8

Test and Time Setting

Test and Time Setting

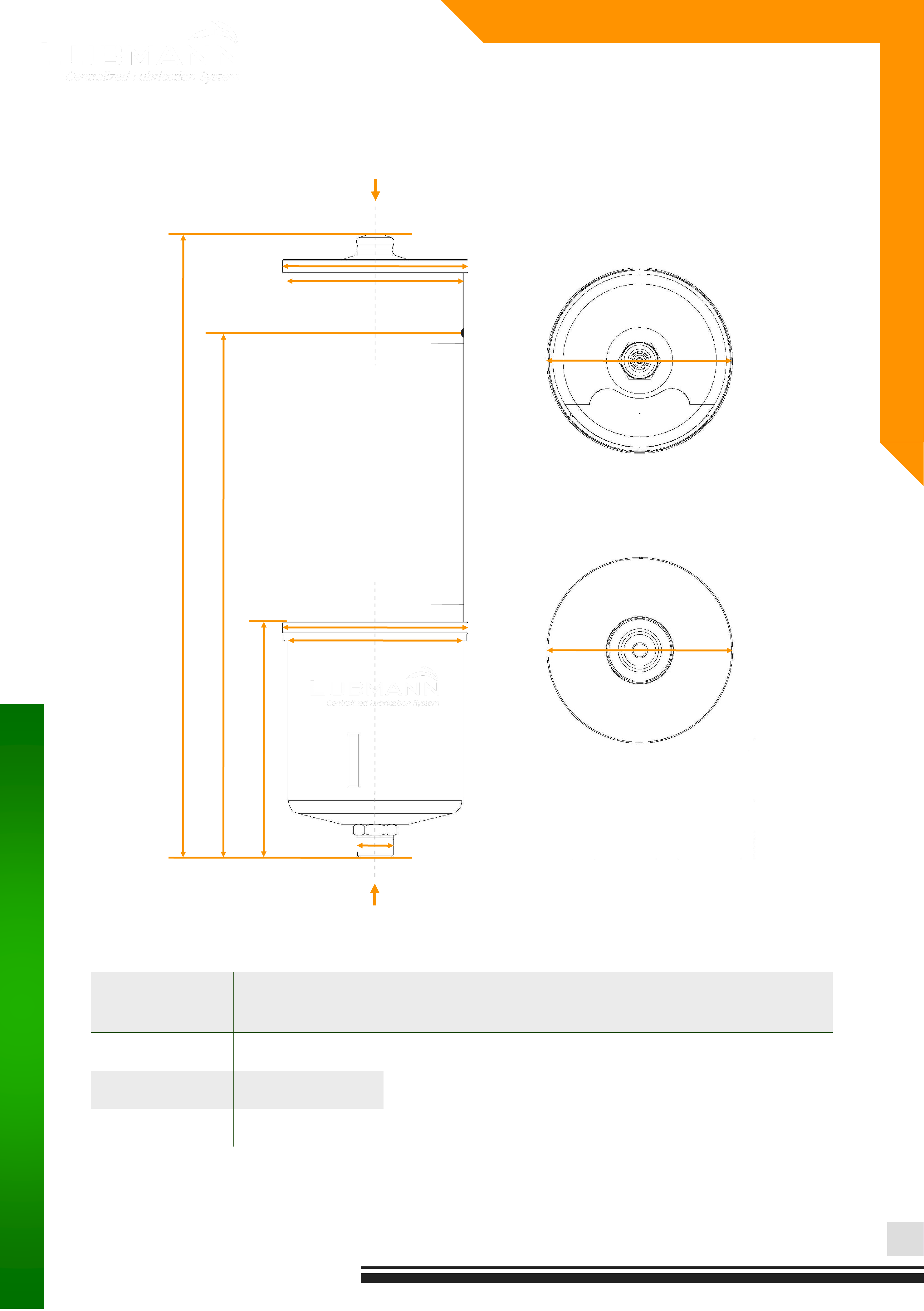

ALP01 Pump

Operation Period Adjustment

To change the preset operation period:

1. Use the magnetic cap vertically close to the Setup EM induction

point to active the setting mode till the preset/default operation

period LED turns on, then move the cap away.

2. Use the magnetic cap close to the induction point again for at

least 3 seconds to adjust the length of the operation period.

3. The light jumps to the next value after removing the cap*.

4. Repeat the step 2 and 3to choose the required length of the

operation period.

5. Move the cap away, let the LED of the required value be lighting

for 5 seconds and flashing once to save the setting.

6. Put the magnetic cap back to the top of the lubricator.

Adjustment of the operation period length finishes.

* The jumping sequence is 1 - 3 - 6 - 12 -24 - 1

The original setting of the operation period length is 6 (6 months)

Test Cycle

Use the magnetic cap close to the Test induction point for at least 3

seconds, then move the cap away. The lubricator starts

immediately a manual greasing cycle (fixed running time as around

20 seconds* and the total greasing volume around 0.6 cm3).

During the running time, use the cap to close the test induction

point again can immediately stop the cycle.

During the test cycle running time, the LED for corresponding

setting of the operation period will continue to flash until the running

cycle ends.

Recommended: After the lubricator is long inactive or the battery

is replaced, start a test greasing cycle to ensure that the lubricator

works in goods position and confirm the current setting of the

operation period.

* The length of the manual running time equals a normal programmed

running time, is around 20 seconds. It can be longed depends on the

working situation and type of lubricant (max. 60 seconds).

Dia. 8.2 Test Greasing

Cycle

Dia. 8.1 Adjustment of

Operation Period Length

About Being Idle

Caution: A function of stopping the lubricator is NOT available in

our standard version. Please take off the battery during a long term

maintenance of the equipment.

Product Manual - ALP01 Single Point Lubricator