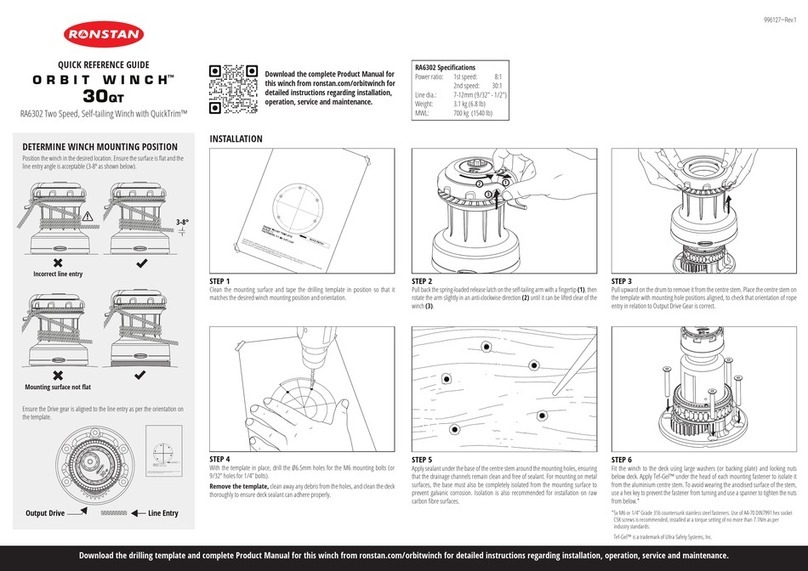

Line EntryOutput Drive

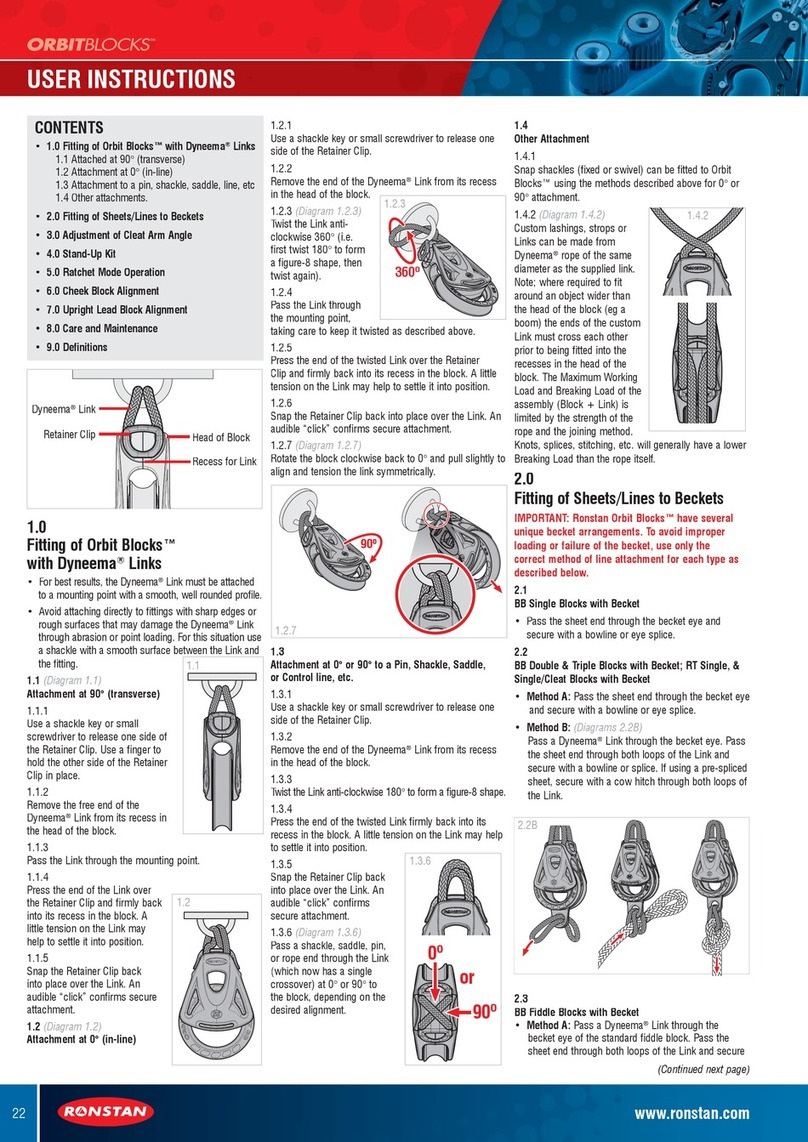

DETERMINE WINCH MOUNTING POSITION

Position the winch in the desired location. Ensure the surface is flat and the

line entry angle is acceptable (3-8º as shown below).

INSTALLATION

QUICK REFERENCE GUIDE

Ensure the Drive gear is aligned to the line entry as per the orientation on

the template.

STEP 2

Pull back the spring-loaded release latch on the self-tailing arm with a fingertip (1), then

rotate the arm slightly in an anti-clockwise direction (2) until it can be lifted clear of the

winch (3).

STEP 5

Apply sealant under the base of the centre stem around the mounting holes, ensuring

that the drainage channels remain clean and free of sealant. For mounting on metal

surfaces, the base must also be completely isolated from the mounting surface to

prevent galvanic corrosion. Isolation is also recommended for installation on raw

carbon fibre surfaces.

Download the drilling template and complete Product Manual for this winch from ronstan.com/orbitwinch for detailed instructions regarding installation, operation, service and maintenance.

STEP 1

Clean the mounting surface and tape the drilling template in position so that it

matches the desired winch mounting position and orientation.

STEP 4

With the template in place, drill the Ø6.5mm holes for the M6 mounting bolts (or

9/32” holes for 1/4” bolts).

Remove the template, clean away any debris from the holes, and clean the deck

thoroughly to ensure deck sealant can adhere properly.

STEP 3

Pull upward on the drum to remove it from the centre stem. Place the centre stem on

the template with mounting hole positions aligned, to check that orientation of rope

entry in relation to Output Drive Gear is correct.

STEP 6

Fit the winch to the deck using large washers (or backing plate) and locking nuts

below deck. Apply Tef-Gel™ under the head of each mounting fastener to isolate it

from the aluminium centre stem. To avoid wearing the anodised surface of the stem,

use a hex key to prevent the fastener from turning and use a spanner to tighten the nuts

from below.*

*

5x M6 or 1/4” Grade 316 stainless steel fasteners. Use of A4-70 DIN912 hex socket cylinder head

screws

is recommended, installed at a torque setting of no more than 7.1Nm as per industry

standards.

Tef-Gel™ is a trademark of Ultra Safety Systems, Inc.

RA6201 Specifications

Power ratio: 1st speed: 18:1

Line dia.: 6-10mm (1/4" - 3/8")

Weight: 1.7 kg (3.7 lb)

MWL: 550 kg (1210 lb)

!

Mounting surface not flat

Incorrect line entry

3-8°

1

2

3

ROPE ENTRY

RA6201 MOUNT TEMPLATE

SCALE 1:1

FASTENERS: 5 x M6 (1/4")

THIS DRAWING /LIBRARY HAS BEEN PRODUCED FOR USE IN DECK PLANS ONLY; SOME DETAILS HAVE BEEN OMITTED.

SHOULD ACCURATE DIMENSIONS BE REQUIRED SUCH AS HOLE SPACING, LENGTHS, ETC.

PLEASE CONTACT RONSTAN FOR FURTHER INFORMATION.

ROPE ENTRY

RA6201 MOUNT TEMPLATE

SCALE 1:1

FASTENERS: 5 x M6 (1/4")

THISDRAWING /LIBRARY HAS BEEN PRODUCED FOR USE IN DECK PLANS ONLY; SOME DETAILS HAVE BEEN OMITTED.

SHOULDACCURATE DIMENSIONS BE REQUIRED SUCH AS HOLE SPACING, LENGTHS, ETC.

PLEASECONTACT RONSTAN FOR FURTHER INFORMATION.

Download the complete Product Manual for

this winch from ronstan.com/orbitwinch for

detailed instructions regarding installation,

operation, service and maintenance.

ORBIT WINCH™

20ST

RA6201 Single Speed, Self-tailing Winch

996124—Rev.1