1 Overview .........................................................................................................................3

1.1 Advantages.........................................................................................................................................3

1.2 Main Application &Testing Range ....................................................................................................3

1.2.1 Main Application ............................................................................................................................3

1.2.2 Testing Range..................................................................................................................................3

1.3 Technical Specifications ....................................................................................................................4

1.4 Configuration.....................................................................................................................................4

1.5 Working Conditions...........................................................................................................................5

2 Structure Feature &Testing Principle ..........................................................................5

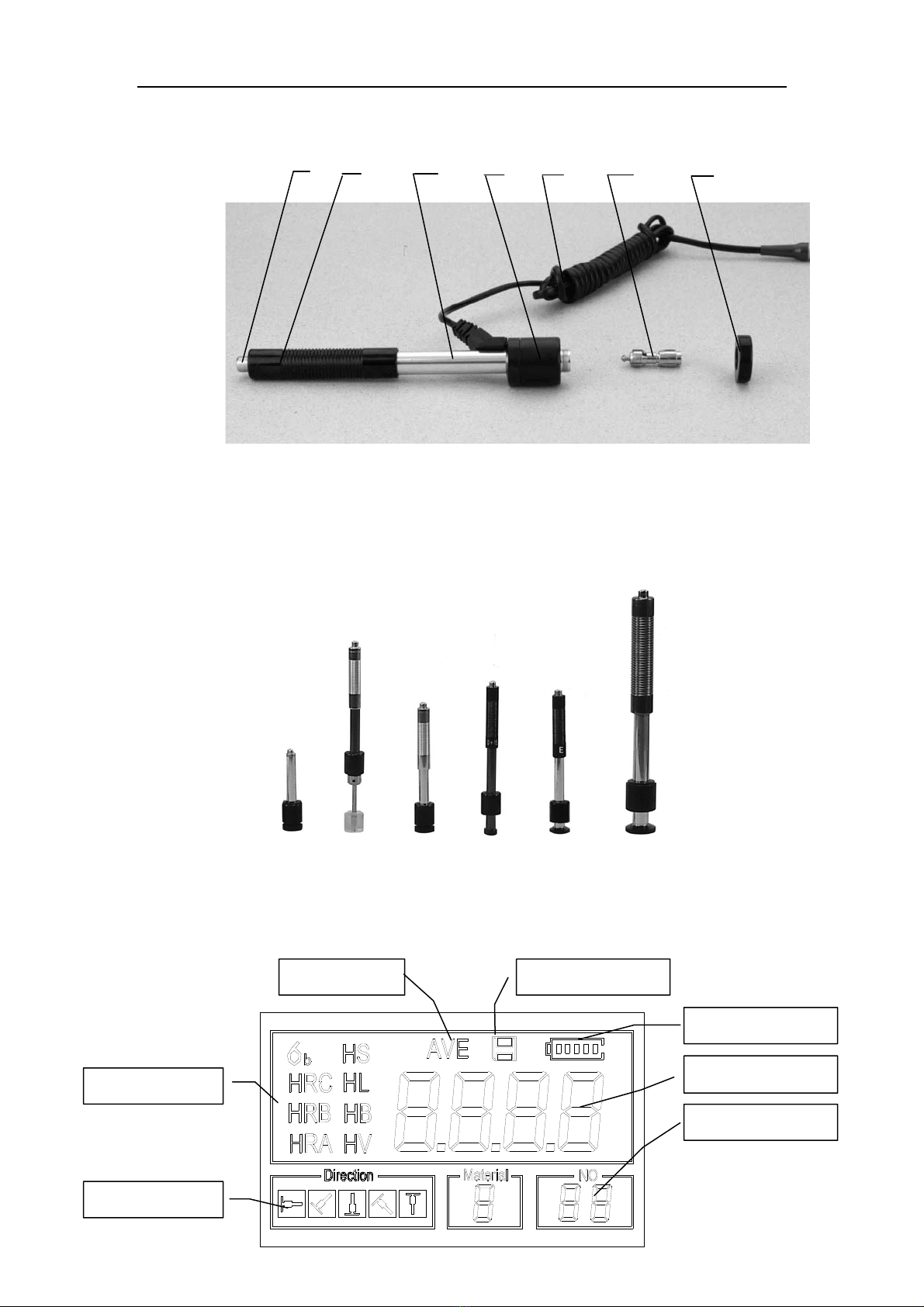

2.1 Structure Feature................................................................................................................................5

2.1.1 D Type Impact Device....................................................................................................................6

2.1.2 Different Types of Impact Device...................................................................................................6

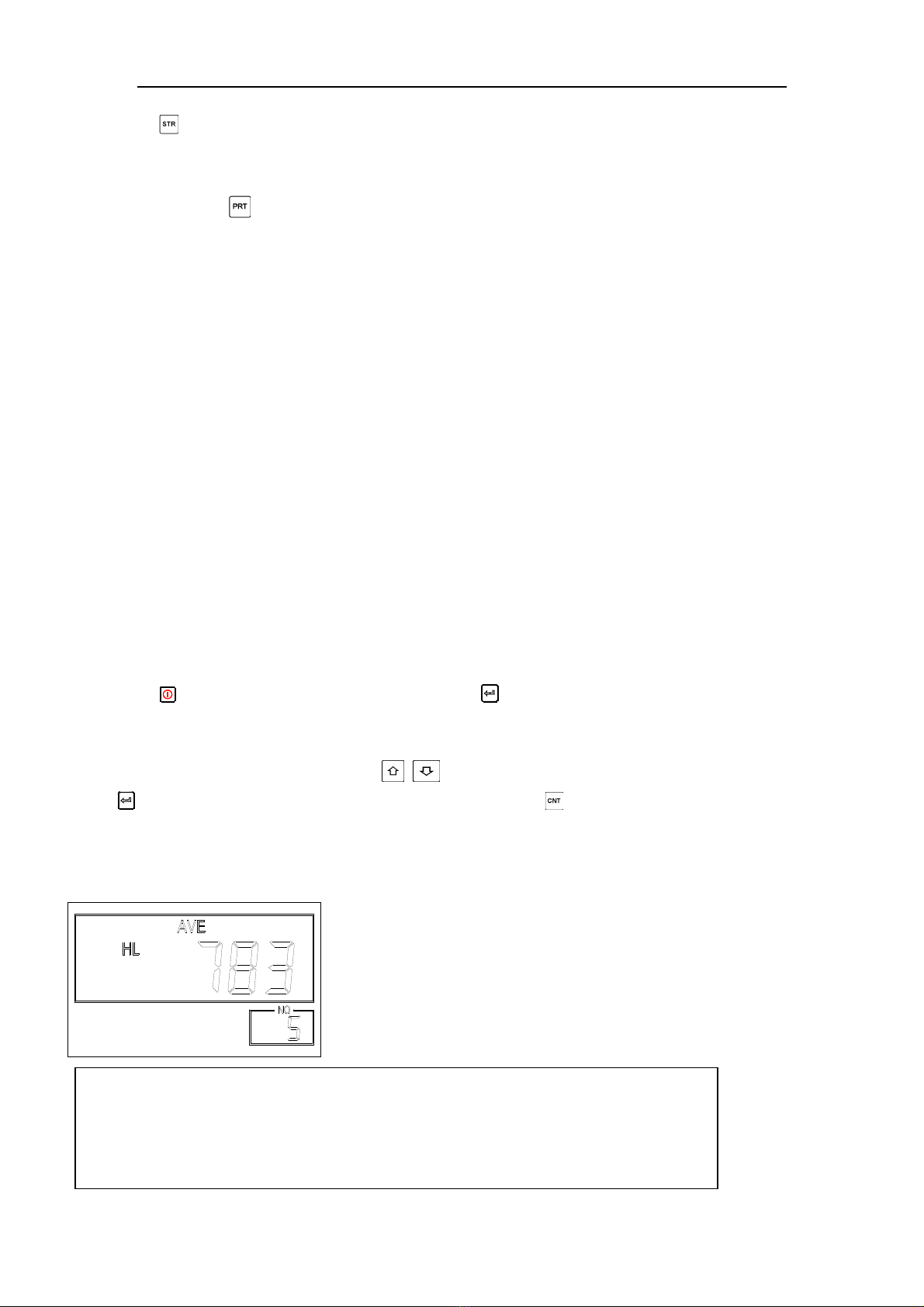

2.2 Main Screen.......................................................................................................................................6

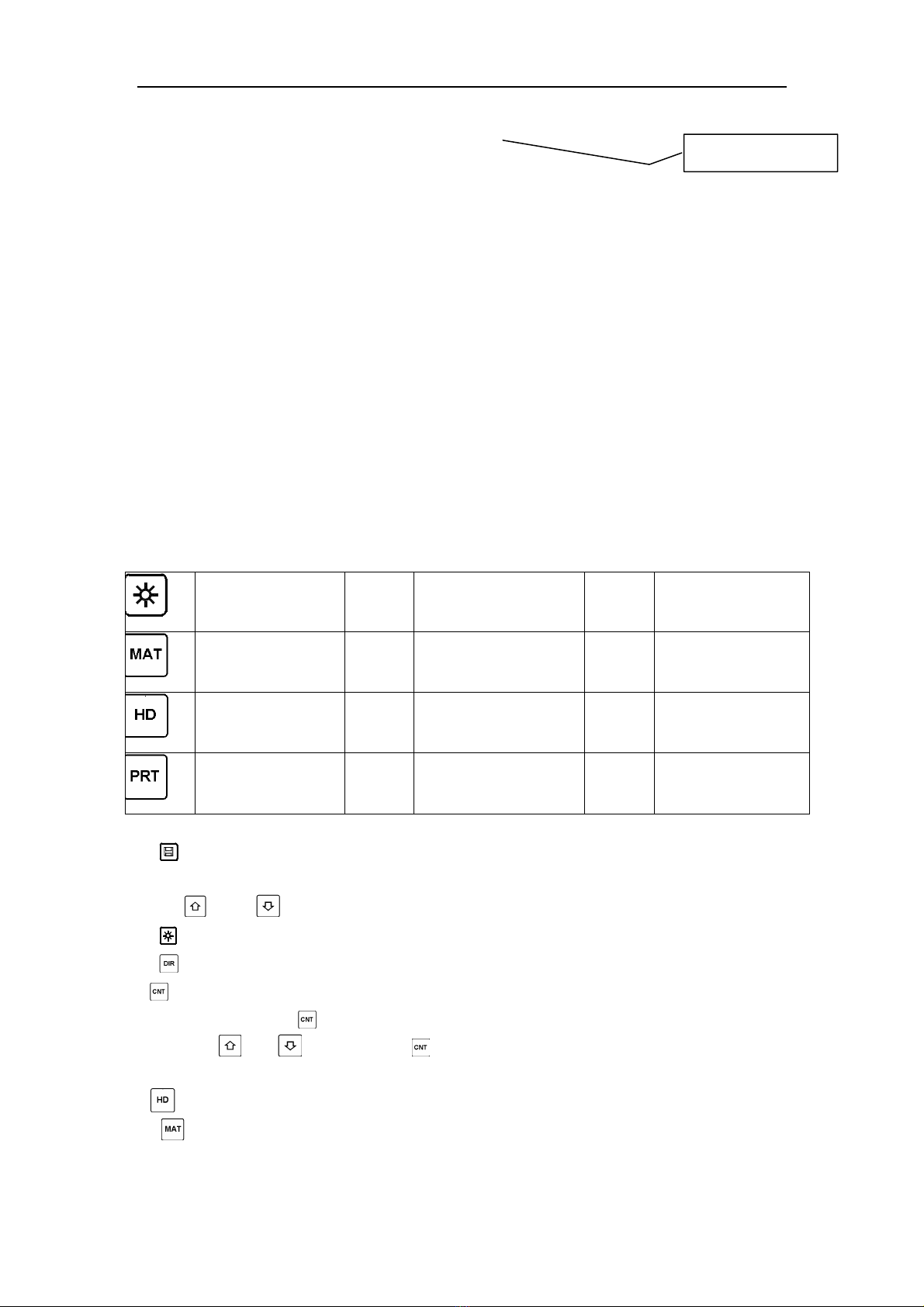

2.3 Keypad Definitions............................................................................................................................7

2.4 Leeb Hardness Testing Principle........................................................................................................8

3 Preparation......................................................................................................................8

3.1 Instrument Preparation and Inspection ..............................................................................................8

3.2 Impact Device Selection....................................................................................................................9

3.3 Preparation of the Sample Surface.....................................................................................................9

4 Testing Program ...........................................................................................................10

4.1 Start-Up............................................................................................................................................10

4.2 Loading............................................................................................................................................10

4.3 Localization .....................................................................................................................................10

4.4 Testing..............................................................................................................................................10

4.5 Read Measured Value ......................................................................................................................11

4.6 Notification......................................................................................................................................11

5 Operation Detail ...........................................................................................................12

5.1 Power On/Off...................................................................................................................................12

5.2 Material Setting................................................................................................................................12

5.3 Hardness/Strength testing ................................................................................................................13

5.4 Impact Direction Setting..................................................................................................................13

5.5 Average Times Setting .....................................................................................................................13

5.6 Data logging.....................................................................................................................................13

5.6.1 Viewing stored file/Group.............................................................................................................13

5.6.2 Clearing selected file/Group.........................................................................................................14

5.7 Print Report......................................................................................................................................14

5.8 System Reset....................................................................................................................................14

5.9 EL Backlight....................................................................................................................................14

5.10 Auto Power Off..............................................................................................................................15

5.11 Battery Replacement......................................................................................................................15

5.12 Connecting to a Computer.............................................................................................................15

5.13 Error Code Reference ....................................................................................................................15

6 Maintenance & Servicing............................................................................................16

1