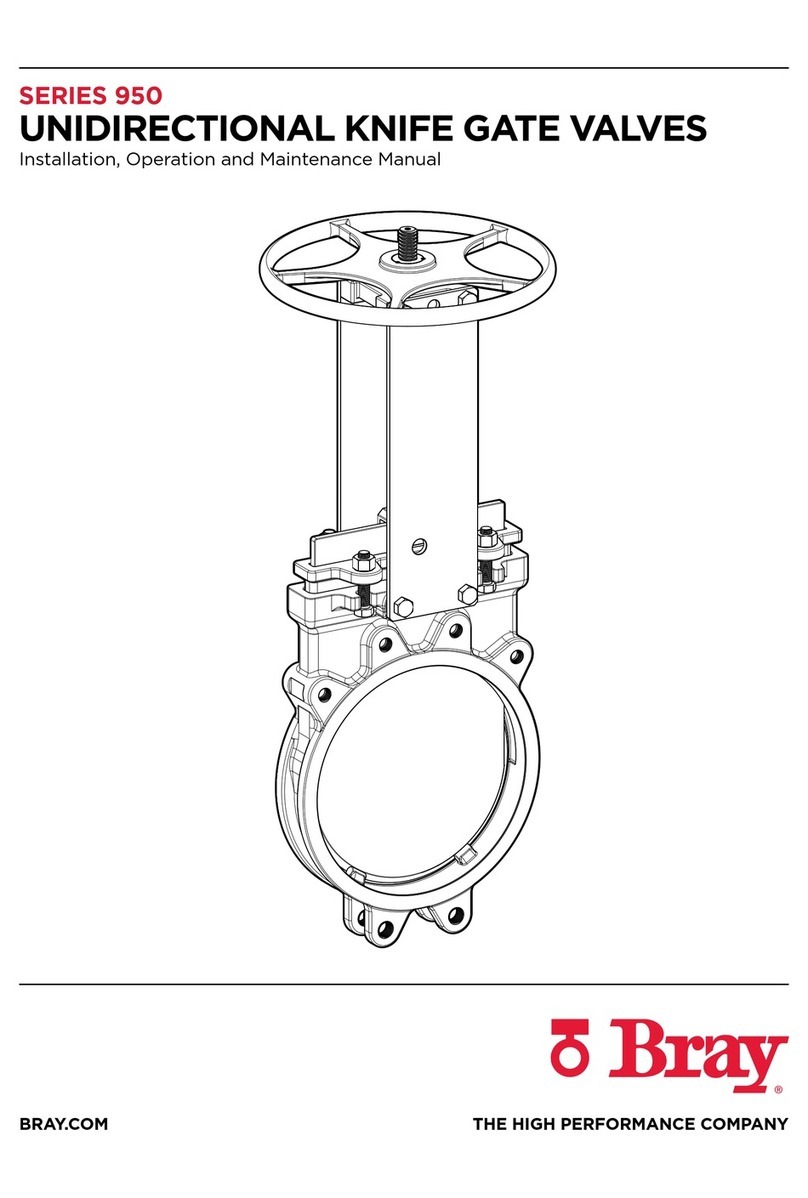

SERIES 740 BIDIRECTIONAL KNIFE GATE VALVE

Installation, Operation and Maintenance Manual

© 2019 BRAY INTERNATIONAL. ALL RIGHTS RESERVED. BRAY.COM The Information contained

herein shall not be copied, transferred, conveyed, or displayed in any manner that would violate its

proprietary nature without the express written permission of Bray International, Inc.

17 of 20

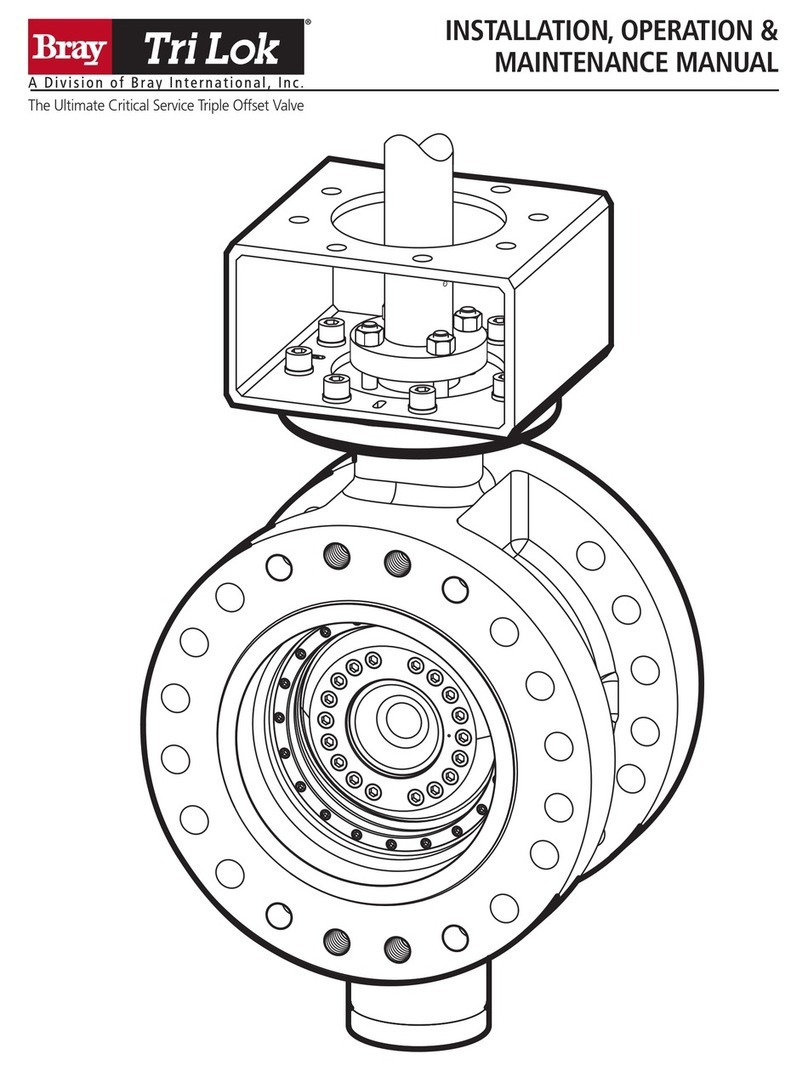

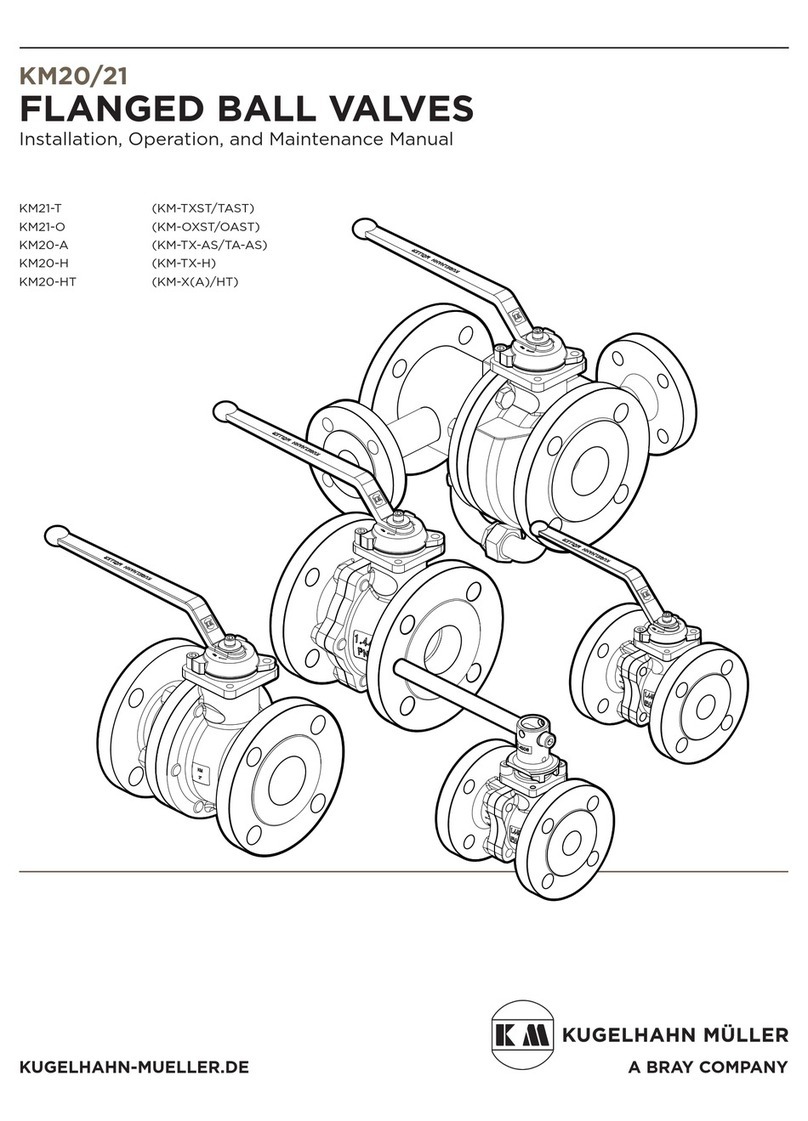

Figure 24: Remove the gate.

14.0 SEAL REPLACEMENT

14.1 Relieve the line pressure and close the valve. Flushing the line may

be necessary. Remove the valve from the line by loosening the

flange mounting bolts, studs, and nuts.

14.2 Clamp the valve in the vertical position to a fixture. Do not block

the valve port when clamping the valve. An overhead hoist may

be needed for larger size valves.

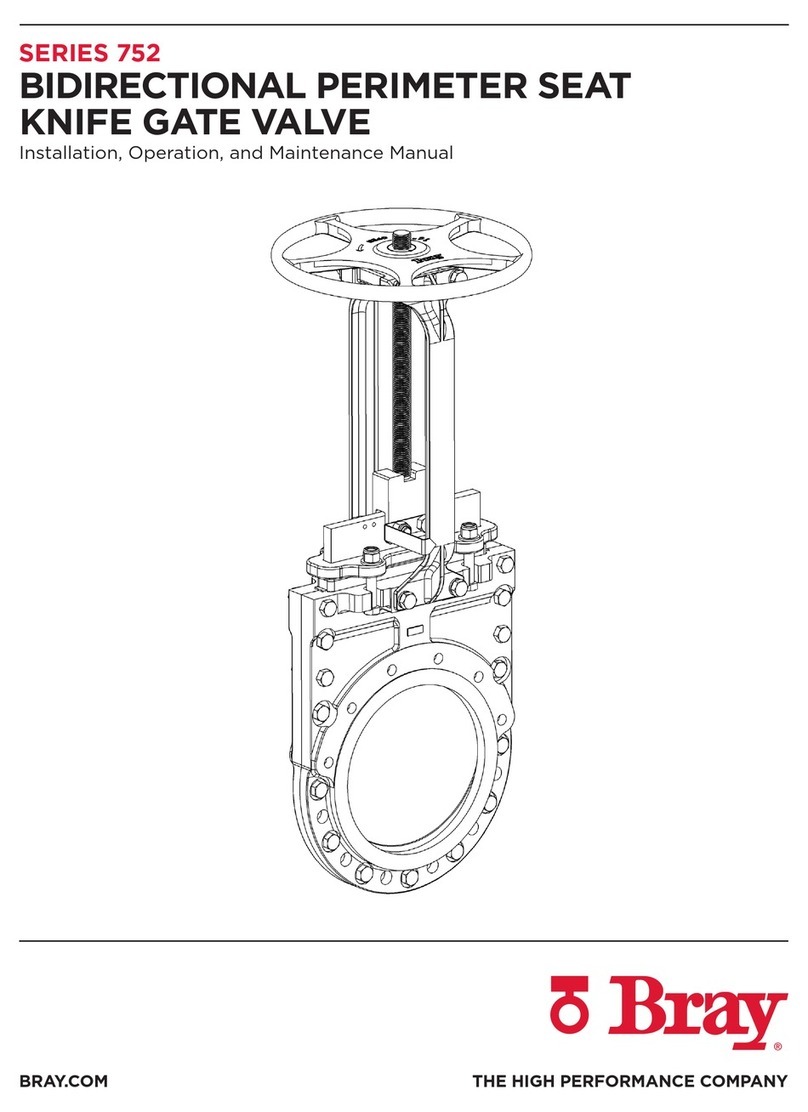

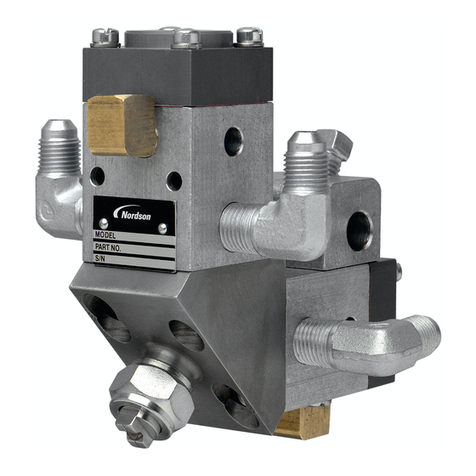

14.3 Disconnect the stem from the gate by removing the clevis, bolts,

and nuts. See Figure 23.

14.4 Remove the actuator and superstructure from the valve.

14.5 Remove the gland nuts, gland, and gland packing from the valve.

14.6 Remove the gate carefully from the valve body. Clean the gate and

smooth out any rough surfaces. Figure 24.

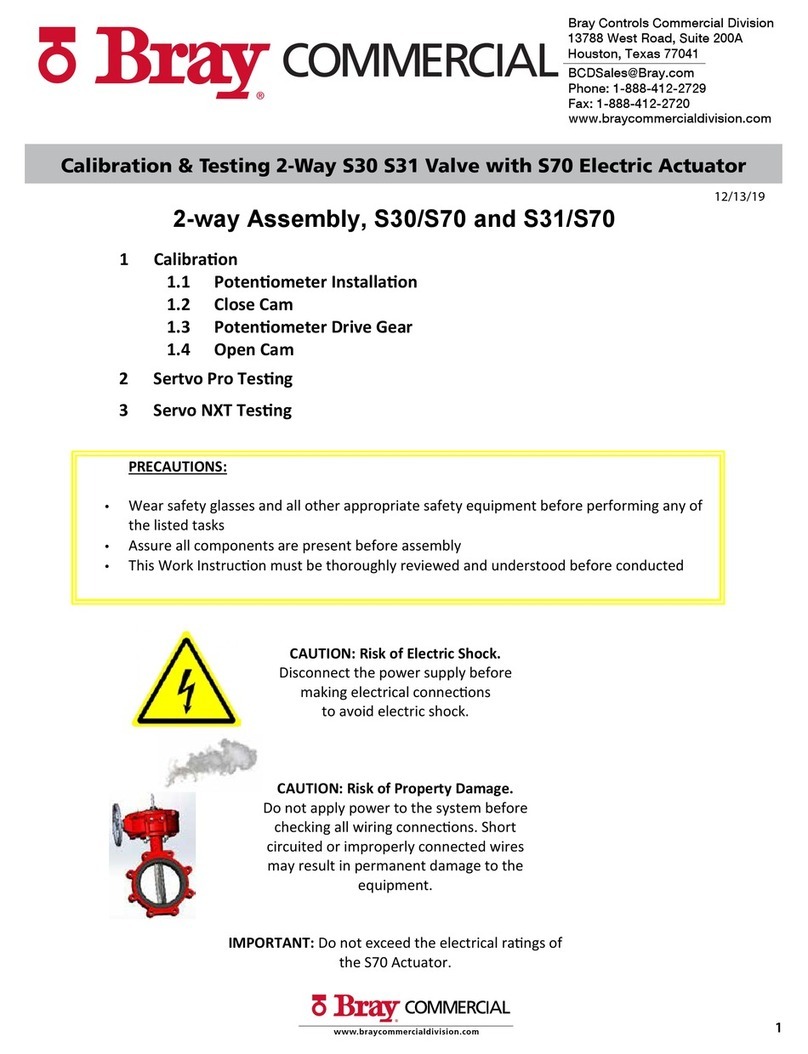

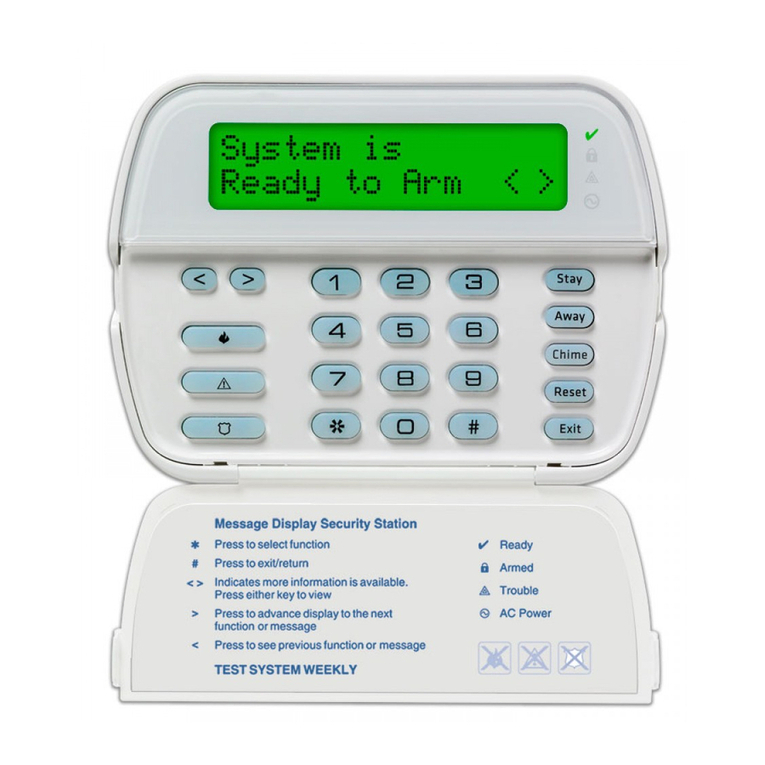

14.7 Remove the seal by pulling it out of the top of the valve body.

Figure 25.

14.8 Clean and inspect the body for any damage, particularly sharp

edges that may cut the seal. Smooth out if necessary.

14.9 Saturate the body seal groove area with a good water–soluble

lubricant that will not affect the seal or process. Inspect the new

seal and saturate both ends of the seal.

14.10 Insert one end of the seal from the top side. Reach into the

port area and pull the seal through the groove of the port area

and pull the seal from the top of the body. Ensure the seal is

not overstretched.

14.11 Install the gate and mount the actuator or handwheel. Operate

the gate to seat the seal into the bottom groove and cycle several

times. With the seal forced fully into the seal groove, cut each end

of the seal off to the required extended length.

Refer to Table 6.

14.12 While leaving the gate in the closed position, retract the actuator

to the open position.

14.13 Install the PTFE wiper and repack the valve. Adjust the packing

for tight shutoff when the valve is installed and pressurized to

operating pressure.

Figure 23: Lift clevis after removing

nuts & bolts.

Figure 25: Remove seal

CAUTION

Relieve line pressure before attempting to remove the valve from the line

to avoid personnel injury and/or equipment damage. If the valve has a

pneumatic actuator, solenoid valve, limit switches, or other accessories,

disconnect electrical and pneumatic supply.

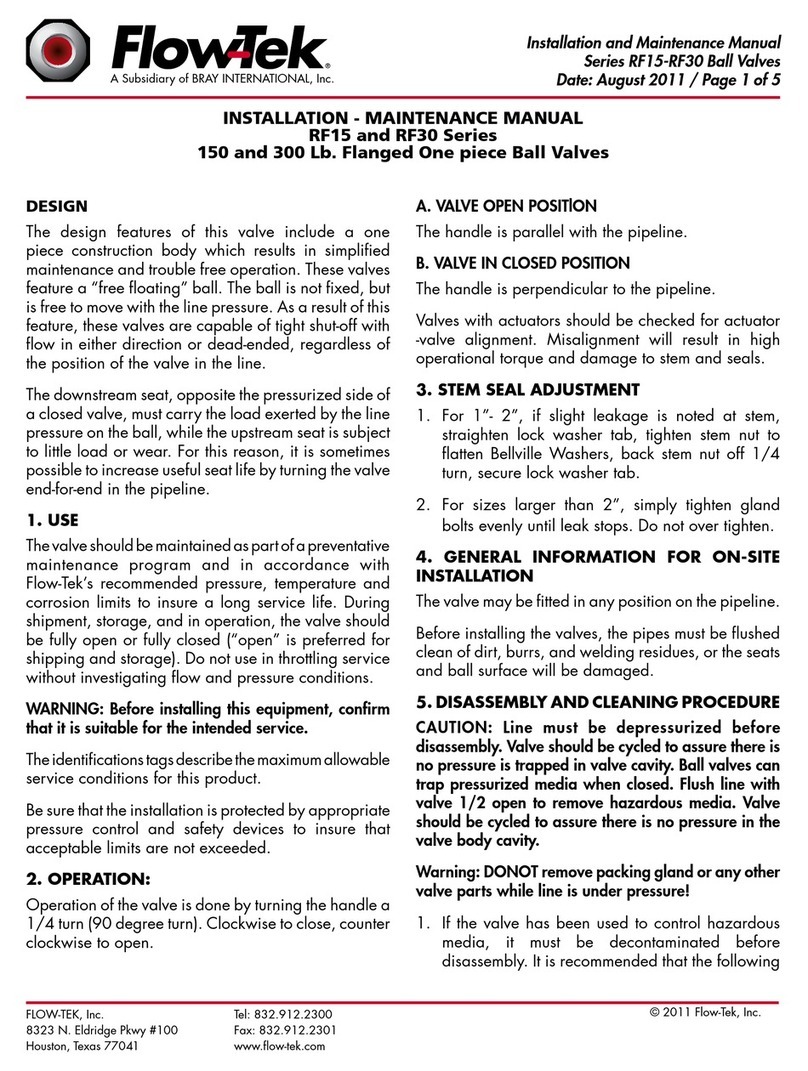

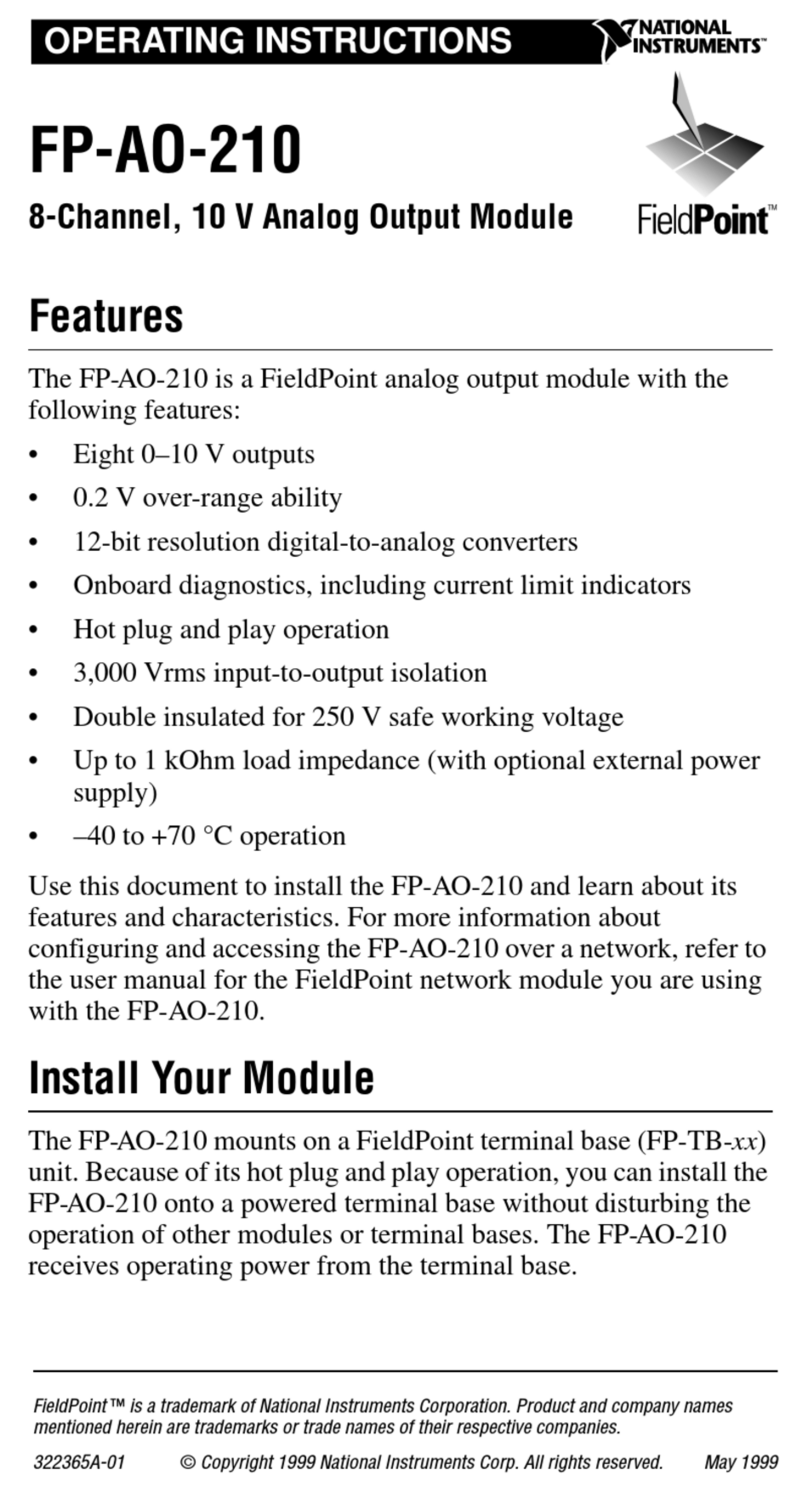

Table 6: Seal Length

Valve Size Max Length

Up to 8" 20 mm

10" - 16" 25 mm

18" and Up 30 mm