PN 97999Ć1028

NM2202AĆXPage 2 of 2

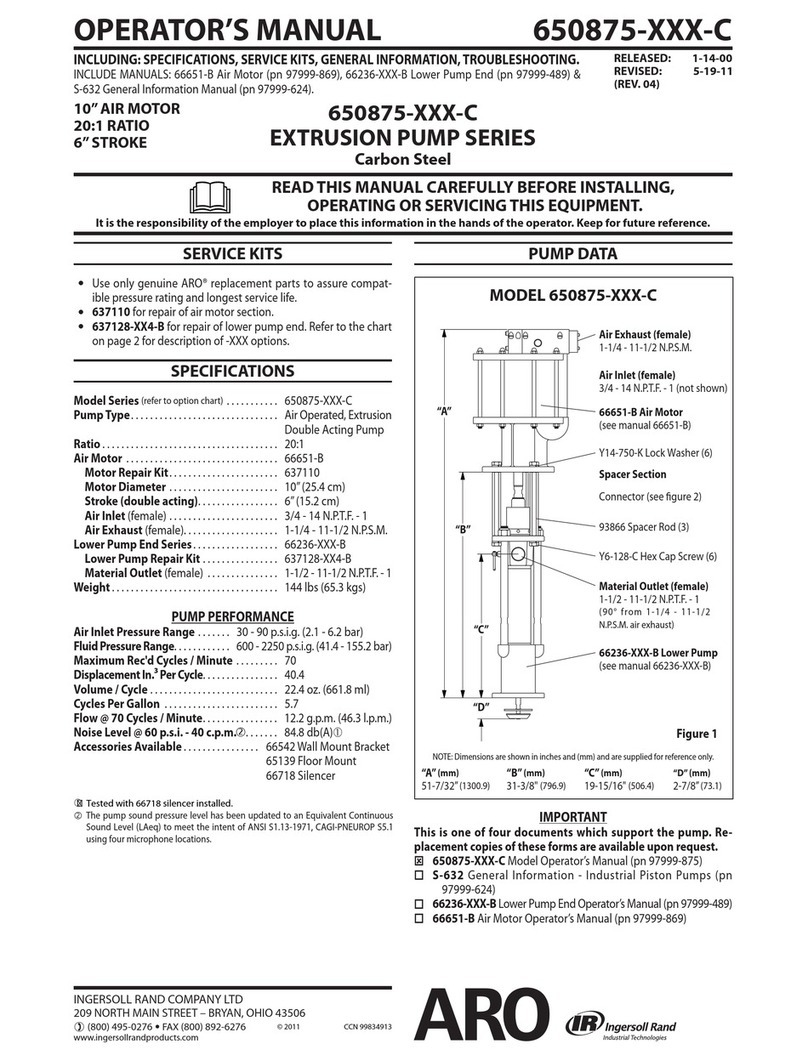

PUMP OPTION DESCRIPTION CHART

NM2202A - X 1 - X 3 1

CONTAINER SUITABILITY

PLUNGER TYPE

SPRING ARRANGEMENT

CONTAINER SUITABILITY PACKING MATERIAL

1 Ć Universal (Stub) 7 Ć Teflon (upper and lower)

4 Ć 55 Gallon B Ć UHM ĆPE (upper) / Teflon (lower)

C Ć UHM ĆPE (upper and lower)

J Ć Polyurethane (upper) / UHM ĆPE (lower)

SPRING ARRANGEMENT PLUNGER TYPE

3 Ć No Spring 1 Ć Standard (Carbon steel)

PACKING MATERIAL

GENERAL DESCRIPTION

Model NM2202AĆX Series twoĆball, double acting pumps are intended

to be used primarily for oil transfer and delivery systems. It is best to use

this pump with low - medium viscosity fluids. It uses carbon steel and

other materials which make it compatible with most petroleum based luĆ

brication products. The twoĆball design provides better priming of the

lower foot valve. Double acting pumps will deliver material on both the up

and down stroke.

NOTE: If this pump was purchased separately (not part of a system),

consult your sales representative for compatible dispensing accessoĆ

ries which will best match the application. All accessories must be able

to withstand the maximum pressure developed by the pump.

WARNING HAZARDOUS PRESSURE. Do not exceed maxiĆ

mum operating pressure of 351 p.s.i. (24.2 bar) at 150 p.s.i. (10.3

bar) inlet air pressure.

PUMP RATIO X MAXIMUM PUMP

INLET PRESSURE TO PUMP MOTOR =FLUID PRESSURE

Pump ratio is an expression of the relationship between the pump motor area and the

lower pump end area. EXAMPLE: hen 150 p.s.i. (10.3 bar) inlet pressure is supplied

to the motor of a 4:1 ratio pump it will develop a maximum of 600 p.s.i. (41.4 bar) fluid

pressure (at no flow) Ć as the fluid control is opened, the flow rate will increase as the

motor cycle rate increases to keep up with the demand.

WARNING Refer to general information sheet for additional

safet precautions and important information.

NOTICE: Thermal expansion can occur when the fluid in the materiĆ

al lines is exposed to elevated temperatures. Example: Material

lines located in a nonĆinsulated roof area can warm due to sunlight.

Install a pressure relief valve in the pumping system.

Replacement warning label (pn 94520) is available upon request.

TROUBLE SHOOTING

Pump problems can occur in either the Air Motor Section or the Lower

Pump End Section. Use these basic guidelines to help determine which

section is affected. Be sure to eliminate any possible nonĆpump probĆ

lems before suspecting pump malfunction.

Pump will not c cle.

•No pressure to the motor. See motor manual.

•Damaged motor. Service motor

No material at the outlet (pump continuall c cles).

•Check the material supply, disconnect or shut off the air supply and

replenish the material, reconnect.

Material on one stroke onl (fast downstroke).

•The lower check may not be seating in the foot valve (see lower

pump disassembly). Remove the check from the foot valve, clean

and inspect the valve seat area. If check or foot valve are damaged,

replace.

Material on one stroke onl (fast upstroke).

•The middle packings may be worn (see lower pump disassembly).

Replace the seals as necessary.

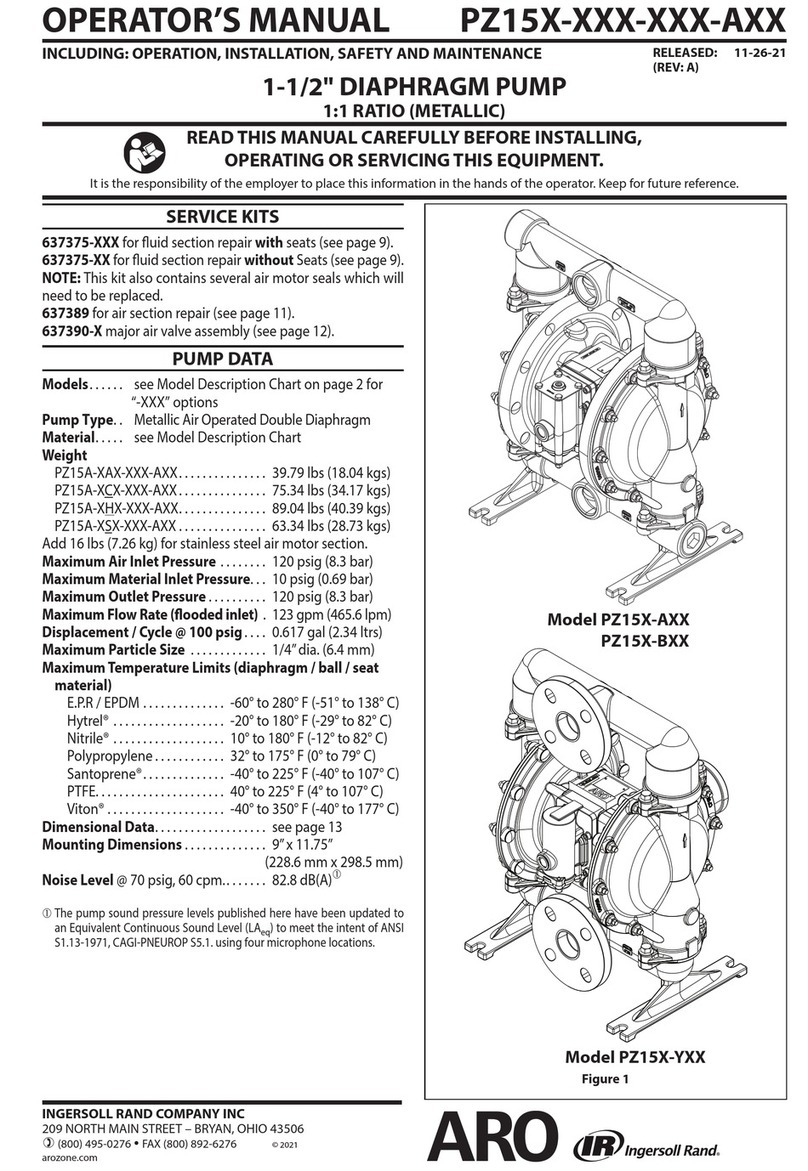

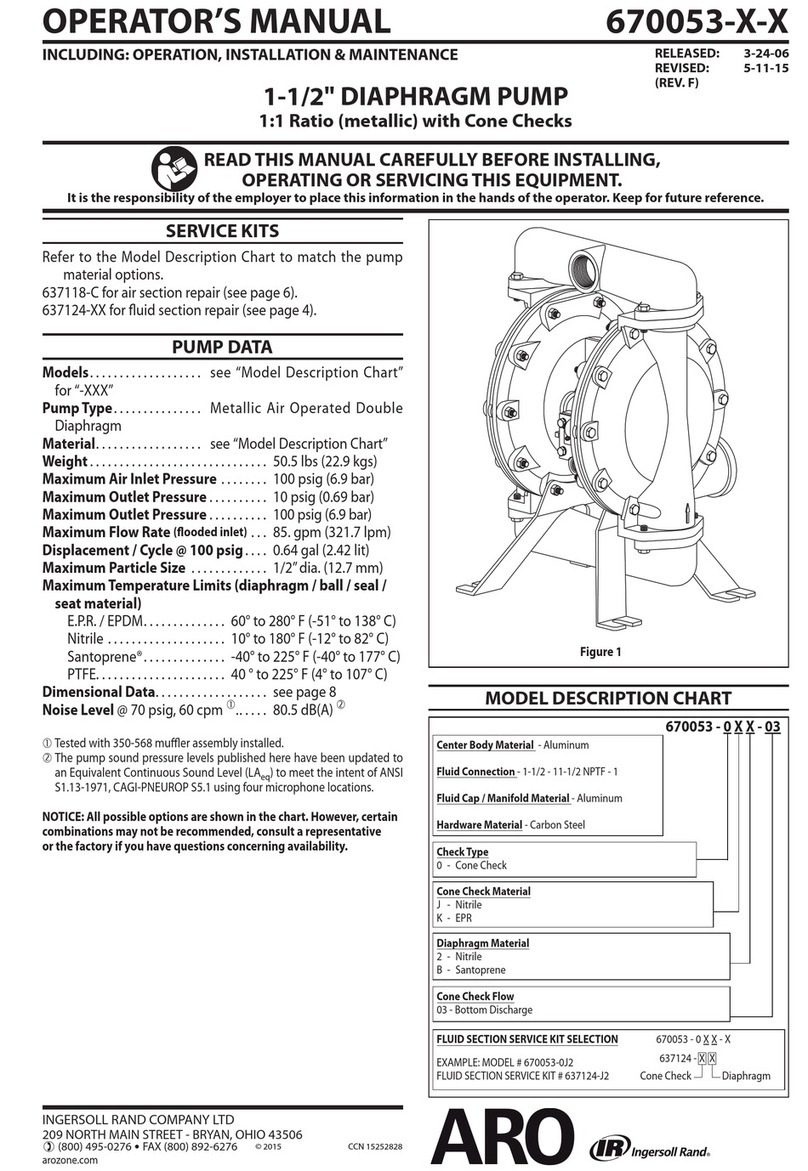

PUMP CONNECTION - UPPER / LOWER

NOTE: All threads are right hand.

1. Lay the pump assembly on a workbench.

2. Remove four (Y99Ć47ĆC) cap screws and pull the air motor from the

lower pump end until the motor piston rod is in the down" position

and the lower pump end rod is in the up" position.

3. Remove the (Y15Ć31ĆC) cotter pin and (96064) pin, releasing the air

motor from the lower pump end.

Lower Pump Rod

Pump Motor Piston Rod

Cotter Pin Y15Ć31ĆC

PUMP CONNECTOR DETAIL

Figure 2

Pin 96064

REASSEMBLY

1. Assemble motor piston rod to the lower pump end rod, aligning thru

holes.

2. Assemble (96064) pin through hole, securing rods.

3. Assemble (Y15Ć31ĆC) cotter pin through hole in pin.

4. Align tie rods with holes in (96068) plate and pump outlet body.

5. Assemble four (Y99Ć47ĆC) cap screws, securing air motor. NOTE:

Tighten cap screws to 50 in. lbs (5.65 Nm).