IMPORTANT SAFETY INSTRUCTIONS

When using this Tidland product, basic safety precautions should always be followed to reduce the

risk of personal injury. Your company's safety instructions and procedures should always be followed.

When using this product with any other equipment or machinery, all safety requirements stipulated by

that equipment or machinery manufacturer must be followed. Compliance with local, state, and federal

safety requirements is your responsibility. No part of these or the following instructions should be

construed as conflicting with or nullifying the instructions from other sources. Be familiar with the

hazards and safety requirements in your work environment and always work safely.

Read and understand all instructions and shaft design application limits before operation.

Never use this product for a purpose or in a machine that it was not specifically designed for. See

Product Safety Data Sheet (PSDS).

Do not exceed the operation loads for this shaft as noted on its PSDS, Product Safety Data Sheet.

Follow all warnings and instructions marked on the product and on the PSDS.

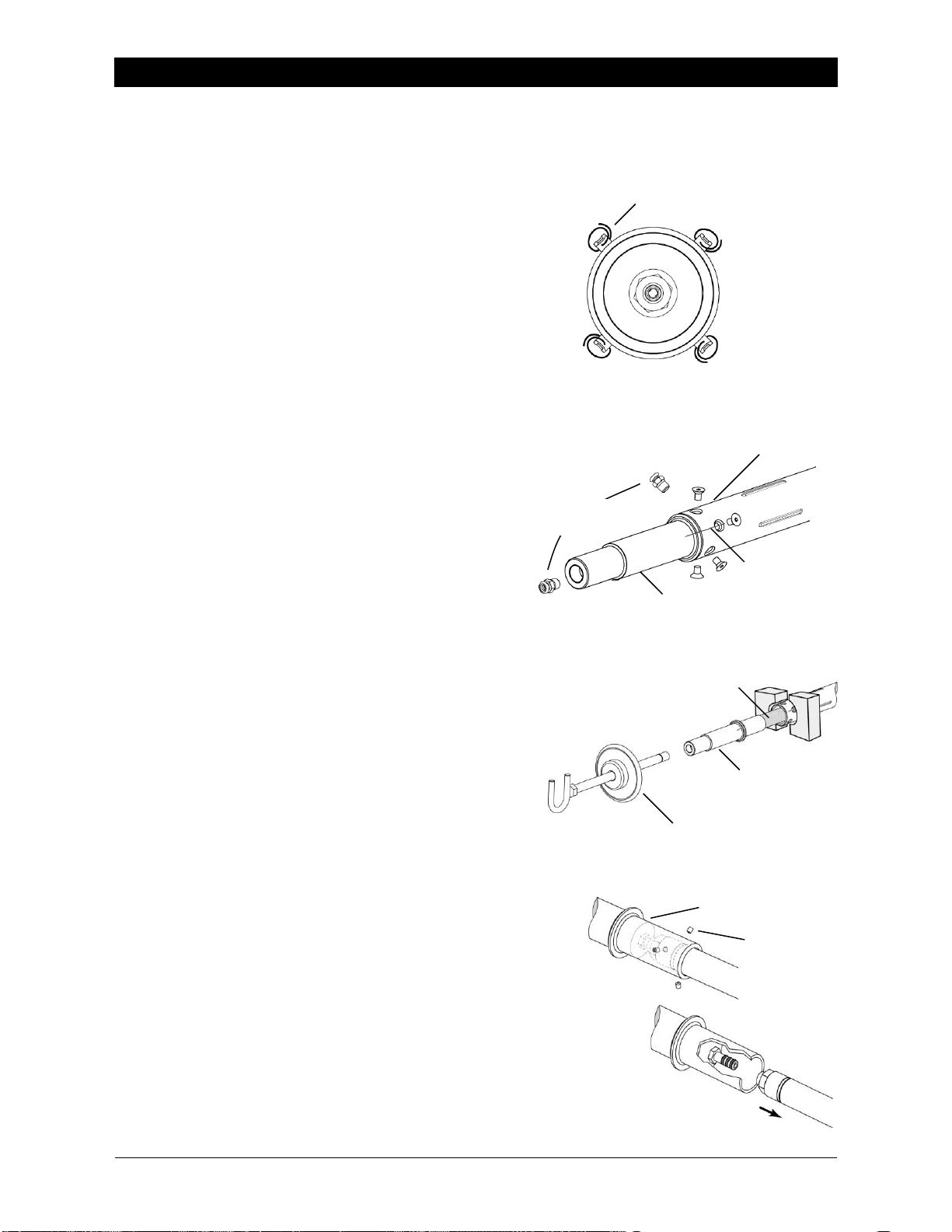

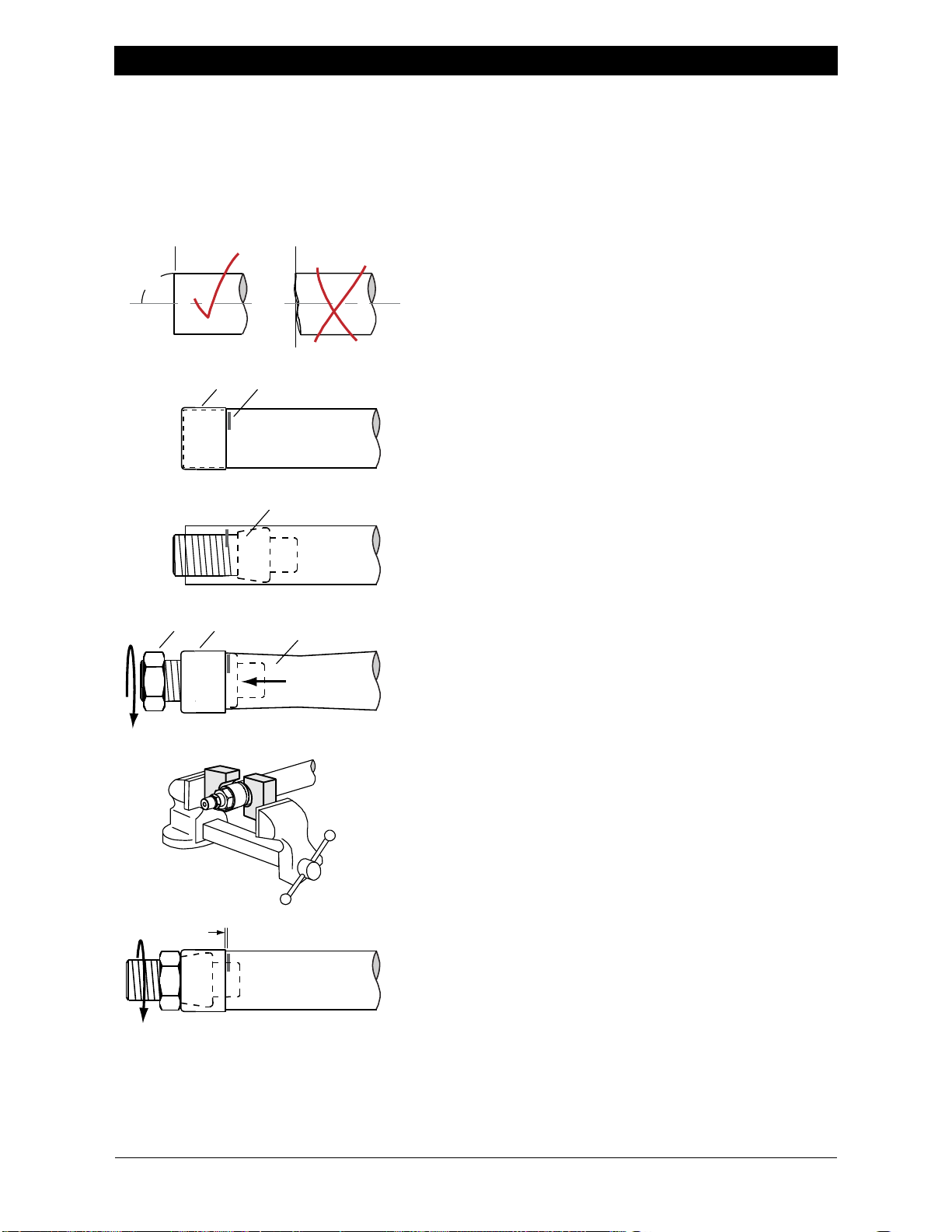

Do not use fingers or other objects to deflate the shaft; Tidland recommends using the Tidland Air

Release Tool (see page 4).

Inspect the shaft for wear and/or other safety and functional deficiencies daily, before each use.

Wear safety glasses or proper eye protection when inflating or deflating or otherwise operating the air

system.

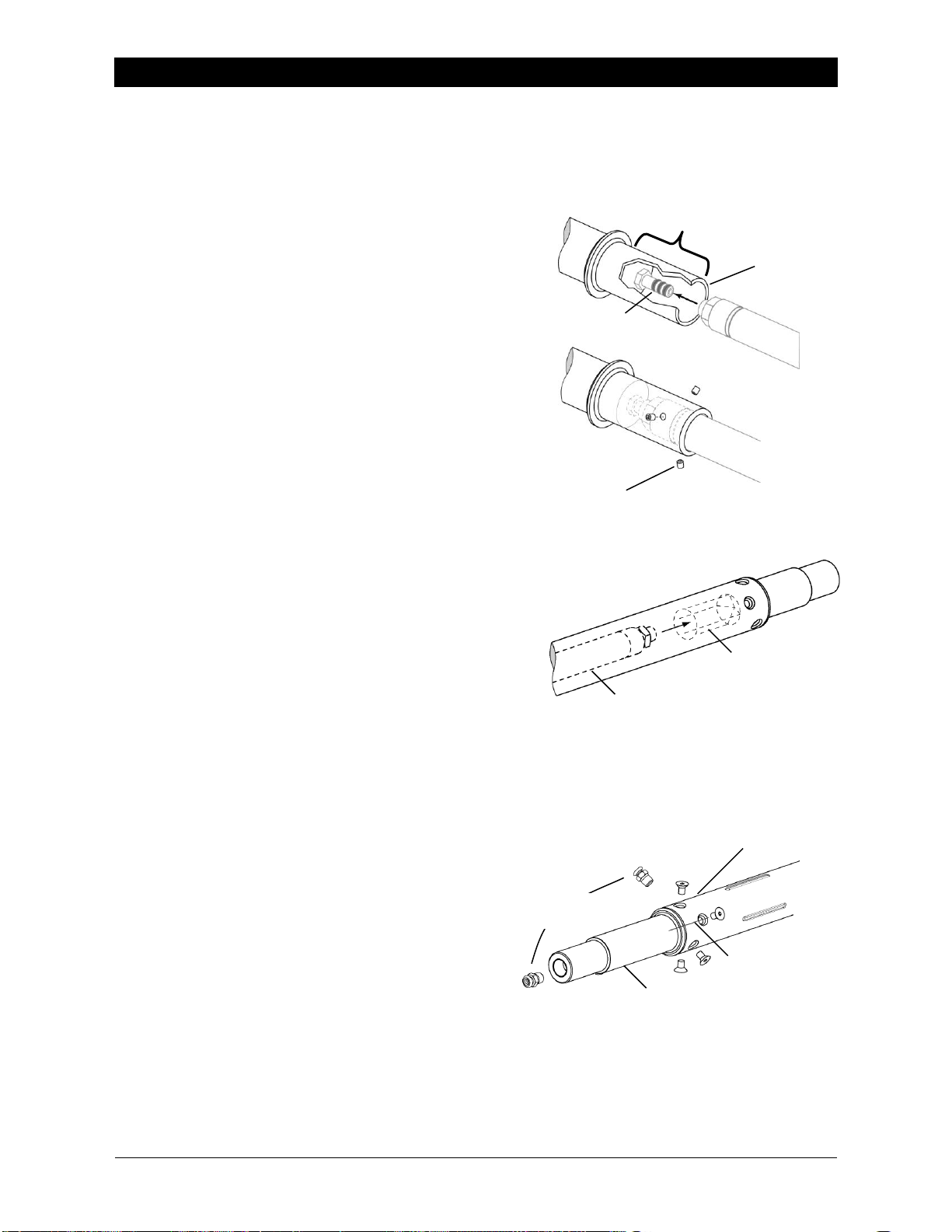

Do not remove or otherwise alter any setscrews or fastening devices prior to using this product.

Do not operate this product if any setscrews or fastening devices are missing.

Do not lift shaft manually if it is beyond your capacity. Loads over 1/3 your body weight may be

prohibitive. Consult your company safety policy.

When lifting a shaft, use proper lifting techniques, keeping back straight and lifting with the legs.

Do not carry or lift this product over wet or slippery surfaces.

Use appropriate mechanical lifting devices, such as a hoist or shaft puller, for heavier shafts.

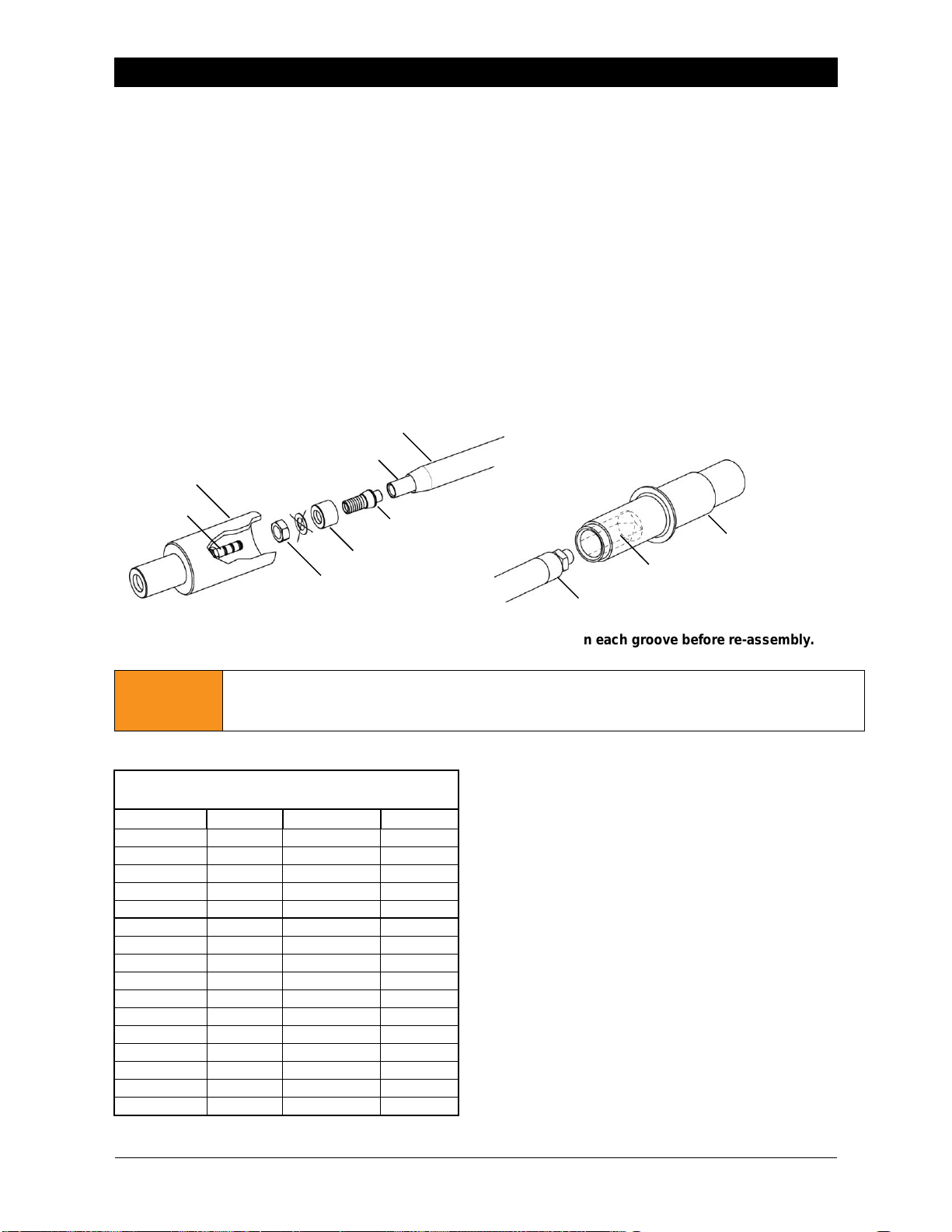

When performing maintenance or repair procedures, do not pressurize the shaft if journal setscrews

are loose or missing.

When performing maintenance procedures, do not pressurize the shaft if the journal is missing.

All replacement parts used on this product should be made to original Tidland specifications.

All maintenance and repair procedures performed on this product should be done to Tidland

specifications by qualified personnel.

If shafts with rubber air systems are stored longer than two weeks - store them

completely deflated, away from electric motors, away from direct sunlight or

florescent light, and in temperatures not exceeding 85ºF (29ºC).

When storing shafts with constant air pressure, the rubber air systems are subject to

distortion or cold flow.