Branick Industries, Inc. 5500 Use and care manual

Branick Industries, Inc. •4245 Main Ave •P.O. Box 1937 •Fargo, North Dakota 58103

P/N: 81-0047C

MODEL 5500

Tire Repair

Station

Installation, Operation

and Repair Parts

Information

1

TABLE OF CONTENTS

_______________________________________________________

SAFETY INSTRUCTIONS 1

DEFINITIONS 1

INSTALLATION INSTRUCTIONS 2

OPERATING INSTRUCTIONS 2

MAINTENANCE INSTRUCTIONS 2

REPAIR PARTS 3-8

REPAIR PARTS LIST 4-8

WARRANTY 11

SAFETY INSTRUCTIONS

_____________________________________________________

§NEVER allow unauthorized personnel to operate this product.

§NEVER use this product for anything other than its intended use.

§THOROUGHLY train new employees in the proper use and care of this product.

§PROHIBIT unauthorized personnel from being in shop area while this product is in use.

DEFINITIONS

_______________________________________________________________

§CAUTION: Indicates a potentially hazardous situation, which if not avoided, may result in damage to

property or minor personal injury.

§HAZARD: A source of potential injury to a person.

§MAINTENANCE: Those actions that preserve the correct and proper conditions under which the

machine shall be used. This may include adjustment, replacement of wear items, lubrication and

cleaning, but not modifications or repair of damage.

§MAY: This word is understood to be permissive.

§MUST: This word is understood to be mandatory.

§OPERATION: The correct and proper use of the machine as described in this manual.

§SAFETY ALERT SYMBOL: A symbol that indicates a potential personal safety hazard. It is

composed of an equilateral triangle surrounding an exclamation point.

§SHALL: This word is understood to be mandatory.

§SHOULD: This word is understood to be advisory.

§WARNING: Indicates a potentially hazardous situation, which if not avoided, may result in death or

serious personal injury.

2

INSTALLATION __________________________________________________________

1) Attach the tire ramp (item 45) and retractor bar (item 46) to the Model 5500 with hardware provided.

Tighten nylon lock nuts enough to allow free rotation at pivot points (see page 2)

2) Position the Model 5500 on a solid level floor leaving a minimum of 36 inches of clearance on operation

sides and 24 inches of clearance on valve tray side.

3) Attach a 1/4 NPT quick coupler nipple (not provided) into the fitting located on lower frame on valve tray

side of machine. Use 1/4 inch air hose with 100 p.s.i. minimum.

OPERATION _____________________________________________________________

1) Make sure the spreader platform is in the lowest position.

2) Pull the spread hook arms out into the upright position.

3) Roll the tire up the ramp and onto the spreader platform rollers. Steady tire with hand and insert spread

hooks between tire beads.

4) Raise the spreader platform to comfortable working height using the platform lift foot valve.

5) Adjust spread hooks to proper height for the tire size being repaired. The spread hook arms are held in

position with a hitch pin. To adjust the spread hook arms, pull the hitch pin and move spread hook arm

up or down to one of the four adjustment holes. Most larger truck tires will use the uppermost adjustment

holes. Both spread hook arms must be adjusted to the same height.

6) Spread tire to desired width using the hand operated valve attached to accessory tray. If tire is lifted off

tire rollers when it is spread, the spread hook arms are positioned too high and should be lowered.

7) After tire repairs are complete, lower the spreader platform to lowest position.

8) Remove spread hook arm pressure and remove spread hook arms from the tire bead.

9) Standing at the end of the ramp, pull the tire down the ramp using both hands.

MAINTENANCE __________________________________________________________

Monthly: On the spread cylinder, remove the slotted plug from the tee fitting at the end of cylinder and put

in a few ounces of 10 or 20 weight oil. On the lift cylinder, put few ounces of oil in the ¼ inch hole in top

cover plate.

CAUTION

♦Before using this product, read and fully understand the operating

instructions and all decals on the product. This is necessary to

prevent injury to the operator and damage to the product.

♦Use this product only for lifting, spreading and repairing tire

casings. Do not use this product for any other purpose.

♦Keep fingers and hands clear of spread hooks during tire spread.

♦Do not use this product if it is visibly worn, distorted or damaged.

♦Always wear appropriate eye protection.

WARNING

♦Keep feet clear of the tire ramp and scissor arms when raising and

lowering spreader platform.

♦All personnel must be clear of the tire lift area during operation.

3

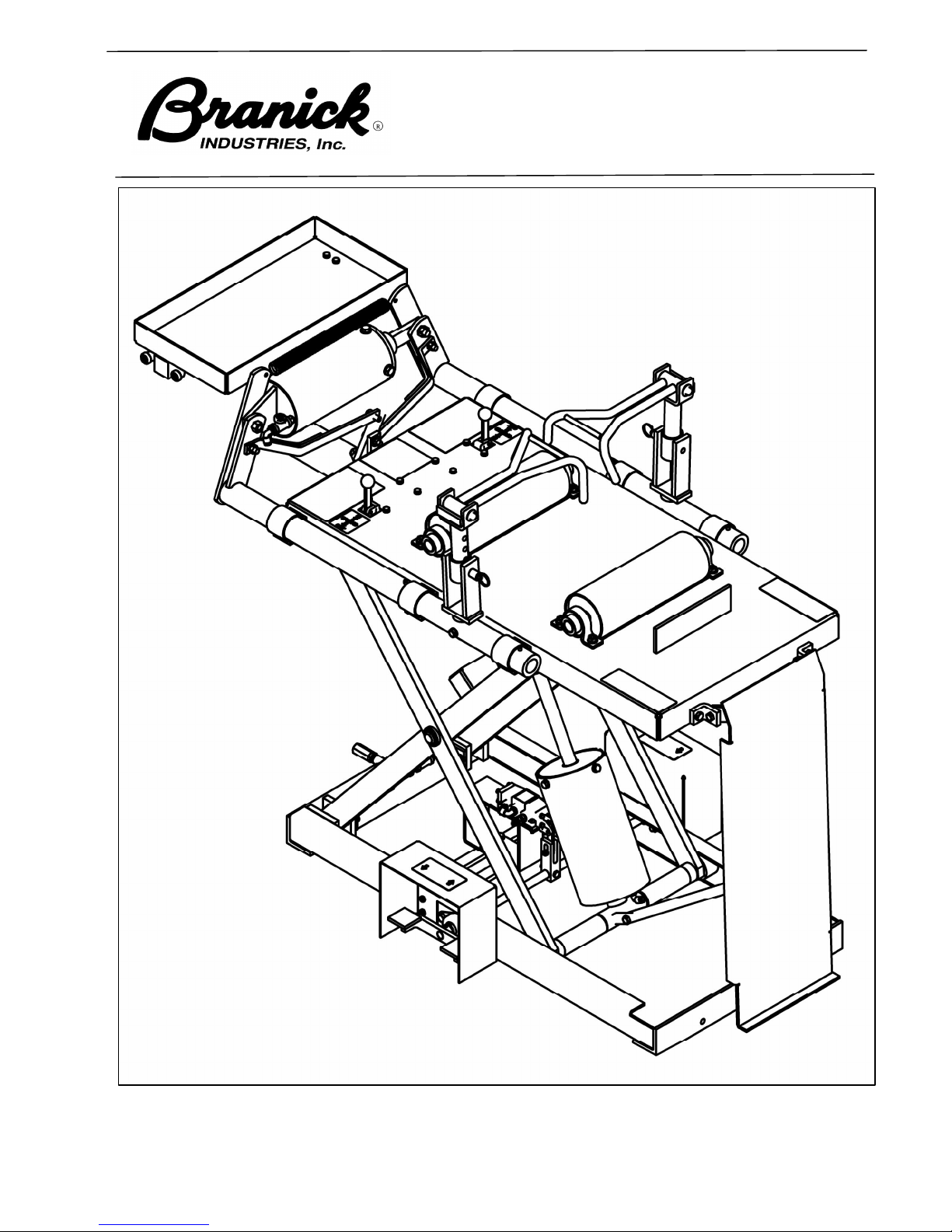

REPAIR PARTS __________________________________________________________

Main Assembly

4

ITEM QTY

PART NO. DESCRIPTION

1 1 01-0179 CYLINDER, 5-1/4" LIFT

2 2 01-0182 ARM, OUTSIDE

3 1 01-0183 ARM, INSIDE

4 1 01-0201 HOSE ASS'Y, SHORT

5 1 03-0036 LINK, PIVOT

6 6 03-0106 PIVOT PIN

7 2 03-0107 PIVOT PIN

8 2 03-0108 ROLLER ROD

9 1 03-0243 FRAME, BASE

10 1 03-0247 SPREADER PLATFORM

11 1 03-0248 ARM, FRONT POWER

12 1 03-0249 ARM, REAR POWER

13 1 03-0250 HOLDER, TOOL TRAY

14 1 03-0256 RAMP WELDMENT

15 2 03-0302 WELDMENT, SPREAD HOOK

16 2 03-0304 WELD, ROLLER

17 2 03-0305 WELD, ADJUSTMENT POST

18 2 03-0308 WELD, HOOK POST

19 1 03-0309 TOOL TRAY WELD.

20 4 11-0023 NYLON ROLLER

21 2 020-024 CAP

22 8 028-010 SCREW, 1/4-20 x 3/4 HHC

23 14 028-012 SCREW, 5/16-18 x 3/4 HHC

24 2 028-021 SCREW, 3/8-16 X 1 HHC

25 1 028-025 SCREW, 1/2NC X 1-1/2 HHC

26 2 028-027 SCREW, 1/4 NC X 1/2 SOC SET

27 8 028-046 SCREW, 3/8-16 X 1-1/4 HEX CAP

28 1 028-047 SCREW, 1/2NC X 1-3/4 HHCS

29 14 028-133 SCREW, 3/8 NC X 3/4 HHC

30 1 028-207 SCREW, NYLON TIP SET

31 4 028-210 SCREW, 1/4-20 UNC X 5/8 HHC

32 6 039-007 1" MACHINERY BUSHING

33 6 044-048 RING, RETAINING

34 1 50-0027 SCREW, 3/8 X 1 SHOULDER

35 2 055-058 NUT, 1/2-13NC BI-WAY LOCK

36 14 055-103 NUT, 3/8-16 SERR HEX FLG

37 1 055-145 NUT, 5/16-18 NYLON HEX LOCK

38 10 055-154 NUT,3/8-16 NYLON HEX LOCK

39 4 061-091 PIN, 1/4 X 7/8 SPRING

40 7 096-004 FITTING, 1/4 NPT HSH PLUG

41 6 096-013 1/4 NPT HEX NIPPLE, BRASS

42 20 108-008 WASHER, 1/4 INT TOOTH

43 4 096-038 1/4-90° ST ELBOW

44 4 096-249 1/4 NPT TEE

45 6 096-342 FITTING, 1/4 TUBE ELBOW

46 10 108-015 WASHER, 3/8 SAE FLAT

47 2 54-0034 PIN, CLEVIS - (1/2 x 3)

48 2 59-0007 RING, SPLIT

49 1 73-0301 LOWER ROLLER ROD

50 1 73-0592 BAR, RETRACTOR

5

ITEM QTY

PART NO. DESCRIPTION

51 2 73-0607 ANCHOR

52 2 73-0661 PIN, STOP

53 2 73-0743 BRACKET, RAMP

54 2 73-0744 MANIFOLD

55 2 74-0076 SLEEVE, CYLINDER SHAFT

56 4 107-020 BEARING, PILLOW BLK

57 4 108-057 WASHER, 3/8 INT TOOTH LOCK

58 14 108-067 WASHER, 5/16 INT TOOTH

59 1 110-011 TENSION SPRING

60 2 110-065 SPRING, CPRSN

61 1 900-187 4-1/2" CYLINDER ASS'Y

62 2 950-553 SHORT LINK

LIFT CYLINDER ASSEMBLY

ITEM

QTY

PART NO DESCRIPTION

1 1 03-0240 LIFT CYL WELD.

2 5 039-041 SLEEVE BEARING

3 1 73-0746 LIFT PISTON ROD

4 1 01-0181 END COVER W/ BUSHING

5 4 028-012 5/16-18 x 3/4 HHC SCREW

6 4 108-067 5/16 WASHER

7 1 061-166 COTTER PIN

8 1 01-0074 ROD END WITH BEARING

9 2 11-0082 STRIP NYLON

10 1 73-0745 LIFT PISTON

11 1 61-0029 QUAD RING SEAL

12 1 055-111 9/16-18 LOCK NUT

13 1 52-0036 MODIFIED WASHER

14 1 041-049 #207 O-RING

6

SPREAD CYLINDER ASSEMBLY

ITEM

QTY

PART NO

DESCRIPTION

1 1 950-194 CYLINDER WELDMENT

2 1 950-195 PISTON & ROD ASS'Y

3 1 098-327 COVER PLATE

4 4 108-038 7/16 WASHER

5 4 028-005 7/16-14 x 3/4 HHC SCREW

6 1 041-202 ROD SEAL

7 1 61-0028 QUAD RING SEAL

8 1 11-0065 NYLON WEAR STRIP

7

PNEUMATICS ASSEMBLY

8

ITEM

QTY

PART NO DESCRIPTION

1 2 01-0199 VALVE SUB-ASS'Y

2 1 01-0200 LONG HOSE ASS'Y

3 1 01-0201 SHORT HOSE ASS'Y

4 2 03-0306 PEDAL WELDMENT

5 1 03-0307 VALVE MOUNT

6 14 028-012 5/16-18 x 3/4 HHC SCREW

7 1 028-078 CAPSCREW, 1/4 NC X 1-1/2

8 8 028-133 SCREW, 3/8 NC X 3/4 HHC

9 8 028-148 1/4 NC X 1/2 TAPPING SCREW

10 4 028-161 #10-24 X 1 PAN HD MC SCREW

11 1 028-353 5/16 X 1 SHOULDER SCREW

12 4 055-057 #10-24 HEX NUT

13 2 055-160 NYLON HEX LOCK NUT

14 2 061-178 3/16 X 1 SPRING PIN

15 7 096-004 1/4 NPT HSH PLUG FITTING

16 6 096-013 1/4 NPT HEX NIPPLE

17 4 096-249 1/4 NPT TEE

18 2 096-339 UNION TEE (1/4 TUBE)

19 6 096-342 1/4 TUBE ELBOW

20 1 60-0047 4-WAY VALVE

21 2 72-0086 FOOT GUARD

22 1 73-0733 VALVE CLEVIS

23 1 73-0734 LEVER ROD

24 12 108-008 1/4 INT TOOTH WASHER

25 14 108-067 5/16 INT TOOTH WASHER

26 1 190-249 1/4 NPT FLOW CONTROL

27 1 885-036 FLOW CONTROL MUFFLER

28 1 932-001 IN-LINE FILTER

29 D20-007 1/4 OD TUBE

9

NOTES:

10

NOTES:

11

COMMERCIAL WARRANTY

This product is warranted by BRANICK INDUSTRIES, INC. to the original user-owner against defective materials or workmanship for a period

of one year from the date of delivery. During the warranty period, product found to be defective will be repaired or replaced at, BRANICK

INDUSTRIES, INC.'s option, without charge. The product must be returned, with prior approval, transportation charges prepaid and with proof

of original delivery date, to BRANICK INDUSTRIES, INC., 4245 Main Ave., Fargo, North Dakota 58107. The repaired or replacement product

will be returned with transportation charges prepaid byBranick.

This warranty does not cover defects in the product caused by ordinary wear and tear, abuse, misuse, overloading, accident (including

shipping damage), improper maintenance, alteration, or any other cause not the result of defective materials or workmanship.

REPAIR OF REPLACEMENT IS THE EXCLUSIVE REMEDY FOR DEFECTIVE PRODUCT UNDER THIS WARRANTY. THIS

WARRANTY IS EXPRESSLY IN LIEU OF ALL OTHER WARRANTIES, INCLUDING ANY IMPLIED WARRANTY OF

MERCHANTABILITY OR ANY IMPLIED WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE OF THIS PRODUCT. BRANICK

INDUSTRIES, INC. SHALL NOT BE LIABLE FOR ANY CONSEQUENTIAL OR INCIDENTAL DAMAGES.

BRANICK INDUSTRIES, INC. reserves the right to make changes in the design or construction of our products without obligation to

incorporate such changes in products already sold and without notice.

Service parts, warranty, and regular repair service for products are available from Branick authorized distributors or from:

BRANICK INDUSTRIES, INC.

4245 Main Ave.

Box 1937

Fargo, North Dakota 58107

701/281-8888

© Copyright 2010 by Branick Industries, Inc. Printed in

U.S.A

Table of contents

Popular Tyre Changer manuals by other brands

HENNESSY INDUSTRIES

HENNESSY INDUSTRIES coats AMMCO RC-45 A coats AMMCO RC-45 E manual

Pittsburgh

Pittsburgh 58920 Owner's manual & safety instructions

Corghi

Corghi Artiglio 5000 Operator's manual

Mondolfo Ferro

Mondolfo Ferro AQUILA TORNADO Operator's manual

GIULIANO

GIULIANO S224 Installation, operation and maintenance guide

LAUNCH TECH

LAUNCH TECH LAUNCH TWC-401NIC manual