FLOW-TEK SERIES F15/F30

2 PIECE FLANGED FULL PORT BALL VALVES

Installation, Operation, and Maintenance Manual

10 of 15© 2022 BRAY INTERNATIONAL, INC. ALL RIGHTS RESERVED. BRAY.COM The Information

contained herein shall not be copied, transferred, conveyed, or displayed in any manner that would

violate its proprietary nature without the express written permission of Bray International, Inc.

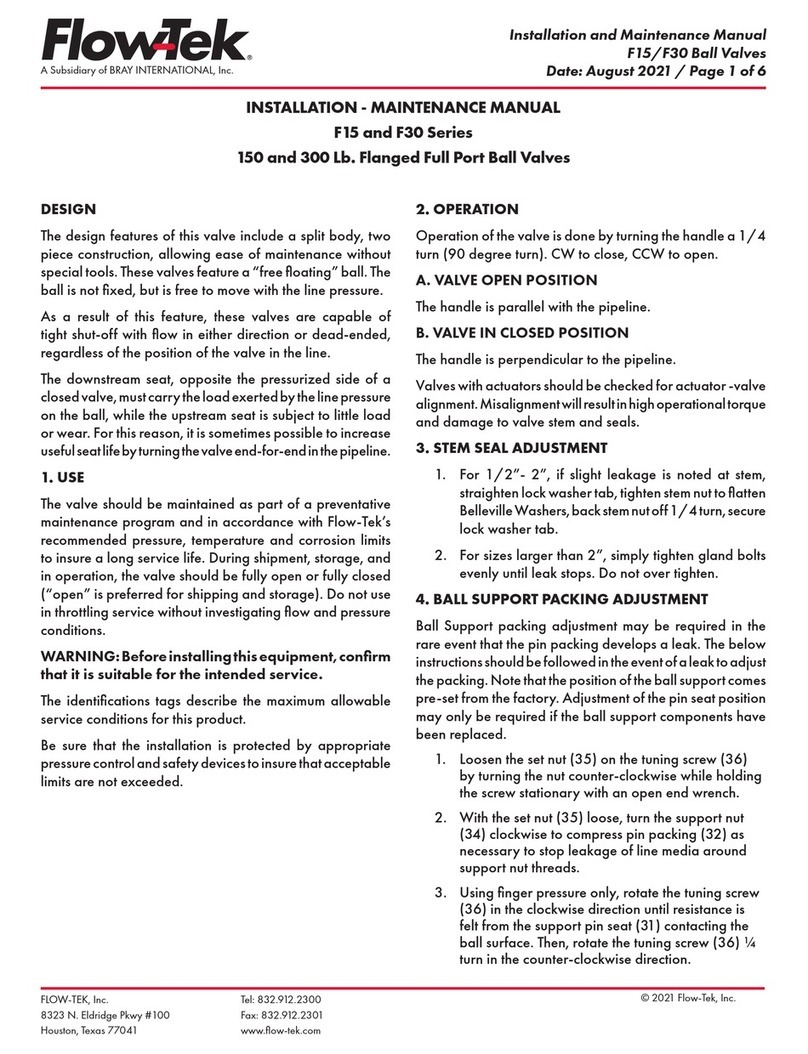

STEM SEAL ADJUSTMENT

For 1/2"- 2", if slight leakage is noted at stem, straighten lock

washer tab, tighten stem nut to flatten Belleville Washers, back

stem nut o 1/4 turn, secure lock washer tab.

For sizes larger than 2", simply tighten gland bolts evenly until

leak stops. Do not over tighten. See Table 1 for recommended

gland nut torque.

WARNING

DO NOT remove packing gland or any other valve parts while line

is under pressure!

Stem seal leakage may be corrected without disassembly by

tightening the packing gland nut until such leakage stops. If the

leakage continues or valve operating torque becomes excessive,

the seals are worn and replacement will be necessary.

Table - Recommended Gland Nut Torque

Valve Size

NPS Recommended Torque

lbs-in Valve Size

DN Recommended Torque

N-m

1/2 53 15 6

3/4 53 20 6

1 53 25 6

1-1/2 132 40 15

2 132 50 15

2-1/2 89 65 10

3 89 80 10

4 89 100 10

6 106 150 12

8 106 200 12

10 124 250 14

12 124 300 14

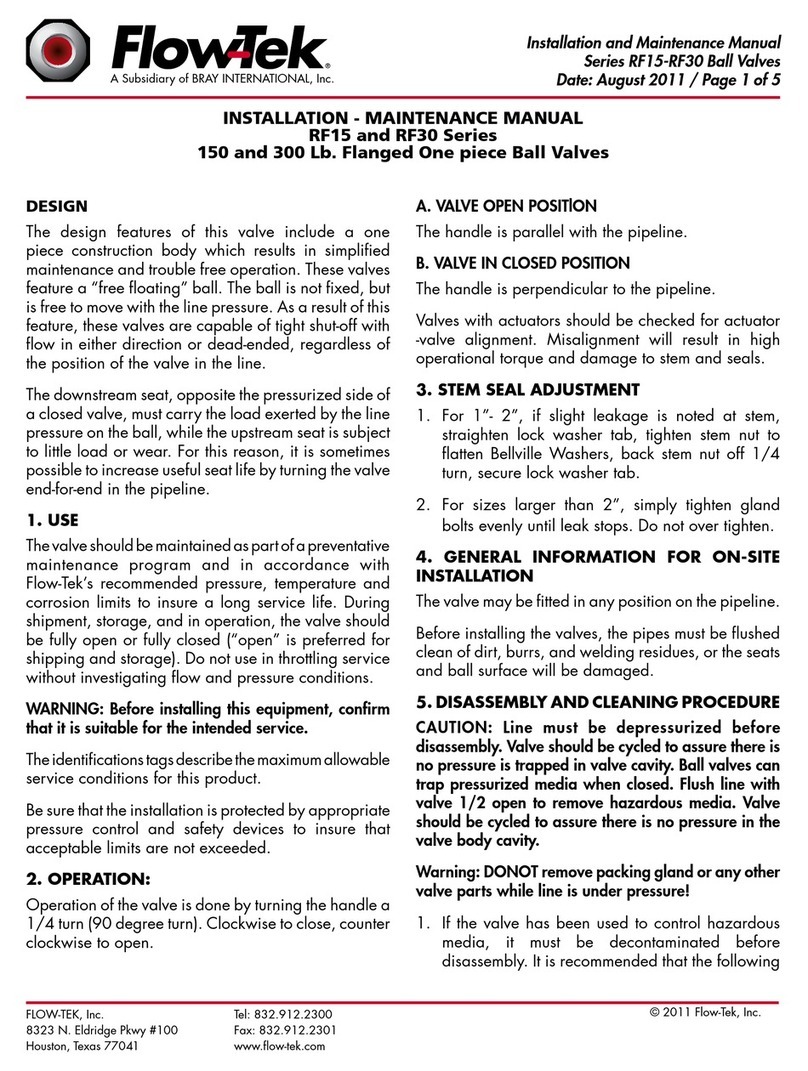

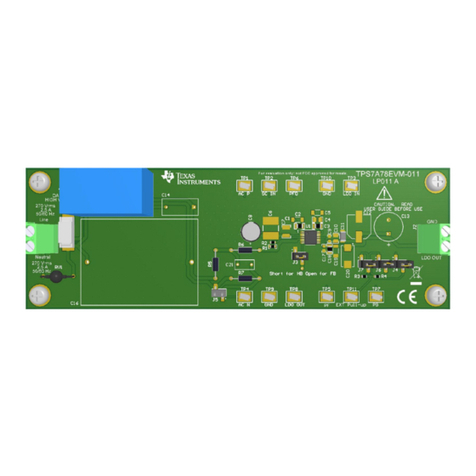

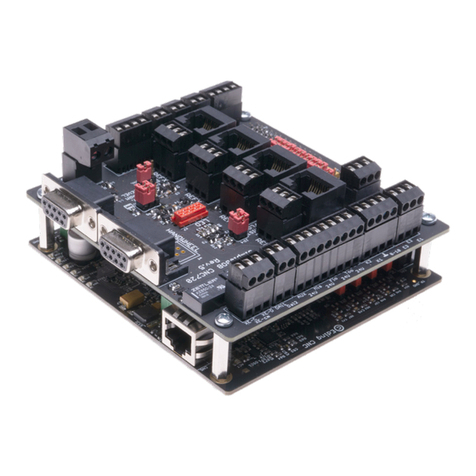

BALL SUPPORT PACKING ADJUSTMENT

Ball Support packing adjustment may be required in the

rare event that the pin packing develops a leak. The below

instructions should be followed in the event of a leak to adjust the

packing. Note that the position of the ball support comes pre-set

from the factory. Adjustment of the pin seat position may only be

required if the ball support components have been replaced.

1. Loosen the set nut (35) on the tuning screw (36) by turning

the nut counter-clockwise while holding the screw stationary

with an open end wrench.

2. With the set nut (35) loose, turn the support nut (34)

clockwise to compress pin packing (32) as necessary to stop

leakage of line media around support nut threads.

3. Using finger pressure only, rotate the tuning screw (36) in the

clockwise direction until resistance is felt from the support

pin seat (31) contacting the ball surface. Then, rotate the

tuning screw (36) ¼ turn in the counter-clockwise direction.

4. Lock the tuning screw (36) in position with the set nut (35)by

holding the tuning screw (36) head stationary with an open

end wrench while firmly tightening the set nut (35) in the

clockwise direction.

Ball

Ball Support

Clockwise

Counter

Clockwise

31 Pin Seat

32 Pin Packing

33 Support Pin

34 Support Nut

35 Set Nut

36 Turning Screw

Clockwise

Counter

Clockwise

31 Pin Seat

32 Pin Packing

33 Support Pin

34 Support Nut

35 Set Nut

36 Turning Screw