Installation and Maintenance Manual

F15/F30 Ball Valves

Date: August 2021 / Page 1 of 6

®

A Subsidiary of BRAY INTERNATIONAL, Inc.

FLOW-TEK, Inc. Tel: 832.912.2300 © 2021 Flow-Tek, Inc.

8323 N. Eldridge Pkwy #100 Fax: 832.912.2301

Houston, Texas 77041 www.flow-tek.com

INSTALLATION - MAINTENANCE MANUAL

F15 and F30 Series

150 and 300 Lb. Flanged Full Port Ball Valves

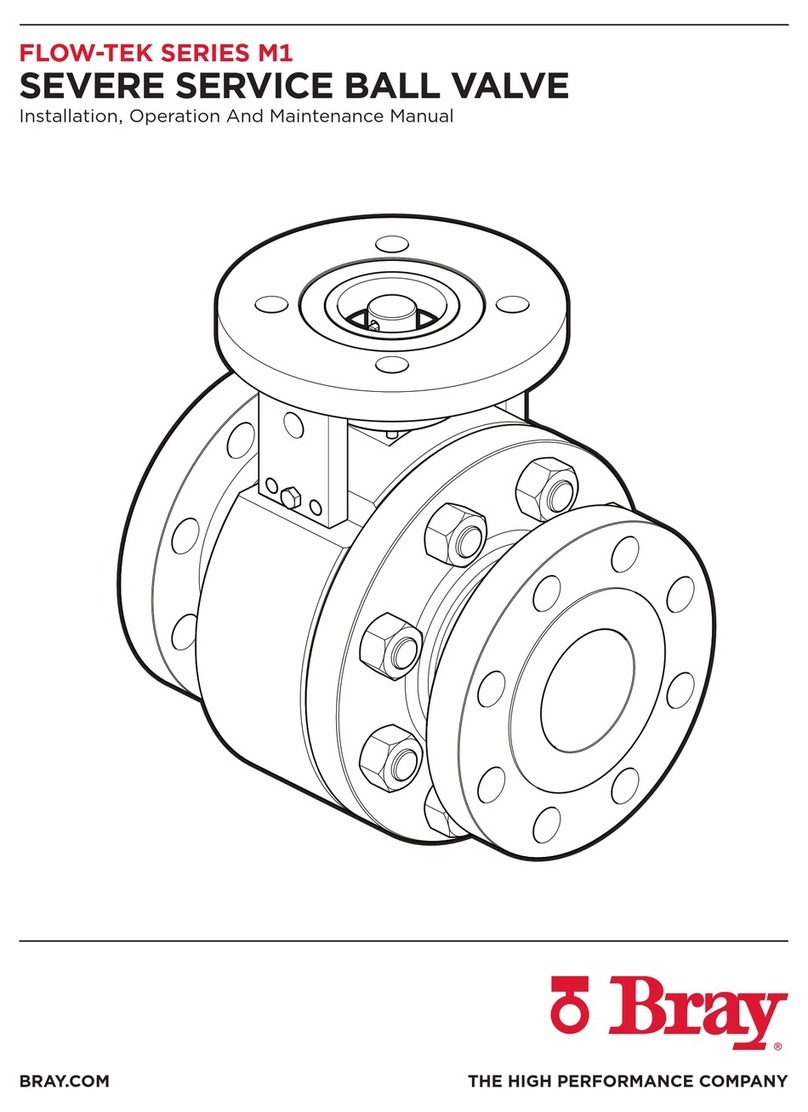

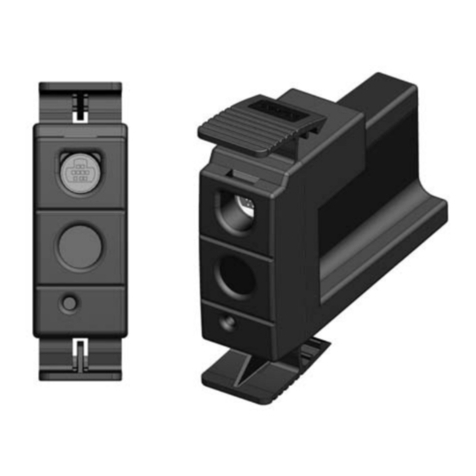

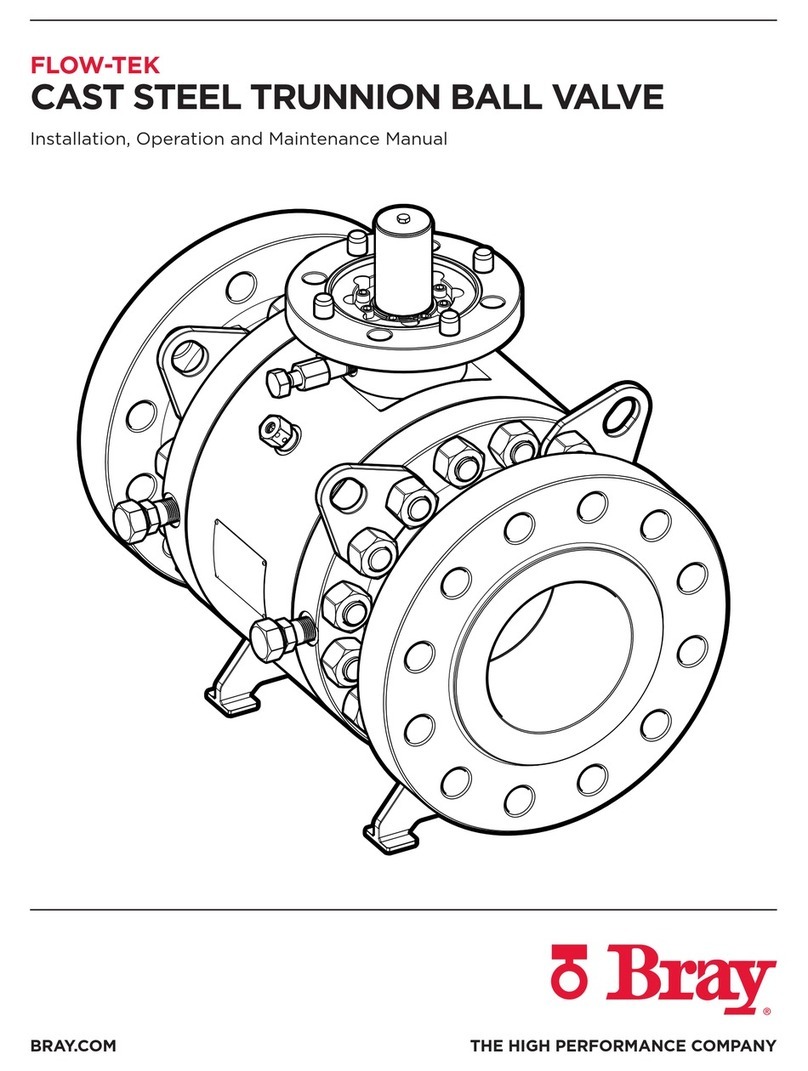

DESIGN

The design features of this valve include a split body, two

piece construction, allowing ease of maintenance without

special tools. These valves feature a “free floating” ball. The

ball is not fixed, but is free to move with the line pressure.

As a result of this feature, these valves are capable of

tight shut-off with flow in either direction or dead-ended,

regardless of the position of the valve in the line.

The downstream seat, opposite the pressurized side of a

closedvalve,mustcarrytheloadexerted bythelinepressure

on the ball, while the upstream seat is subject to little load

or wear. For this reason, it is sometimes possible to increase

usefulseatlifebyturningthevalveend-for-endin thepipeline.

1. USE

The valve should be maintained as part of a preventative

maintenance program and in accordance with Flow-Tek’s

recommended pressure, temperature and corrosion limits

to insure a long service life. During shipment, storage, and

in operation, the valve should be fully open or fully closed

(“open” is preferred for shipping and storage). Do not use

in throttling service without investigating flow and pressure

conditions.

WARNING: Beforeinstallingthis equipment, confirm

that it is suitable for the intended service.

The identifications tags describe the maximum allowable

service conditions for this product.

Be sure that the installation is protected by appropriate

pressure control and safety devices to insure that acceptable

limits are not exceeded.

2. OPERATION

Operation of the valve is done by turning the handle a 1/4

turn (90 degree turn). CW to close, CCW to open.

A. VALVE OPEN POSITION

The handle is parallel with the pipeline.

B. VALVE IN CLOSED POSITION

The handle is perpendicular to the pipeline.

Valves with actuators should be checked for actuator -valve

alignment.Misalignment willresultin high operationaltorque

and damage to valve stem and seals.

3. STEM SEAL ADJUSTMENT

1. For 1/2”- 2”, if slight leakage is noted at stem,

straighten lock washer tab, tighten stem nut to flatten

BellevilleWashers,backstemnut off1/4turn,secure

lock washer tab.

2. For sizes larger than 2”, simply tighten gland bolts

evenly until leak stops. Do not over tighten.

4. BALL SUPPORT PACKING ADJUSTMENT

Ball Support packing adjustment may be required in the

rare event that the pin packing develops a leak. The below

instructionsshouldbe followedintheeventofaleaktoadjust

the packing. Note that the position of the ball support comes

pre-set from the factory. Adjustment of the pin seat position

may only be required if the ball support components have

been replaced.

1. Loosen the set nut (35) on the tuning screw (36)

by turning the nut counter-clockwise while holding

the screw stationary with an open end wrench.

2. With the set nut (35) loose, turn the support nut

(34) clockwise to compress pin packing (32) as

necessary to stop leakage of line media around

support nut threads.

3. Using finger pressure only, rotate the tuning screw

(36) in the clockwise direction until resistance is

felt from the support pin seat (31) contacting the

ball surface. Then, rotate the tuning screw (36) ¼

turn in the counter-clockwise direction.