2/54

Bosch Rexroth AG, MIT: LU 2, 3 842 358 814/2017-01

The data specified only serve to describe the product. The information provided in the instructions on how to use the supplied product

should only be considered application examples and suggestions. Catalog information is not binding. The information given does not

release the user from the obligation of own judgment and verification. Our products are subject to a natural process of wear and aging.

© This document, as well as the data, specifications and other information set forth in it, are the exclusive property of Bosch Rexroth

AG. It may not be reproduced or given to third parties without its consent.

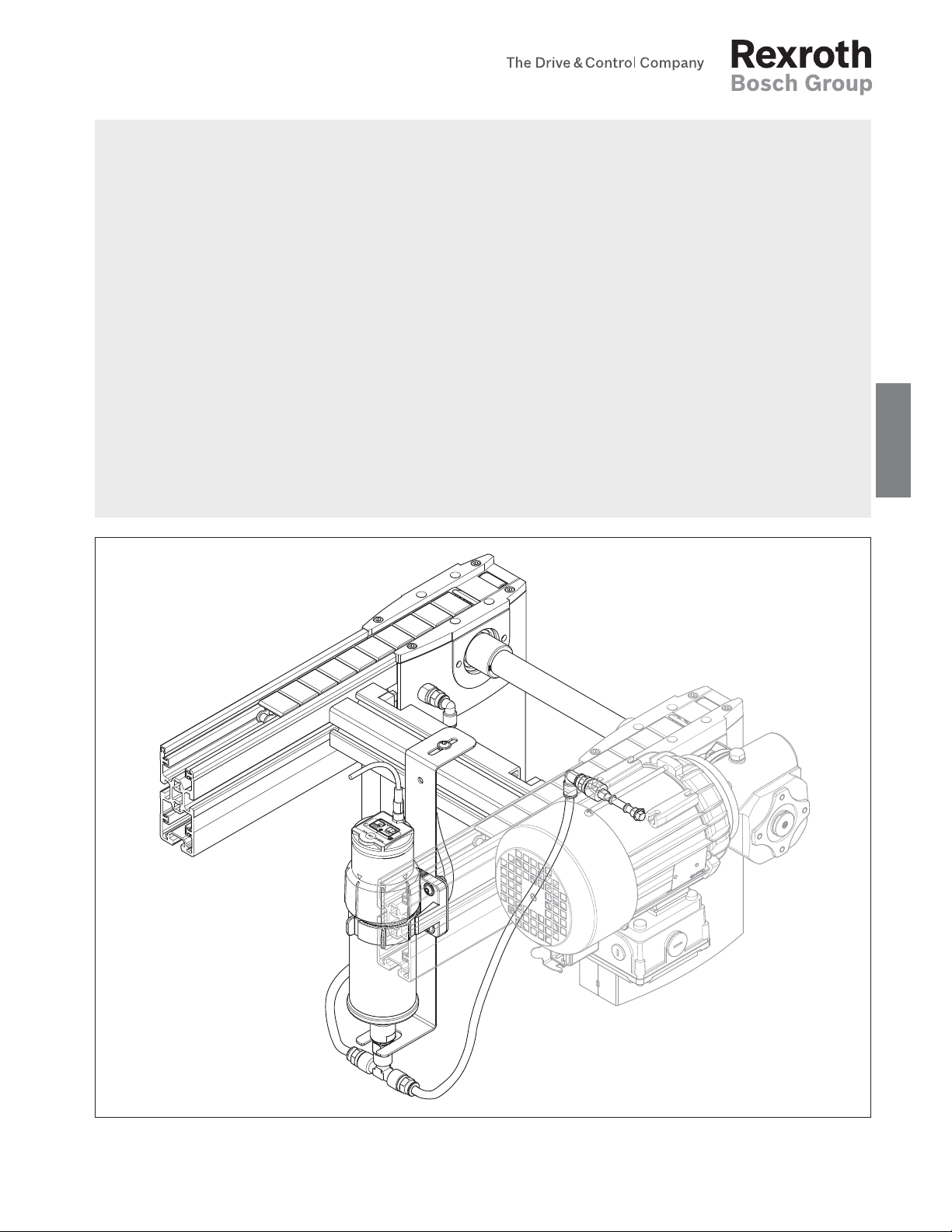

An example configuration is shown on the title page. The delivered product may thus vary from the illustration.

The original assembly instructions were generated in German.

DE Die vorliegende Montageanleitung ist in den hier angebenen Sprachen verfügbar. Weitere Sprachen auf Anfrage.

Als gedruckte Version (print) oder als PDF-Datei (media) zum Download aus dem Medienverzeichnis:

www.boschrexroth.com/medienverzeichnis

Geben Sie in die Suchmaske (oben rechts, unter „Suche“) 3 842 358 814 ein, dann klicken Sie auf „fSuche“.

EN These assembly instructions are available in the languages indicated here. Other languages on request.

They come in a hard copy (print) or a PDF file (media) that can be downloaded at:

www.boschrexroth.com/mediadirectory

Enter 3 842 358 814 in the search mask (at the top right, under “Search”), then click “fSearch”.

FR Les présentes instructions de montage sont disponibles dans les langues spécifiées ici. Autres langues sur demande.

En version imprimée (print) ou en version PDF (media) téléchargeable sur le répertoire multimédia :

www.boschrexroth.com/mediadirectory

Saisissez 3 842 358 814 (en haut à droite, sous « Search »), puis cliquez sur « fSearch ».

IT Le presenti istruzioni di montaggio sono disponibili nelle lingue seguenti. Altre lingue su richiesta.

Scaricabile come versione stampata (print) o come file PDF (media) dal Media Directory:

www.boschrexroth.com/mediadirectory

Digitare il codice 3 842 358 814 nel campo di ricerca “Search” (in alto a destra), quindi fare clic su “fSearch”.

ES Las presentes instrucciones de montaje están disponibles en los idiomas indicados. Hay más idiomas a petición.

Las instrucciones están disponibles como versión impresa (print) o como archivo PDF (media) para descargar del archivo de

medios: www.boschrexroth.com/mediadirectory

En el buscador (en la parte superior derecha, donde pone "Search") introduzca 3 842 358 814, a continuación haga clic en

"fSearch".

PT-

BR

Este manual de montagem está disponível nos idiomas especificados aqui. Outros idiomas mediante pedido.

Como versão impressa (impressão) ou como arquivo PDF (mídia) para download do índice de mídias:

www.boschrexroth.com/mediadirectory

Entre na máscara de pesquisa (canto superior direito, em «Search») 3 842 358 814 e clique em «fSearch».

ZH 本安装说明书有这里给出的语言版本。有印刷版本 (print) 或者电子版 PDF 文件 (media) 供使用,电子版文件可在下列的公司网站媒体网

页上下载: www.boschrexroth.com/mediadirectory

1. 在搜索窗口 (右上角,“Search”窗口) 内输入编号 3 842 546 292。2. 点击“fSearch”。

CS Tento návod k montáži je k dispozici ve zde uvedených jazycích. Jako tištěná verze (print) nebo jako soubor PDF (media) je ke

stažení z adresáře médií: www.boschrexroth.com/mediadirectory

1. Zadejte do vyhledávací obrazovky (nahoře vpravo, pod „Search“) MTCS 358 814. 2. Klikněte na „fSearch“.

PL Dana instrukcja montażu jest dostpna w podanych tutaj językach. W postaci wydrukowanej lub w wersji pdf (media) do

pobrania ze strony: www.boschrexroth.com/mediadirectory

1. Do wyszukiwarki wpisać (w prawym górnym rogu „Search“) MTPL 358 814 . 2. KKliknać „fSearch“

HU A jelen szerelési utasítás az itt megadott nyelveken áll rendelkezésre. További nyelvek rendelésre. A nyomtatott (print) változat

vagy a PDF-fájl (media) letölthető a médiakönyvtárból: www.boschrexroth.com/mediadirectory

Írja be a keresőmezőbe (fent jobbra a „Search“alatt) MTHU 358 814, majd kattintson a „fSearch“gombra.

3 842 358 814 print media LU 2 Automatische Schmiereinheit DE Deutsch

3 842 358 814 print media LU 2 Automatic lubrication unit EN English

3 842 358 814 print media LU 2 Unité de lubrifi cation automatique FR Français

3 842 358 814 print media LU 2 Unità di lubrifi cazione automatica IT Italiano

3 842 358 814 print media LU 2 Unidad de lubricación automática ES Español

3 842 358 814 print media LU 2 Unidade de lubrifi cação automática PT Português

3 842 546 292 print media LU 2 自动润滑单元 ZH 中文

MTCS 358 814 media LU 2 Automatická mazací jednotka CS Česky

MTPL 358 814 media LU 2 Zespół automatycznego smarowania PL Polski

MTHU 358 814 media LU 2 Automatikus kenőegység HU Magyar

358814_2017_01_EN.indd 2 16.01.2017 13:38:18