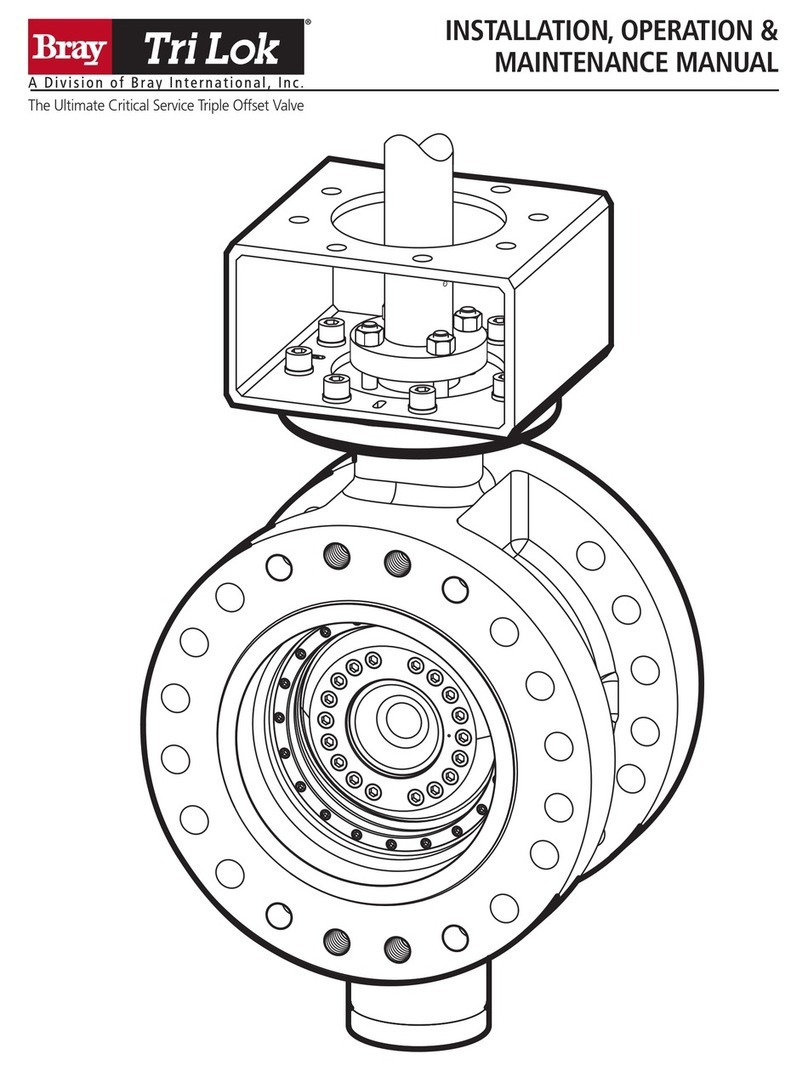

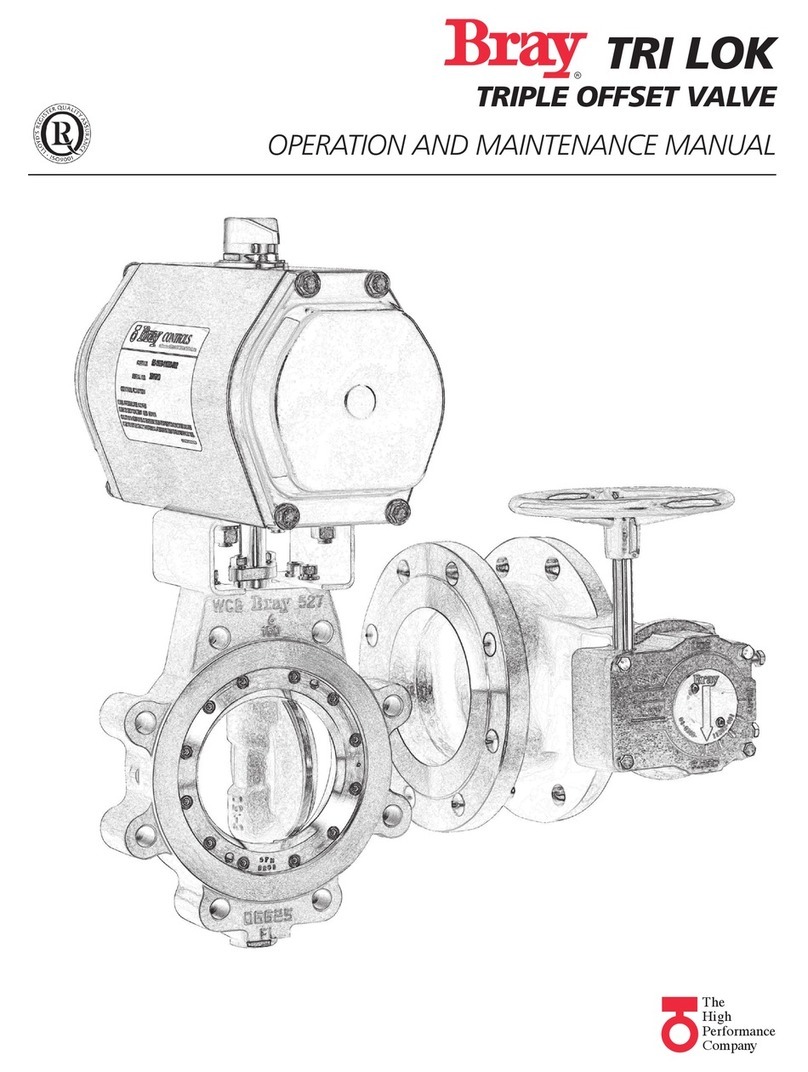

Tri Lok®

Installation, Operation and Maintenance Manual

13 |BRAY.COM

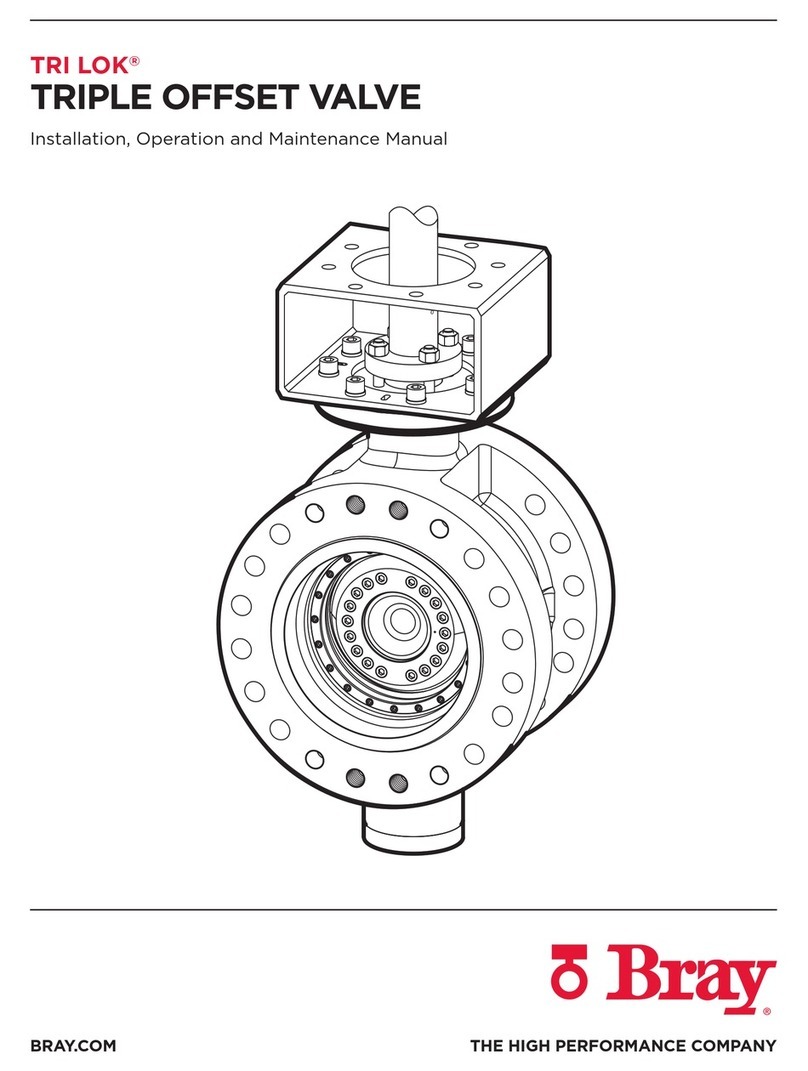

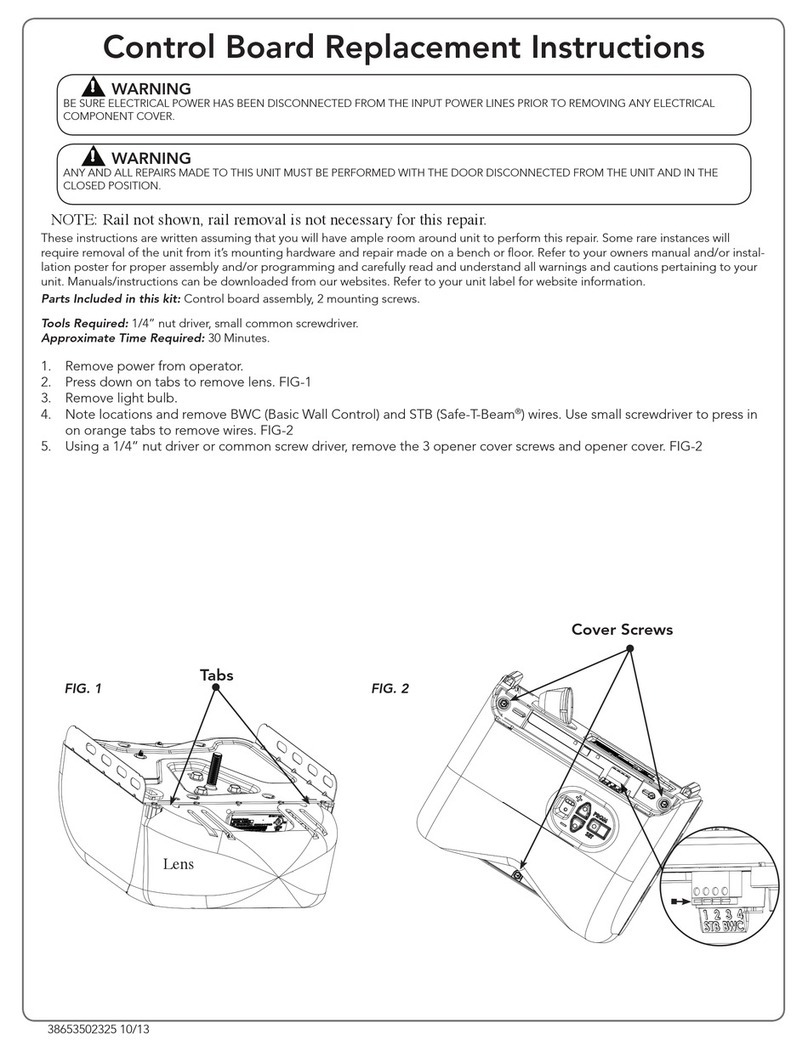

9.4.1 Seal ring replacement with the seat in

the valve (Class 150)

1. Remove valve from the pipeline. Remove the actuator

from the valve.

2. Clean the surface of the valve with compressed air,

blow out all debris around the seal ring retainer (C4)

and clean out the hex sockets of the seal ring retainer

cap screws (C5).

3. Loosen all seal ring retainer cap screws (C5), but leave

them in the valve with the seal ring retainer (C4)

attached to the disc (C1).

4. Using a wrench, rotate the valve stem (D1)

counterclockwise past the fully open position far

enough so the disc is in a position to allow seal ring

retainer and seal ring removal (C2). Be careful not to

over-rotate the stem (D1) to the point where the seal

ring (C2) or disc edge (C1) contact the body (A1). Make

sure the packing gland retainer nuts (H7) are tight

enough to prevent the valve stem (D1) from rotating on

its own under the eccentric weight of the disc (C1).

5. Remove the seal ring retaining cap screws (C5) and lock

washers (C6), and extract disc seal ring retainer (C4)

and the seal ring (C2).

6. Rotate the disc (C1) as necessary to access the seal

face on the disc (C1). Using soft tools and suitable wire

brush, carefully clean any remnants of old gasket and

foreign matter from the face of the disc (C1). Blow

out all threaded holes and the gasket groove with

compressed air.

7. Rotate the disc (C1) to its previous position to facilitate

installation of the seal ring (C2). Place a new seal ring

gasket (C3) into the groove on the disc face (C1). The

mating side of the seal ring gasket can be lightly greased

to improve retention in the groove. Place the seal ring

(C2) onto the disc (C1) making sure the alignment line

on the disc seal ring matches the locating dimple on

the disc face. Place the seal ring retainer (C4) over the

seal ring. Apply anti-seize compound to the seal ring

retainer cap screws (C5). Install all seal ring retainer cap

screws (C5) with lock washers (C6). The cap screws (C5)

should be fully threaded into the disc (C1), but remain

only finger-tight at this time.

8. Lubricate (refer to lubrication table) the sealing

surfaces of the seal ring (C2) and the seat (B1). Using

a suitable actuator, close and open the valve 2-3 times,

only closing the valve to the point where the seal ring

engages the seat. Check each time that the seal ring

makes full contact without torquing into the seat.

Attention should be paid in the closing stroke that the

seat does not scratch the seal ring. This will allow the

seal ring and seat to be properly aligned.

9. Orient the valve with the seat side facing up. Verify that

all four alignment marks (body, seat, seal ring and seal

ring retainer) are aligned.

10. Tighten the seal ring retainer cap screws (C5) using a

cross bolting technique to the torque specified in Table

3 (Pg. 15).

11. Re-apply lubricant to the sealing surfaces of the valve.

Reinstall operator or actuator and test the valve.

9.4.2 Seal ring replacement with the seat in

the valve (Class 600)

1. Remove valve from the pipeline. Remove the actuator

from the valve.

2. Clean the surface of the valve with compressed air,

blow out all debris around the seal ring retainer (C4)

and clean out the hex sockets of the seal ring retainer

cap screws (C5).

3. Loosen all seal ring retainer cap screws (C5), but leave

them in the valve with the seal ring retainer (C4)

attached to the disc (C1).

4. Using the appropriate size hex key, completely remove

the upper set screw fasteners (B6) from the seat retainer

ring (B3).

5. Below these dowels are seat retainer lower set screws

(B5) that compress the seat (B1) against the valve body.

Unscrew them until the Seat retainer ring (B4) above the

retaining ring is free to move. Remove the seat retainer

ring (B4) from the body. Carefully clean the seat retainer

ring (B3) and upper set screw fasteners (B6).

6. Extract the seat ring retainer (B3), remove the seat

alignment button (B7) that retains the seat within the

body and then remove the seat (B1).

7. Slightly grease the gasket groove in the replacement

seat, install the new seat gasket (B2), place this seat/

gasket sub-assembly into the valve body paying

attention that the groove of the seat is aligned with the

body groove and insert the seat alignment button (B7).

8. Replace set screw if necessary.

9. Adjust the seat retainer ring lower set screws (B5) until

they are flush with the bottom of the seat retainer

ring (B3). Install the seat retainer ring (B3) and the seat

retainer ring (B4) in its groove in the body.

10. Using a cross bolting technique, tighten the seat retainer

lower set screws (B5) to 50% of torque specified in

Table 4 (Pg. 16). Once all set screws are tightened to the

same torque, proceed to fully tighten them to 100% of

the listed torque value.