Brano Z 500 L User manual

BRANO a.s, 747 41 Hradec nad Moravicí

Czech Republic

tel.:+420/ 553 632 318, 553 632 345

fax:+420/ 553 632 407, 553 632 151

http://www.brano.cz info brano.cz

O ERATION MANUAL

SAFETY RINCI LES, O ERATION AND MAINTENANCE

FOR

RO E WITH HOOK

Type: Z 500 L

Read carefully this manual before using this product. This manual contains important

information on safety, use, operation, maintenance and check of the product. Make

this manual available to all responsible persons.

Keep for further use!

Edition 1.

MAY 2006

Evidence number 1-52473-0-1

2

CONTENT

1 DEFINITION ............................................................................................................ 3

2 DEVICE PURPOSE................................................................................................. 3

3 SAFETY PRINCIPLES............................................................................................. 3

3.1 SAFETY SUMMARY ......................................................................................... 3

3.2. SAFETY PRINCIPLES ..................................................................................... 3

4 PACKING, STORAGE AND MANIPULATION......................................................... 5

4.1 PACKING .......................................................................................................... 5

4.2 STORAGE......................................................................................................... 5

5 MAIN TECHNICAL PARAMETERS ......................................................................... 5

6 USE OF THE ROPE ................................................................................................ 5

6.1 GENERALLY..................................................................................................... 5

6.2 SUSPENDING AND BINDING OF THE ROPE................................................. 6

6.3 CHECK OF THE ROPE..................................................................................... 6

6.4 SAFETY WORKING ENVIRONMENT .............................................................. 6

6.5 DURABILITY OF THE ROPE ............................................................................ 6

7 INSPECTION OF THE ROPE.................................................................................. 6

7.1 INSPECTION .................................................................................................... 6

7.2 ROPE RECORDING ......................................................................................... 7

8 PUTTING OUT OF

OPERATION – DISPOSAL....................................................... 7

9 RELATED DOCUMENTATION................................................................................ 8

10 FINAL REQUIREMENTS OF THE MANUFACTURER TO THE CUSTOMER ...... 8

3

1 DEFINITION

! DANGER

Danger is used to indicate the presence of hazard which will

cause death or severe injury if the warning is ignored.

! WARNING

Warning is used to indicate the presence of a hazard which can

cause death or severe injury if the warning is ignored.

! CAUTION

Caution is used to indicate the presence of a hazard which can

cause minor injury if the warning is ignored. Caution can warn

against dangerous practices as well.

Carrying capacity (Q): indicates the maximum permitted mass of the load (working

load limit), which the rope has been designed for under conditions defined by this

operation manual.

2 DEVICE UR OSE

The polyamide rope with the hook (hereinafter referred to as the “rope”) is determined

for manual lifting and lowering of free loads by means of the bricklayer’s pulley of the

Z500 type or other applicable pulley under normal climatic conditions in the workplace.

Consult any other application with the manufacturer prior to use.

The load weight must not exceed the given permitted carrying capacity of the rope and

pulley used as well.

3 SAFETY RINCI LES

3.1 SAFETY SUMMARY

A danger exists when lifting loads, particularly when the rope is not used properly or is

poorly maintained. Since an accident or serious injury could result, special safety

precautions must be observed in the course of work with the rope and its checking.

Safety principles for the bricklayer’s pulley are defined in the separate "Operation

Manual" supplied with any pulley.

! WARNING

NEVER load rope more than carrying capacity shown on the rope label.

ALWAYS work with rope only by man power.

ALWAYS read operation manual and safety instructions.

Keep in mind that the operating staff is responsible for proper binding technique,

lifting and lowering loads.

3.2. SAFETY RINCI LES

4

! WARNING

3.2.1 rior to use

ALWAYS ensure physically fit, qualified and instructed persons older than 18 years

of age, familiarized with this manual and trained in safety conditions and

way of work, operate the rope.

ALWAYS check rope according to the section 7.1before starting to work.

ALWAYS make sure the length of rope is sufficient for intended work.

ALWAYS ensure the carrying rope is clean and without defect.

ALWAYS use original rope only.

ALWAYS ensure the rope is not damaged and is adequately clean.

NEVER pull rope by means of the machine drive.

NEVER use rope with jumped out or missing pawl of hook.

NEVER use rope without label with marking.

NEVER use rope damaged by chemicals.

NEVER allow the rope come into touch with chemicals.

ALWAYS consult use of the rope in non-standard or extreme environment with the

manufacturer or his authorized representative.

3.2.2 When in use

ALWAYS make sure the load is properly seated in the hook.

ALWAYS make sure the hook pawl works in the correct way.

ALWAYS pay attention to the limit positions.

ALWAYS use man power only.

NEVER use mechanically damaged rope.

NEVER hitch load on tip of hook.

NEVER pull rope over any edge.

NEVER expose rope to aggressive environment or excess temperature.

NEVER tie other parts for lengthening the rope.

3.2.3 Maintenance

ALWAYS enable qualified persons to inspect rope regularly.

ALWAYS ensure the rope is clean and undamaged.

5

4 ACKING, STORAGE AND MANI ULATION

4.1 ACKING

Ropes are supplied packed in bundle tied by binding band.

4.2 STORAGE

Store ropes in dry and clean stocks free of chemical influences and vapours.

(1) Roll up the rope so that it is not twisted.

(2) Lubricate the spring of the hook pawl and contact area of the hook eye with

thimble.

5 MAIN TECHNICAL ARAMETERS

Rope carrying capacity

( according to the binding method )

over the pulley directly with eye

Safety

Rope

diamete

r (mm)

Operation

temperatu

re range

Rope

length

(m)

Rope

weight

(kg/m)

8 : 1 ∅11

-20°C

to

+50°C

20 0,77

310 kg

310 kg

248 kg

6 USE OF THE RO E

6.1 GENERALLY

The rope is designed for lifting of loads by means of the Z 500 bricklayer’s pulley,

eventually of other pulley of suitable carrying capacity. Peruse the operation manual

for the rope and bricklayer’s pulley as well prior to use.

! WARNING

The maximum weight of a lifted load must not

exceed the carrying capacity of the rope and used

pulley as well.

When using the Z 500 bricklayer’s pulley it is

necessary to respect the maximum carrying

capacity of the pulley, i.e. the maximum load

constitute 250 kg (see pic. 6.1).

6

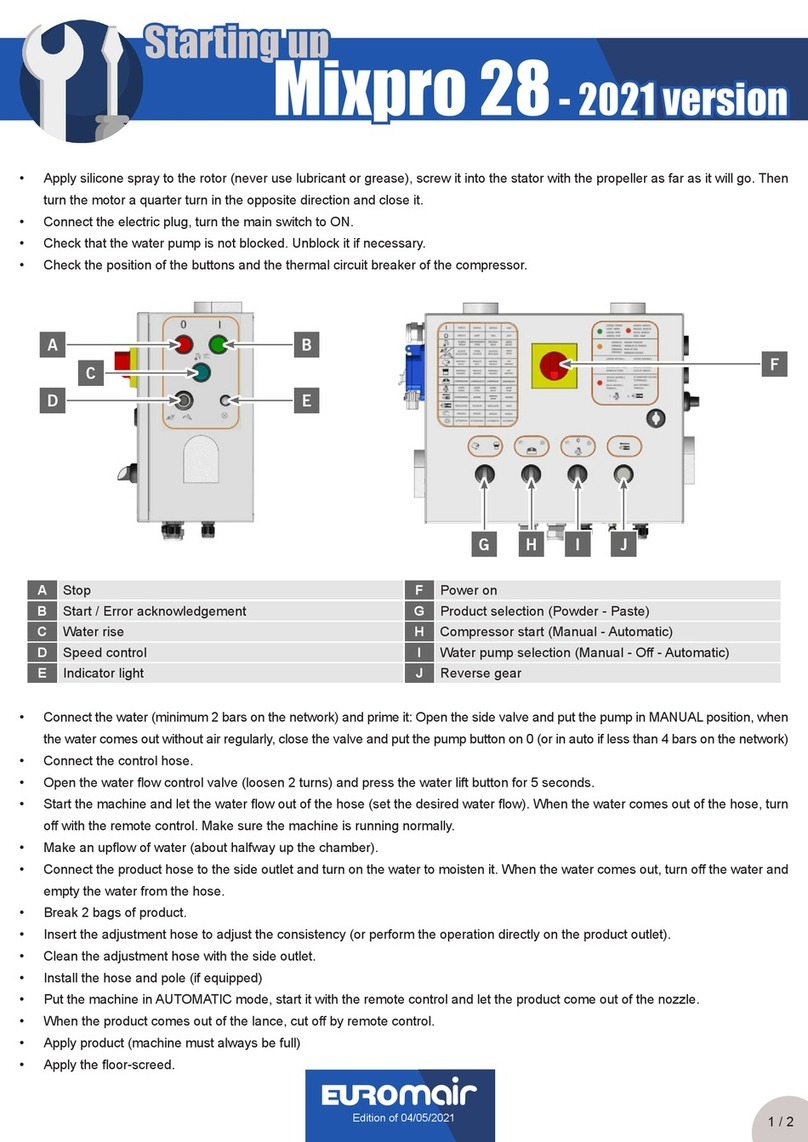

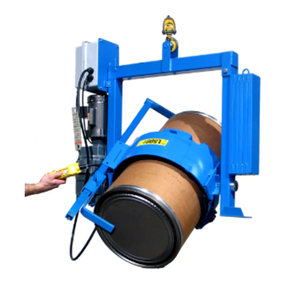

Pic.6.1

6.2 SUS ENDING AND BINDING OF THE RO E

! WARNING

6.2.1 On the rope only such subjects can be suspended or tied that by their shape

and stiffness enable safety binding.

6.2.2 Hook the load or bind it on the eye so that the gravity centre of the load is in

the axis of the hook.

6.2.3 When binding on the eye the carrying capacity of the rope is reduced by 20%.

6.2.4 The free end of the rope must be stretched preventing the rope

disentanglement.

6.3 CHECK OF THE RO E

Check whether the rope is not twisted or damaged. Should the rope is twisted turn it

back to its correct position. Should the rope is damaged replace it.

! CAUTION

(1) First see again through the previous articles of this manual and make sure all steps

were correctly done.

(3) Check whether the hook pawl is properly snapped in.

6.4 SAFETY WORKING ENVIRONMENT

! WARNING

(1) The operating staff must be familiarized in detail with this operation manual and

national regulations relating to the operation of pulleys used in interaction with the

rope.

(2) In the course of work with the rope the operating staff must be equipped with

helmet and gloves.

(3) When working with the rope in limited areas you must prevent the rope does not

rub against obstacle.

6.5 DURABILITY OF THE RO E

The maximum durability of the rope is 5 year from first use. After expiration of this

period ropes must be put of use.

However the real lifetime of the rope is given by the frequency and method of use.

7 INS ECTION OF THE RO E

7.1 INS ECTION

7.1.1 Keep the rope reasonably clean.

7.1.2 The rope and hook must be:

a) visually checked before first use in each shift;

b) checked at least once per:

- 1 month in metallurgy industry and aggressive environments;

- 3 months in other operations including uncovered or outdoor ones;

- 6 months at ropes occasionally used.

7

7.1.3 When inspecting the rope check visually:

- rope marking (marking label with data);

- overall condition of the rope;

- wear and tear;

- change of the rope surface by effect of heat, acids and other chemical

substances;

- condition of eyes and their entangling and condition of cable ends.

Hooks with eye – limits for discard

dimension

"A"

(mm)

dimension

"B"

(mm)

dimensio

n "C"

(mm)

carrying

capacity

(t) standard

limit standard

limit limit max.

0,5 14 12,6 20 18 27,5

7.1.4 The ropes, at which the defects endangering safety, were found out during

inspection or checking procedures, must not be used longer and must be

professionally repaired or put out of operation.

7.1.5 Put out of operation the rope in cases as follows:

a) should the rope is not marked;

b) after expiry of the defined period from the date of its production;

c) at reduction of its cross section by 15% and more (i.e. at min. ∅ of the rope 9,4mm)

d) should the eye entanglement is damaged;

e) when mechanically damaged;

f) should the change of its surface by the effect of heat takes place.

7.2 RO E RECORDING

Keep record of the rope. Except for the evidence number and technical data the

results of performed checks or eventual repairs of the rope must be recorded.

8 UTTING OUT OF O ERATION – DIS OSAL

The rope does not contain any harmful substances. After putting it out of operation

remove the hook and thimble and give it to a firm dealing with waste disposal.

Send the rope for recycling to the address: Singing Rock

Poniklá 317

512 42 Poniklá

8

9 RELATED DOCUMENTATION

EC declaration of conformity

This Operation Manual was elaborated in accordance with following technical

regulations, technical standards and national regulations:

• Ministerial order No.24/2003 of the Coll. of Law as amended (EP and Council

directive 98/37/EC)

• Ministerial order No.23/2003 of the Coll. of Laws as amended (EP and Council directive

94/9/EC)

•

ČSN EN ISO 12100

- 1

• ČSN EN ISO 12100 - 2

• ČSN EN 1050

• ČSN EN 13 157

10 FINAL REQUIREMENTS OF THE MANUFACTURER TO

THE CUSTOMER

Any changes of the product can be realized only based on the approval of the

manufacturer.

When not observing this condition the producer does not guarantee safety of

his product. In this case any manufacturer’s guarantees do not apply to the

product.

Table of contents

Other Brano Industrial Equipment manuals