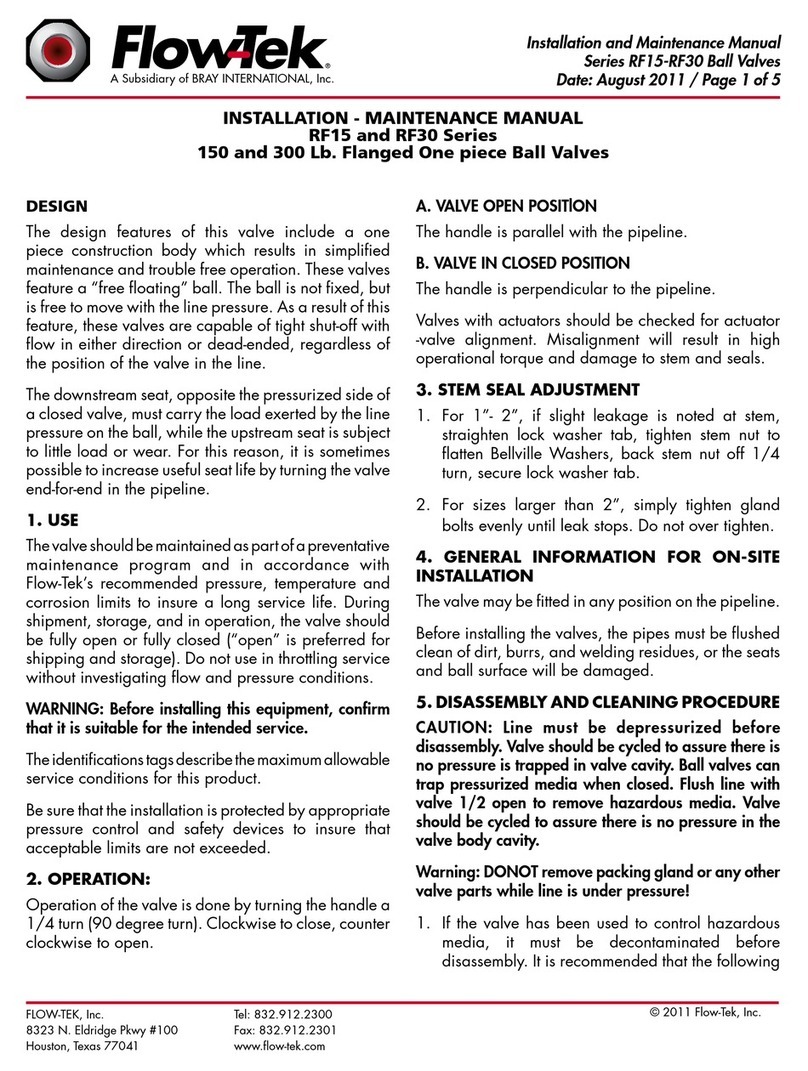

Installation and Maintenance Manual

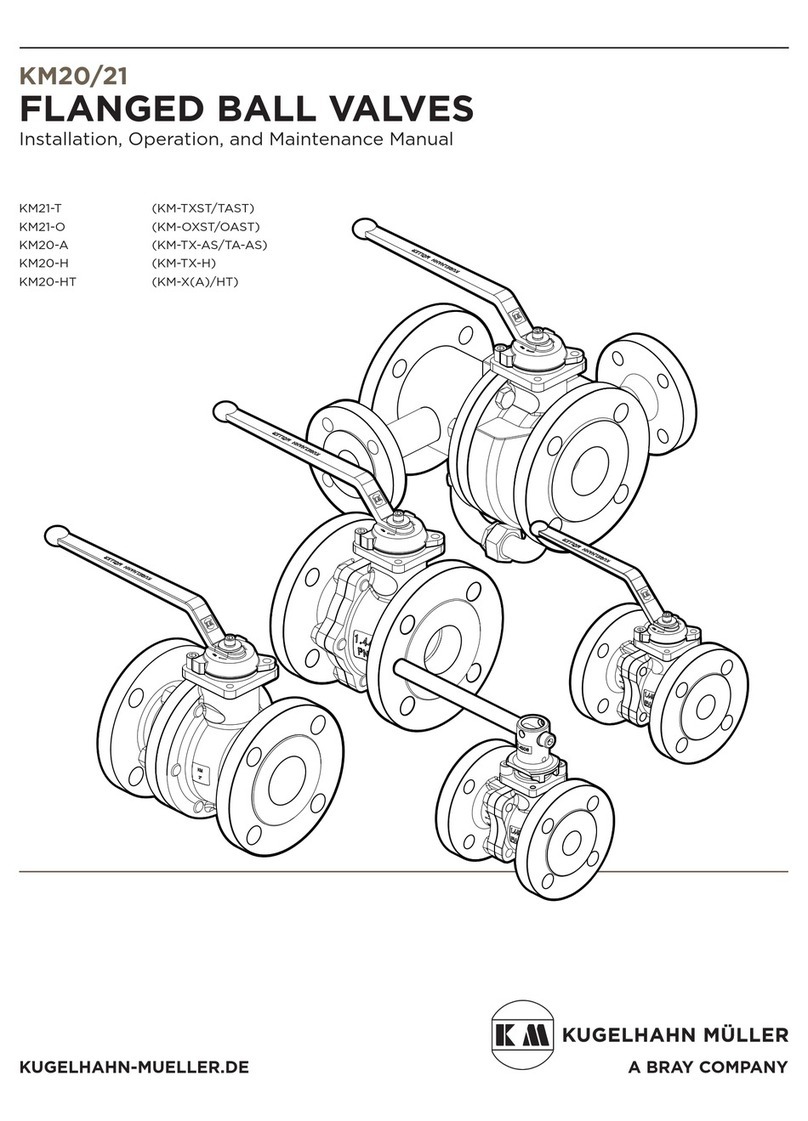

Series RF15-RF30 Ball Valves

Date: August 2020 / Page 2 of 5

®

A Subsidiary of BRAY INTERNATIONAL, Inc.

FLOW-TEK, Inc. Tel: 832.912.2300 © 2020 Flow-Tek, Inc.

8323 N. Eldridge Pkwy #100 Fax: 832.912.2301

Houston, Texas 77041 www.flow-tek.com

2. As shipped from the factory, valves contain a Silicone

based lubricant. This is for break-in and may be removed,

if it is objectionable for a particular application, by

disassembling and solvent washing.

Stem seal leakage may be corrected without disassembly

by tightening the packing gland nut until such leakage stops.

If the leakage continues or valve operating torque becomes

excessive, the seals are worn and replacement will be

necessary.

If the valve has been used to control hazardous media, it must

be decontaminated before disassembly.

It is recommended that the following steps be taken for safe

removal and assembly.

As shipped from the factory, Valves contain Silicone based

lubricant. This is for break-in and may be removed by

disassembly and solvent washing.

6. DISASSEMBLY

Stem seal leakage may be corrected without disassembly.

Tighten the packing gland nuts until leakage stops. If leakage

continues or valves operating torque becomes excessive, the

seals are worn and replacement will be necessary.

Warning: DO NOT remove packing gland or any

other valve parts while line is under pressure! Under

no circumstance! Line must be depressurized before

disassembly.

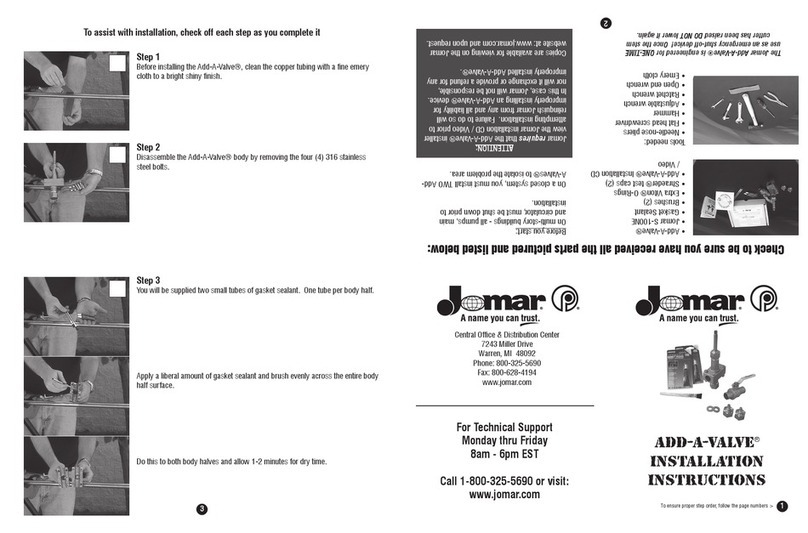

A. Remove valve from line and clamp in vise with handle

and removable body insert in an accessible position.

B. Put ball in the OPEN position. Insert spanner wrench

into slot in the retainer and rotate the counter-clockwise.

C. Remove body seal from body. Use caution to prevent

damage to metal parts; discard seal.

D. Turn handle to CLOSED position so that the stem tang

and ball slot are in line with the port opening. Lift or roll

ball out of insert end.

E. If stem seals are to be replaced, remove handle retainer

nut, stop plate and packing gland. Push stem into valve

cavity and remove from retainer end.

F. Remove seats from insert and body cavity, remove stem

seals.

7. VISUAL INSPECTION:

Clean and inspect metal parts. It is not necessary to replace

the hall and stem unless the seating surfaces have been

damaged by abrasion or corrosion. Replacement of all soft

parts whenever the valve is disassembled for reconditioning

is strongly recommended. This is the surest protection against

subsequent leakage after valve assembly. The replacement

parts can he ordered in kit form.

NOTE: The valve may be assembled and operated

dry where no lubricants are allowed in the system;

however, a light lubrication of mating parts will aid

in assembly and reduce initial operating torque.

Lubricantused must becompatible with theintended

line fluid.

8. ASSEMBLY:

1. Install one seat in the body cavity with the spherical

curvature facing the ball.

2. Install thrust washer on stem and slide the stem up

through the body. Install packing and packing gland

with packing gland bolt.

3. Install stop plate, handle and handle nut.

4. Turn the handle to the CLOSED position. Line up the ball

slot with the stem tang and slide the ball into position.

Open the valve to hold the ball in place.

5. Install the remaining seat in the insert with the spherical

curvature facing the ball. Install body gasket.

6. Carefully center the insert and press down until the

threads are engaged. Start the threads clockwise by

hand tightening with the tool used for removal. The end

cap should be tightened until the end cap is flush with the

flange face. The insert bottoms out in a metal to metal fit.

7. Cycle the valve slowly, with a gentle back and forth

motion, to build gradually to the full quarter turn. By

cycling slowly, the seat lips will assure a permanent seal

shape against the ball. A fast turning motion, at this point,

may cut the seats before they have a chance to form the

proper seal.

8. If a tester is available, pressure test valve prior to

reinstallation.