Table of contents Brielmaier Motormäher GmbH

4 Twister

Table of contents

1 Twister.................................................................................................................. 6

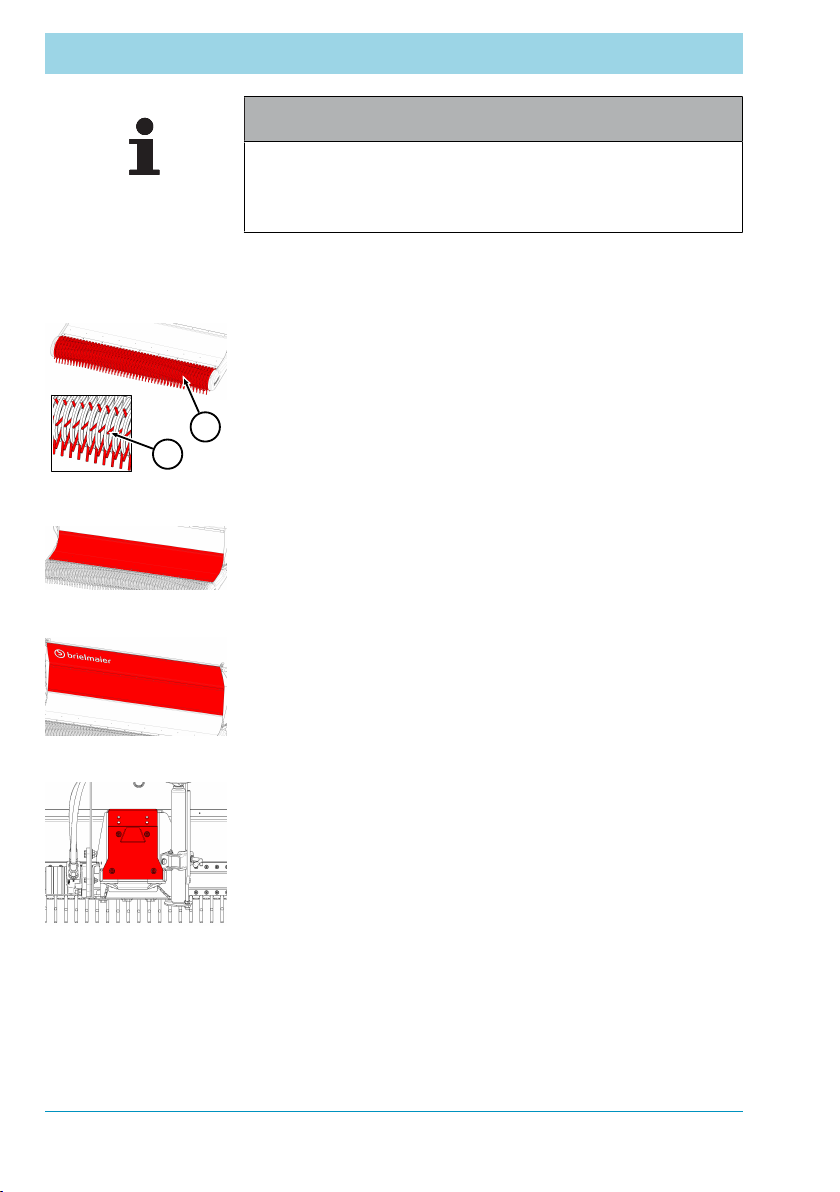

1.1 Overview ................................................................................................................... 6

1.2 Mode of operation ................................................................................................... 7

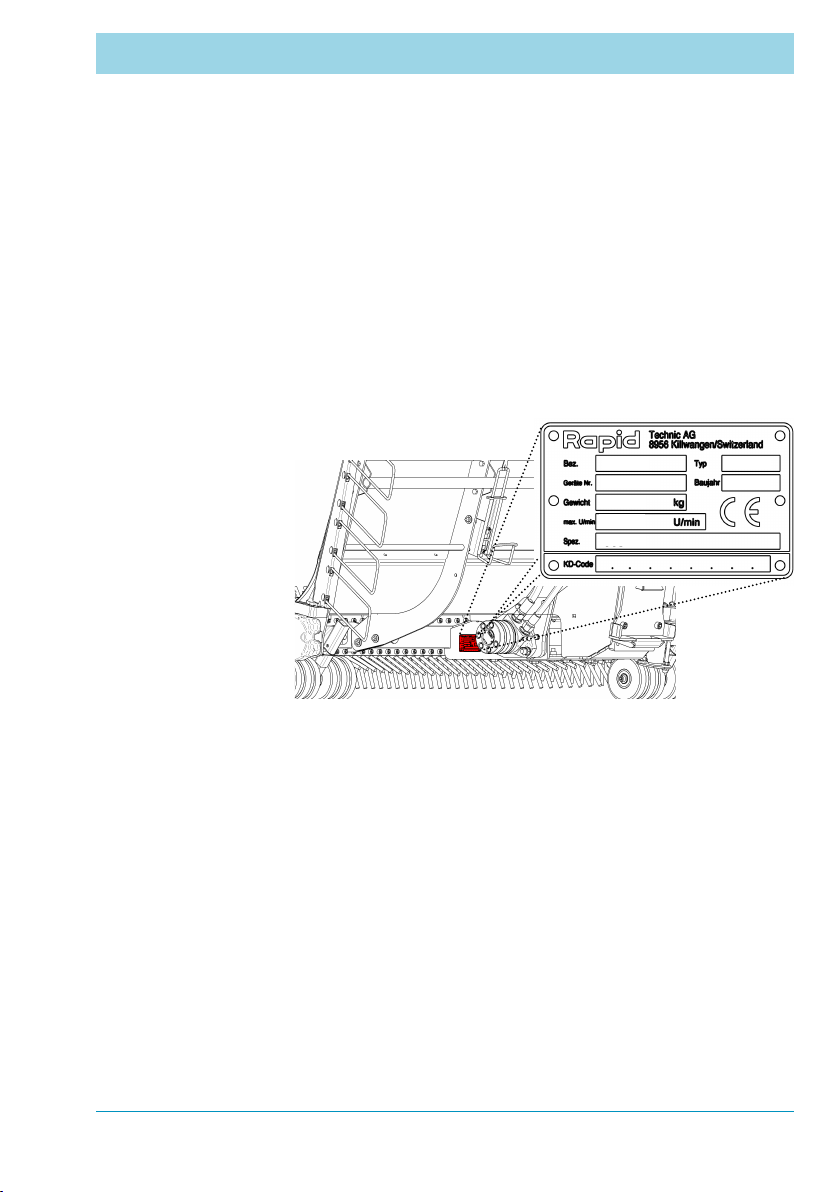

1.3 Name/type plate ....................................................................................................... 7

1.4 Attachment elements............................................................................................... 8

1.5 Operating elements.................................................................................................. 11

1.6 Scope of delivery ...................................................................................................... 12

2 Safety ................................................................................................................... 13

2.1 Structure of warning notices/symbols in these instructions................................... 13

2.2 Intended use ............................................................................................................. 15

2.3 Foreseeable misuse................................................................................................... 15

2.4 Fundamental dangers .............................................................................................. 16

2.5 Working zones and danger zones........................................................................... 20

2.6 Safety equipment ..................................................................................................... 21

2.7 User requirements .................................................................................................... 22

2.8 Responsibility of the owner ..................................................................................... 23

2.9 Personal protective equipment ............................................................................... 25

2.10 Labelling.................................................................................................................... 26

2.11 Environmental protection........................................................................................ 26

3 Transport and storage......................................................................................... 27

3.1 Safety during transport............................................................................................ 27

3.2 Load securing............................................................................................................ 28

3.3 Storing the attachment............................................................................................ 28

4 Start-up ................................................................................................................ 29

4.1 Safety during start-up .............................................................................................. 29

4.2 Coupling/uncoupling the attachment..................................................................... 30

4.3 Adjusting the working height ................................................................................. 32

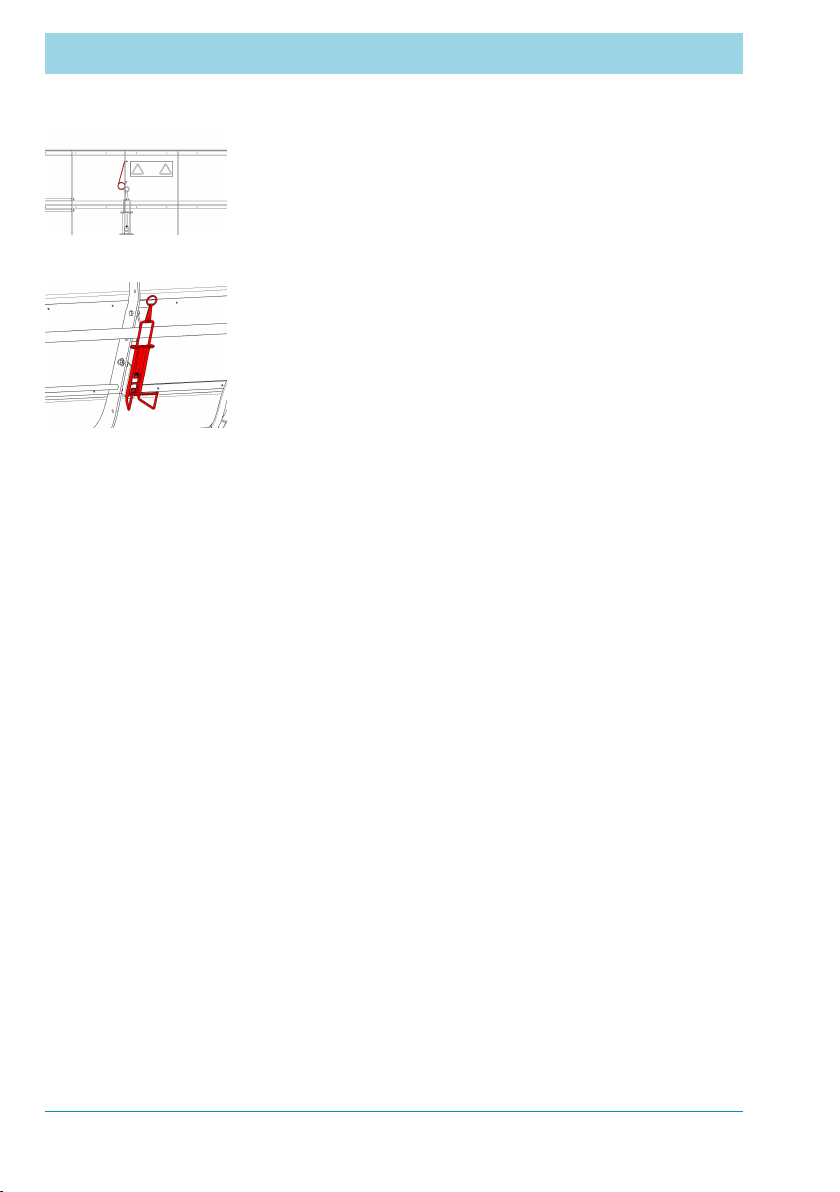

4.4 Adjusting the removal post ..................................................................................... 34

4.5 Installing and dismantling the side parts................................................................ 35

4.6 Setting the side parts to the transport/deflection position ................................... 36

4.7 Fitting the attachment grille (optional).................................................................. 37

5 Working with the attachment............................................................................ 38

5.1 Safety during operation........................................................................................... 38

5.2 Switching the machine on and off .......................................................................... 38

5.3 Operating the pick-up roller (manual operation) .................................................. 39

5.4 Operating the pick-up roller with radio remote control (optional)...................... 40