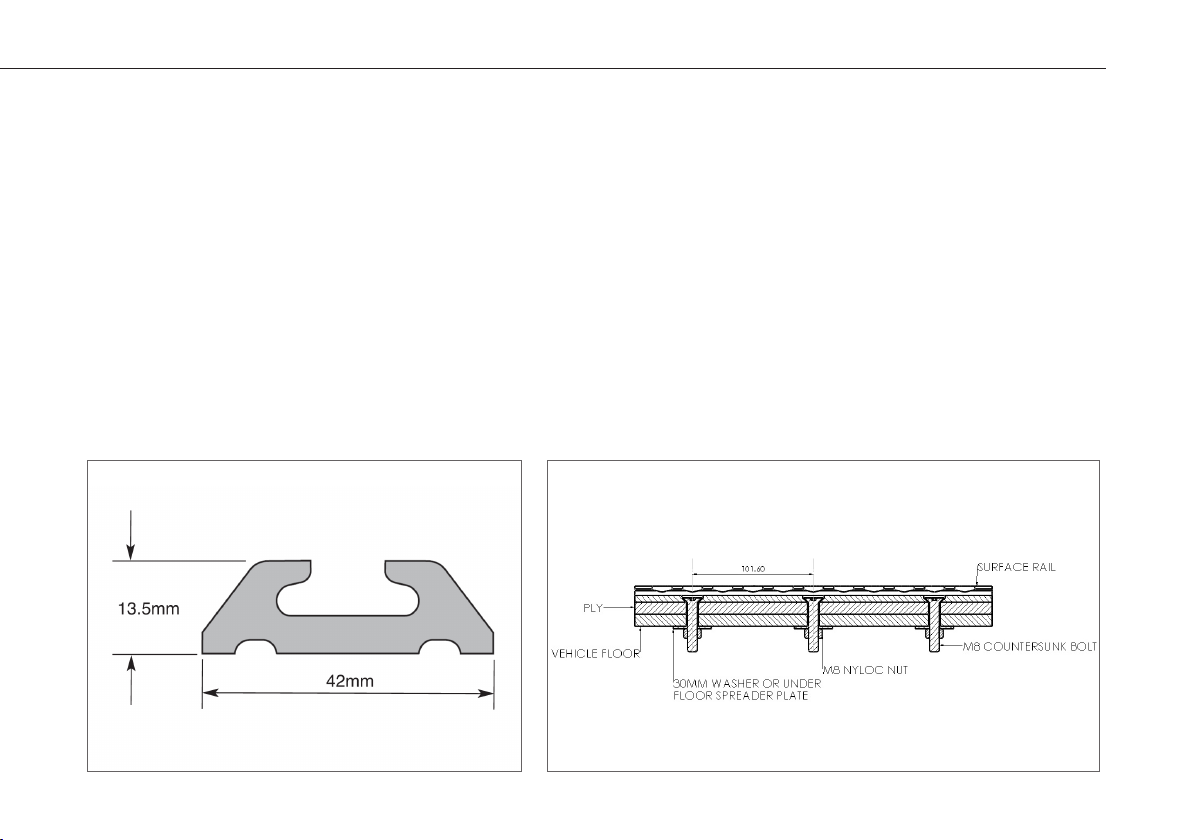

Fitting Low Prole and Surface Rails - Important notice

Fit and use

1. The minimum acceptable length of rail that can safely be installed in a vehicle to accommodate a

wheelchair is 1300 mm. This will allow one wheelchair positioned centrally. The rail must be tted

ensuring fasteners are tted to the extreme end hole positions.

2. For details of the space required within a vehicle for a wheelchair installation, reference should be made

to the guidelines within the British or International standard ISO 10542-1 part 2, ”Technical systems and

aids for disabled or handicapped persons - Wheelchair Tiedown and Occupant Restraint Systems”.

Some vehicle layouts may have problems using Low Prole and Surface rail with pre-drilled countersunk

holes due to under oor obstructions, such as box sections or angle brackets. In these situations where

a hole is “missed”, it is required to generate two new holes, one on either side of the original, with the

maximum distance between them being 101 mm.

3. If the distance of the box section is greater than 101mm, we recommend drilling through the box section

and adding a crush spacer to accommodate the new hole.

4. The original unused hole must nally be lled with a short self-tapping screw with a matching head.

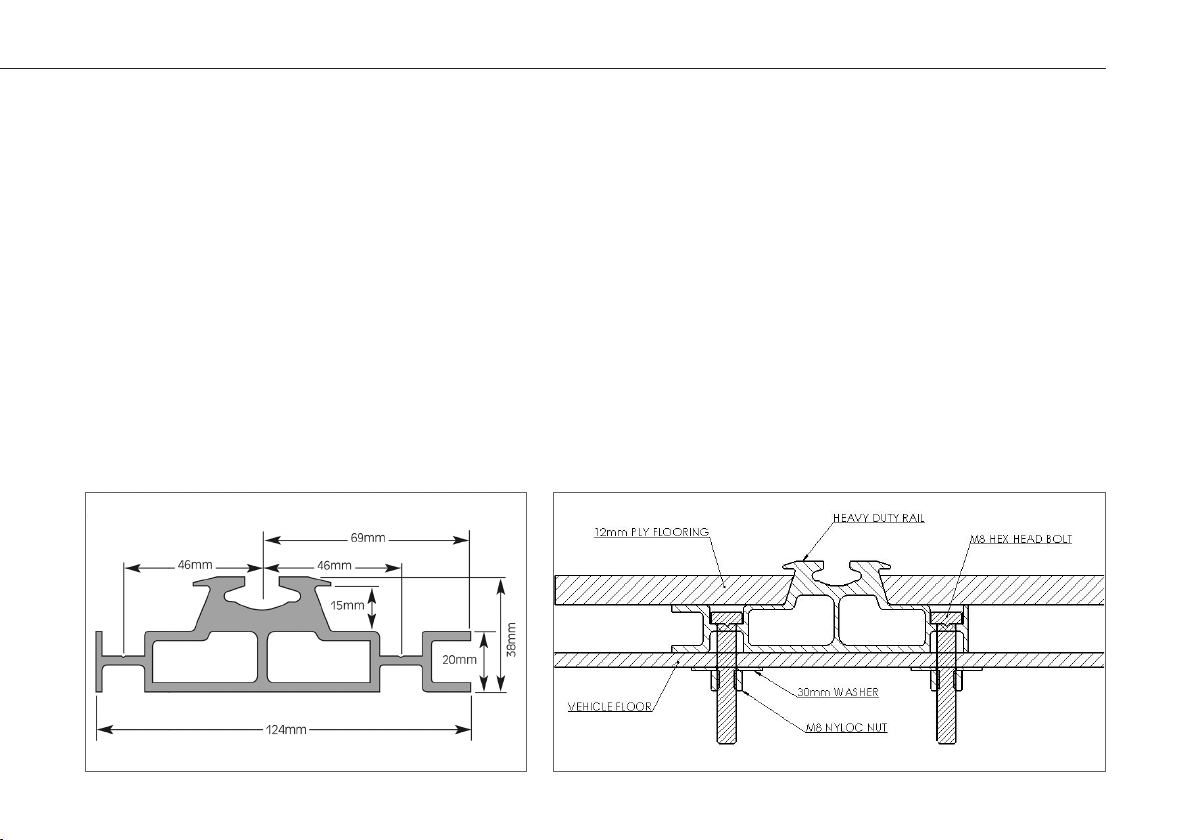

5. It is critical that the installed rail is at along its length and correctly positioned relative to any other rail

lengths tted in the vehicle oor. Elements within a pattern of rails must also be parallel to one another.

This is particularly important if tting Unwin “Fixed Base Equipment” or manufacturing removable seats,

to ensure they will t universally along the rails.

6. We recommend that installers use a rail jig to ensure that paired rails are parallel with each other within

acceptable tolerances. Our seat xtures, when correctly tted to the seat legs, will accept a rail tting

tolerance of +/- 1mm on nominal set leg centres. Rail centre to centre variations outside this tolerance

and may lead to seats jamming or to seats not being able to be tted easily in the rail at difference

positions.

7

Rails

EN

Fit and use