Bray TRI LOK User manual

The

High

Performance

Company

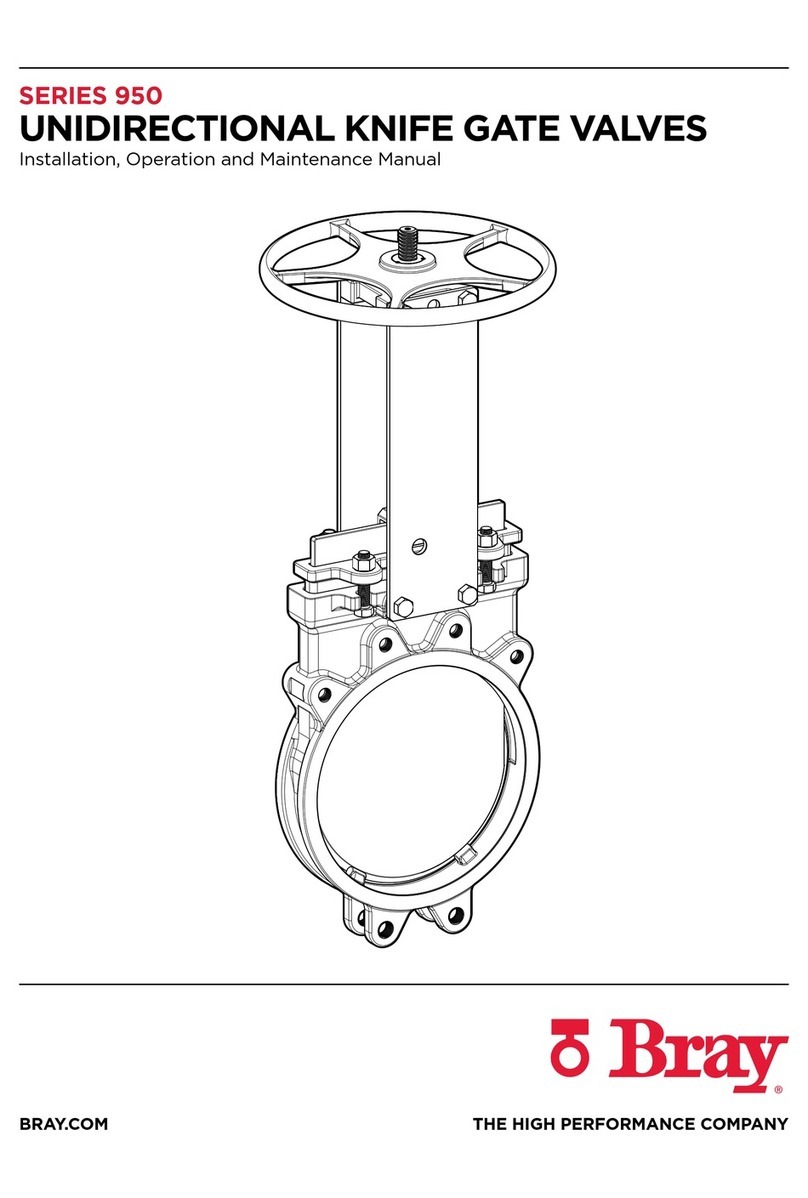

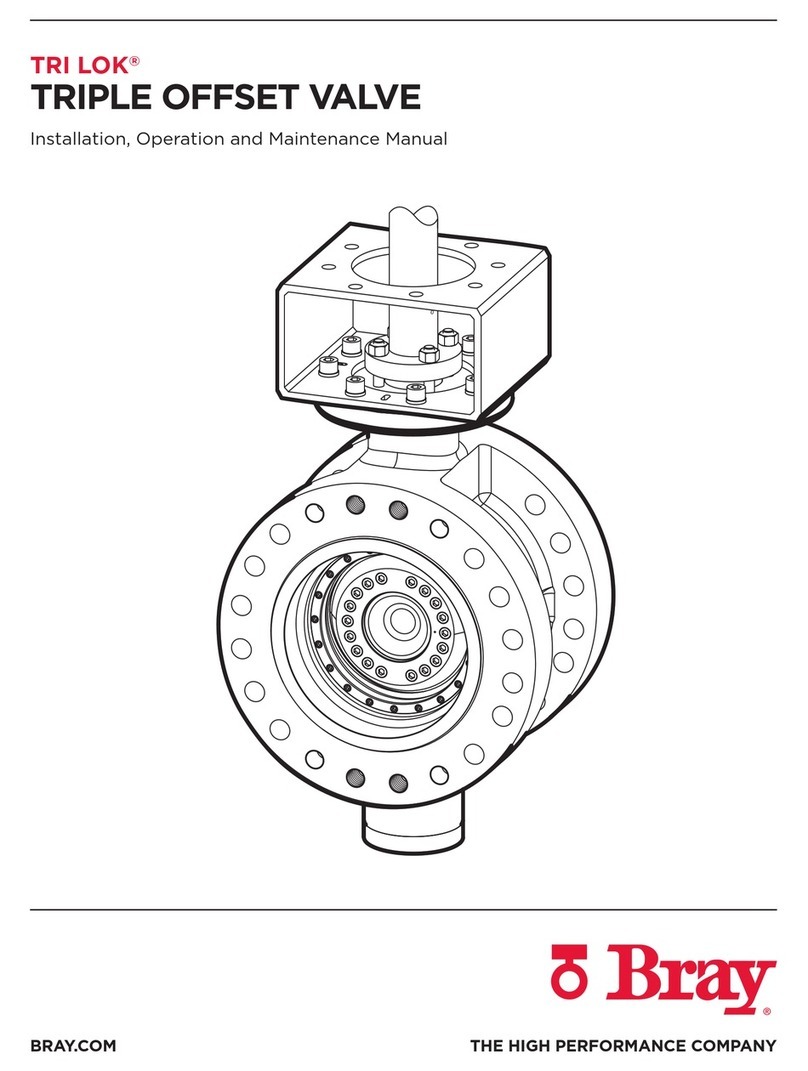

TRI LOK

TRIPLE OFFSET VALVE

OPERATION AND MAINTENANCE MANUAL

1

BRAY Tri Lok Triple Offset Valve

Operation and Maintenance Manual

Table of Contents

1.0 Safety Information .........................................................................................2

1.1 DenitionofTerms ........................................................................................2

1.2 ATEXDirective94/9/EC ...............................................................................2

2.0 Introduction....................................................................................................3

3.0 Installation......................................................................................................3

3.1 Table1:Min.AllowablepipeIDforInstallation...........................................4

4.0 Maintenance...................................................................................................5

4.1 StemSealReplacement..................................................................................5

4.2 Table2:No.ofStemSeals&TorqueValuesforGlandRetainingUnits ......5

4.3 BodySeatReplacement .................................................................................6

4.4 DiscSealRingReplacement..........................................................................7

4.5 Table3:TighteningTorqueValues

ForIndividualBodySeats&DiscSealRings...............................................9

5.0 CompleteValveDisassembly.........................................................................9

6.0 ValveAssembly............................................................................................10

7.0 ValvePartDiagram ......................................................................................11

FOR MORE INFORMATION ON THIS PRODUCT AND OTHER BRAY PRODUCTS

PLEASE VISIT OUR WEBSITE – www.bray.com

2

BRAY Tri Lok Triple Offset Valve

Operation and Maintenance Manual

1.2 ATEX DirEcTivE 94/9/Ec

WARNING

When using this product in hazardous environments,

the national directives and laws which apply in your

country for hazardous areas must be followed. The

specications of the examination certicate valid in

country of operation must be also observed.

1.2.1 MArking

Certificate Number: LRVL 10ATEX0003X

Certification Code:

Non-Mining Applications

0038 II 1 G c

Mining Applications

0038 I M1 c

Ambient Range: TX See Special Conditions for Safe Use

Serial Number: As appropriate

Year of Manufacture:

Warnings:

1.2.2 Sp EciAlconDiTionS for SAfE USE

The following factors must be carefully considered in

order to ensure the valve is compatible with the atmosphere

in which it is applied. The system designer and/or end

user should be formally address each item and carefully

document the reasoning behind specic measures taken

to ensure continued compliance throughout the life of

the Tri Lok valve.

MATEriAlconSiDErATionS

Titanium is not to be used in Group I, mining applications

due to the potential of ignition due to mechanical sparks

from impacts such as a spanner being dropped on the

valve. Please see ES11A-0736 for details regarding

material limitations.

TEM p ErATUrE conSiDErATionS

The surface temperature of the Tri Lok valve is wholly

dependent onthe ambient temperaturein combination with

the temperature of the process medium. The maximum

surface temperature of the Tri Lok valves may be calcu-

lated from the maximum ambient temperature plus the

maximum process medium temperature as shown below:

Equation 1 - Surface Temperature Calculation

Ts(max) = Ta(max) + Tp(max)

The system designer is responsible for ensuring the

maximum temperature, either inside the valve body or on

the external surface, will remain well below the ignition

temperature of the atmosphere. Additional protective

devices may be required to ensure a sufcient thermal

safety margin, including but not limited to: thermal shut-

off devices, cooling devices.

STATic ElEcTriciTy conSiDErATionS

Where the process medium is a liquird or semi-solid

material with a surface resistance in excess of 1 G-ohms,

special precautions should be taken to ensure the process

does not generate electro-static discharge. This may be

done through ensuring the ow rate of the process media

remains below 1 m/s or providing sufcient discharge

1.0 Safety InformatIon

1.1 DEfiniTion of TErM S

WARNING indicates a potentially hazardous situation which, if not avoided, could result

in death or serious injury.

CAUTION indicates a potentially hazardous situation which, if not avoided, may result in

minor or moderate injury.

NOTICE

used without the safety alert symbol indicates a potential situation which, if

not avoided, may result in an undesirable result or state, including property

damage.

!

!

!

3

BRAY Tri Lok Triple Offset Valve

Operation and Maintenance Manual

points along the process path to eliminate electro static

build-up. Consultation to EN 50404 is recommended.

Appropriate grounding may be necessary through the

use of grounding straps or other means.

STrAy ElEcTric cUrrEnT conSiDErATionS

Where the Tri Lok valve is used near sources of high cur-

rent or magnetic radiation, provisions shall be made to

ensure a secure bonding to earth ground so as to prevent

ignition due to inductive currents or a rise in temperature

due to these currents.

filTrATion of procESS MEDiUM

conSiDErATionS

Special consideration should be made regarding the l-

tration of the process medium if there is a potential for

the process medium to contain solid particulates. The

process medium is recommended to be ltered to allow

particles no greater than 1.0 mm in diameter through the

valve assembly where there is a high probability of solid

particulates. Larger particulate sizes may be deemed ap-

propriate based on the possibility of particulates within

the process medium and the area classifcation. The deci-

sion regarding ltration levels and limits should be well-

documented by the system designer and/or end user to

ensure continued compliance through the life of the valve.

2.0 inTroDUcTion

This manual covers Tri Lok valves in the following range:

ASME Classes: 150 and 300

Sizes: 3” - 24” (800 mm - 600 mm)

Body Style: Wafer, Lug, Double Flange and

Gate face-to-face conguration

The Bray Tri Lok metal seated valve is fully rated to

ASME B16.34.

The design of the valve complies with ASME B16.34

and API 609.

Tri Lok is torque-seated. Torque must be continually ap-

plied by an actuation device (manual gearbox or power

valve actuator) to the valve stem to ensure the valve seals

against the line pressure.

WARNING

Do not remove or de-energize actuation devices while

the valve is under line pressure.

The valve is inherently re safe, and has been qualied

to ISO 10497 and API 607, fth edition standards.

Tri Lok is suitable for bi-directional zero leakage tight

shutoff. More actuation torque is required to seal the

valve in the non-preferred direction.

The preferred direction of valve installation is with the

upstream line pressure on the stem side and the body seat

on the downstream side. The non-preferred direction of

valve installation is with the upstream line pressure on

the body seat side and the stem on the downstream side.

The preferred direction of ow is indicated by an arrow

on the valve nameplate.

3.0 inSTAllATion

1. Tri Lok is designed to be installed between ASME

B16.5 and ISO 7005 anges. When the valve is open,

a portion of the disc may protrude into the pipe. Wafer

and lug congurations will protrude on both sides

of the valve. In the double ange version and some

gate sizes, the open disc may protrude into the pipe

on the seat side of the valve. Adjacent piping must be

large enough to allow the open disc to clear the pipe.

Table 1 ( Pg. 4 ) shows both the minimum allowable pipe

ID and standard pipe ID. In general, Class 150 valves

will clear Schedule 40 pipe, and Class 300 will clear

Schedule 80 pipe adequately.

2. The valve closes with clockwise rotation of the stem,

and opens with counterclockwise rotation.

CAUTION

Avoid uncontrolled rotation of the disc beyond

fully-open position (counterclockwise) as this could

damage the sealing surfaces.

Over-rotation into closed position (clockwise) is not

possible, as the disc will stop against the seat in the

normal operating manner.

!

!

4

BRAY Tri Lok Triple Offset Valve

Operation and Maintenance Manual

3. To benet from the most favorable low operating torque

and best sealing conditions, install the valve with the

stem on the upstream (pressure side) of the installation.

The valve tag is marked with an arrow indicating the

preferred direction of the ow in the line.

4. Whenever possible, install the Tri Lok with the stem

in horizontal position with respect to the ground. If

this installation is not possible, Bray recommends

orienting the stem at an inclined angle with respect

to the ground,with the actuator above the horizontal

centerline. This will prevent process debris from ac-

cumulating in the stem bearing area. In addition, with

the valve stem horizontal, the weight of the disc will

be supported along the full length of bearing journals.

These positions will minimize operational wear.

5. Flange gaskets should conform to the requirements

of ASME B16.20 (supersedes API Standard 601) for

ASME B16.5 anges. Spiral wound gaskets, such as

Flexitallic® CG or CGI series, conforming to ASME

B16.20 are recommended.

6. When bolting the valve into the line, use standard

bolting torque as recommended by respective piping

standards. The valve body seat is independent of the

ange bolting, hence additional force from the ange

bolts is not required.

Notes for Table 1:

a. Minimum allowable ID of pipe with recommended

clearances (per API 609) have been calculated by

adding the minimum recommended diametric clear-

ance to the larger chordal dimension of the disc at

the valve face.

b. This table assumes that the valve is perfectly centered

in the pipe anges.

c. A minimum of 1/16” (1.6 mm) thick gasket is used

between the pipe ange and the face of the valve body.

d. When using a pipe whose ID is smaller than the

recommended minimum allowable ID of pipe with

adequate clearance, a spacer of appropriate thickness

and a proper gasket could be used at the ange face

to clear the disc. Alternately, for butt-welded pipe

anges, a 45 degree chamfer of required size to clear

the disc edge could be provided. Chamfering which

would cut into the internal weld at the ange ID is

not allowed in slip-on pipe anges.

TAb lE 1 - MiniM UM AllowAb lE p ip E iD for Tri lok inSTAllATion -

STAnDArD p ip E iD givEn for rEfErEncE.

Valve Size

Pipe Size

In (mm)

Min. Pipe ID.

Class 150

In (mm)

Min. Pipe ID.

Class 300

In (mm)

Nom. Pipe ID.

Schedule 40

In (mm)

Nom. Pipe ID.

Schedule 80

In (mm)

Nom. Pipe ID.

Schedule 100

In (mm)

3 (80) 2.0 (50.8) 2.0 (50.8) 3.1 (77.9) 2.9 (73.7) -

4 (100) 3.1 (77.7) 3.1 (77.7) 4.0 (102.3) 3.8 (97.2) -

6 (150) 5.0 (127.8) 4.8 (120.7) 6.1 (154.1) 5.8 (146.3) -

8 (200) 6.8 (171.7) 6.5 (164.6) 8.0 (202.7) 7.6 (193.7) 7.4 (189.0)

10 (250) 8.7 (220.5) 8.6 (218.9) 10.0 (254.5) 9.6 (245.2) 9.3 (236.6)

12 (300) 10.6 (270.0) 10.9 (276.9) 11.9 (303.2) 11.4 (289.0) 11.1 (281.0)

14 (350) 11.8 (300.0) 11.6 (293.9) 13.1 (333.3) 12.5 (317.5) 12.1 (308.0)

16 (400) 13.8 (349.5) 13.2 (335.0) 15.0 (381.0) 14.3 (363.6) 13.9 (354.0)

18 (450) 15.5 (392.4) 15.0 (380.7) 17.0 (428.7) 16.1 (409.6) 15.7 (398.5)

20 (500) 17.7 (450.3) 16.8 (427.2) 18.8 (477.9) 17.9 (455.6) 17.4 (442.9)

24 (600) 21.1 (539.9) 20.7 (526.5) 22.6 (574.7) 21.6 (547.7) 20.9 (531.8)

*See Notes below

5

BRAY Tri Lok Triple Offset Valve

Operation and Maintenance Manual

4.0 MAinTEnAncE

WARNING

Reasonable precaution should be taken before begin-

ning any work on the valve.

Protective clothing, as required by specic line uid

and appropriate safety codes, should be worn.

Depressurize the line and close the valve before

removing the actuation device from the valve.

Depressurize the line before loosening any packing

gland nuts.

Do not pressurize the line without an actuation device

properly installed and working on the valve.

CAUTION

The Tri Lok valve must be in closed position to be

removed from the line. Otherwise, the sealing edge

could be damaged.

1. When replacing the body seat and/or disc seal ring

with the valve in the line in dead-end installation,

or with the piping on the body seat side removed,

depressurize the line and marginally crack-open the

disc before loosening any of the valve trim fasteners.

2. Begin all work on a valve that has been removed from

the line by cleaning the valve, removing any grit or

scale. When handling the valve, care should be taken

not to scratch the disc seal ring, the body seat, and

gasket faces on both sides of the valve.

3. Replacement body seats, disc seal rings, and other

parts are available from authorized distributors.

Contact your Bray distributor or sales representative

for details on price and delivery.

4.1 STEM SEAlring rEp lAcEM EnT:

Refer to the parts diagram for parts identication by

reference numbers in parentheses. ( Pg. 13 )

1. If the valve is installed in the line, depressurize the

line. Remove operator or actuator from the valve.

Remove socket head cap screws and lock washers

(25). Remove mounting bracket or mounting plate

(26), depending on valve size. Note assembly posi-

tions of the operator or actuator and the mounting

hardware for subsequent reinstallation.

2. Remove packing gland retainer nuts (24) and lock

washers (23). Remove gland retainer (22), anti-

blowout retaining ring or split ring (21) depending

on valve size and gland ring (19).

3. Extract all stem seals (18A and 18B), taking care not

to scratch the stem or the bore of the stufng box.

!

TAb lE 2. - nUM b Er AnD Typ E of STEM SEAlringS AnD TorqUE vAlUES

for glAnD rETAining nUTS.

Valve Size

in (mm)

Number of Rings

Class 150

Number of Rings

Class 300

Gland Nut Torque

Class 150

lb-in. (Nm)

Gland Nut Torque

Class 300

lb-in. (Nm)

3 (80) 2 B plus 2 F 2 B plus 2 F 35 (4.0) 45 (5.1)

4 (100) 2 B plus 2 F 2 B plus 2 F 35 (4.0) 45 (5.1)

6 (150) 2 B plus 2 F 2 B plus 2 F 45 (5.1) 65 (7.3)

8 (200) 2 B plus 2 F 2 B plus 2 F 45 (5.1) 80 (9.0)

10 (250) 2 B plus 2 F 2 B plus 2 F 65 (7.3) 100 (11.3)

12 (300) 2 B plus 2 F 2 B plus 2 F 65 (7.3) 100 (11.3)

14 (350) 2 B plus 4 F 2 B plus 6 F 80 (9.0) 125 (14.1)

16 (400) 2 B plus 4 F 2 B plus 7 F 100 (11.3) 150 (16.9)

18 (450) 2 B plus 7 F 2 B plus 7 F 100 (11.3) 150 (16.9)

20 (500) 2 B plus 7 F 2 B plus 8 F 100 (11.3) 150 (16.9)

24 (600) 2 B plus 8 F 2 B plus 6 F 150 (16.9) 200 (22.6)

B = braided carbon yarn packing stem seal ring, F = solid formed graphite stem seal ring.

!

6

BRAY Tri Lok Triple Offset Valve

Operation and Maintenance Manual

Do not remove the thrust washer (17) unless further

valve disassembly is required.

4. Examine the stufng box bore and the stem and clean

as necessary to remove any corrosion or foreign mat-

ter before installing new stem seals.

5. Install new stem seals in stufng box one at a time.

The number and type of stem seal rings for individual

valve sizes and pressure class are listed in Table 2.

Insert bottom braided packing ring stem seal (18A)

into the stufng box. The splice in this ring has to

be oriented perpendicular to ow direction. Using

packing tube, tamp the braided packing ring stem

seal rmly into position.

6. Insert all solid graphite stem seal rings (18B). If the

rings are not endless, stagger splices at 180 degrees

intervals, making sure the splices remain located

perpendicular to the ow direction. Use a packing

tube to set individual rings rmly, but without exces-

sive effort as not to crush the graphite.

7. Insert top braided packing ring stem seal ring (18A)

into the stufng box. The splice in this ring must be

oriented perpendicular to the ow direction, and at

180 degrees to the splice in the ring immediately

below. Using a packing tube, tamp the top ring rmly

into position.

8. Reinstall gland ring (19), anti-blowout retaining ring

(21) and gland retainer (22). Re-install lock washers

(23) and nuts (24). Tighten gland nuts (24) evenly and

alternately to the proper torque value given in Table 2.

9. Reinstall mounting bracket or mounting plate (26)

with cap screws and lock washers (25). Remount

actuation device on top of the valve.

10. Operate the valve open and closed several times

to check for binding and to set the stem seal rings.

Loosen gland nuts (24) and retighten to torque value

given in Table 2.

4.3 boDy SEAT rEp lAcEM EnT:

Refer to the parts diagram for parts identication by

reference numbers in parentheses. ( Pg. 13 )

Bray recommends that both the body seat (8) and the disc

seal ring (13) be replaced at the same time. However,

individual components are not matched in pairs and can

be replaced separately if desired.

CAUTION

Exercise extra care when handling the body seat and

disc seal ring to avoid damage to the sealing areas.

Close the valve and remove the operator or actuator

as applicable. Place the valve on a at stable surface,

with the body seat (8) facing up.

1. Carefully cleanthe surface ofthe body seatand remove

all foreign matter from the hex sockets of the seat

retaining cap screws (9). Blow out the gap between

the body seat OD and the wall of the retaining cavity

in valve body (6). Apply a suitable penetrant (WD40,

etc.) into the gap between the body seat OD (8) and

the body (6) to help in extracting of the body seat

(8) from the body cavity.

2. Using a suitable wrench, remove all body seat retain-

ing socket cap screws (9).

3. Using a hard wood or aluminum drift and a light

hammer, tap the top of the body seat (8) lightly all

around to loosen the body seat in the retaining cavity.

4. Using full-threaded bolts or suitable threaded rod

matched to the threads in all tapped jacking holes,

commence jacking the body seat (8) evenly out from

the retaining cavity. Tap the body seat lightly with

the drift as necessary to keep it in alignment with the

walls of the retaining cavity in the body (6) while

jacking. Remove the body seat (8) from the body (6).

Table 3 lists the thread sizes of jacking bolts for individual

valve sizes. ( Pg. 9 )

5. Using soft tools and suitable wire brush, carefully

clean any remnants of old gasket and foreign matter

within the retaining cavity. Blow out all threaded

holes and gasket grooves with compressed air.

6. Remove the disc seal ring retaining screws (10) and

lock washers (11) from the disc seal ring retainer

(12). Remove the disc seal ring retainer (12). If the

old disc seal ring (13) is to be reinstalled, extract it

carefully. Wipe the disc seal ring (13) clean, removing

!

7

BRAY Tri Lok Triple Offset Valve

Operation and Maintenance Manual

all remnants of old gasket and foreign matter. Place

the old disc seal ring (13) aside for reinstallation

(if not replacing the disc seal ring with a new one).

7. Using soft tools and suitable wire brush, carefully

clean any remnants of old gasket and foreign matter

from the face of the disc (15). Blow out all threaded

holes and the gasket groove with compressed air.

8. Place a new disc gasket (14) into the groove on the

disc face (15). The mating side of the disc gasket can

be lightly sprayed with adhesive to improve retention

in the groove. Place the disc seal ring (13) onto the

disc, making sure the alignment line on the disc seal

ring matches the locating dimple in the disc face.

Place the disc seal retainer (12) over the disc seal

ring. Apply anti-seize compound to the disc seal ring

retaining cap screws (10). Install all disc seal ring

retaining cap screws (10) with lock washers (11).

The disc seal retaining cap screws (10) should to

be fully threaded into the disc (15), but remain only

nger-tight at this time.

9. Place the body seat gasket (7) into the groove in the

body seat (8). It is highly recommended to apply a

light lm of spray adhesive to the mating side of the

body seat gasket to secure its position in the groove.

Apply a suitable lubricant to the sealing surfaces of

the body seat (8) and disc seal ring (13). Insert the

body seat (8) into the body (6) over the disc seal

ring (13), making sure the alignment dimples in the

body seat (8) and the retaining cavity in the body

(6) both match. Apply anti-seize compound to body

seat retaining cap screws (9) and install the screws

(9) nger-tight.

10. Verify that all four alignment marks match (body,

body seat, disc seal ring and disc seal ring retainer)

and then tighten the body seat retaining cap screws

(9) evenly and rmly using a crisscross pattern when

tightening. The tightening torque is specied in the

Table 3 (Pg. 9).

11. Using a suitable wrench at the end of the splined stem

(5), partially open and quickly close the disc (15)

seating it rmly into the body seat (8) a few times.

12. Close the valve. Tighten all the disc seal ring retainer

screws (10) using a crisscross pattern. Tighten all the

disc seal retainer screws (10) to the torque specied

in Table 3 (Pg. 9).

13. Re-apply lubricant to the sealing surfaces of the valve.

Reinstall actuation device and test the valve.

4.4 DiSc SEAlring rEp lAcEM EnT:

Refer to the parts diagram for parts identication by

reference numbers in parentheses.

Bray recommends that both the disc seal ring (13) and

the body seat (8) be replaced at the same time. However,

individual components are not matched in pairs, and can

be replaced separately.

CAUTION

Exercise extra care when handling the body seat and

disc seal ring to avoid damage to the sealing areas.

The disc seal ring (13) can only be replaced in two ways:

replacing the disc seal ring (13) without removing the

body seat (8); or replacing the disc seal ring (13) with

the body seat (8) removed.

To remove the disc seal ring (13) without removing the

body seat (8) requires the valve actuation device be re-

moved from the valve and the valve ipped over to allow

access to both sides of the valve. For that reason, this

procedure is not suitable for occasions where the disc

seal ring (13) needs to be replaced in a valve installed

in the pipeline. In addition, this procedure is not recom-

mended for large Tri Lok valves where ipping the valve

over may be more difcult than removing the body seat

(8) and installing the disc seal ring (13) solely from the

body seat side.

Disc Seal Ring replacement with the Body Seat in

the valve:

1. Remove the valve from the pipeline. Remove the

actuator or operator from the valve.

2. Clean the surface of the valve, blow out all debris

around the disc seal ring retainer (12) and clean out

the hex sockets of the disc seal ring retaining cap

screws (10).

!

8

BRAY Tri Lok Triple Offset Valve

Operation and Maintenance Manual

3. Loosen up all the disc seal ring retaining cap screws

(10), but leave them in the valve with the disc seal

ring retainer (12) attached to the disc (15).

4. Using a suitable wrench, rotate the valve splined

stem (5) counterclockwise passed the fully open

position far enough only such that the disc is in a

position that will facilitate extraction of the disc

seal ring retainer (12) and the disc seal ring (13). Be

careful not to over-rotate the splined stem (5) to the

point where the disc seal ring (13) or disc edge (15)

would contact the body (6). Make sure the packing

gland retainer nuts (24) are tight enough to prevent

the valve splined stem (5) to rotate on its own under

the eccentric weight of the disc (15).

5. Remove the disc seal ring retaining cap screws (10)

and lock washers (11), and extract the disc seal ring

retainer (12) and the disc seal ring (13).

6. Rotate the disc (15) as necessary to access the seal

face on the disc (15). Using soft tools and suitable

wire brush, carefully clean any remnants of old gasket

and foreign matter from the face of the disc (15).

Blow out all threaded holes and the gasket groove

with compressed air.

7. Rotate the disc (15) back to the position required to

facilitate installation of the disc seal ring (13). Place

a new disc (15) seal ring gasket (14) into the groove

on the disc face (15). The mating side of the disc seal

ring gasket can be lightly sprayed with adhesive to

improve retention in the groove. Place the disc seal

ring (13) onto the disc (15) making sure the alignment

line on the disc seal ring matches the locating dimple

in the disc face. Place the disc seal ring retainer (12)

over the disc seal ring. Apply anti-seize compound

to the disc seal ring retaining cap screws (10). Install

all retaining cap screws (10) with lock washers (11).

The cap screws (10) need to be fully threaded into the

disc (15), but remain only nger-tight at this time.

8. Lubricate the sealing surfaces of the disc seal ring

(13) and the body seat (8). Using a suitable wrench,

rotate the valve splined stem (5) clockwise until the

disc seal ring (13) approaches closed position. Do

not force the disc seal ring (13) into the body seat (8).

9. Flip the valve over such that the seat side faces upward.

Verify that all four alignment marks (body, body seat,

disc seal ring, disc seal ring retainer) are aligned (i.e.

verify that the body seat (8) and disc seal ring (13) are

in proper positions). Using the wrench, slowly rotate

the disc (15) into the body seat (8) making sure that

the sealing edges line up properly without binding.

The disc seal ring retaining cap screws (10) should

still be only nger tight at this time.

10. Using a suitable wrench at the end of the splined stem

(5), partially open and quickly close the disc (15)

rmly into the body seat (8) a few times. Close the

valve. Tighten the disc seal ring retainer cap screws

(10) using a crisscross pattern. Occasionally open and

quickly close the valve while tightening the disc seal

ring retainer cap screws (10) to the torque specied

in the Table 3 (Pg. 9).

11. Re-apply lubricant to the sealing surfaces of the valve.

Reinstall operator or actuator and test the valve.

Disc Seal Ring replacement with the Body Seat re-

moved from the valve:

This procedure follows the procedure for replacing the

body seat (8) described above. If the old body seat (8) is

to be reused, exercise extra care when extracting it from

the retaining cavity in the valve body (6). When using the

jacking bolts to extract the body seat, avoid forcing the

jack screws unevenly which could result in permanent

deformation (pretzel twist) of the body seat (8). If the

old body seat (8) is to be reused, make absolutely certain

that the body seat (8) slides out of the retaining cavity

easily in a balanced and level manner.

9

BRAY Tri Lok Triple Offset Valve

Operation and Maintenance Manual

5.0 coM p lETE vAlvE DiSASSEM b ly:

1. Refer to the parts diagram for parts identication by

reference numbers in parentheses.

2. Close the valve. As applicable, remove operator or

actuator from the valve. Remove socket head cap

screws and lock washers (25). Remove mounting

bracket or mounting plate, (26) depending on valve

size. Note assembly positions of the operator or

actuator and the mounting hardware for subsequent

re-installation.

3. Clean all surfaces of the valve and blow out any loose

debris and foreign matter. Place the valve on a at

stable surface, with the body seat (8) side facing up.

4. Remove the body seat (8), following the procedure

described above in the section “Body Seat Replace-

ment”.

5. Remove disc seal ring retainer (12) and disc seal

ring (13) following the relevant portion of the pro-

cedure described above in the sections “Body Seat

Replacement”.

6. Remove the stem plug (1) at bottom of the valve

body (6).

7. Remove packing gland retainer nuts (24) and lock

washers (23). Remove gland retainer (22), anti-

blowout retaining ring or split ring, (21) depending

on valve size, and gland ring (19). Extract locating

dowels (16) if desired.

8. Verify the valve disc (15) is properly supported. Using

a rubber mallet or an aluminum drift with a hammer,

tap on the top of the splined stem (5) and extract it

through the bottom of the body (6). The lower bearing

(3) will come out with the splined stem (5). Remove

the disc (15) from the valve body (6).

9. Extract all the stem seals (18A and 18B), thrust

washer (17) and upper bearing (3), taking care not

to scratch the stem or the bore of the stufng box.

10. Remove all remaining gaskets and stem seals that

have not dislodged during the previous disassembly.

These items are: bearing gaskets (4), plug gasket (2),

disc seal ring gasket (14) and body seat gasket (7).

11. Clean all individual items as required for reassembly.

Valve

Size

In (mm)

Class 150 Valves Class 300 Valves

Seat Torque

lb-in (Nm)

Seal Torque

lb-in (Nm)

Jacking

Bolt

Seat Torque

lb-in (Nm)

Seal Torque

lb-in (Nm)

Jacking

Bolt

3 (80) 50 (5.6) - 60 (6.8) 40 (4.5) - 45 (5.1) 1/4-20 NC 50 (5.6) - 60 (6.8) 40 (4.5) - 45 (5.1) 1/4-20 NC

4 (100) 100 (11.3) - 120 (13.6) 60 (6.8) - 70 (7.9) 1/4-20 NC 100 (11.3) - 120 (13.6) 60 (6.8) - 70 (7.9) 1/4-20 NC

6 (150) 100 (11.3) - 120 (13.6) 100 (11.3) - 110 (12.4) 5/16-18 NC 170 (19.2) - 180 (20.3) 110 (12.4) - 120 (13.6) 5/16-18 NC

8 (200) 170 (19.2) - 180 (20.3) 120 (13.6) - 130 (14.7) 5/16-18 NC 300 (33.9) - 320 (36.2) 160 (18.1) - 180 (20.3) 5/16-18 NC

10 (250) 300 (33.9) - 320 (36.2) 170 (19.2) - 190 (21.5) 5/16-18 NC 300 (33.9) - 320 (36.2) 210 (23.7) - 230 (26.0) 5/16-18 NC

12 (300) 300 (33.9) - 320 (36.2) 220 (24.9) - 240 (27.1) 5/16-18 NC 300 (33.9) - 320 (36.2) 230 (26.0) - 250 (28.2) 5/16-18 NC

14 (350) 300 (33.9) - 320 (36.2) 230 (26.0) - 250 (28.2) 5/16-18 NC 500 (56.5) - 530 (59.9) 320 (36.2) - 340 (38.4) 5/16-18 NC

16 (400) 300 (33.9) - 320 (36.2) 310 (35.0) - 330 (37.3) 5/16-18 NC 500 (56.5) - 530 (59.9) 360 (40.7) - 380 (42.9) 5/16-18 NC

18 (450) 500 (56.5) - 530 (59.9) 330 (37.3) - 350 (39.5) 5/16-18 NC 500 (56.5) - 530 (59.9) 440 (49.7) - 470 (53.1) 5/16-18 NC

20 (500) 500 (56.5) - 530 (59.9) 400 (45.2) - 430 (48.6) 3/8-16 NC 800 (90.4) - 840 (94.9) 470 (53.1) - 500 (56.5) 3/8-16 NC

24 (600) 500 (56.5) - 530 (59.9) 470 (53.1) - 500 (56.5) 3/8-16 NC 800 (90.4) - 840 (94.9) 540 (61.0) - 570 (64.4) 3/8-16 NC

TAb lE 3. - TighTEning TorqUE vAlUES for boDy SEAT rETAining cAp ScrEwS

AnD DiSc SEAlring rETAining cAp ScrEwS (LBf-in).

10

BRAY Tri Lok Triple Offset Valve

Operation and Maintenance Manual

6.0 vAlvE ASSEM b ly:

When reassembling the Tri Lok valve, all gaskets, pack-

ing, and seals should be new. Cap screws can be reused

if in good condition, but Bray recommends that all lock

washers be renewed.

CAUTION

Exercise extra care when handling the body seat and

disc seal ring to avoid damage to the sealing areas.

Make sure the gasket faces on both sides of the valve

body (6) are protected from scratching and other damage

when handling the valve body (6).

Assembly is essentially the reverse of disassembly with

the following notable points:

1. The alignment of the driving ats or keyway of the

splined stem (5) with respect to the disc face (15) must

be such that the disc face (15) is rotationally about

two to three degrees ahead of the splined stem (5)

in clockwise direction when viewed from top. This

ensures that the disc seal ring (13) lodges into the

body seat (8) before the valve operator or actuator

reaches 90 degrees travel. Use anti-seize compound

in the splined connection between the splined stem

(5) and the disc (15).

2. Both bearings (3) should be installed after the disc

(15) and splined stem (5) have been placed in the

valve body (6). Spray lubricant on the ends of the

splined stem (5) and carefully thread the bearing

gaskets (4) onto the splined stem (5) ends. Slide the

upper bearing (3) over the end of the splined stem

(5) pushing the bearing gasket (4) along the splined

stem (5). Make sure the bearing gasket (4) does not

hang on the ats of the splined stem (5) (or keyway

as applicable). Gently push the upper bearing (3)

into the body cavity (6). Repeat the procedure, very

carefully, when installing the lower bearing (3).

3. Use liberal amount of lubricant on the sealing surfaces

of the disc seal ring (13) and the body seat (8) when

nalizing the alignment of these parts.

4. Test the valve.

5. Recommended lubricant for valve components during

valve assembly and/or disassembly are as follows:

Valve Component Lubricant

Bearing Area & Shaft

Machined Surfaces Light Spray

Threaded Connections Anti-Seize

Seat/Seal Contact

Surfaces

Dry Graphite

Spray

!

11

BRAY Tri Lok Triple Offset Valve

Operation and Maintenance Manual

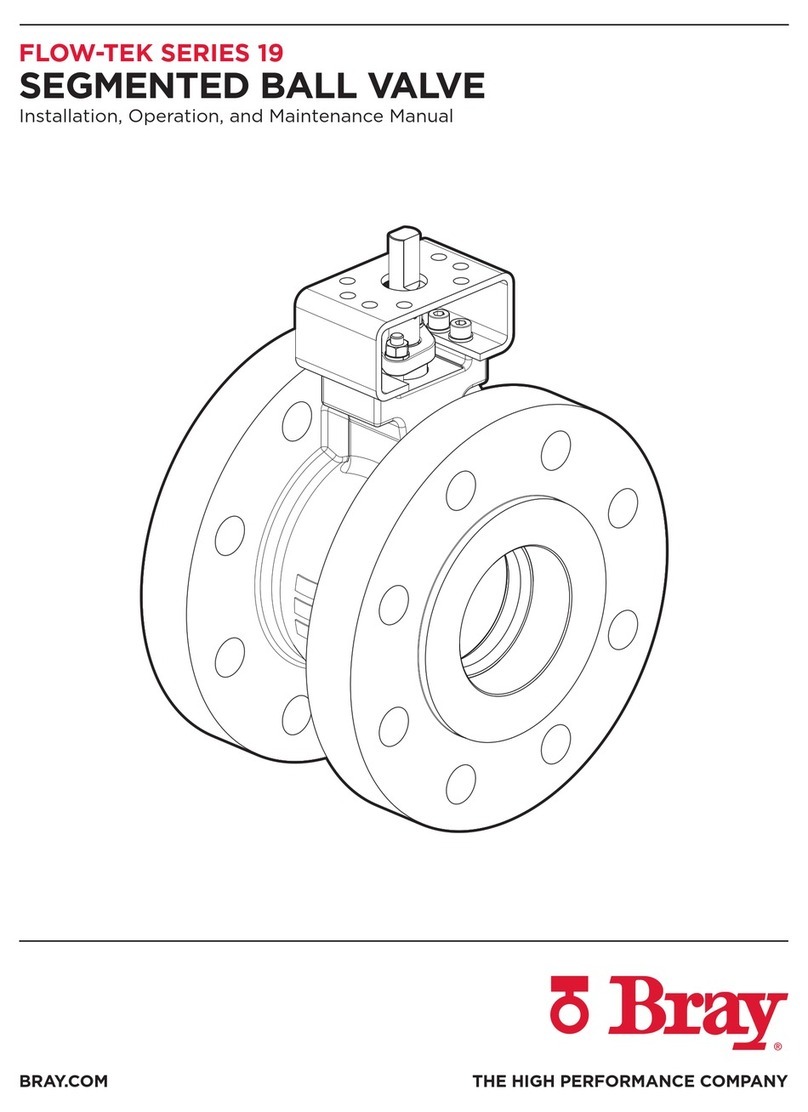

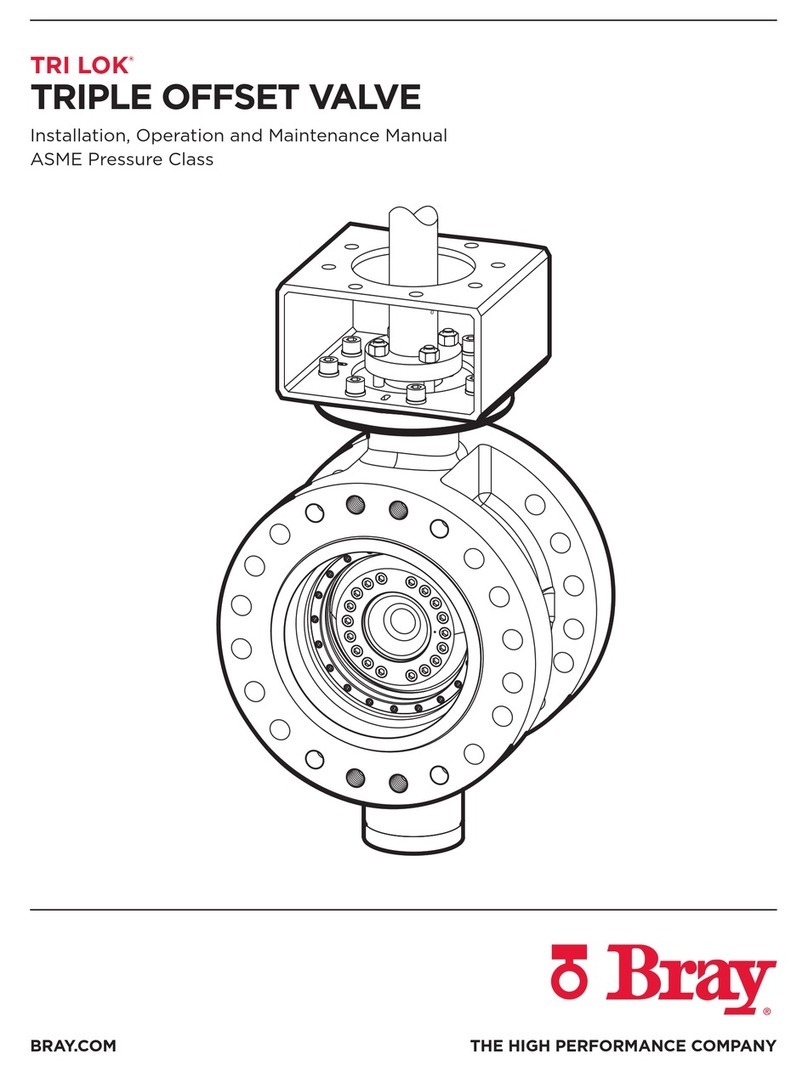

7.0 ValVe Part Diagram

1 STEM PLUG

2 PLUG GASKET

3 UPPER/LOWER BEARING

4 BEARING GASKET

5 SPLINED STEM

6 VALVE BODY

7 BODY SEAT GASKET

8 BODY SEAT

9 BODY SEAT RETAINING

CAP SCREWS (HEX)

10 DISC SEAL RING

RETAINING CAP

SCREWS (HEX)

11 LOCK WASHERS

12 DISC SEAL RING RETAINER

13 DISC SEAL RING

14 DISC SEAL RING GASKET

15 DISC

16 LOCATING DOWELS

17 THRUST WASHER

18A BRAIDED PACKING RING

18B SOLID GRAPHITE RINGS

19 GLAND RING

20 PACKING GLAND SCREW

21 ANTI-BLOWOUT RETAINING

RING/ SPLIT RING

22 GLAND RETAINER

23 LOCK WASHERS

24 PACKING GLAND

RETAINER NUTS

25 SOCKET HEAD SCREWS

W/ LOCK WASHERS

26 MOUNTING

BRACKET / PLATE

6” (150mm) tri lok Wafer

aNSi 150

12

BRAY Tri Lok Triple Offset Valve

Operation and Maintenance Manual

noteS

13

BRAY Tri Lok Triple Offset Valve

Operation and Maintenance Manual

noteS

14

BRAY Tri Lok Triple Offset Valve

Operation and Maintenance Manual

A Division of BRAY INTERNATIONAL, Inc.

13333 Westland East Blvd. Houston, Texas 77041

281/894-5454 FAX 281/894-9499 www.bray.com

Bray® is a registered trademark of BRAY INTERNATIONAL, Inc.

© 2011 Bray International. All rights reserved. OM-24-002 02-2011

R

CONTROLS

Other manuals for TRI LOK

4

Table of contents

Other Bray Control Unit manuals

Bray

Bray 63 Series User manual

Bray

Bray FLOW-TEK 19 Series User manual

Bray

Bray 768 Series User manual

Bray

Bray Flow-Tek Triad Series Instruction Manual

Bray

Bray RF15 Manual

Bray

Bray FLOW-TEK Series User manual

Bray

Bray 950 Series User manual

Bray

Bray S30/S70 User manual

Bray

Bray FlowTek F15 Series Manual

Bray

Bray TRI LOK Series User manual

Bray

Bray TRI LOK User manual

Bray

Bray FLOW-TEK Series User manual

Bray

Bray TRI LOK User manual

Bray

Bray TRI LOK Instruction manual

Bray

Bray MCCANNALOK User manual

Bray

Bray 62 SERIES Manual

Bray

Bray 752 Series User manual

Bray

Bray FLOW-TEK M1 Series User manual

Bray

Bray TRI LOK User manual

Bray

Bray ACRIS 24 Series 24 User manual