7

MUST BE CARRIED OUT TO ENSURE THERE ARE NO GAS LEAKING HAZARDS.

NEVER STORE ANY FLAMEABLE LIQUIDS/VAPOURS IN VACINITY OF THIS APPLIANCE. NEVER

SPRAY AEROSOLS IN THE VICINITY OF THIS APPLIANCE WHILE IT IS IN OPERATION.

ENSURE ANY TRANSIENT PROTECTION IS REMOVED BEFORE INSTALLING THE APPLIANCE

ENSURING ANY POSSIBLE DAMAGE TO THE APPLIANCE OR COMPONENTS/ PARTS THAT MAY HAVE

BEEN SUSTAINED DURING TRANSPORTATION IS REPORTED TO THE MANUFACTURER.

THIS APPLIANCE IS NOT INTENDED TO BE USED IN A MARINE ENVIRONMENT. ENSURE APPLIANCE

IS INSTALLED IN A STABLE POSITION.

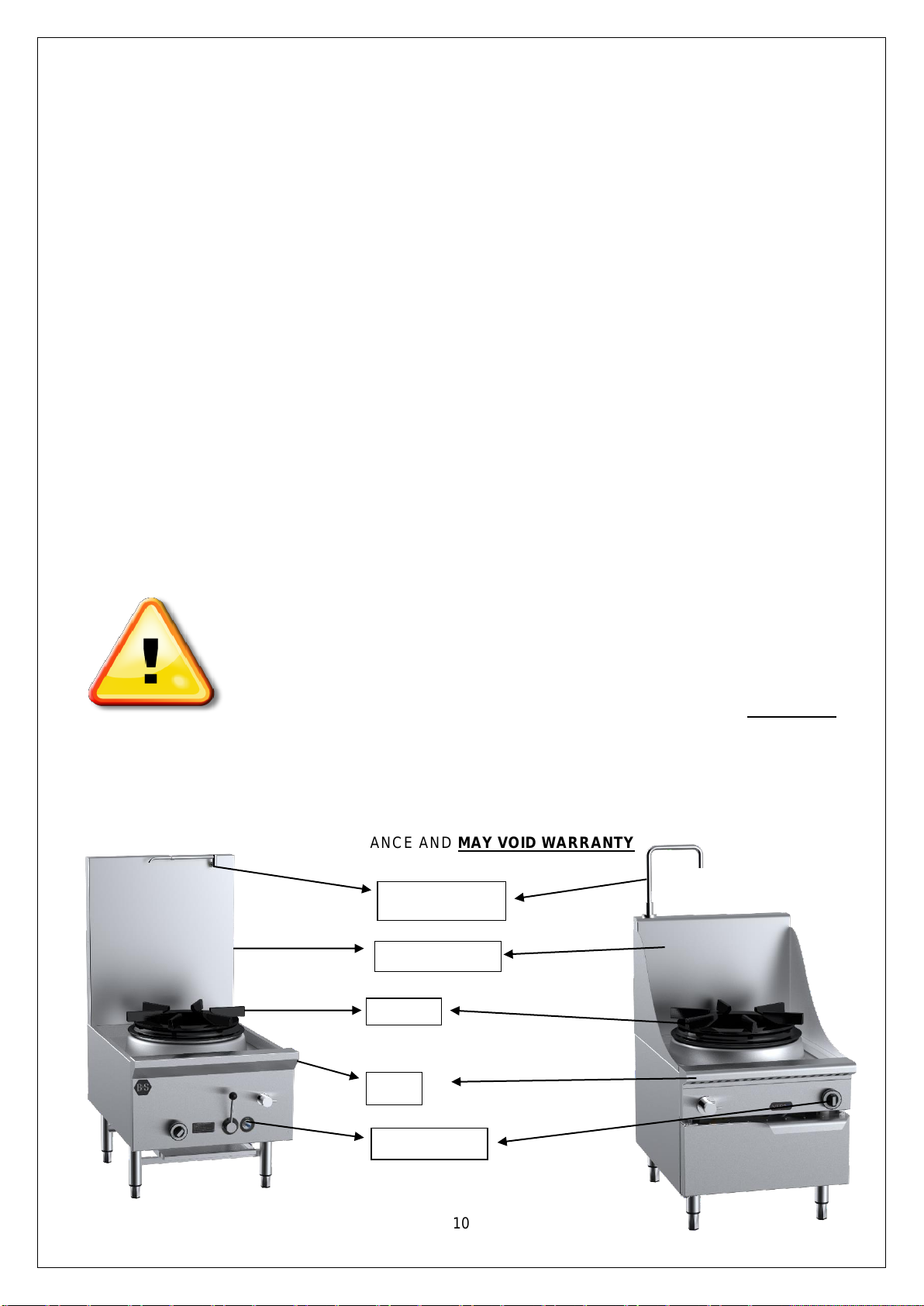

FAILURE TO FOLLOW THE INFORMATION PROVIDED IN THIS BOOKLET WILL VOID THE B&S

WARRANTY AND MAY RESULT IN DAMAGE TO EQUIPMENT OR INJURY TO PERSONNEL.

Please note that checking and adjusting of burner pressures on commercial catering appliances is an

obligation of gasfitters.

The relevant legislation is as follows from the Plumbing Regulations 2008 administered by the Victorian

Building Authority:

Gas fitting work defined

(1) Gas fitting work is the construction, installation, replacement, repair, alteration, maintenance, testing

or commissioning of any pipe, appliance, flue, fitting, apparatus, control or other item that is

involved with the supply or use of gas and that is fitted downstream of the outlet of a customer billing

meter or a consumer's gas storage container

As per AS/NZS5601.1, clause 6.11.1, this gas appliance must be commissioned by a suitably authorized

person who;

(a) Installed the appliance when gas is available at the time of installation; or

(b) Makes gas available to the appliance if gas was not available at the time of installation

As per AS/NZS5601.1, clause 6.11.3, the commissioning of this appliance shall take full account of special

design features, the manufacturer’s instructions and the appliance safety requirements.

As per AS/NZS5601.1, clause 6.11.4, the commission of this appliance shall include all of the following;

(a) Testing and purging of the appliance and installation as appropriate.

(b) Checks to ensure the appliance is in safe working order.

(c) Ignition of each burner of the appliance and where necessary adjustment, in accordance with the

manufacturer’s instructions.

(d) Testing of flue performance.

(e) Testing of all safety devices for correct operation.

(f) Instruction of the consumer, where available, on the safe and correct operation of the appliance

and any auxiliary equipment.

(g) Handing of the appliance operating instructions to the consumer, or if the consumer is not present,

leaving the instructions in a suitable location on the premises.

Installation Instructions

Regulations

The appliance must be installed only by authorised persons and in accordance with the manufacturer’s

installation instructions, local gas fitting regulations, municipal building codes, AS 5601 –Gas Installations

and any other health and safety regulations, local authority, gas, electrical any other statutory regulations.

Data Label

The data label is located on the front of the appliance. This appliance is suitable for Natural Gas and LPG.

Please ensure that the gas supply matches the Data Label ensuring that the gas supply is correct for the

appliance being installed and that adequate supply pressure and volume is available –refer to appliance

data plate for MJ/h consumption, injector sizes of main burners/pilots, etc.