2.4 Marine installation, recommendations

No oil cooler manufacturer can guarantee that their products will have an

indenite life and for this reason, we suggest that the cooling system is

designed to minimise any damage caused by a leaking oil cooler. This can be

achieved as follows:

1. The oil pressure should be higher than the sea water pressure, so that in

the event of a leak occurring, the oil will not be contaminated.

2. When the hydraulic system is not being used, the coolers should be

isolated from sea water pressure.

3. The sea water outlet pipe from the cooler should have a free run to waste.

4. Stainless steel sea water pipes and ttings should not be used adjacent to

the oil cooler.

2

6

5. Important note for marine applications: during commisioning, shutdown

and standby periods, if the oil cooler has not been used over 4-6 day

period, it should be drained, cleaned and kept dry. Where this procedure is

not possible, drain the stagnant water and rell the oil cooler with clean

sea or fresh water, which should be replaced with oxygenated sea water

every 2-3 days to avoid further decomposition.

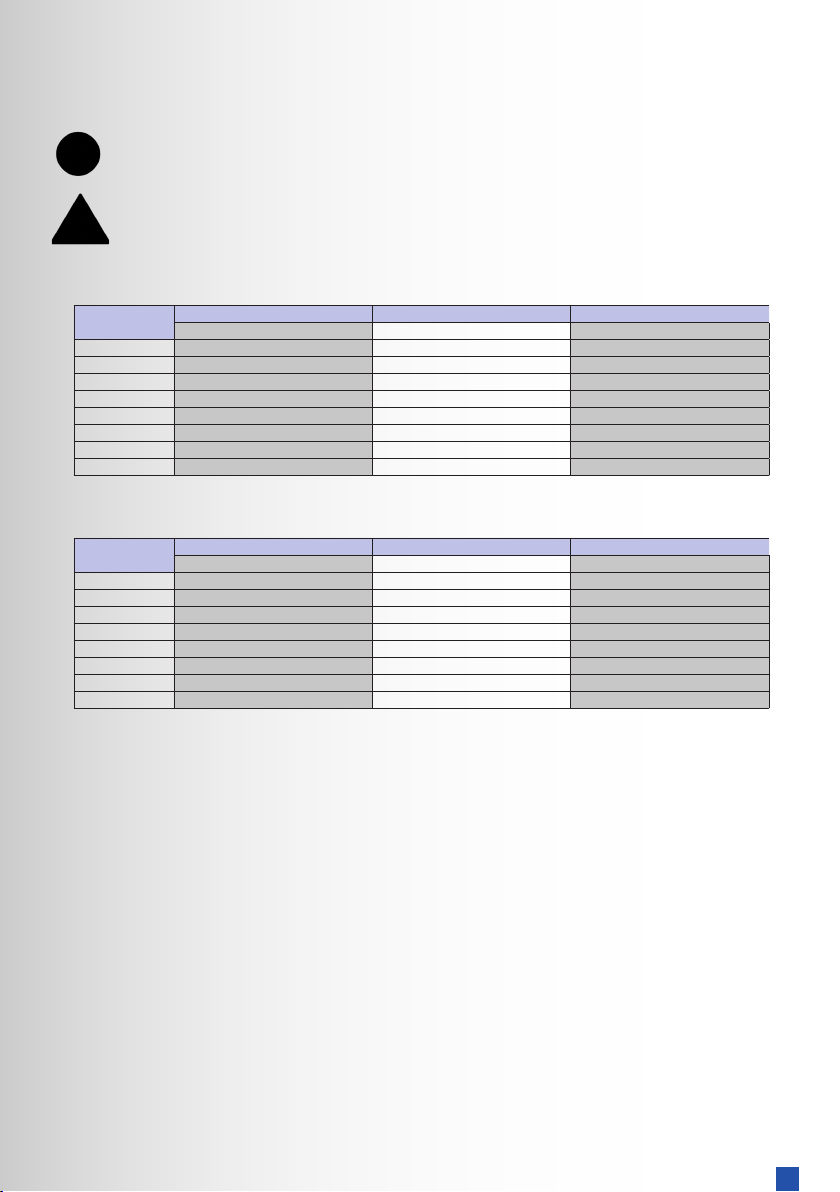

2.5 Orifice Plates

If the sea water supply is taken from a ship’s main, it is important to ensure that

the recommended ow cannot be exceeded.

This will normally mean that an orice plate must be tted in the pipework at

least 1m before the oil cooler, with the orice size calculated to ensure that the

maximum sea water ow rate cannot be exceeded.

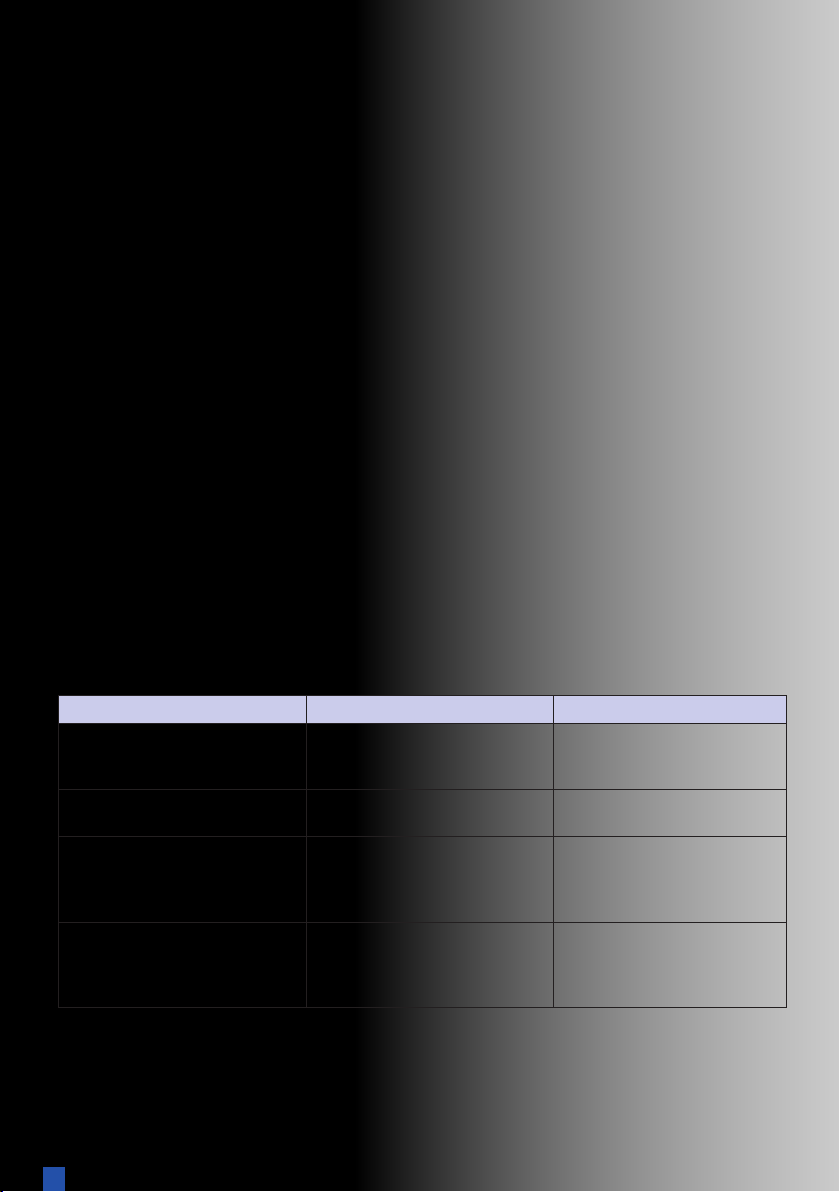

The correct orice diameter can be determined from the table below.

Oil Cooler

Series

Max. Sea water

ow I/min

1 bar 2 bar 3 bar 4 bar 5 bar 6 bar 7 bar 8 bar 9 bar 10 bar

EC 50 11 9.5 8.5 8 7.5 7.2 6.8 6.7 6.5 6.3

FC 80 14 12 11 10 9.5 9 8.7 8.4 8.2 8

FG 110 17 14 13 12 11 10 10 9.8 9.6 9.3

GL 200 23 19 17 16 15 14 14 13 13 13

GK 300 28 23 21 19 18 17 17 16 16 15

JK 400 32 27 24 22 21 20 20 19 18 18

PK 500 41 34 31 28 27 26 25 24 23 23

RK 900 48 40 36 34 32 30 29 28 27 26

2.6 Composite end cover water pipe installation

For marine versions supplied with composite end covers, it is recommended

that a bonded seal is used in conjunction with the tting and tightened to the

appropriate torque gure given below to ensure sucient sealing.

The following tables gives maximum ow rates for either single two or three pass

conguration, using either sea water or fresh water cooling.

Orice diameter in mm for max. sea water ow

Three Pass Bowman

Oil Coolers

Size Torque (Nm)

EC range (3/4” BSP) 10

FC range (1” BSP) 15

FG range (1 ¼” BSP) 20

GL range (1 ½” BSP) 25