Allied Systems W12E User manual

Table of contents

Other Allied Systems Winch manuals

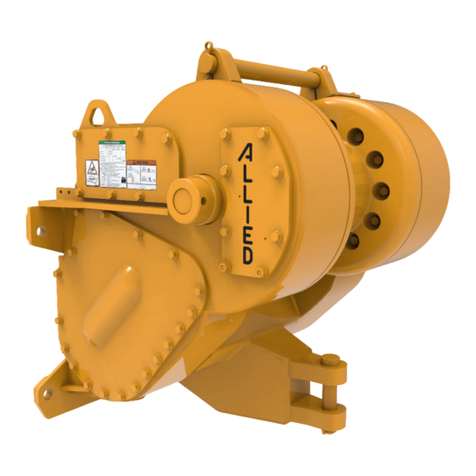

Allied Systems

Allied Systems W6F User manual

Allied Systems

Allied Systems H5C Series User manual

Allied Systems

Allied Systems W8L User manual

Allied Systems

Allied Systems W8L User manual

Allied Systems

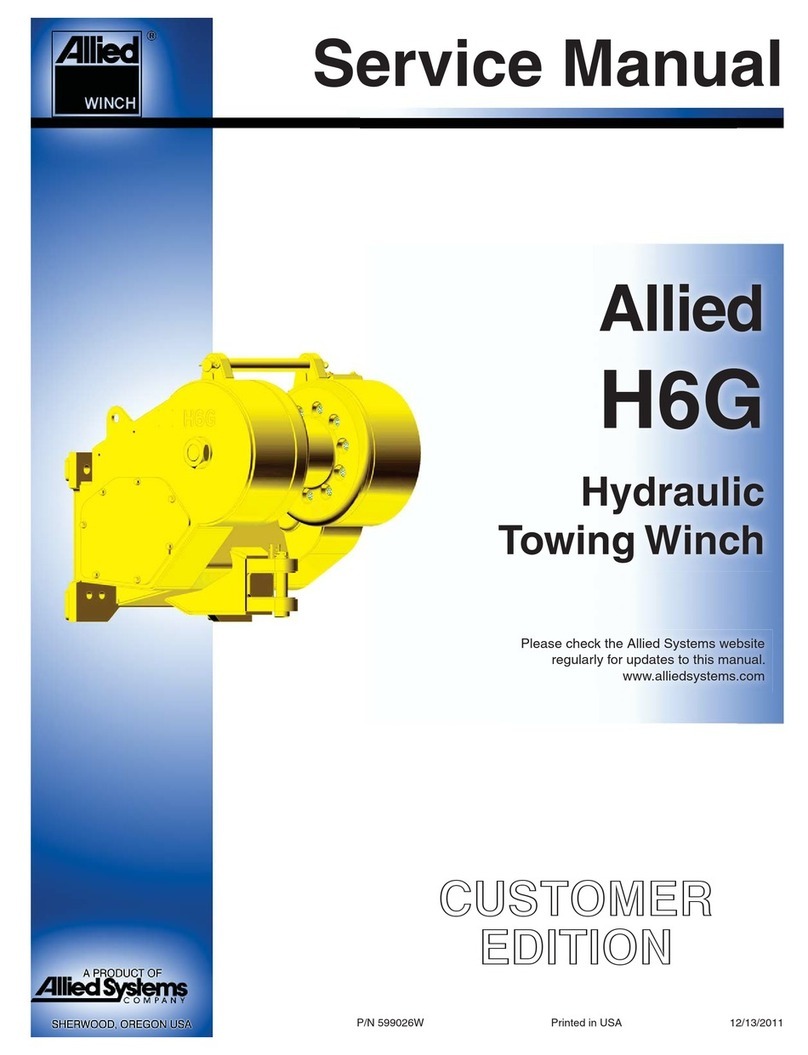

Allied Systems Allied H6G Series User manual

Allied Systems

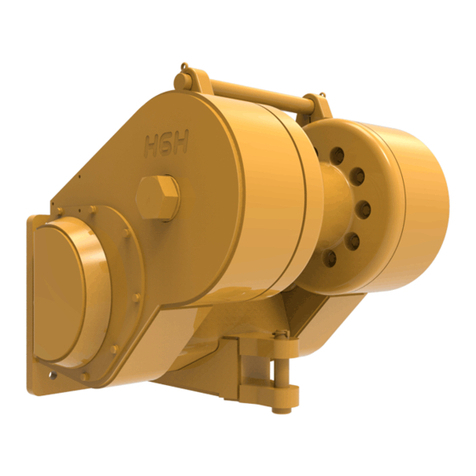

Allied Systems H6H User manual

Allied Systems

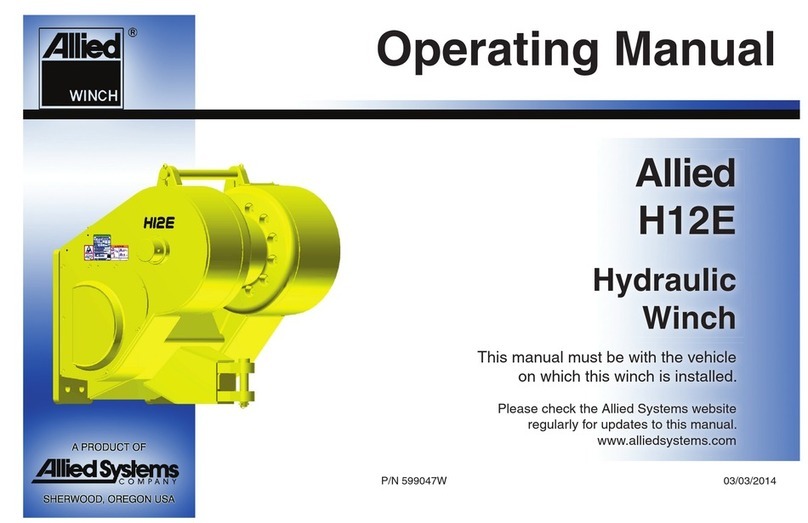

Allied Systems H12E User manual

Allied Systems

Allied Systems H4A User manual

Allied Systems

Allied Systems H6H User manual

Allied Systems

Allied Systems W6G User manual

Popular Winch manuals by other brands

Westfalia

Westfalia 82 45 37 instruction manual

Farmi Forest Corporation

Farmi Forest Corporation 290 OPERATION, MAINTENANCE AND SPARE PARTS MANUAL

VITO

VITO PRO-POWER instruction manual

Ramsey Winch

Ramsey Winch Powermaster 15,000 Operating, Service and Maintenance Manual

Ramsey Winch

Ramsey Winch RPH 8000 Operating, Service and Maintenance Manual

Mile Marker

Mile Marker PE2500 Installation & operator's manual