2

Table of Contents

INSTALLATION, OPERATING AND SERVICING INSTRUCTION MANUAL....................1

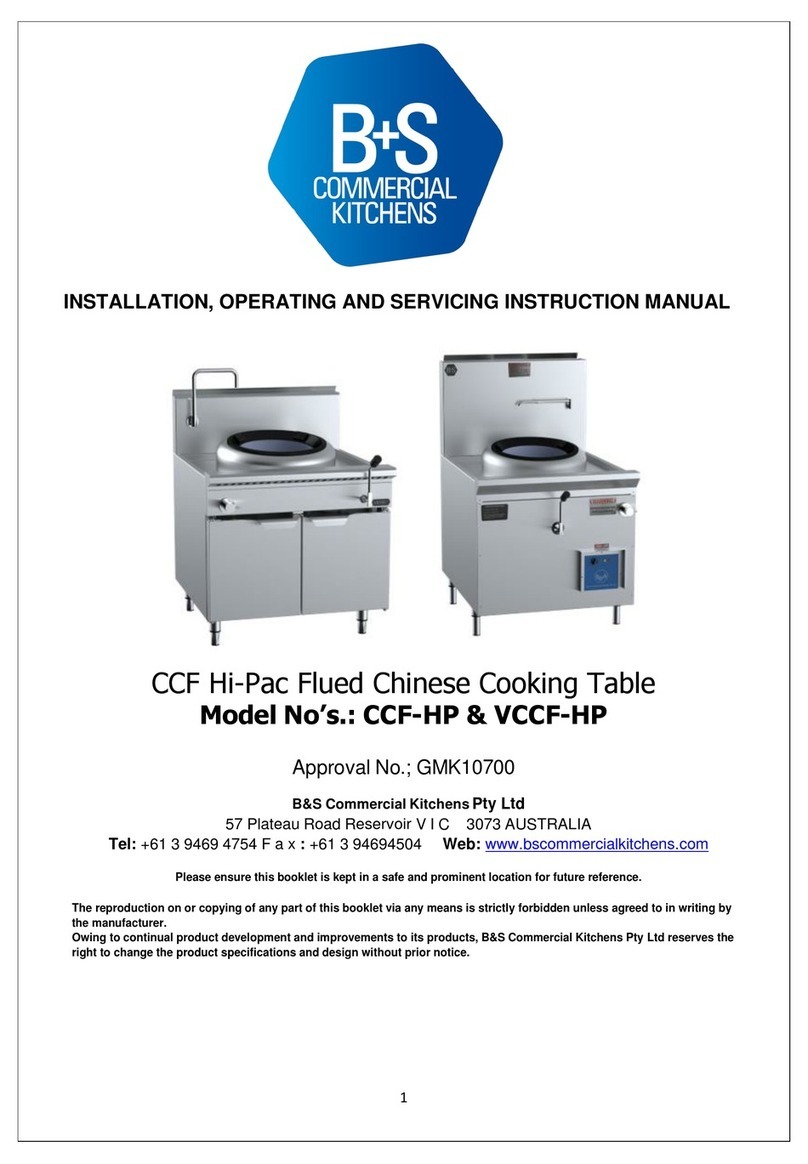

NC Series Commercial Noodle Cooker/Steamer.........................................................1

Product Specifications & Introduction ............................................................................3

Table 1: Nominal Terminal Input Rates & Injector Sizes ...................................................................................3

Table 2: Standard Model General Information...................................................................................................4

Figure 1: Plumbing Connections -Black & Verro NC-6......................................................................................4

Table 3: Plumbing Connections.........................................................................................................................4

Figure 2: Plumbing Connections -Black & Verro NC-9......................................................................................5

Table 4: Plumbing Connections.........................................................................................................................5

IMPORTANT WARNINGS..................................................................................................5

Installation Instructions ....................................................................................................6

Regulations ........................................................................................................................................................6

Data Label..........................................................................................................................................................6

Ventilation...........................................................................................................................................................6

Combustible Surfaces........................................................................................................................................7

Plinth Mount Models...........................................................................................................................................8

Gas Connection .................................................................................................................................................8

Pressure Test Point............................................................................................................................................8

Water Connection ..............................................................................................................................................8

Burner Adjustment .............................................................................................................................................8

Before Leaving - Commissioning.......................................................................................................................8

Operating Instructions ......................................................................................................9

IMPORTANT WARNING!....................................................................................................9

Lighting Instructions..............................................................................................................................10

Shutdown Procedure.............................................................................................................................10

Boil Out Procedure................................................................................................................................10

Laundry Arm Activation.........................................................................................................................10

IMPORTANT NOTE!........................................................................................................................................10

Maintenance and Care..........................................................................................................................10

Servicing Instructions.....................................................................................................11

Abnormal Operation..............................................................................................................................11

Panel Removing....................................................................................................................................11

Controls.................................................................................................................................................11

Thermostat............................................................................................................................................12

Pilot Assembly.......................................................................................................................................12

Piezo Assembly.....................................................................................................................................12

Burners..................................................................................................................................................12

Gas Valve..............................................................................................................................................12

Table 4: Troubleshooting .................................................................................................................................12

STANDARD WARRANTY CONDITIONS .........................................................................13