8

4.0 IMPORTANT SAFETY INSTRUCTIONS

When using your garage equipment, basic safety precautions should

always be followed, including the following:

1. Read all instructions.

2. Care must be taken as burns can occur from touching hot parts.

3. Do not operate equipment with a damaged cord or in case the

equipment has been dropped or damaged, until it has been

examinedbyaqualiedserviceperson.

4. Do not let a cord hang over the edge of the table, bench, or

counter or come in contact with hot manifolds or moving fan

blades.

5. Ifanextensioncordisnecessary,acordwithacurrentrating

equal to or more than that of the equipment should be used.

Cords rated for less current than the equipment may overheat.

Care should be taken to arrange the cord so that it will not be

tripped over or pulled.

6. Always unplug equipment from electrical outlet when not in use.

Never use the cord to pull the plug from the outlet. Grasp plug

and pull to disconnect.

7. Let equipment cool completely before putting away. Loop cord

loosely around equipment when storing.

8. To reduce the risk of fire, do not operate equipment in the vicinity

of open containers of flammable liquids (gasoline).

9. Adequate ventilation should be provided when working on

operating internal combustion engines.

10. Keep hair, loose clothing, fingers, and all parts of body away

from moving parts.

11. To reduce the risk of electric shock, do not use on wet surfaces

orexposetorain.

12. Use only as described in this manual. Use only manufacturer’s

recommended attachments.

13. ALWAYS WEAR SAFETY GLASSES. Everyday eyeglasses only

have impact resistant lenses, they are not safety glasses.

SAVE THESE INSTRUCTIONS

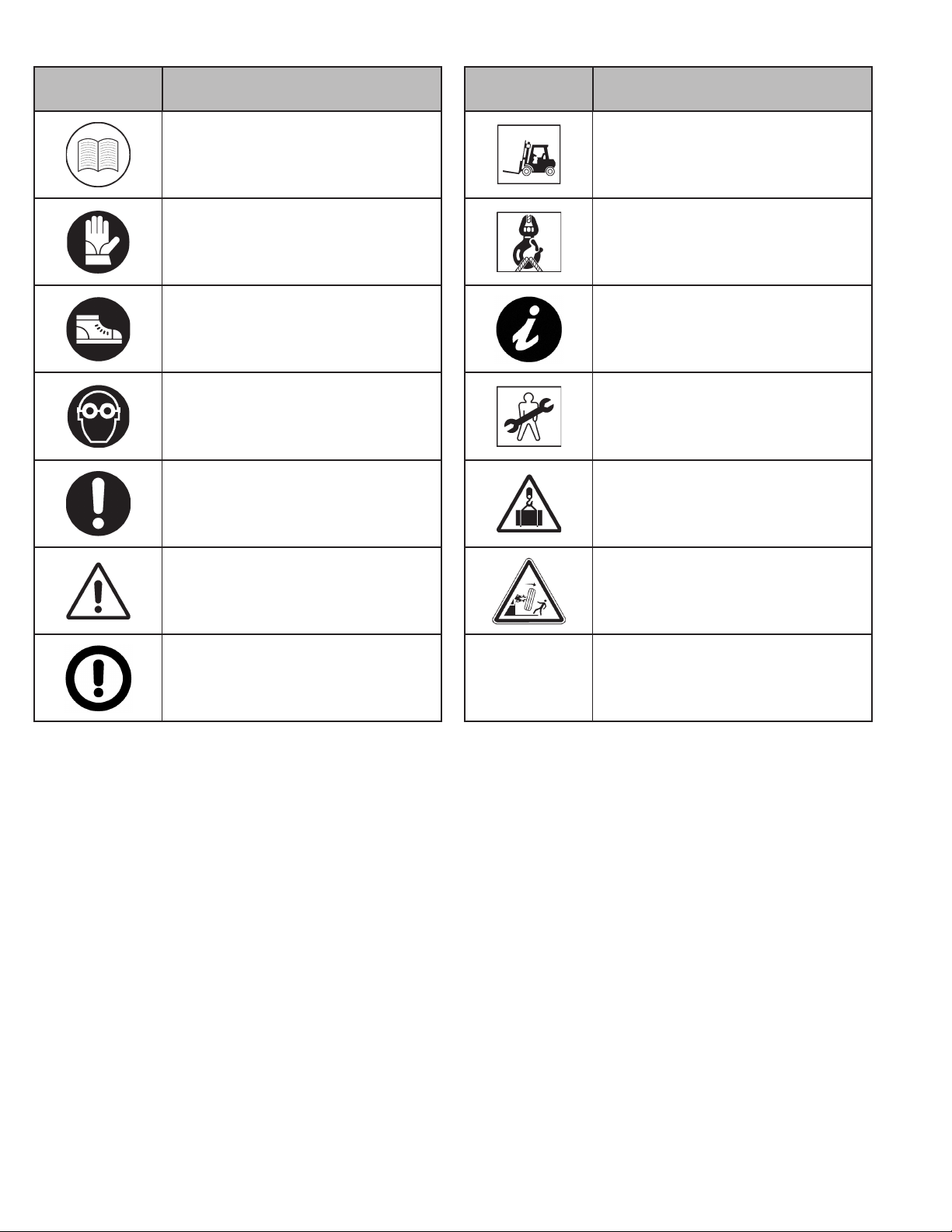

3.0 SAFETY DEVICES

DAILY CHECK THE INTEGRITY AND THE FUNC-

TIONALITY OF THE SAFETY AND PROTECTION

DEVICES ON THE EQUIPMENT.

All the machines are equipped with:

• hold-to-runcontrols(immediatestopofoperationwhenthecontrol

is released);

• controlslogicdispositiontopreventtheoperatorfromdangerous

mistakes;

• thermalswitchonthesupplylineofthepowerunitmotor:avoids

the motor overheating in case of intensive use;

NO MODIFICATION OR CALIBRATION OF THE

OPERATING PRESSURE OF THE MAXIMUM

PRESSURE VALVE OR OF THE HYDRAULIC

CIRCUIT PRESSURE LIMITER IS PERMITTED.

• controlledcheckvalveson:

- opening of self-centering chuck jaws,

- lifting of self-centering chuck.

These valves will stop unintended movement of the jaws and of

wheel clamping self-centering unit.

• Fusesontheelectricsupplylineofself-centeringchuckmotor;

• automaticpowersupplydisconnectwiththeopeningoftheelec-

tric cabinet.

•xedprotectionsandguards.

3.1 Residual risks

The equipment was subjected to a complete analysis of risks ac-

cording to reference standard EN ISO 12100.

Risks are as reduced as possible in relation with technology and

equipment functionality.

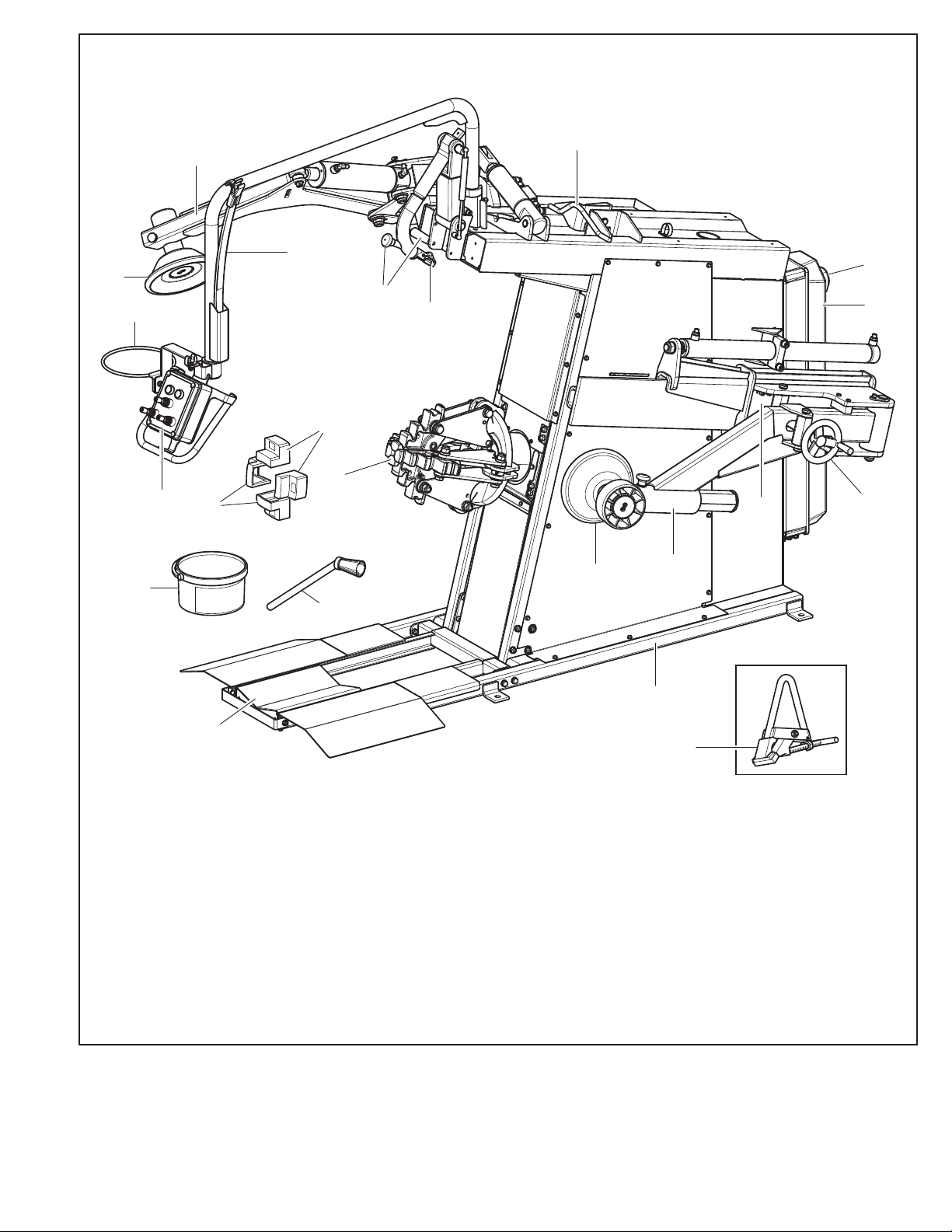

This manual stresses possible residual risks, also highlighted in

pictograms on the present manual and adhesive warning signals

placed on the equipment: their location is represented in “PLATES

LOCATION DRAWING” (see Fig._2).