BL6100

Mk4 Series Instruction

Manual

Problem Solving Guide

Maintenance: No maintenance of the internal parts should be necessary. If the lock is being used on an

exterior application it is advisable to periodically remove the keypad and give the coding chamber a light

spray with a PTFE based lubricating spray.

Do not use oil as a lubricant as it will cause excessive wear to the internal parts.

Guarantee: If your lock should develop a fault within 1 year from date of purchase, due to inferior

materials or workmanship the goods will be repaired or replaced free of charge.

Please call our helpline for spares, repairs and technical advice - UK: 0800 44 88 377

- International: +44 (0) 1708 225700

Disclaimer: Under no circumstances should the lock be dismantled as this will invalidate our warranty.

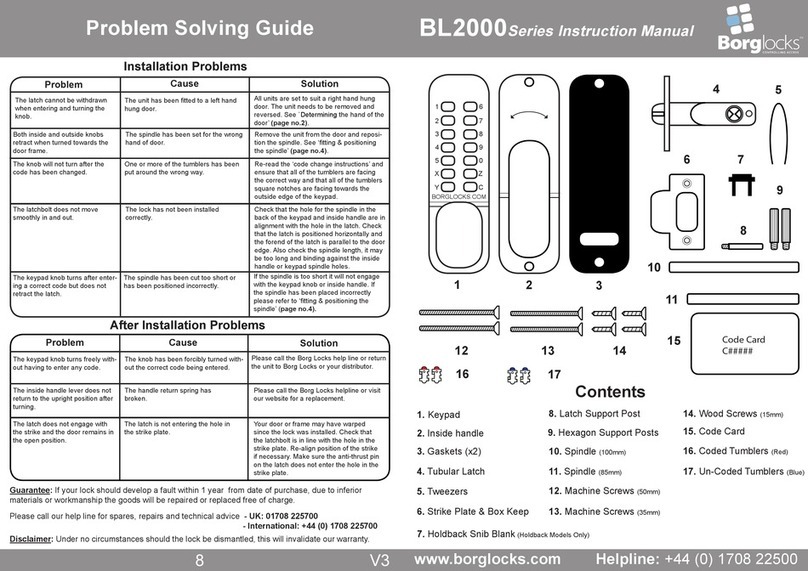

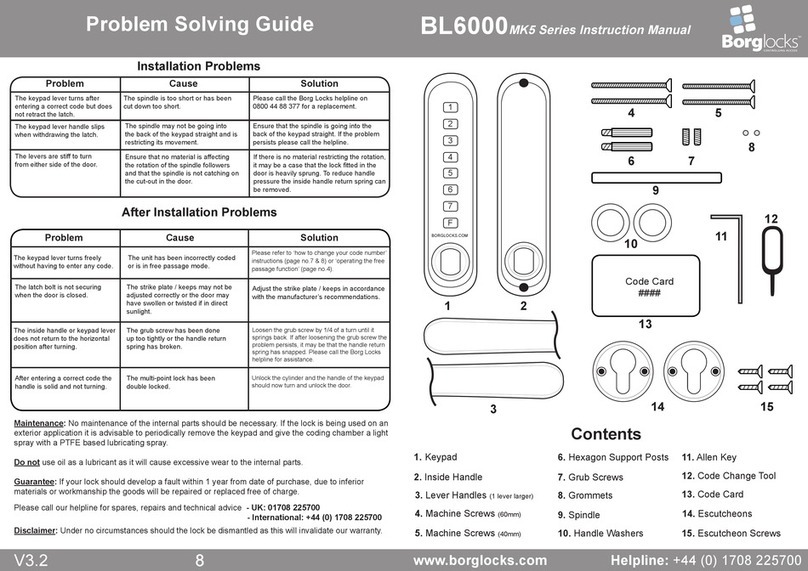

Problem Cause Solution

V1

Installation Problems

8

controlling access

Borglocks

Contents

After Installation Problems

Problem Cause Solution

The keypad lever turns freely

without having to enter any code.

The unit has been incorrectly coded

or is in free passage mode.

Please refer to ‘how to change your code number’

instructions (page no.7 & 8) or ‘operating the free

passage function’ (page no.4).

The inside handle or keypad lever

does not return to the horizontal

position after turning.

The grub screw has been done

up too tightly or the handle return

spring has broken.

Loosen the grub screw by 1/4 of a turn until it

springs back. If after loosening the grub screw the

problem persists, it may be that the handle return

spring has snapped. Please call the Borg Locks

helpline for assistance.

The latch bolt is not securing

when the door is closed.

The strike plate / keeps may not be

adjusted correctly or the door may

have swollen or twisted if in direct

sunlight.

Adjust the strike plate / keeps in accordance

with the manufacturer’s recommendations.

The keypad lever turns after

entering a correct code but does

not retract the latch.

The spindle is too short or has been

cut down too short.

Please call the Borg Locks helpline on

0800 44 88 377 for a replacement.

After entering a correct code the

handle is solid and not turning.

The multi-point lock has been

double locked.

Unlock the cylinder and the handle of the keypad

should now turn and unlock the door.

The keypad lever handle slips

when withdrawing the latch.

The spindle may not be going into

the back of the keypad straight and is

restricting its movement.

Ensure that the spindle is going into the

back of the keypad straight. If the problem

persists please call the helpline.

The levers are stiff to turn

from either side of the door.

Ensure that no material is affecting

the rotation of the spindle followers

and that the spindle is not catching on

the cut-out in the door.

If there is no material restricting the rotation,

it may be a case that the lock tted in the

door is heavily sprung. To reduce handle

pressure the inside handle return spring can

be removed.

1

2

3

4

5

6

7

F

BORGLOCKS.COM

Code Card

####

9 10

13 14

15

16

17 18

19

20

1 2

3

3

87

4 5

6

11

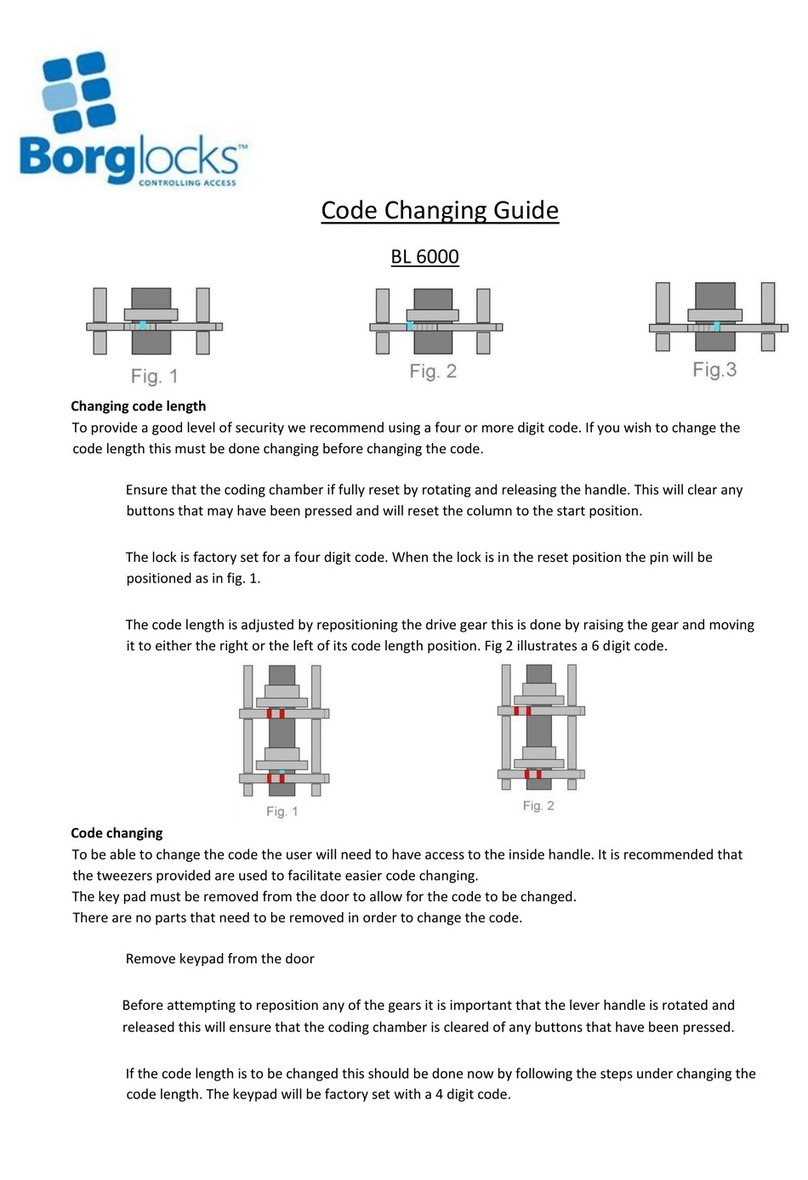

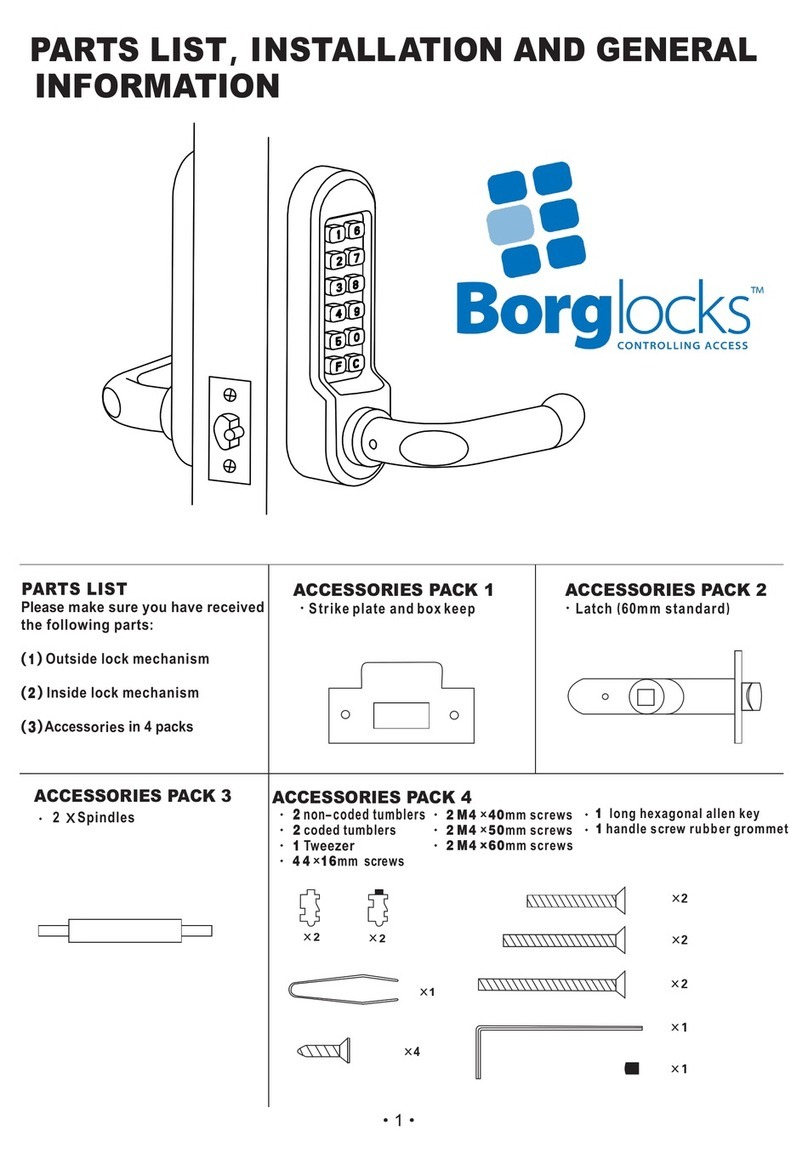

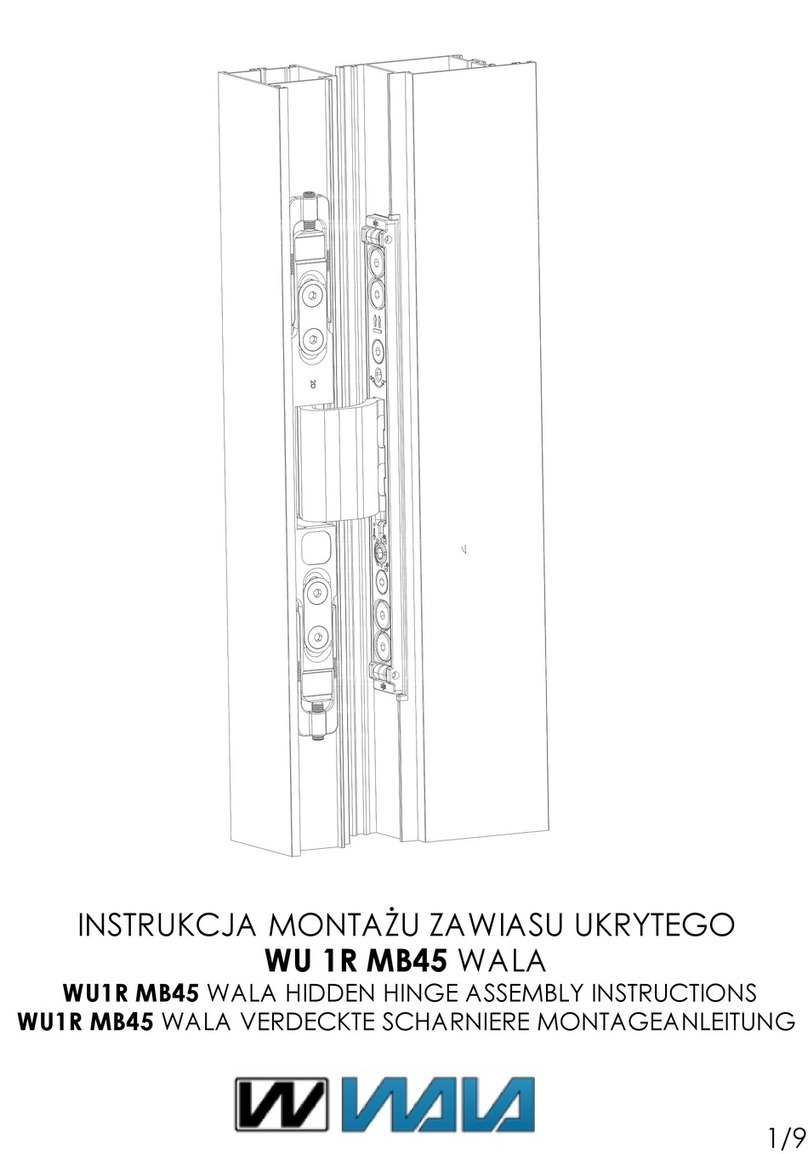

1. Keypad

2. Inside Handle

3. Lever Handles

4. Keypad Extension Plate

5. Inside Handle Extension Plate

6. Escutcheons

7. Keypad Retaining Screws (M5)

8. Inside Handle Retaining Screws (M4)

9. Machine Screws (80mm)

10. Machine screws (60mm)

11. Machine screws (40mm)

12. Machine screws (25mm)

13. Hexagon Support Posts

14. Grub Screws

15. Grommets

16. Spindle

17. Handle Washers

18. Allen Key

19. Code Change Tool

20. Code Card

12