Page Number 2 of 24

QLS 301

Subject to modifications

2.1B-38006-A99 Form 402865

InstallationandOperationInstructions

Table of Contents

Safety Instructions ......................................................2

Installation Instructions...............................................3

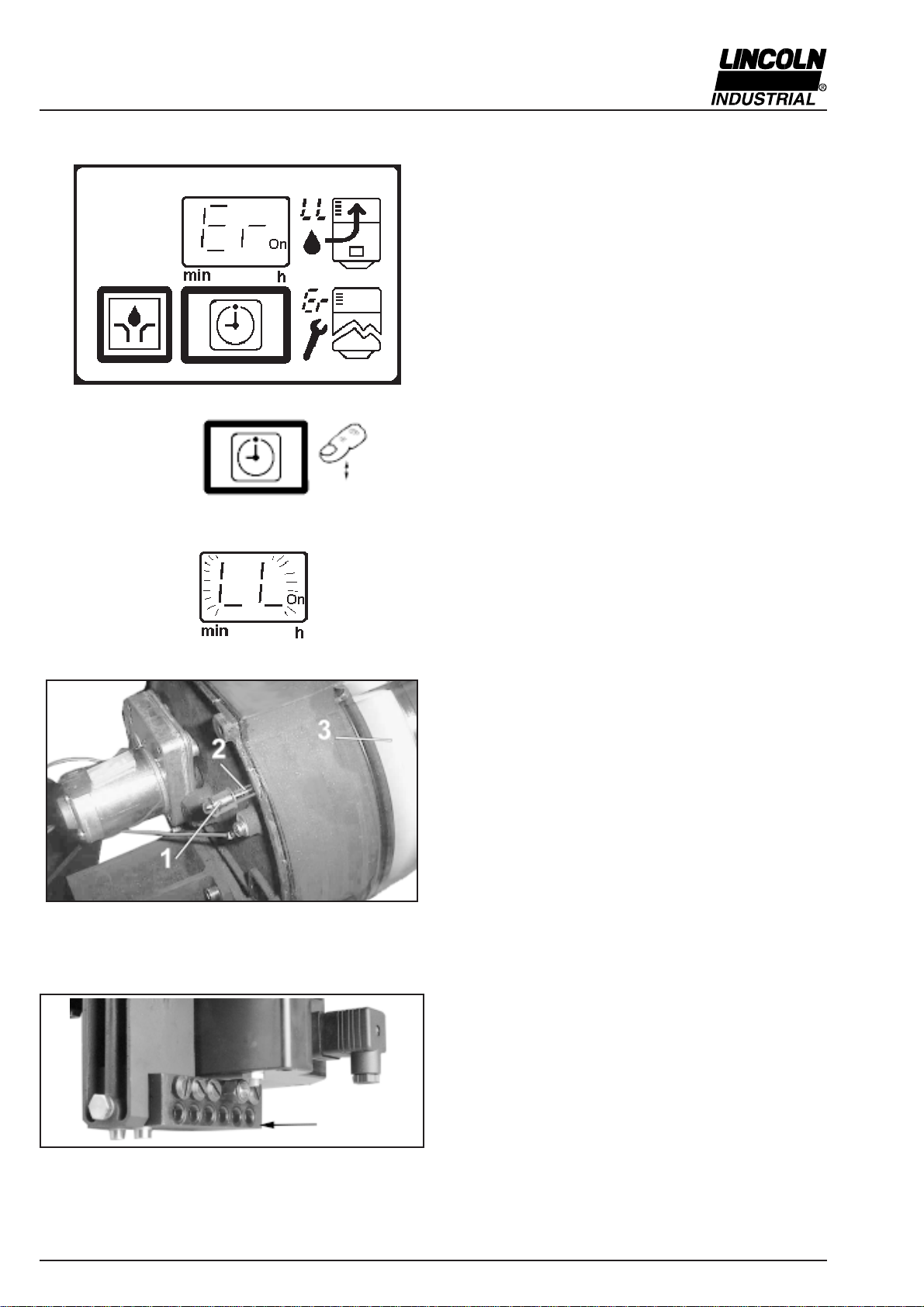

Pump ............................................................................3

SSV Divider Block .........................................................3

Crossporting of the SSV Divider Block.........................3

Check valves .................................................................4

Feedback of supplied lubricant....................................4

Installing Zerk-Locks onto grease fittings ...................4

Connecting Feed Lines ................................................5

Filling of reservoir....................................................5

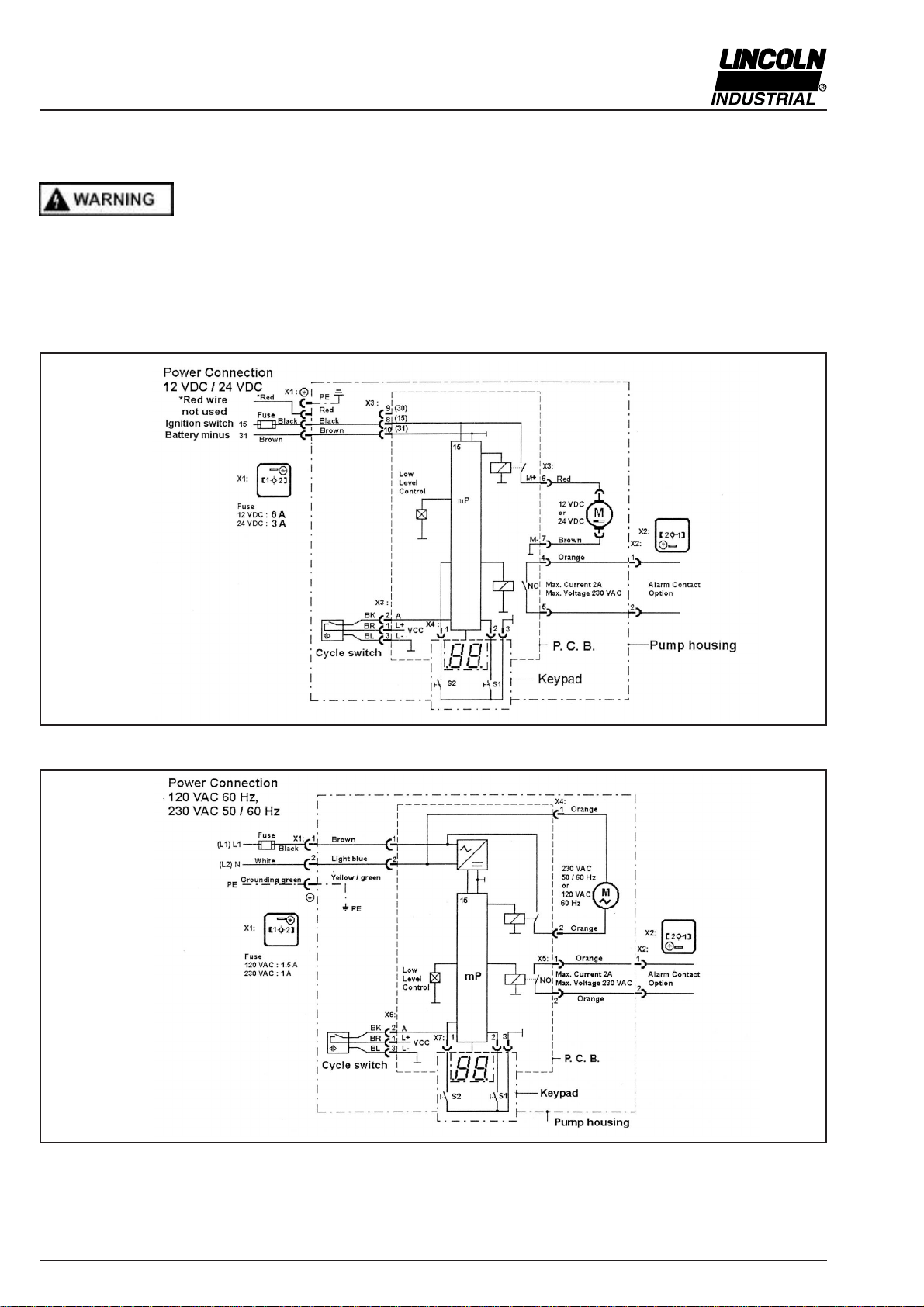

Setting of lubrication cycle time intervall ................5

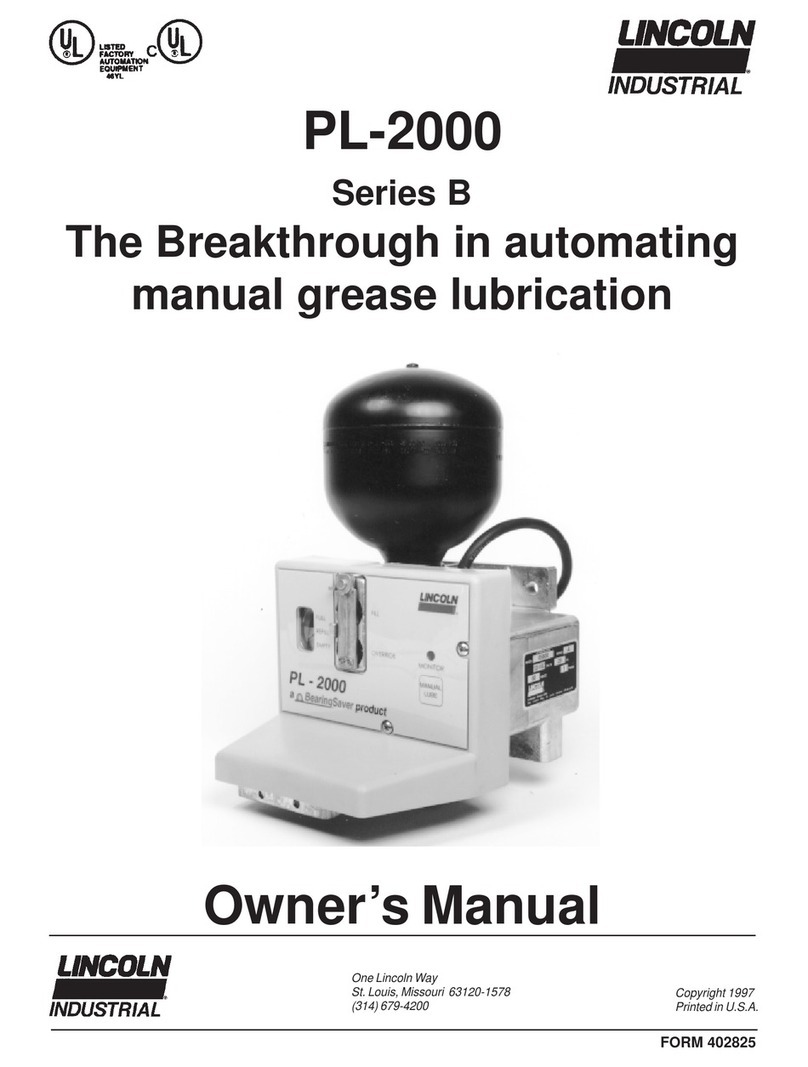

Electrical Connection Diagrams ..................................6

QLS 301Selection Guide ..............................................7

Description of QLS 301 ...............................................8

Operating of QLS 301 ..................................................8

Pressure relief valve .....................................................9

Pump Display Window ................................................. 9

Monitoring time/malfunction .........................................9

Acknowledging the malfunction............................10

Low-level control ...................................................10

Acknowledging the low level indication................10

Malfunction/low level indication ............................10

Monitoring relay ...........................................................10

Metering of the lubricant .............................................10

Setting and operation

of the QLS 301 ............................................................ 11

Display mode .............................................................. 11

Operating mode ..........................................................12

Programming mode ...................................................13

Maintenance, Repair and Test ..................................14

Maintenace..................................................................14

Refilling reservoir ..................................................14

Repair..........................................................................14

Functional Test ............................................................14

Troubleshooting .........................................................15

Technical Data ............................................................17

Dimensions ................................................................18

Service Part of the QLS 301......................................19

Manufacturer’s declaration .........................................24

Safety Instructions

Appropriate Use

• Use QLS 301 only for the delivery of lubricants. The pump

is designed for intermittent operation. QLS 301 is desi-

gned of supplying lubricant to a maximum of 18 lube

points per cycle.

• Do not use QLS 301 with SSV block in bottom mounting

position for mobile applications. Don’t install the pump

in areas exposed to shock.

General safety Instructions

• Do not over pressurize reservoir when filling the pump.

Refill QLS 301 pump with clean lubricant.

• Incorrect use may result in bearing damage caused by

poor or over-lubrication.

• Each outlet used must be equipped with an appropriate

check valve see page 4, Fig.3.

• Unauthorized modifications or changes to an installed

system are not recommended and will void warranty. Any

modifications must be subject to prior consultation with

the manufacturer of the QLS 301.

Regulations for prevention of accidents

• To prevent accidents, observe all city, state and federal

safety regulation of the country in which the product will

be used.

For pumps with 120 VAC and 230 VAC, switch off the power

supply before beginning maintenance or repair work.

• QLS 301 operates automatically. However, a regular

check (approximately every 2 weeks) should be made to

ensure that lubricant is being dispensed from all lubricant

points.

• Used or contaminated lubricants must be disposed of in

accordance with local environmental regulations, see

technical data sheets of lubricants.

• The manufacturer of the centralized lubrication system

will not accept any liability for:

- damage due to the use of greases which are not or are

only conditionally pumpable in centralized lubrication

systems.

- damage caused by insufficient lubricant and irregular

refilling of pump.

- damage caused by the use of contaminated lubricants.

- damage caused by inadequate disposal of used or

contaminated lubricants.

- damage caused by unauthorized modification of system

componenets.

- damage caused by the use of unapproved parts (voids

the pump warrenty).

Operation, Repair and Maintenace

• Repairs should only be performed by authorized

personnel who are familliar with the instructions.

Explanation of symbols:

= explanation

* = describes and action

- = listing within a section

• QLS 301 must only operate with mounted or connected

SSV divider blocks.

• Pump must be regularly refilled with clean lubricant.