Chapter 7 Product maintenance....................................................................................14

Chapter 8 Trouble analysis and recovery methods..................................................16

SHANGHAI BOQU INSTRUMENT COMPANY WWW.BOQUINSTRUMENT.COM

- 1 -

Foreword

Thank you very much for your company to buy my company's pH / redox online analyzer.

This manual describes the functions, wiring methods, setting methods, operation methods and

fault handling methods that can be realized by the instrument in detail. Before the instrument

is put into operation, it is necessary to read this manual in detail, to understand the use of the

method and then to carry out specific operations, to avoid unnecessary damage caused by the

wrong operation, if the manual described in the method other than the operation, and

sometimes damage the instrument Provide protection, if it is due to breach of these

precautions arising from the failure and the accident, our company is not responsible.

Please read this manual carefully before using the instrument. Under the premise of full

understanding, must be on the scene of the relevant electrical professionals in order to install

the instrument, operation and maintenance. Incorrect installation or operation can result in

damage to the instrument or personal injury

The company promises to the user, the instrument should be provided when the supply of

hardware, accessories in the material and manufacturing processes are not any flaws. From

the date of purchase of the instrument from the date of calculation, in the warranty period, if

the user received a notice on such defects, the company is indeed defective products for

unconditional free maintenance or free replacement. The company for all products will

guarantee life-long maintenance.

In order to comply with the principles of sustainable development, the Company reserves the

right to modify the performance parameters described in this manual without prior notice.

Reserves the right to revise or revoke this manual without prior notice. When the instrument

changes certain performance parameters may lead to serious accidents, the company must

inform the user in advance. For the improved instrument, the company will have a new

version of the instructions or improved instructions. If there is a deviation from the

description in this manual, please prevail in kind.

No modification of the instrument! Due to unauthorized transformation of the product caused

by the accident, the company is not responsible.

SHANGHAI BOQU INSTRUMENT COMPANY WWW.BOQUINSTRUMENT.COM

- 2 -

Instructions used in this manual

Remark

Name

Note

Danger

Failure to take appropriate precautions can result

in serious personal injury, damage to the

instrument, or loss of significant property.

Warning

Remind you of the important information about

the product or the special part of this manual.

Caveat

Be careful to do this, and execution errors can

cause significant problems.

Note

Please read this note carefully, it is very helpful to

operate the instrument correctly.

Danger

Do not use the instrument in flammable and explosive atmospheres or where there

is steam.

The instrument can work normally in general. If the fault of the instrument may

cause serious accident or damage other equipment, need to set the emergency stop

circuit and protection circuit.

Make sure that the supply voltage is consistent with the rated voltage before

running.

In order to prevent electric shock, misuse, display is not normal or measurement

of a larger error, be sure to carry out a good grounding protection.

Must be mine construction facilities: common grounding grid equipotential

grounding, shielding, reasonable wiring, the appropriate use of SPD surge

protector and so on.

Some internal parts with high pressure, non-company or non-I recognized the

maintenance staff, do not open the front panel, in order to avoid electric shock.

Make sure that the power is turned off before performing any inspection to avoid

electric shock.

Check the terminal screws and mounting screws regularly. If they are found loose,

please use them before tightening.

Never allow unauthorized removal, processing, alteration or repair of the

instrument, otherwise it may cause abnormal action, electric shock or fire

accident.

SHANGHAI BOQU INSTRUMENT COMPANY WWW.BOQUINSTRUMENT.COM

- 3 -

Please use a dry cotton cloth to wipe the instrument, can not use alcohol, gasoline

or other organic solvents. Beware of a variety of liquid splashed on the

instrument, if the instrument fell into the water, please immediately cut off the

power, or leakage, electric shock and even fire accidents.

Check the grounding protection and fuse status regularly. Do not run if you think

that the protective measures such as earthing protection and fuses are not perfect.

Ventilation holes in the instrument housing must be kept smooth so as to avoid

high temperature failure, abnormal action, shortened life and fire.

Please follow the instructions in this manual, otherwise it may damage the

instrument protection device.

Warning

If you find out if the instrument is damaged or deformed, please do not use it.

Install to avoid dust, thread, iron or other substances into the instrument,

otherwise it will occur abnormal action or failure.

During operation, if you want to modify the configuration, signal output, start,

stop and other operations, should take full account of operational safety, error

operation may lead to instrumentation and equipment failure or even damage.

Parts of the instrument have a certain period of life, in order to ensure long-term

use, be sure to carry out regular maintenance and maintenance.

Scrap the product, according to industrial waste disposal, to avoid pollution of the

environment.

SHANGHAI BOQU INSTRUMENT COMPANY WWW.BOQUINSTRUMENT.COM

- 4 -

User Notice

Please observe the operating instructions and precautions in this manual.

The instrument can be operated normally. If the malfunction of the instrument may result in a

major accident or damage to other equipment, the emergency stop circuit and the protection circuit

shall be provided. Otherwise, the Company will not be responsible for any consequences.

The instrument has only one electrode input. When selecting the PH mode, the PH electrode

should be installed. The OPR electrode should be installed in the ORP mode.

In order to make the measurement more accurate, the glass electrode shelf life of one year,

the factory a year later, regardless of whether the use of its performance will be affected,

should be replaced.

The first use of the PH electrode or long-term no use of the PH electrode, must be sink into

3mol/ L of KCL for 24 hours.

Preheat the instrument for about half an hour before performing calibration work.

When measuring, should be washed in distilled water (or deionized water), and filter the

paper to absorb moisture, to prevent impurities into the measured liquid.

In the course of the use of the instrument if the work is abnormal or damaged, please contact

the manufacturer, do not repair themselves.

SHANGHAI BOQU INSTRUMENT COMPANY WWW.BOQUINSTRUMENT.COM

- 5 -

Chapter 1 Production introduction

PHG-2091 Online pH / ORP Analyzer is one of the intelligent online chemical analysis

instruments, is a widely used in thermal power, chemical fertilizer, metallurgy, environmental

protection, pharmaceutical, biochemical, food and tap water solution PH value or OPR Value and

temperature of the continuous monitoring.

Continuous monitoring data through the transmission output connection recorder to achieve

remote monitoring and recording, you can also connect the RS485 interface through the

MODBUS-RTU protocol can be easily connected to the computer to achieve monitoring and

recording.

1.1 Features

Board modular design, assembly configuration more convenient.

■ Using 2.4-inch 12864 dot matrix screen

■ Use isolated output, less interference

■ Isolated RS485 communication

■ Can be PH / ORP measurement, temperature measurement, high and lower limit control,

transmission output, RS485 communication

■ Configurable temperature manual, automatic compensation function

■ Can set high and low alarm function, and hysteresis

■ Can be set buzzer, LCD backlight switch function

■ Increase the universal password function

■ Industrial control watchdog to ensure that the instrument does not crash

1.2 Technical indexes

■ Isolated 4-20 mA current output, the maximum load 750Ω, 0.1% FS

■ Measuring range: PH (0-14 pH); ORP (-2000- + 2000 mV)

■ Accuracy: ± 0.03 pH; ± 2mV

■ Resolution: ± 0.01 pH; ± 1mV

■ Stability: ≤ 0.02 pH / 24H; ≤ 3 mV / 24H

SHANGHAI BOQU INSTRUMENT COMPANY WWW.BOQUINSTRUMENT.COM

- 6 -

■ Input impedance: ≥10 ^ 12

■ Temperature type: NTC10K

■ Temperature measurement range: 0-99.9 ℃, accuracy: ± 0.5 ℃

■ Temperature compensation: 0-99.9 ℃ manual / automatic

■ RS485 function, compatible with standard MODBUS-RTU communication protocol

■ Power supply: AC220V ± 10%, 50 / 60Hz

■ Alarm relay AC250V, 3A

Chapter 2 Installation

2.1 Meter installation

Please describe the installation method and installation method of this instrument. Be sure to

read this section when installing.

Installation Precautions

The instrument is equipped with relay switch output, generally used for alarm prompts, if the

user will use this function to participate in loop control, if the instrumentation, the instrument is

used to control the instrument, The failure may lead to major accidents or damage to other

equipment, the need to set the emergency stop circuit and protection circuit complement,

otherwise the consequences, the company is not responsible.

This instrument is disk mounted.

Please install indoors, avoid wind and rain and direct sunlight.

In order to prevent the internal temperature rise of the instrument, please install in a well

ventilated place.

When installing this instrument, please do not tilt left and right, as far as possible (can be tilted

<30 °).

Avoid the following places during installation

The area where the sunlight is directly irradiated and the vicinity of the heat instrument.

Work where the ambient temperature exceeds 60 ° C.

Work where the ambient humidity exceeds 85%.

Near the electromagnetic source.

SHANGHAI BOQU INSTRUMENT COMPANY WWW.BOQUINSTRUMENT.COM

- 7 -

Mechanical vibration strong place.

The temperature change is easy to condensation place.

Fumes, steam, moisture, dust and corrosive gases.

Installation method

Open a 92.5 * 92.5 mounting hole on the instrument cabinet or mounting panel to insert the

instrument into the mounting hole fixing screw.

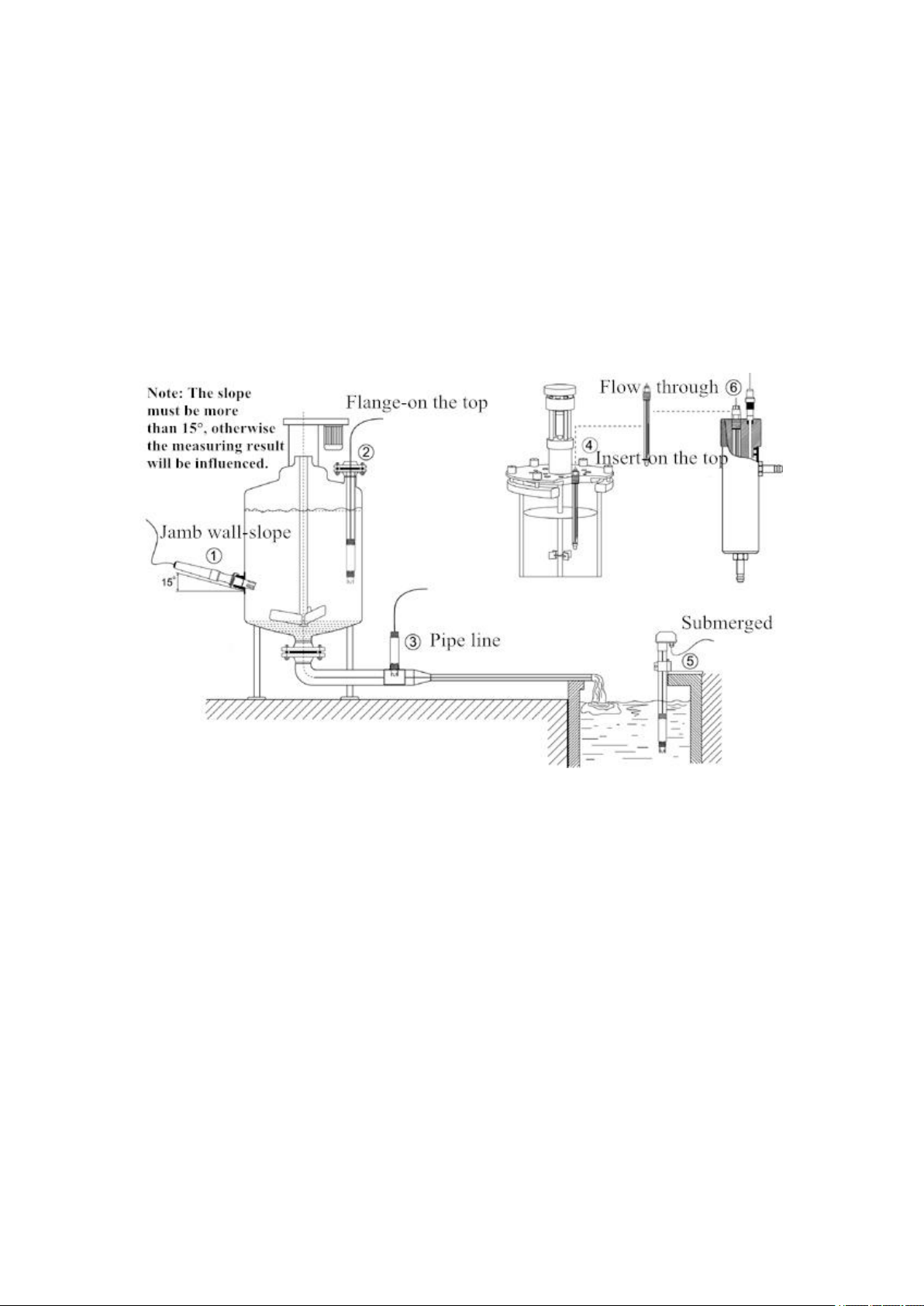

2.2 Electrode Installation

Common installation diagram

2.3 Meter wiring

Terminal definition

■ INPUT: Electrode measurement terminal

■ REF: Sensor reference

■ NC: None

■ TEMP2:Temperature compensation 2

■ TEMP1:Temperature compensation 1

■ RS485(A+): RS485 Communication protocol A+

■ RS485(B-): RS485Communication protocol B-

■ 4-20mA(I+): 4-20mA Output +

SHANGHAI BOQU INSTRUMENT COMPANY WWW.BOQUINSTRUMENT.COM

- 8 -

■ 4-20mA(I-): 4-20mA Output -

■ AC220V(L): AC220V Zero wire

■ AC220V(N): AC220V Fire wire

■ HC: High limit normally close

■ HO: High limit normally open

■ LC: Low limit normally close

■ LO: Low limit normally open

■ COM: Relay common port

Notice:

To prevent electric shock, make sure that the meter is not energized before connecting the

signal cable.

To prevent fire, use a double insulated wire.

Do not place the live product near the signal terminals, which may cause malfunction.

SHANGHAI BOQU INSTRUMENT COMPANY WWW.BOQUINSTRUMENT.COM

- 9 -

Chapter 3 Button operation

Button description

Remark

Name

Function description

Menu

“Monitoring interface” enter into main menu

“Main menu” to exit

Exit

“Monitoring interface” to check alarm status

“Main menu” to exit to the last page

“Calibration” jump over the calibration process

Right

shift

Cycle select the number of parameters

Next

“Main menu” to select relevant menu

Set the state to modify the relevant value

Enter

“Main menu” enter into sub-menu or confirm the modify

Chapter 4 Meter display and operation

Monitoring interface

The instrument is equipped with monochrome dot matrix LCD display with a resolution of 128 *

64.

Use the 【Menu】to enter the password verification screen, input the password and enter into the

main menu screen.

SHANGHAI BOQU INSTRUMENT COMPANY WWW.BOQUINSTRUMENT.COM

- 10 -

Use 【ESC】to enter the alarm query screen, query the current alarm settings information.

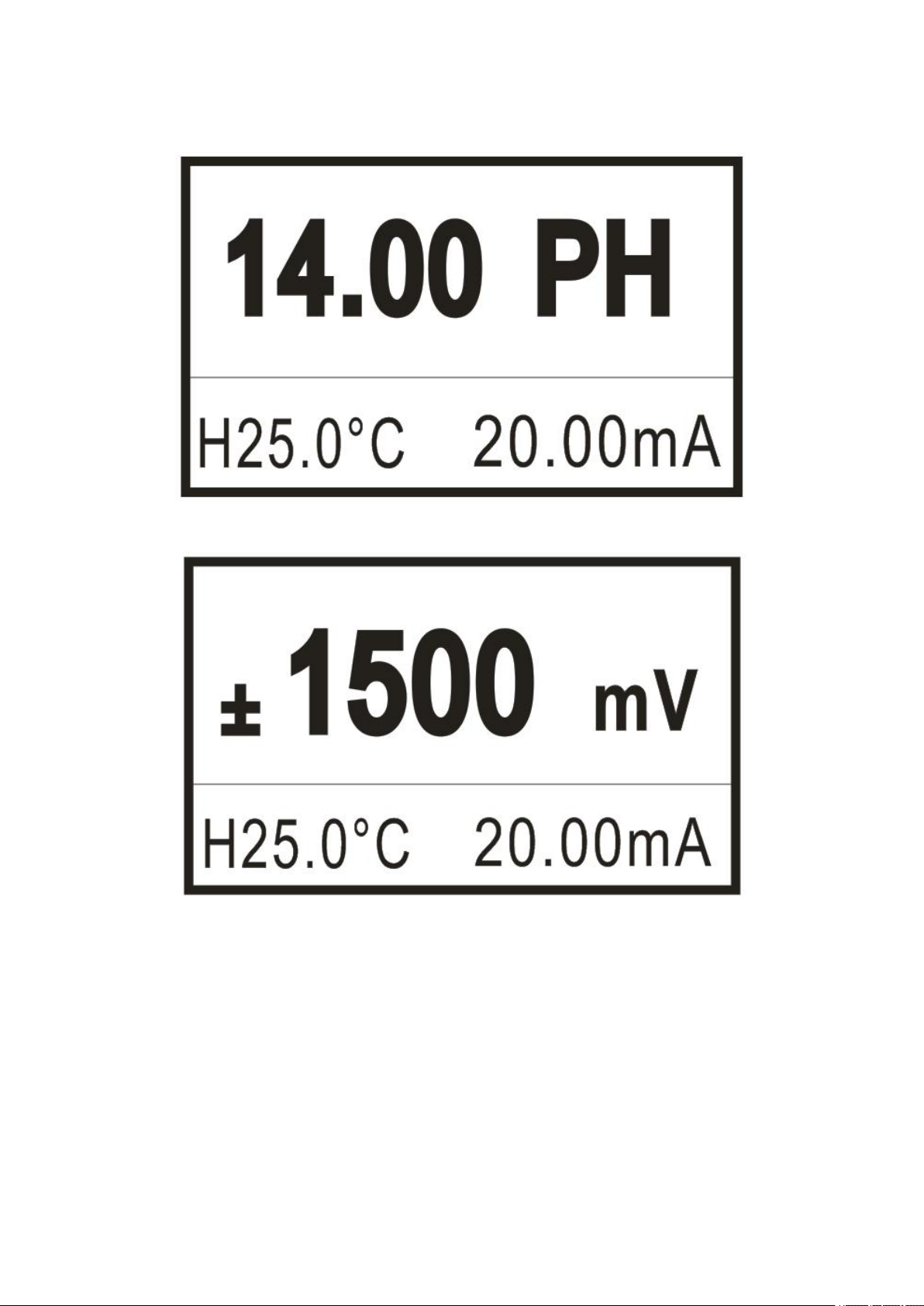

Monitoring interface of pH value

Monitoring interface of ORP value

Password verification screen

After entering the password, use [ENT] to enter the main menu screen.

Initial password is 0000, you can use the password modification function to change the password.

If you forget your password, please contact us.

----Password----

0000

SHANGHAI BOQU INSTRUMENT COMPANY WWW.BOQUINSTRUMENT.COM

- 11 -

Main menu

----Main menu----

1.System Setting

2. Signal Setting

3. Online Calibration

4. Remote Setting

5. Alarm Setting

6. Information inquiry

System Setting: buzzer and backlight settings, password changes and factory settings.

Signal Setting: switching of the electrode type and automatic switching of the warm-up hand.

Online Calibration: Calibration and correction of PH and ORP signals.

Remote Setting: RS485 and current transmission output parameter settings.

Alarm Settings: high alarm and low alarm parameter settings.

Information Inquiry: current version number.

Chapter 5 Settings

5.1 System setting

----System setting----

1. Language

2. Buzzer

3. Backlight

4. Password Modify

5. Factory Setting

Language: Chinese and English switch

Buzzer: Sets the buzzer switch when the alarm is set.

Backlight Setting: set the LCD backlight switch.

Password Modify: change the password and use the new password login.

Factory Setting: return to factory settings.

SHANGHAI BOQU INSTRUMENT COMPANY WWW.BOQUINSTRUMENT.COM

- 12 -

5.2 Signal setting

----Signal setting----

1. Electrode Type

2. Temp compensation

Electrode Type: set the electrode type, PH electrode and ORP electrode two types.

Temperature compensation: set the automatic temperature compensation or manual temperature

compensation, the temperature range of 0-99.9 ℃.

5.3 Online Calibration

----Online Calibration----

1. pH Calibration

2. pH Modification

3. ORP Calibration

4. ORP Modification

PH Calibration: enter into PH calibration screen, put the PH electrode into 4.00PH standard

solution firstly, standing for a moment, after the value stable, press the ENT; Then put the PH

electrode into 6.86PH standard solution, standing for a moment, after the value stable, press the

ENT; Finally, put the PH electrode into 9.18PH standard solution, standing for a moment, after the

test is stable, press the ENT, indicating that the calibration is successful , The PH calibration

process finished.

PH correction: The measured PH value can be corrected between 2 PH values.

ORP Calibration: enter into ORP calibration screen, put the ORP electrode into the 86mV

standard solution firstly, standing for a moment, after the value stable, press the ENT; then put the

ORP electrode into 256mV standard solution, Moment, after the value stable, press the ENT,

display calibration is successful, ORP calibration process is finished.

ORP Correction: The measured ORP value can be corrected between 300mV.

SHANGHAI BOQU INSTRUMENT COMPANY WWW.BOQUINSTRUMENT.COM

- 13 -

5.4 Remote Setting

----Remote Setting----

1. RS485

2. 4-20mA setting

RS485: Set the address and baud rate of 485 communication.

4-20mA Setting: set 4-20mA output 4mA corresponds to the value and 20mA corresponding

value.

5.5 Alarm Setting

----Alarm Setting----

1. pH High Alarm

2. pH Low Alarm

3. ORP High Alarm

4. ORP Low Alarm

PH High Alarm: when the measured value is higher than the high value set, the high alarm relay

pull, when the measured value is lower than the high value set, the high alarm relay disconnect.

PH Low Alarm: when the measured value is higher than the low value set, the lower alarm relay

pull, when the measured value is lower than the low value set, the low alarm relay off.

ORP High Alarm: when the measured value is higher than the high value set, the high alarm

relay pull, when the measured value is lower than the high value set, the high reported relay

disconnect.

ORP Low Alarm: When the measured value is lower than the low value set, the low alarm relay

pull, when the measured value is higher than the low value set, the low alarm relay off.

5.6 Information Inquiry

----Information Inquiry----

1. Ver Information

Version information: query the current hardware and software version, strong traceability.

SHANGHAI BOQU INSTRUMENT COMPANY WWW.BOQUINSTRUMENT.COM

- 14 -

Chapter 6 Communication protocol

The instrument provides standard RS485 serial communication interface, using the international

standard MODBUS-RTU communication protocol, support 03 read to keep the register command.

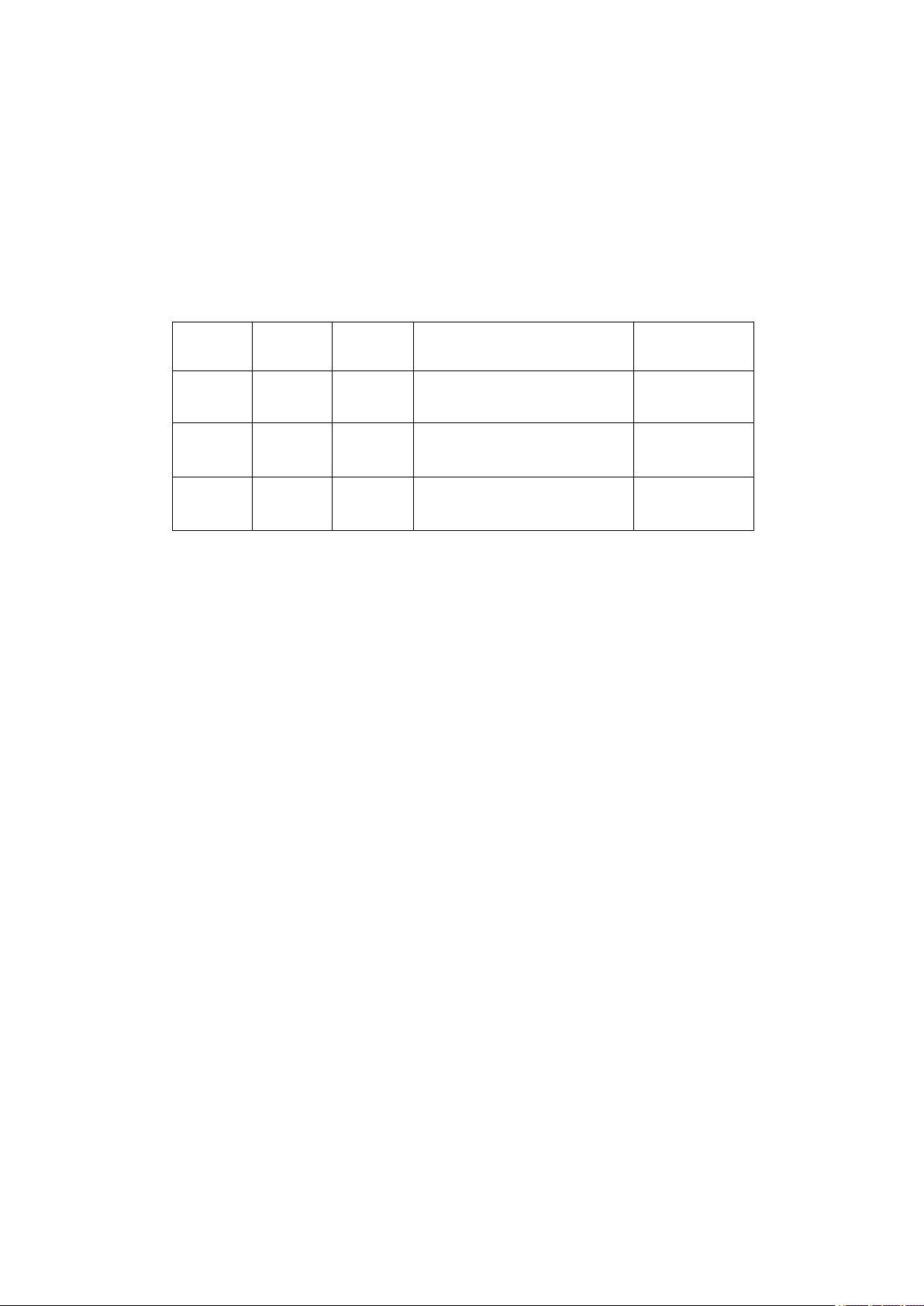

Register address

The communication data and the register address are as follows:

Communication sample:

The computer sends: 00 03 00 00 00 01 85 DB

PH / ORP meter returns: 00 03 02 02 AE 05 58

Return command comment: 00 is 485 address;

03 is the function code;

02 is the data length of the return PH value: 2 bytes;

02 for the return of the PH value of 686 (hexadecimal high byte);

AE for the return of the value of 686 (hex low byte);

05 58 is the CRC check value;

Chapter 7 Product maintenance

1. pH glass electrode storage, short-term: stored in the pH 4 buffer solution; long-term: stored in

the pH7 buffer solution.

2. pH glass electrode cleaning, glass electrode bulb contamination may make the electrode

response time longer. CCl4 or soap can be used to wipe the dirt, and then immersed in distilled

water for 24 hours and then continue use. When the pollution is serious, can be use 5% HF

Address

Data type

Function

code

Description

Access

permission

0x0000

unsigned

short

0x03

PH value

(Default two decimal places)

Read only

0x0001

unsigned

short

0x03

Temp value

(Default one decimal places)

Read only

0x0002

short

0x03

ORP value

(Signed integer)

Read only

SHANGHAI BOQU INSTRUMENT COMPANY WWW.BOQUINSTRUMENT.COM

- 15 -

solution for 10 to 20 minutes, immediately rinse with water, and then immersed in 0.1N HCl

solution for 24 hours and then continue use.

3. Glass electrode aging treatment: the aging of the glass electrode and the gradual change in the

structure of the glue layer. Old electrode response is slow, film resistance is high, slope is low.

Exfoliation of the outer layer with HF can often improve electrode performance. If this method

can be used to regularly remove the inner and outer layers, the electrode life is almost unlimited.

4. The storage of the reference electrode Silver - silver chloride electrode, the best storage solution

is in saturated potassium chloride solution, high concentration of potassium chloride solution can

prevent the silver chloride in the liquid junction precipitation, and maintain the liquid junction in

the work status. This method also applies to the storage of composite electrodes.

5. The reference electrode regeneration reference electrode problems caused by the vast majority

of liquid junction caused by blockage, the following methods can be resolved:

(1) Soaking fluid interface: 10% saturated potassium chloride solution and 90% distilled water

mixture, heated to 60 ~ 70 ℃, the electrode immersed in about 5cm, soak for 20 minutes to 1

hour. This method dissolves the crystallization of the electrode tip.

(2) Ammonia Soaking: When the liquid interface is blocked by silver chloride can be leaching

with concentrated ammonia. The specific method is to clean the electrode, the liquid vent after

immersion in ammonia 10 to 20 minutes, but do not let ammonia into the electrode inside.

Remove the electrode with distilled water to wash, re-add the internal liquid and continue to use.

(3) Vacuum method: the hose to match the reference electrode fluid interface, the use of water

suction pump, suction part of the liquid through the fluid interface, remove the mechanical

blockage.

(4) boiling fluid junction: silver - silver chloride reference electrode liquid interface immersed in

boiling water for 10 to 20 seconds. Note that the next time you boil, the electrode should be cooled

to room temperature.

(5) When the above methods are invalid, you can use sandpaper grinding mechanical method to

remove the blockage. This method may cause the sand under the grinding into the liquid interface.

Causing permanent clogging.

SHANGHAI BOQU INSTRUMENT COMPANY WWW.BOQUINSTRUMENT.COM

- 16 -

Chapter 8 Trouble analysis and recovery methods

1. The controller no display?

A: Check whether the power wiring is connected, the power supply is on.

2. Measurement value is bouncing?

A: Check around the frequency converter and other interference equipment, pay attention to

stay away from these interference equipment or do shielding measures.

3. PH instrument can not be calibrated?

A: The standard solution is not properly formulated or the electrode is damaged.

4. After calibrated by standard solution PH4.00, PH6.86, PH9.18, the test is not test?

A: The standard solution may polluted, replace the standard liquid and re-calibration.

5. The measurement value is slow response?

A: The electrode bulb is covered with dirt, the reaction will slow down, according to the type of

pollutants according to the corresponding cleaning method, it’s normal phenomenon in winter.

Table of contents

Other BOQU Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

HYDAC FILTER SYSTEMS

HYDAC FILTER SYSTEMS FMM-P-L Installation and maintenance instruction

Reftek

Reftek 180-SM 2 Series user guide

Seikom Electronic

Seikom Electronic NLSW45-5 manual

FW Murphy

FW Murphy TDX6 Installation and operation instructions

Precision Digital Corporation

Precision Digital Corporation PD686 quick start guide

Maxcess

Maxcess MAGPOWR DTM instruction manual