The fixings supplied with the 5001 are the same as a

normal 5000 plus the following; 2×off-set spindle (1

right handed & 1 left handed),1 strike plate, 1 box

keep,1 60mm tubular latch & 1 brass support post.

For correct installation you will need to read the

following instructions carefully.

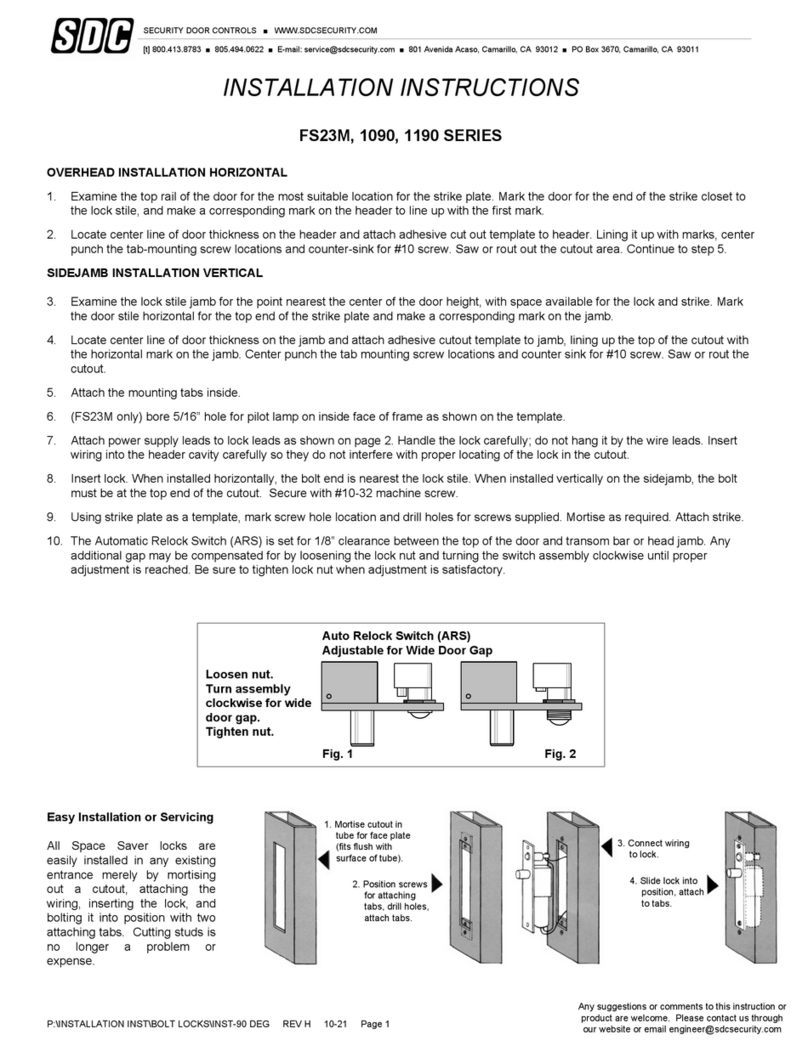

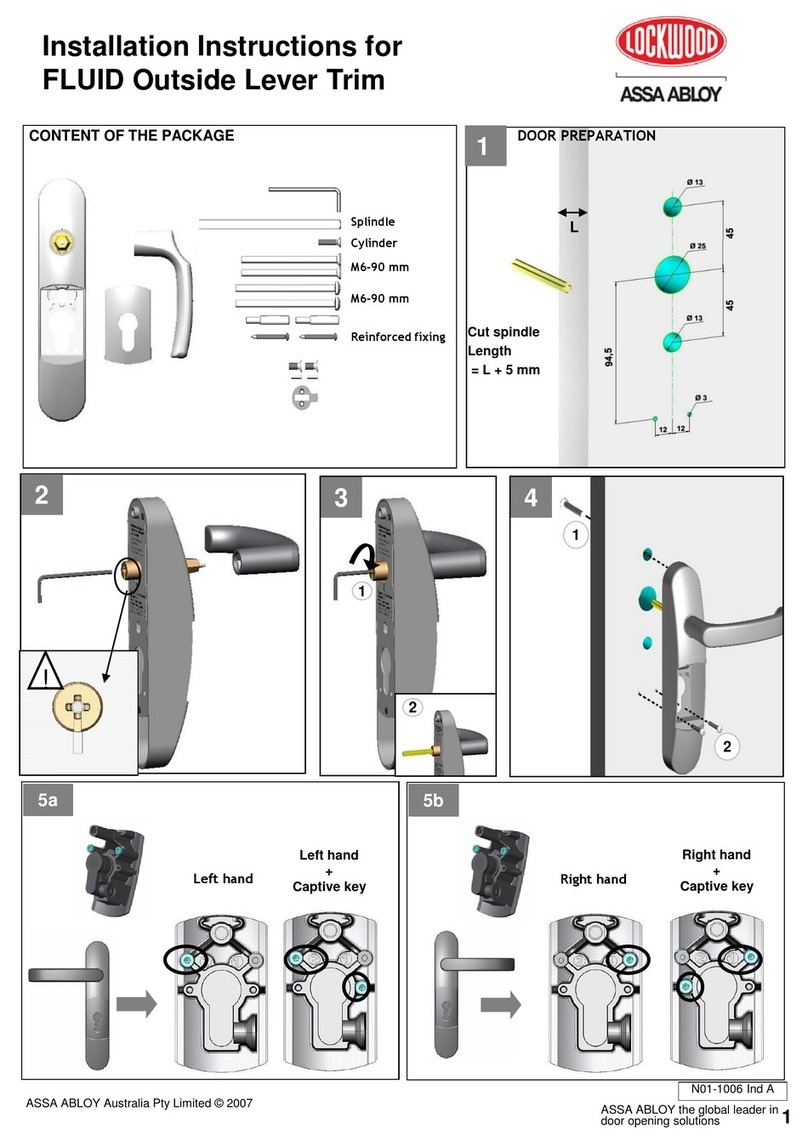

1. Mortise a hole (30 mm diameter 85mm deep) in

the edge of the door to take the tubular latch.

2. With the hole drilled, you will need to check that the

latch will slide in and out freely and operate wihtout

catching on the inside of the hole. Then you will

need to mark out the size of the faceplate on the

door, use a Stanley knife to do this to avoid splitting

when you chisel out a rebate to make the faceplate

flush with the door edge.

3. You will now need to drill the two small holes that will

accommodate the fixing posts and screws. Also you

will need to drill a hole to slot the spindle though. it

is very important the holes are in line, as

mis alignment will cause the lock to malfunction or

even break up within a very short period. So please

take care to align these locks very carefully. To stop

the splitting and make the holes more accurate you

should drill the holes from both sides (not all the

way through)

4. The most important part of installing this lock is to

make sure that you have selected the correct

spindle. If uncertain, please refer to the handing

chart provided. Once you have the correct spindle,

you should assembly and install the spindle as

described earlier in this manual. At this point, you

should also screw in the brass support post. As this

part helps to keep the alignment of the unit and

latch once the unit has been installed. (You should

now follow the final installation instruction on page

2)

For any further detlils or information about you lock

please call the Borg Helpline on 0800 44 88 377

OTHER LOCKCASES

The 5000 can be fitted with other makes of

locks and lockcases, and we can provide special fixings

pack where necessary.

For more information and advice, please call our

help ine number.l

5. Now replace the covering panel and hand tighten

6. The code has now been changed, please check to

see that it is working correctly, also make a note

of the code for future reference. Once satisfied

that the lock is working as normal you are ready to

fit/re-fit the lock.

NOTES ABOUT THE CODE

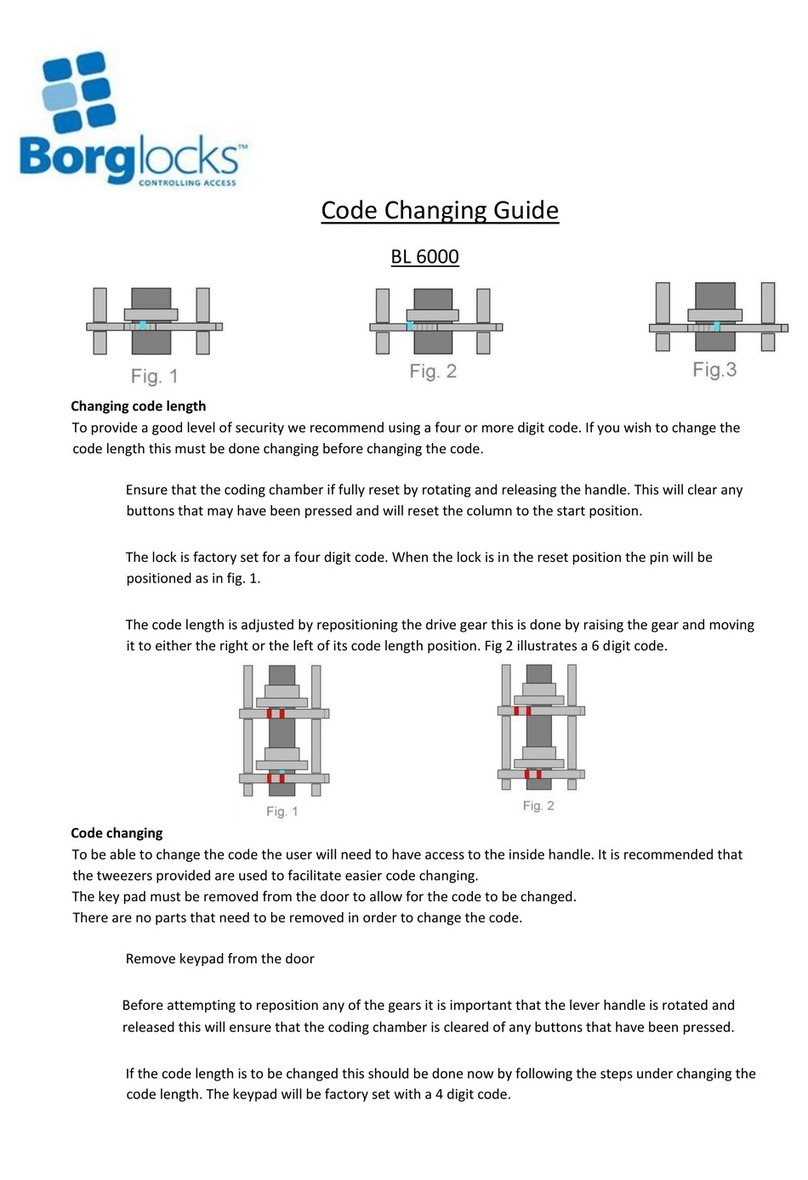

You will have been provided with 4 spare tumblers

( 2 red and 2 blue ) these are to shorten or lengthen

your code.

N. B Your code can be entered in any order or

sequence e. g. 1234 or 4321 or 2431. There

are over 1,000 different combinations

avallable.

The button activates the code free entry feature, so if

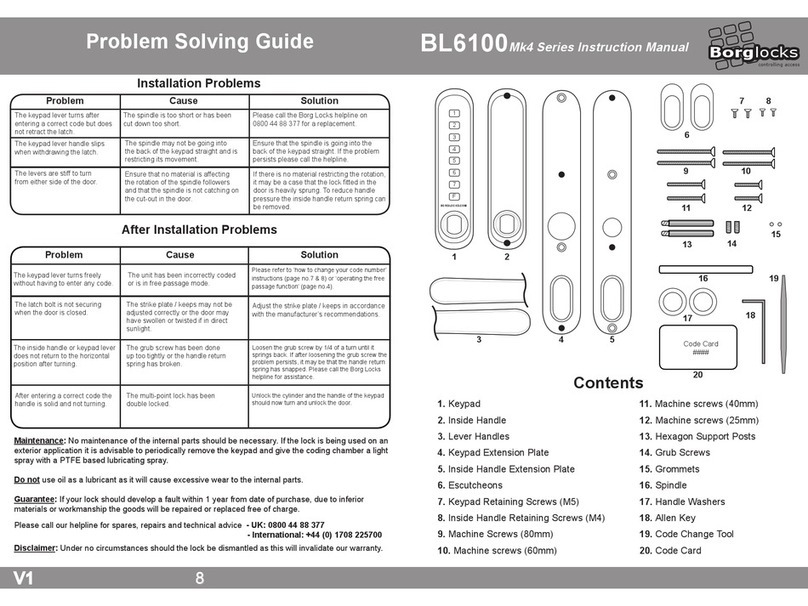

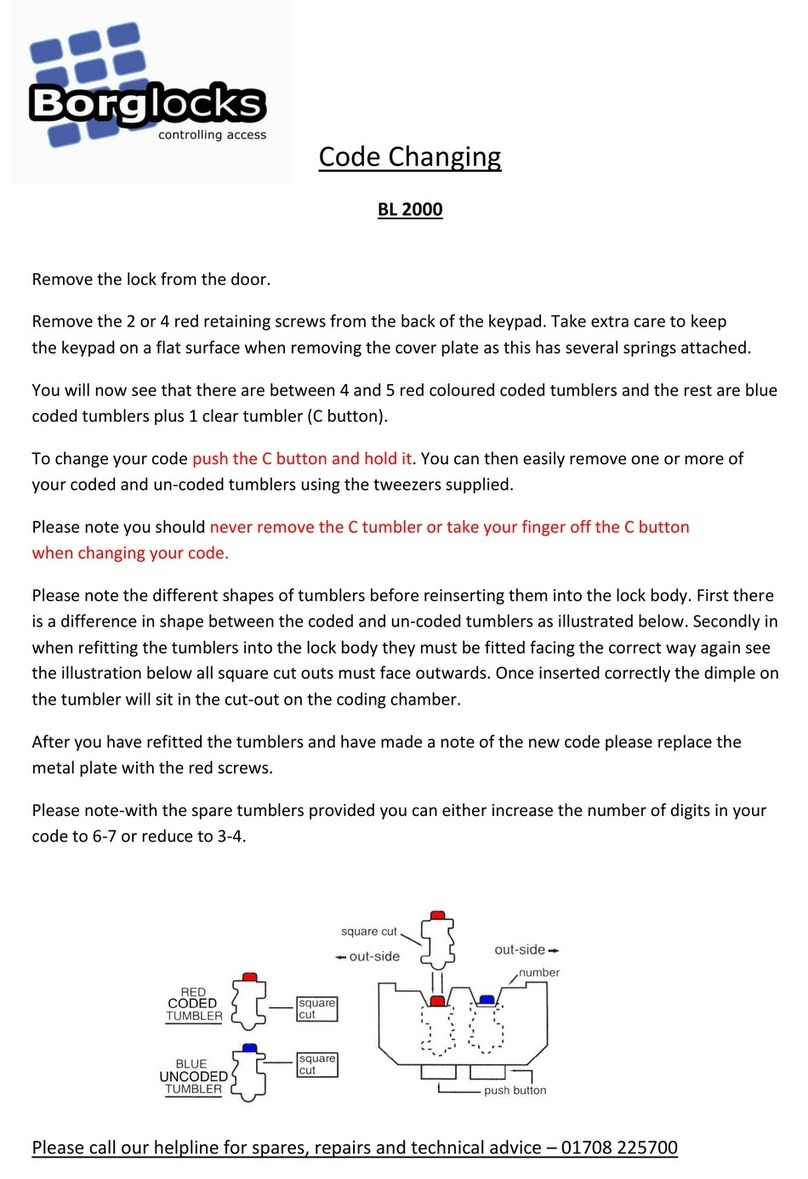

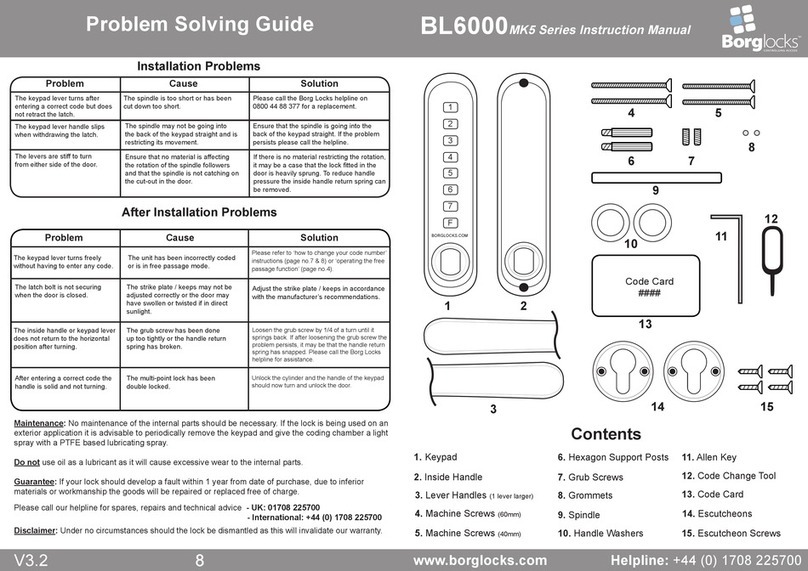

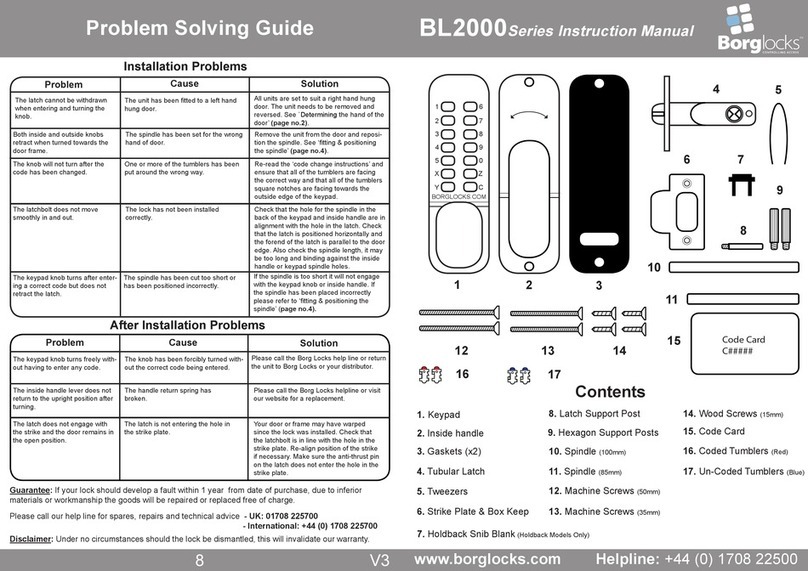

1. Firstly, you will need to check that the original

2. Turn the keypad over and remove the 4 red

screws.

3. You will now be able to lift off the covering panel (

please be careful as there are 12 springs attached

to this panel). Please note that the red tumblers

will relate to the code printed on the card

provided. Also note that the C tumbler is un -

coloured and is NOT to be removed.

4. To change your code you will now need to hold

the keypad face down, Next depress & hold the C

tumbler ( if this is not done you may damage

some of the internal components.) Now using the

tweezers provided, you can reposition the

tumblers to the code you want ( red tumblers are

coded and blue tumblers are uncoded). Please

ensure that the space cut-out on each tumbler is

facing the outside of the lock body, also make

sure that the coloured mark is facing upwards. If

any one tumbler is upside down or the wrong way

round the lock will not work and if forced will

break the internal components. Please note that

the code must always start with a C.

To change the code on this lock you will need to

follow the instructions below very carefully, as any

mistake may damage or cause the lock to

malfunction.

CODE CHANGING PROCEDURE

5001 INSTALLATION INSTRUCTIONS

you require continuous free passage you will need to

proceed as follows:

If the function is not required, it can be easily removed

by unscrewing the 4 red screws on the back of the keypad

to expose the tumblers. Depress the button and keep

it depressed, and using the tweezers provided to lift out the

tumbler. Now replace the metal cover and 4 red screws.

1 .Enter your access code, but before depressing the

lever press the button.

2. You will now be able to rotate the handle freely

without entering the code.

3. To cancel the free entry feature, press the button

followed by the button and this will reset the unit.

F

F

F

F

F

C

C

Square

cut-out Red Coded

Tumbler

Buttons

Square

cut-out

Square

cut-out

Outwards

Square

cut-out

Blue Non-Coded

Tumbler

Outwards