2of 27

Table of Contents

Introduction ..............................................................................................................................................................3

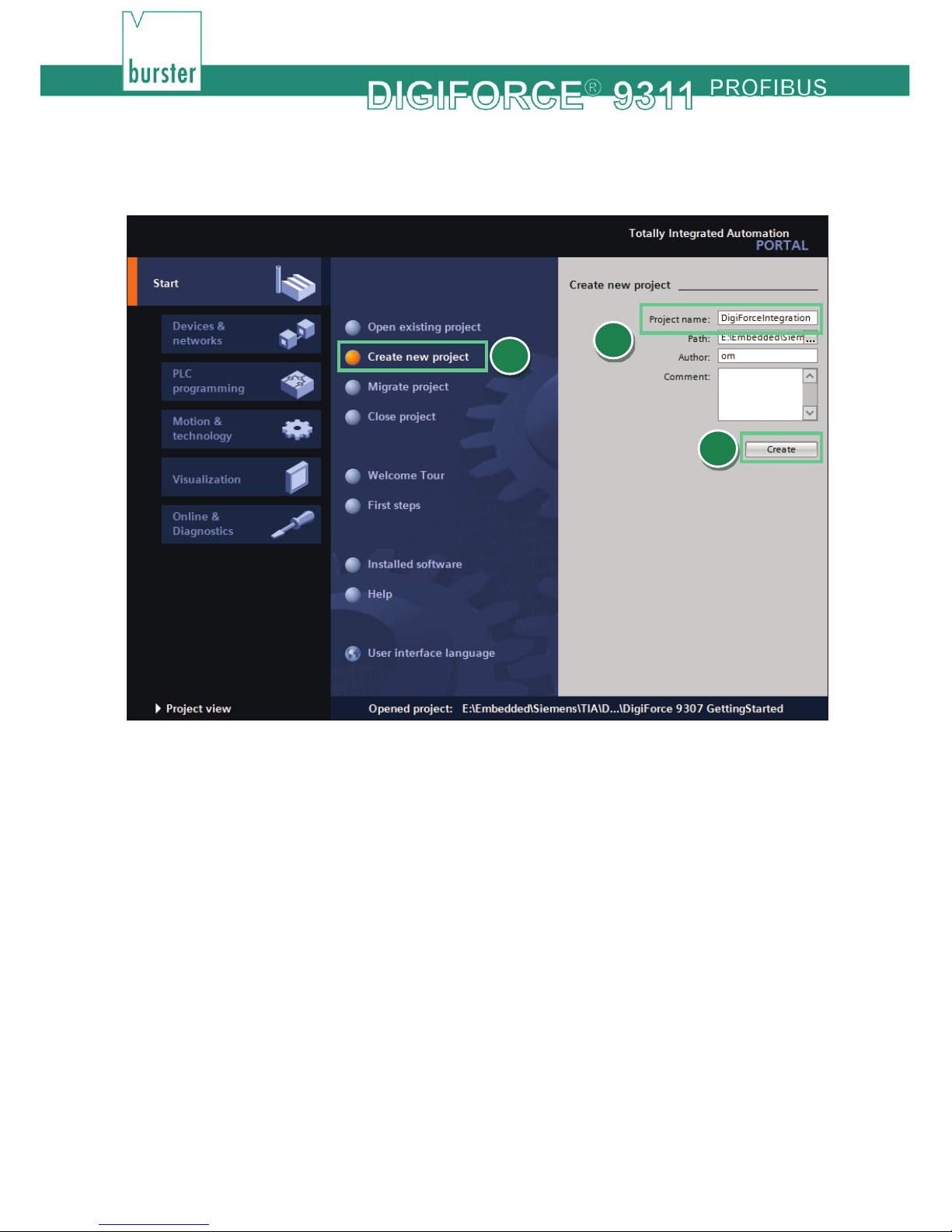

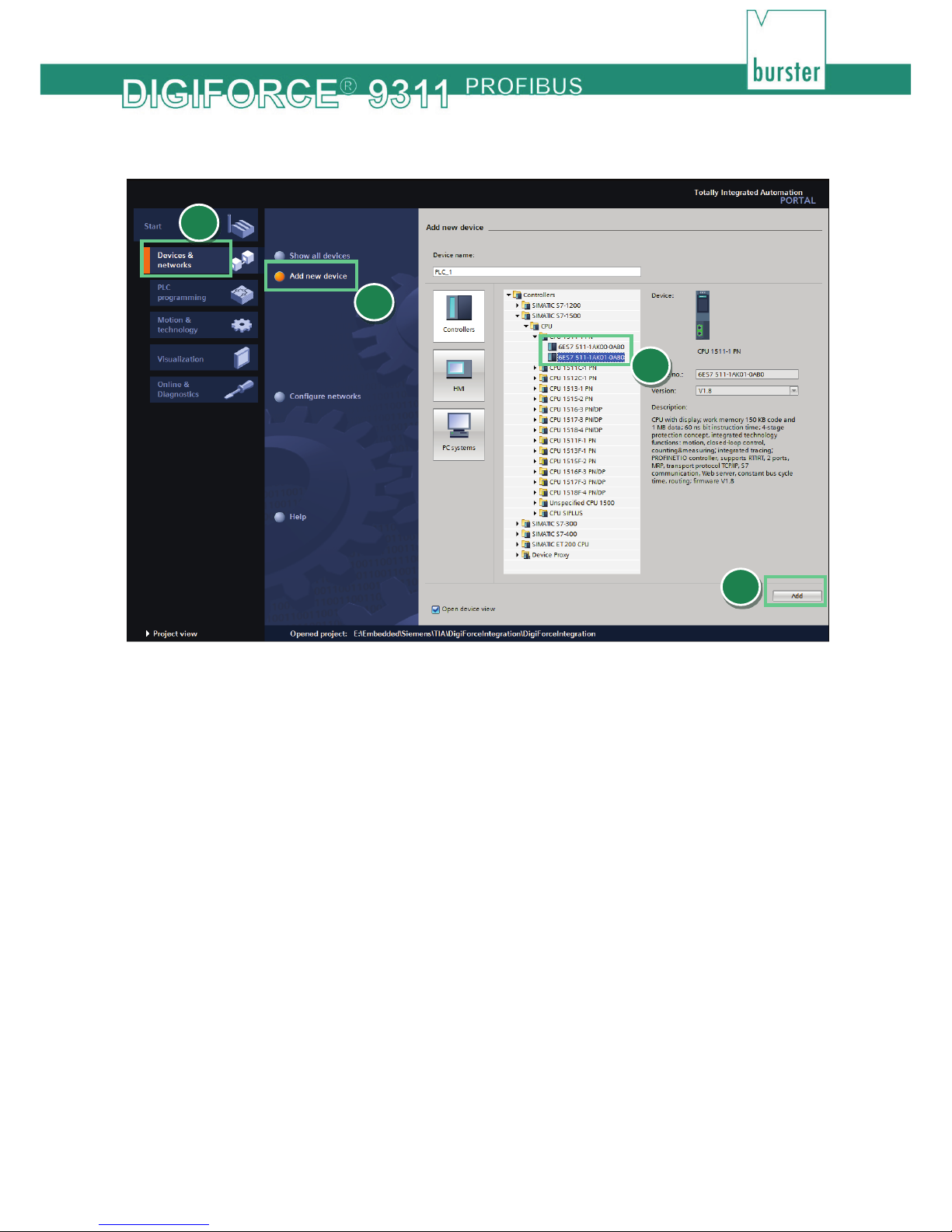

1. Creating new project.........................................................................................................................................4

2. Installation of GSD file ......................................................................................................................................6

3. Creation of network connections ......................................................................................................................7

4. Create a sample program:..............................................................................................................................13

5. Further Examples ...........................................................................................................................................18

5.1 Reading and Writing of string data types.................................................................................................19

5.2 Retrieving of measurement results ..........................................................................................................22

5.3 Changing of window limits .......................................................................................................................25