Retrofitting is possible: Most detectors can be

retrofitted to accept the LED light. Carefully

cut open the back of the PMT socket. Once the

MCA is plugged onto the PMT, the assembly is

light tight again. In integral detectors the PMT

is glued directly to the crystal and the

environmental seal is usually between the side

of the PMT and the magnetic shield. Hence,

opening up the back of the PMT does not cause

a problem.

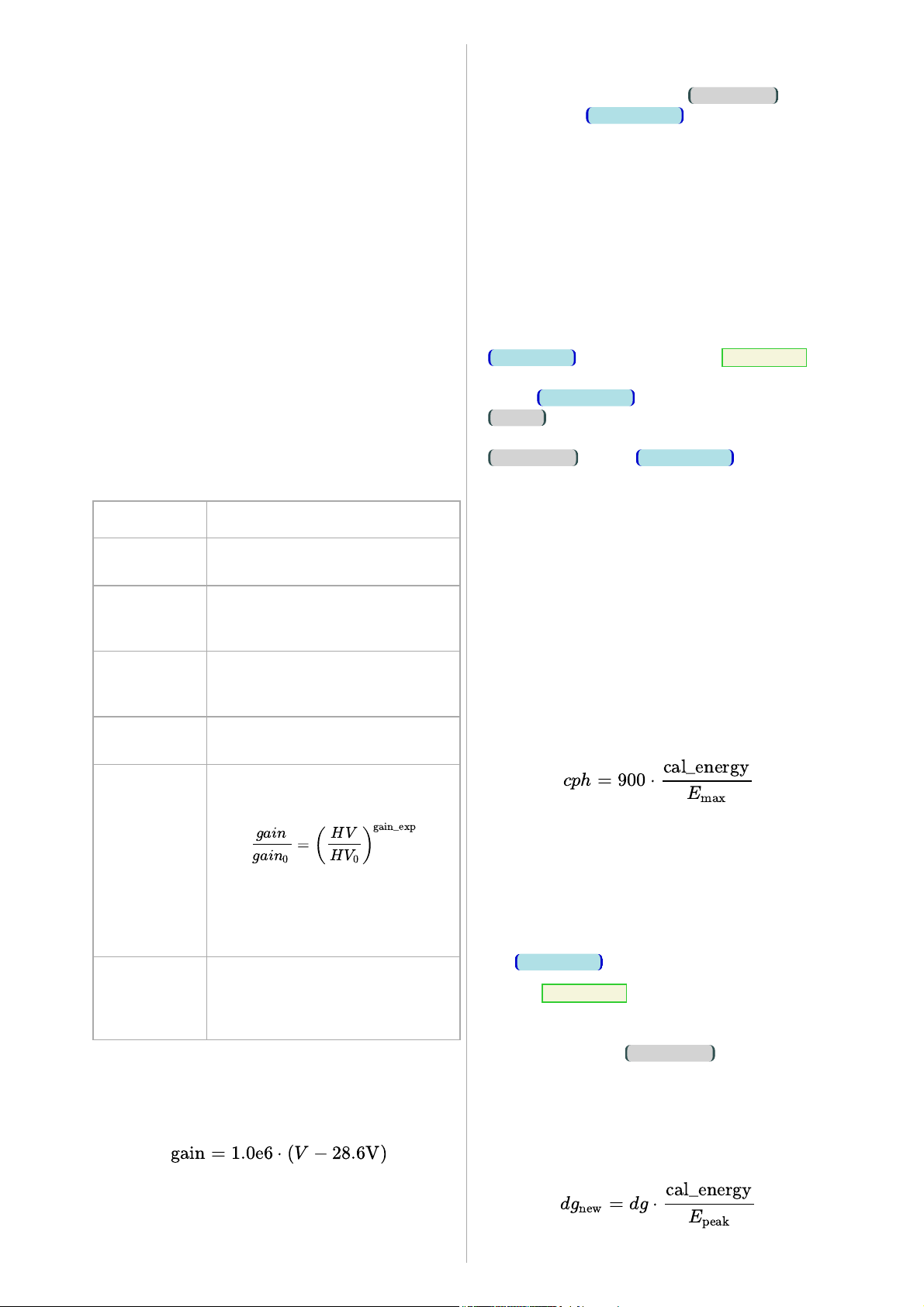

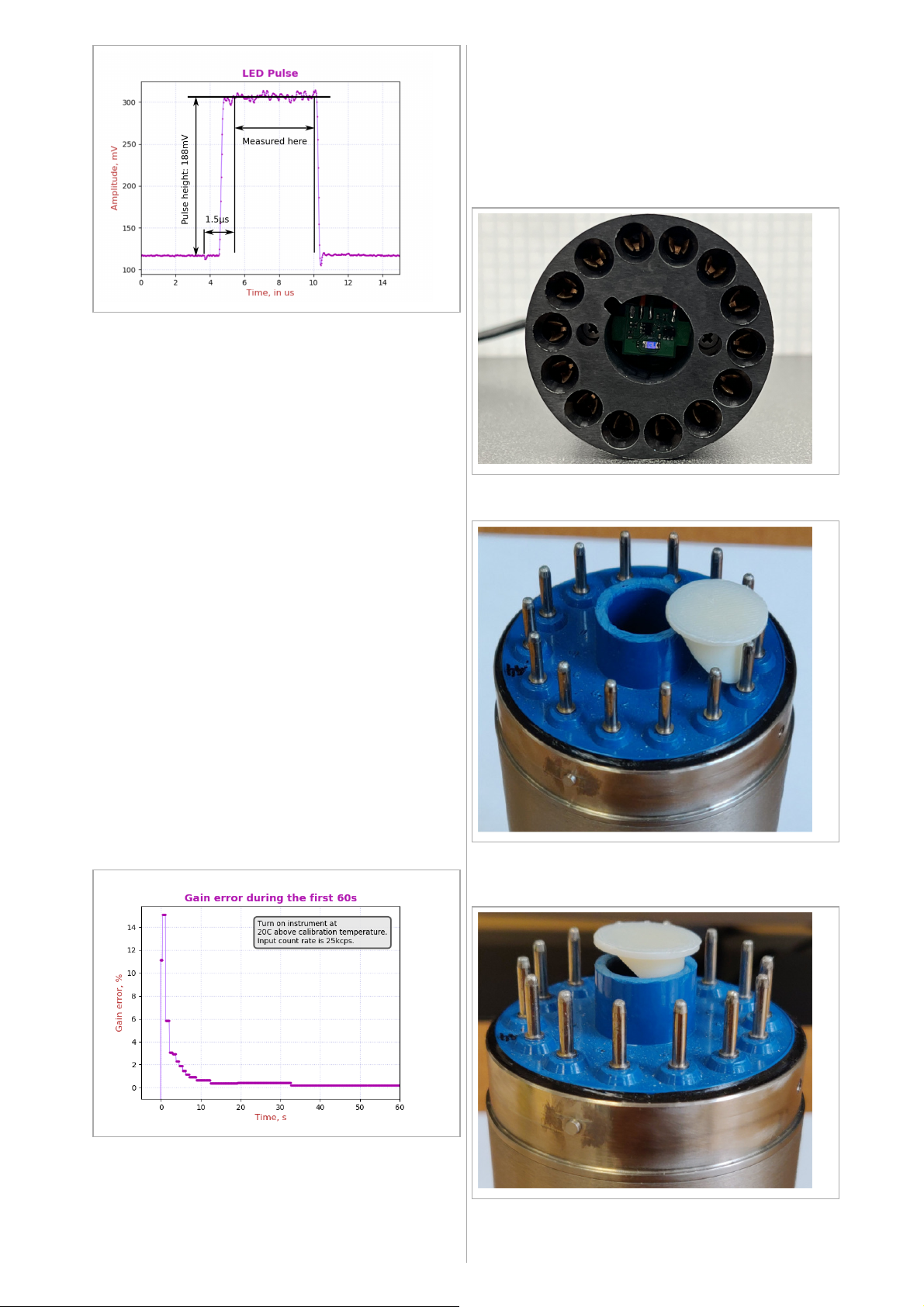

Adjusting the diffuser: First keep the LED off

and adjust the gain of the detector as desired.

Then, insert the diffuser, turn the LED on, set

sel_led=1 , trace_mode=0 and acquire a few

traces. You will see a rectangular LED pulse

with a width that can be controlled with the

led_width control. For now we are only

concerned about the pulse height.

In the MCA the LED is placed off-center and

the light diffuser is asymmetric. Turning the

light diffuser changes the amount of LED light

transmitted into the PMT. You have to unplug

the PMT-3000 from the PMT in order to turn

the light diffuser. Note that you have to power

down the MCA before plugging and

unplugging. Never hot-plug the PMT-3000. It

would damage the device.

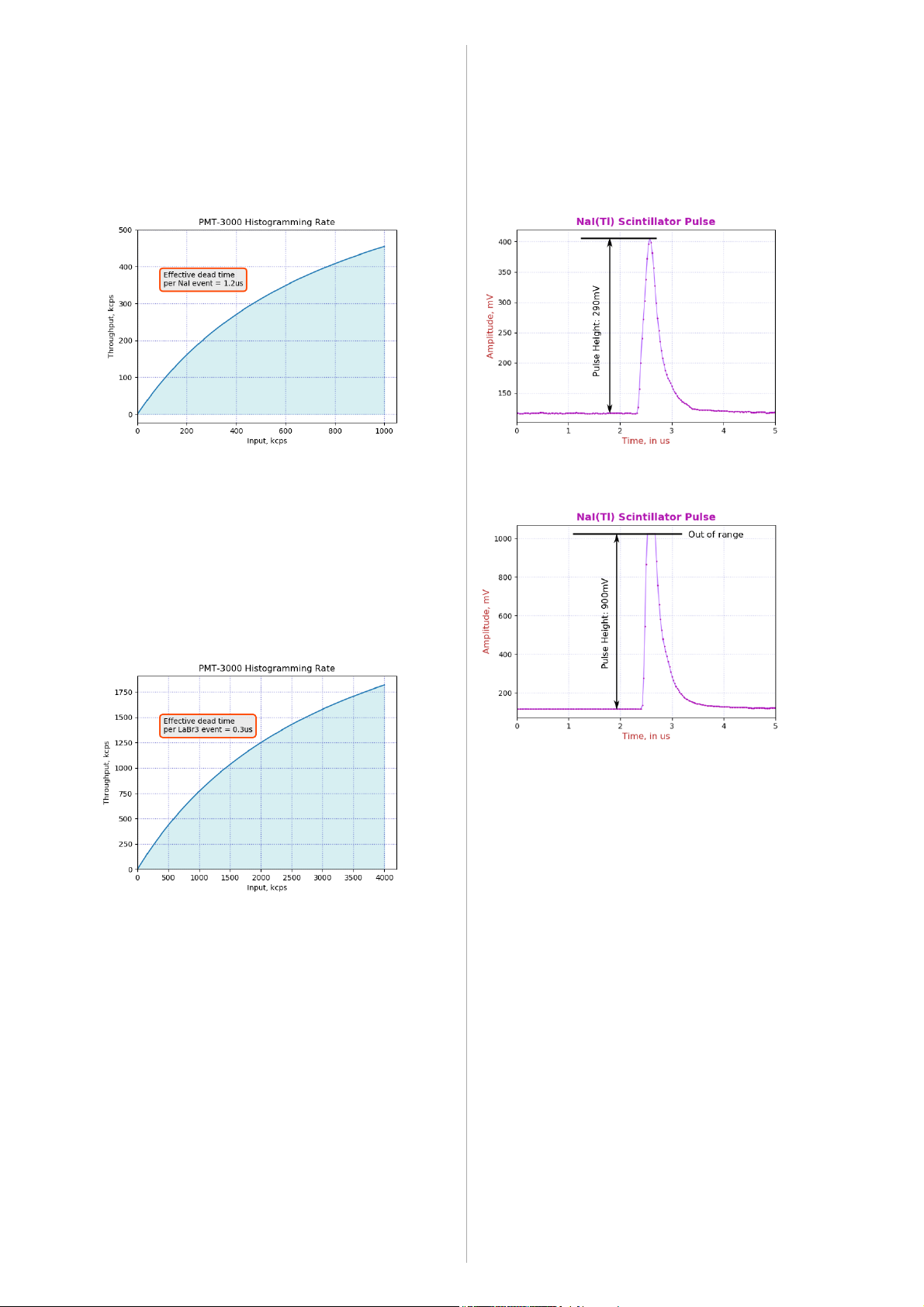

Aim for LED pulses of around 200mV ±50mV,

cf Fig. 5. Then glue the light diffuser into the

opening. For precise operation, the diffuser

must be securely glued in, otherwise it will

change its position during temperature cycles.

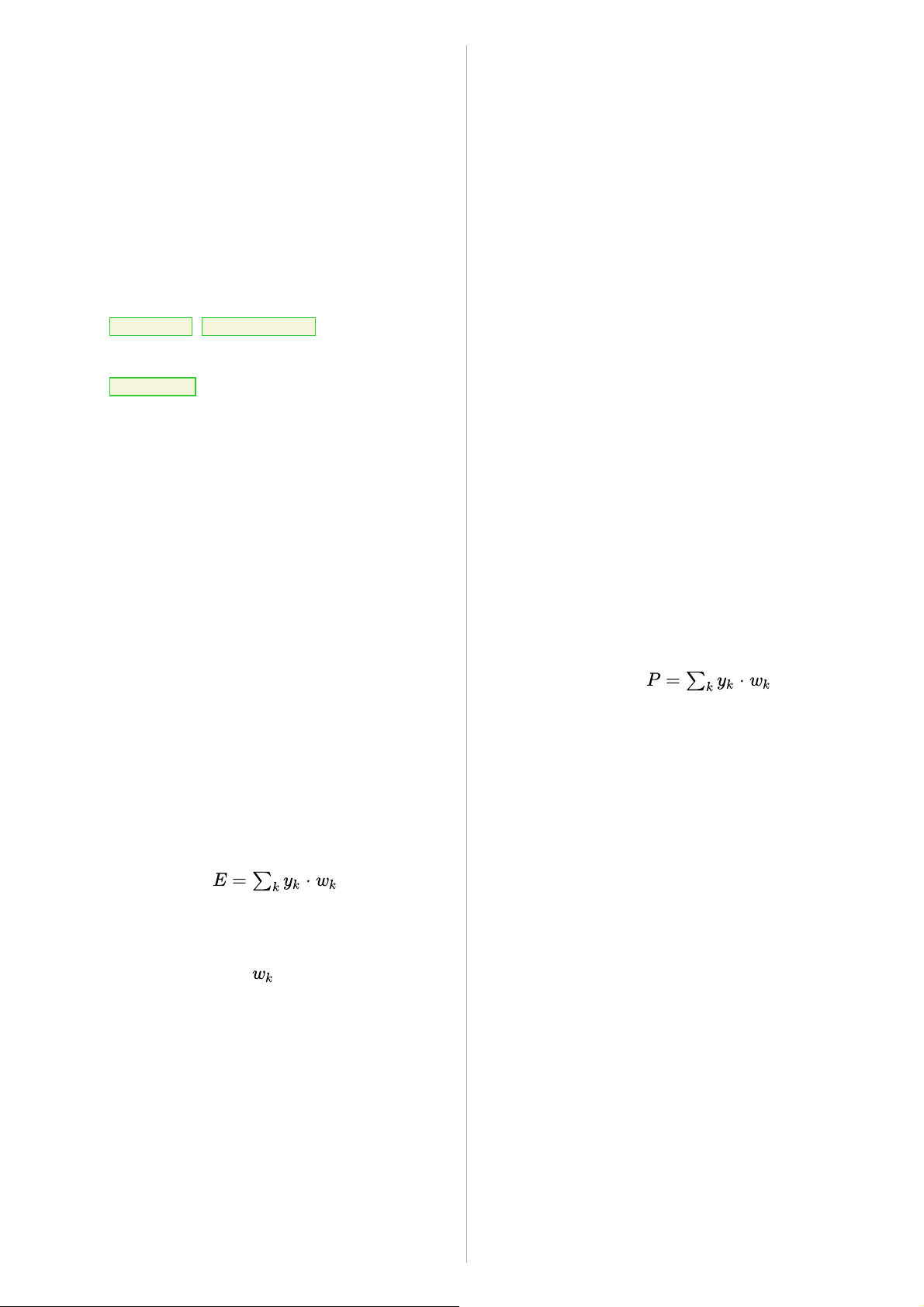

6. Summation Weights

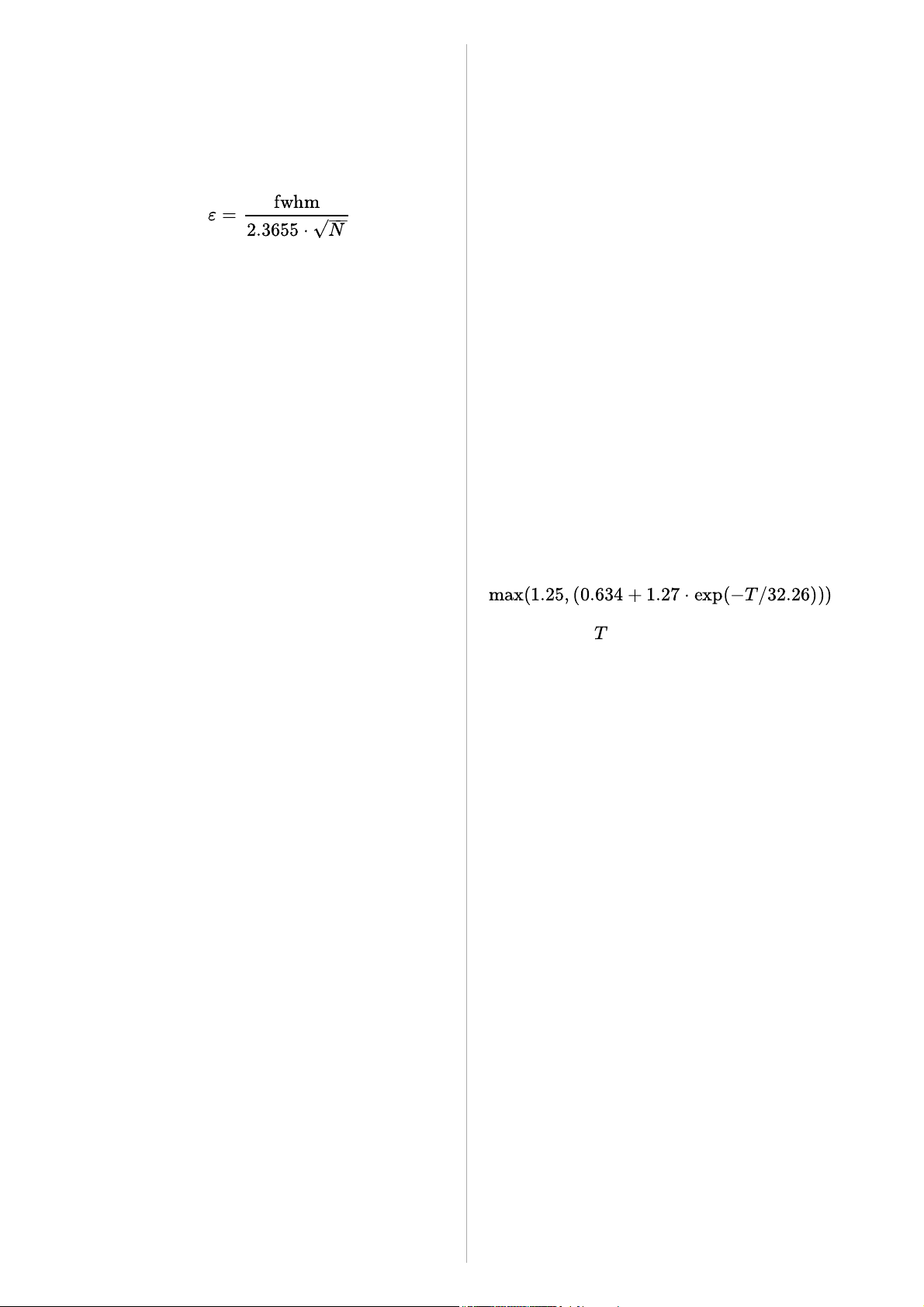

Normally the MCA-3000 measures a pulse

energy by first subtracting the DC-baseline,

and then by summing all ADC samples over an

integration time. All ADC samples are weighed

equally. But the MCA-3000 offers a more fine-

tuned control:

Improve the performance of certain

scintillators. In some unusual scintillators the

energy resolution can be improved if the

summation weights are not all equal. One

example is SrI(Eu) where in big crystals the

self-absorption of its own scintillation light can

create significantly different pulse shapes for

the same amount of energy deposited in the

crystal; say for 662keV. The scintillator grower

may have a recommendation, or the user can

apply iterative or machine learning methods to

find an optimized set of summation weights.

Most often, however, summation weights will

be advantageously used to create powerful

pulse shape discrimination algorithms as

discussed in the section.

Within the FPGA, 1024 consecutive

summation weights are stored, which covers

integration times up to 8.53µs (@120MHz

ADC speed) or up to 51.2µs (@20MHz ADC

speed).

Ignore if not needed. By default all

summation weights are set to 32767. For the

purpose of energy measurement, the weights

are considered to be unsigned 16-bit integers,

with a range from 0 to 65535. Unless this

feature is used, users can completely ignore

this.

There is only one set of weights. When

psd_on=0, the weights are treated as uint16_t

and are used in the computation of the energy

sum. When psd_on=1, the weights are used for

the psd sum instead of the energy sum.

The software ships with a big examples

section, where the user can find short python

scripts to program custom weights into the

FPGA, and even store them in the ARM

processor's non-volatile memory.

7. Pulse Shape Discrimination

PSD is controlled by the user. Both MCA-

3000 support a very general, patented, pulse

shape discrimination method that gives the user

great control. The user can define 16-bit signed

weights to apply to each ADC sample in a

pulse after triggering. . For

each event the firmware classifies the event as

being type 0 or 1.

When PSD is turned on, the firmware separates

type 0 and 1 events into two separate halves

(2Kx32) of the available histogram memory.

Type 0 events are always histogrammed in the

lower half, while type-1 events are recorded in

the upper half. For both types of events there is

a separate event counter to measure count rates.

When PSD is turned on, the firmware separates

type 0 and 1 events into two separate halves

(2Kx32) of the available histogram memory.

Type 0 events are always histogrammed in the

lower half, while type-1 events are recorded in

the upper half. For both types of events there is

a separate event counter to measure count rates.

This feature is compatible with loss-less

histogram acquisition where the histogram is

split into two separate banks. In that case there

will be four 1Kx32 spectra.

See wxMCA/examples on how to program

the weights. Consult the examples folder of the

software to find code examples that write

summation weights to the FPGA of the MCA-

3000 and to the non-volatile memory of the

ARM processor.