Ingersoll-Rand HDL2 Manual

Other Ingersoll-Rand Industrial Equipment manuals

Ingersoll-Rand

Ingersoll-Rand PAL250K User manual

Ingersoll-Rand

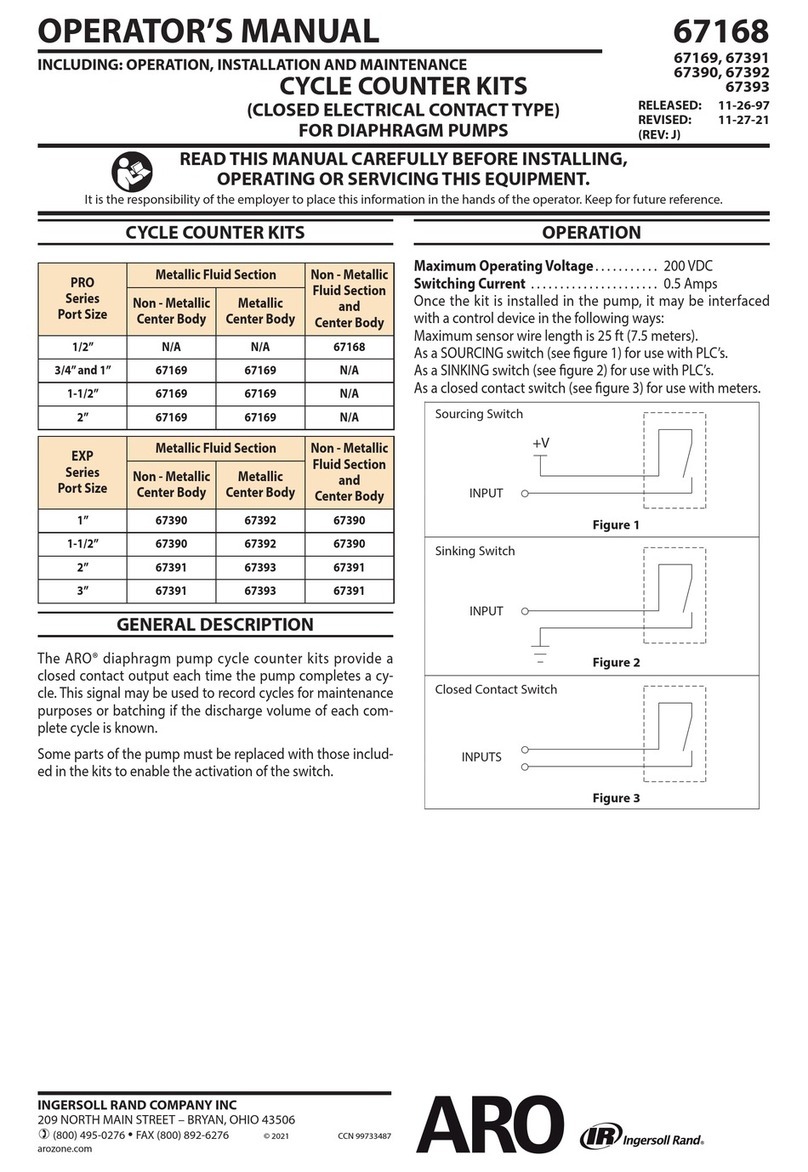

Ingersoll-Rand ARO PRO Series User manual

Ingersoll-Rand

Ingersoll-Rand ZA Series User manual

Ingersoll-Rand

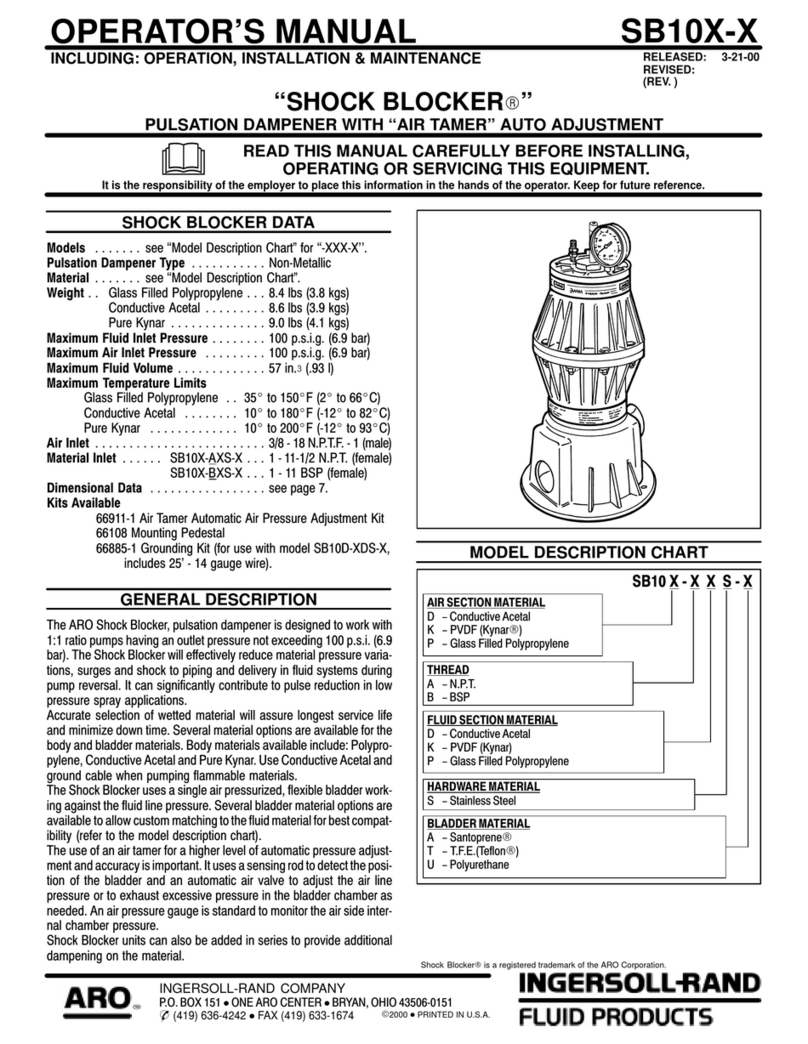

Ingersoll-Rand SHOCK BLOCKER User manual

Ingersoll-Rand

Ingersoll-Rand EP 20-ESP User manual

Ingersoll-Rand

Ingersoll-Rand EMS-3000 Series User manual

Ingersoll-Rand

Ingersoll-Rand ARO PM0450L2 Series User manual

Ingersoll-Rand

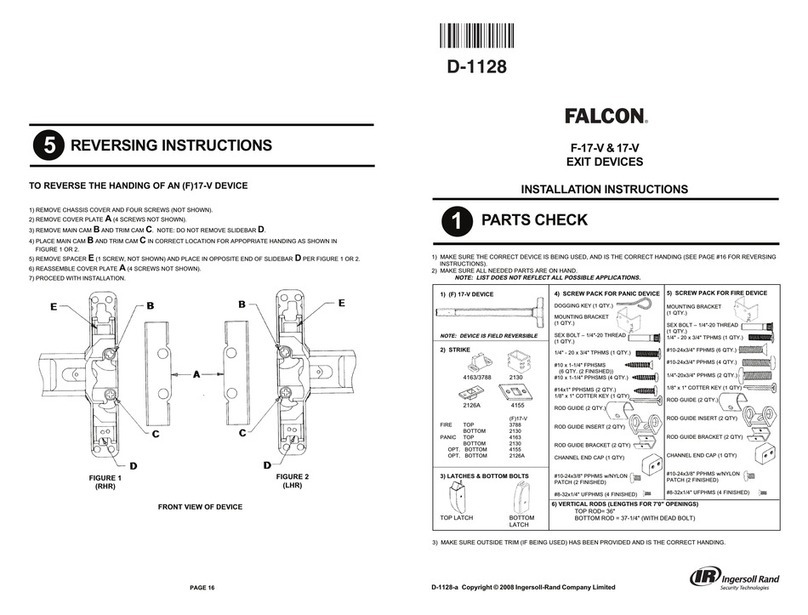

Ingersoll-Rand FALCON F-17-V User manual

Ingersoll-Rand

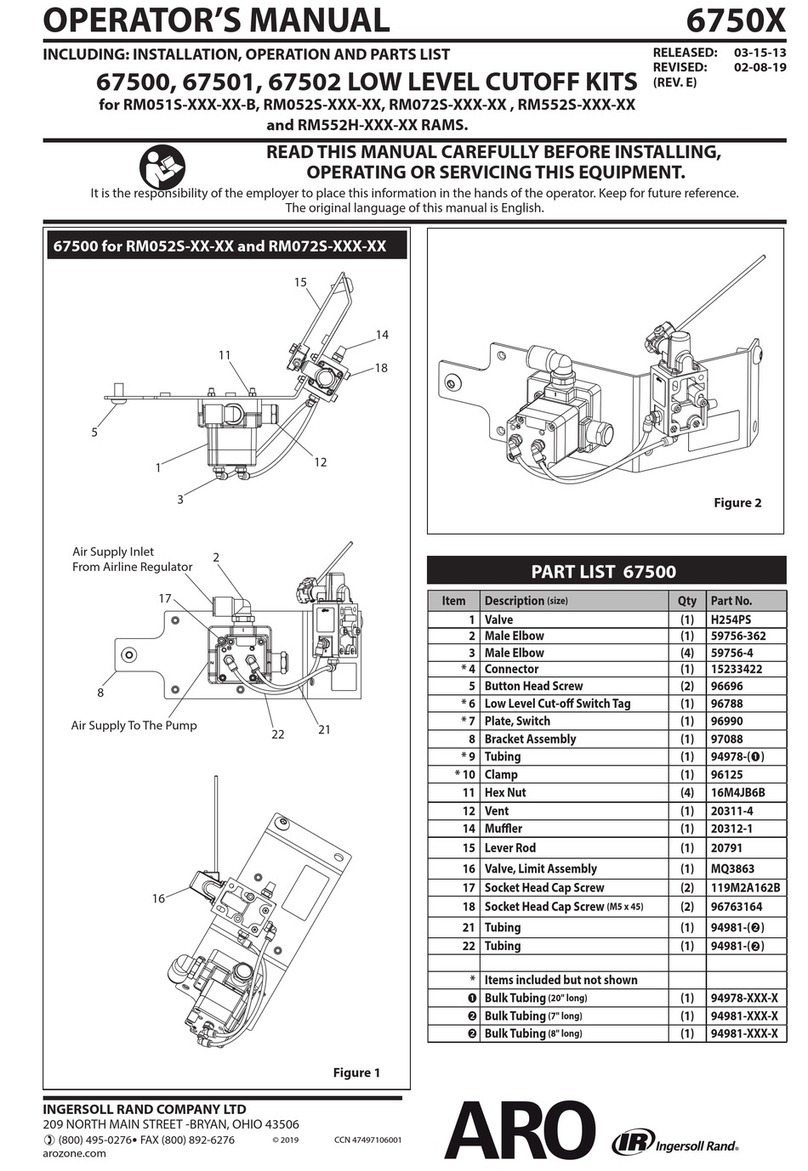

Ingersoll-Rand ARO 67500 User manual

Ingersoll-Rand

Ingersoll-Rand PB35A User manual

Ingersoll-Rand

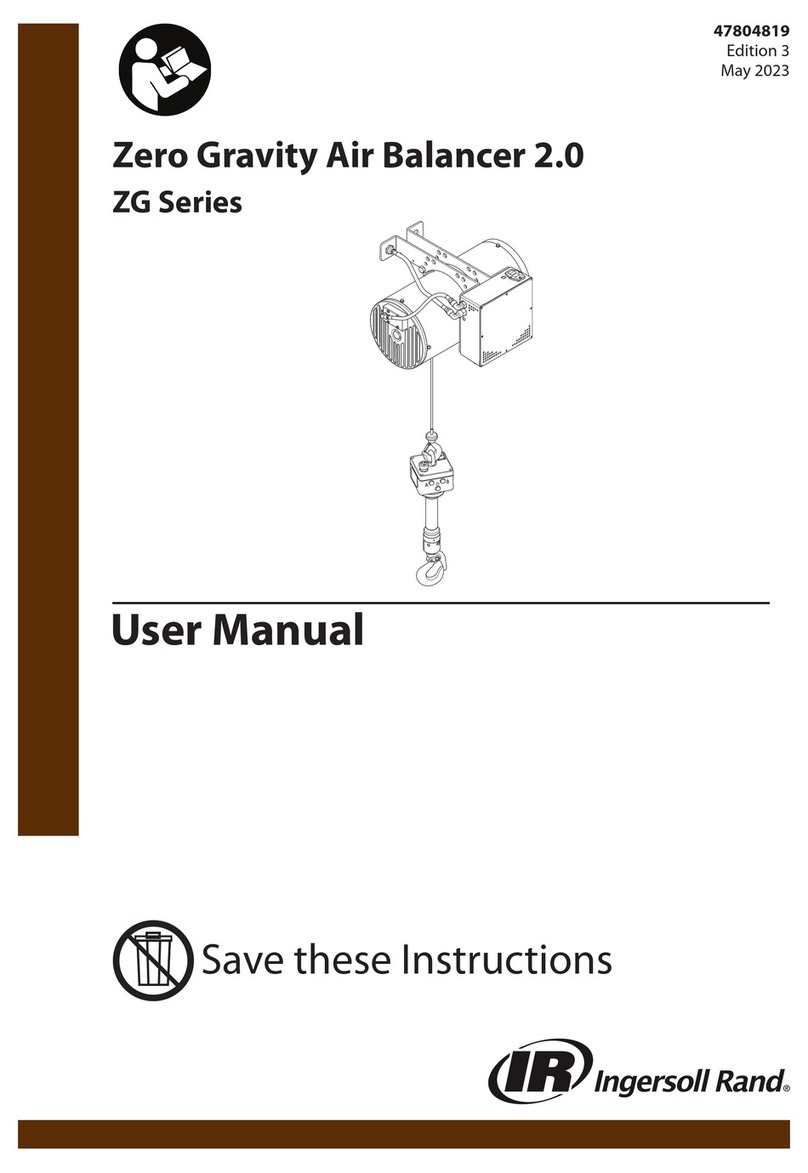

Ingersoll-Rand Zero ZG Series User manual

Ingersoll-Rand

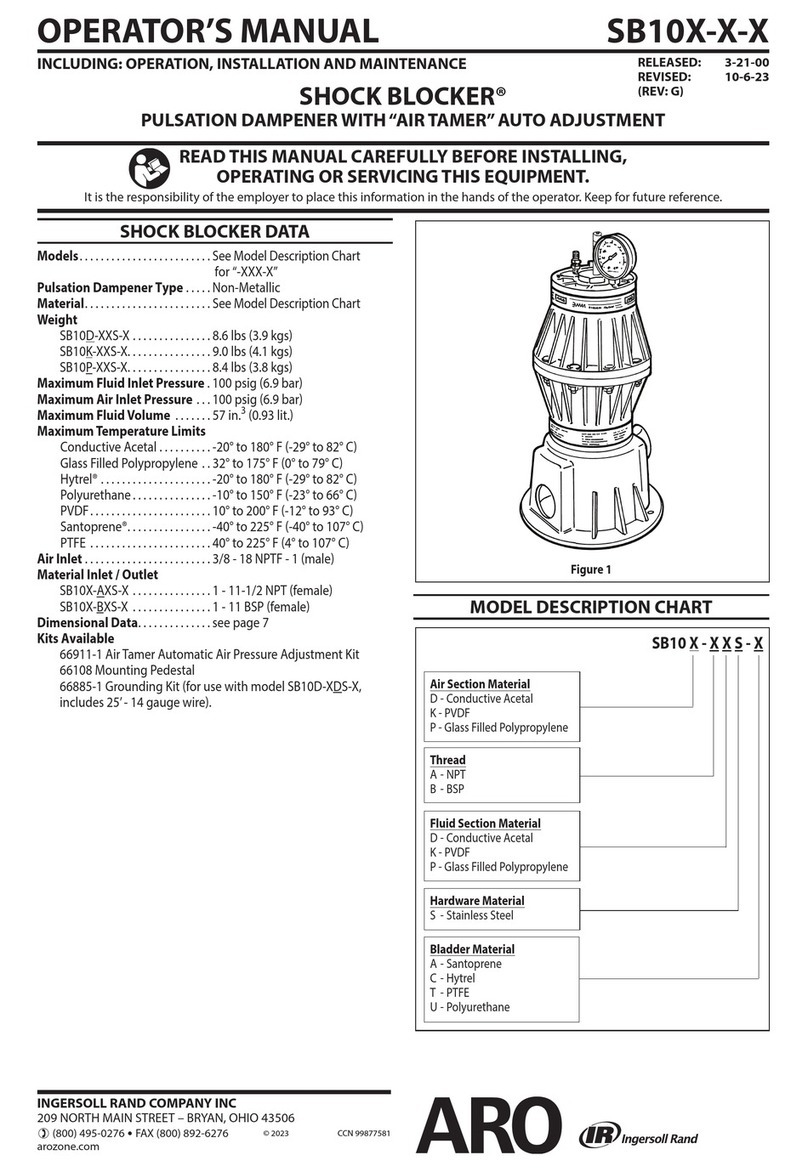

Ingersoll-Rand ARO SHOCK BLOCKER SB10 Series User manual

Ingersoll-Rand

Ingersoll-Rand Doosan XHP1070CM-1800 User manual

Ingersoll-Rand

Ingersoll-Rand Genuine 10208 User manual

Ingersoll-Rand

Ingersoll-Rand SSR UP5 11 User manual

Ingersoll-Rand

Ingersoll-Rand IR60VR Series User manual

Ingersoll-Rand

Ingersoll-Rand ARO SB20 Series User manual

Ingersoll-Rand

Ingersoll-Rand C-Series User manual

Ingersoll-Rand

Ingersoll-Rand LC2A015SIP3LVU-E Series User manual