2English Manual 1018671-B

================================================================================================

INDRODUCTION

SAFETY LABELS AND NOTATION

=================================================================

This symbol will help to point out important safety precautions

throughout this manual. It means: ATTENTION! BECOME

ALERT! Your safety is involved.

The safety labels shown in this section are placed in important areas on your product

to draw attention to potential safety hazards.

On your product safety labels, the words DANGER, WARNING and CAUTION are

used with the safety-alert symbol. DANGER identies the most serious hazards.

The operator’s manual also explains any potential safety hazards whenever necessary

in special safety messages that are identied with the word, CAUTION, and the safety-

alert symbol.

CUSTOMER RESPONSIBILITIES

- Please read & retain this manual. The instructions will enable to assemble and maintain your product properly.

- Please carefully read and observe the SAFETY SECTION of this manual.

- Follow a regular schedule in maintaining and caring for your Brinly-Hardy product.

CONGRATULATIONS on the purchase of your new Brinly-Hardy Roger 180º Dump Kit! This accessory has been designed,

engineered and manufactured to give you the best possible dependability and performance.

Should you experience any problem you cannot easily remedy, please do not hesitate to contact our knowledgeable customer

service department toll-free at 1-877-728-8224. We have competent, well trained technicians to help you with the assembly and

use of your product.

TABLE OF CONTENTS

=======================

INTRODUCTION ...............2

SAFETY .....................2

HARDWARE IDENTIFIER ......3

PART LIST . . . . . . . . . . . . . . . . . . 4

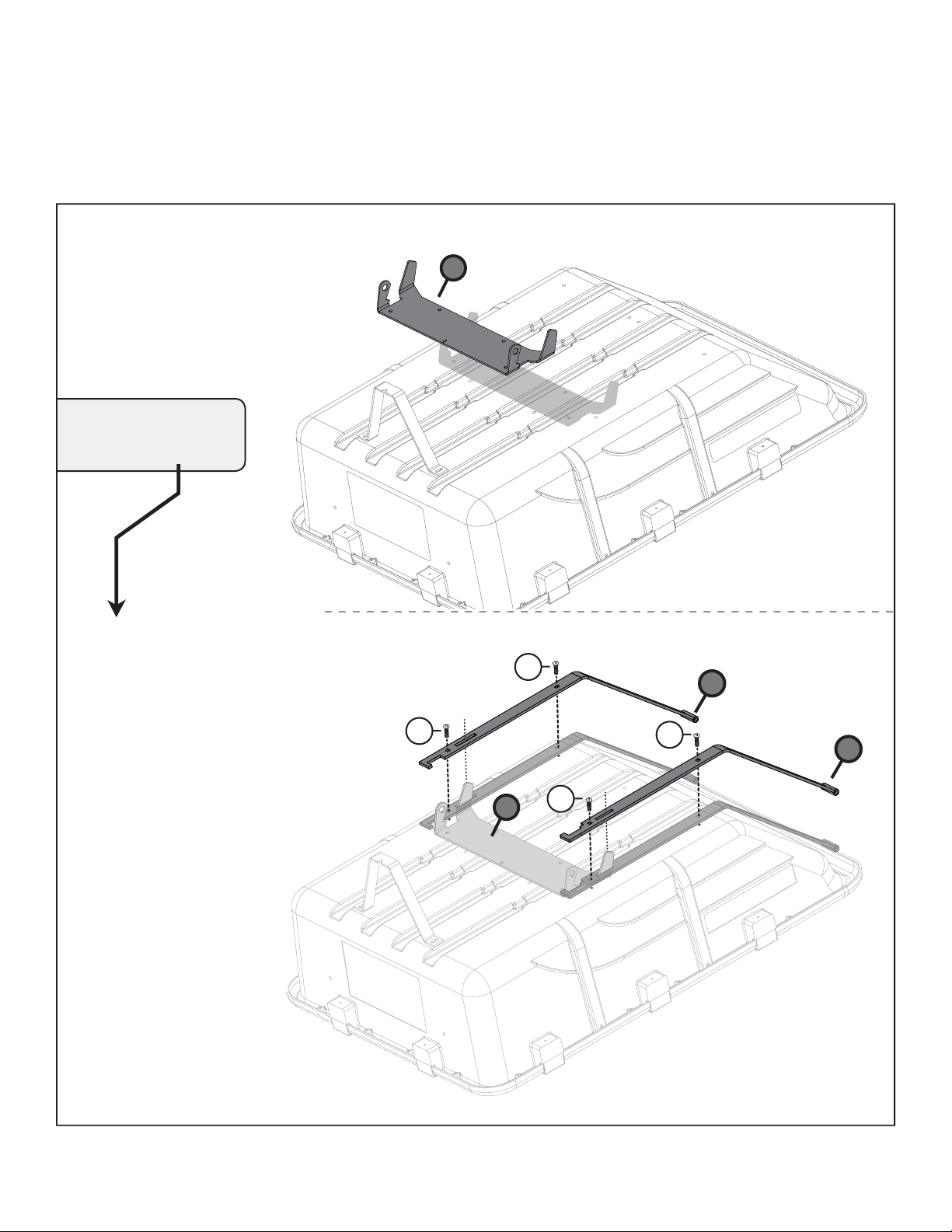

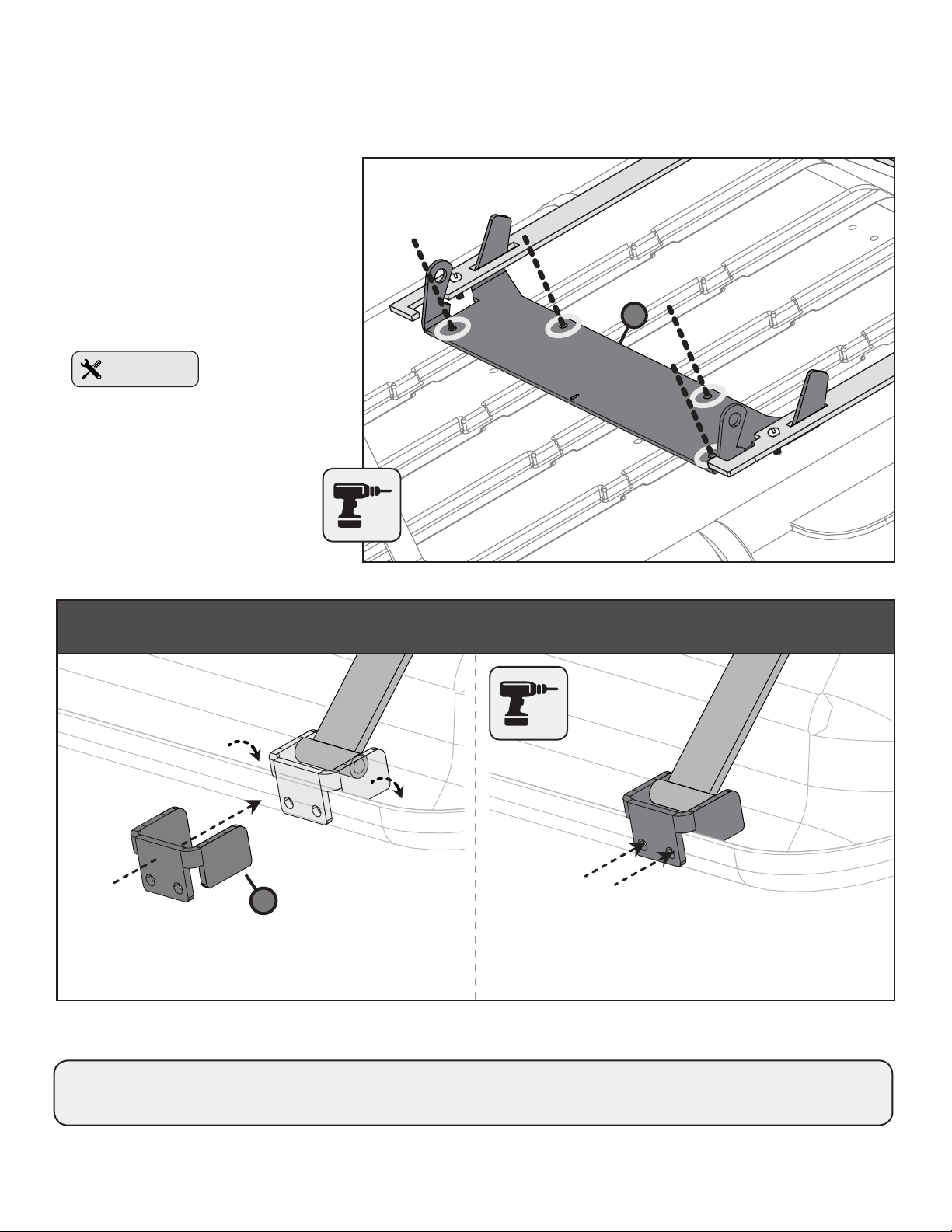

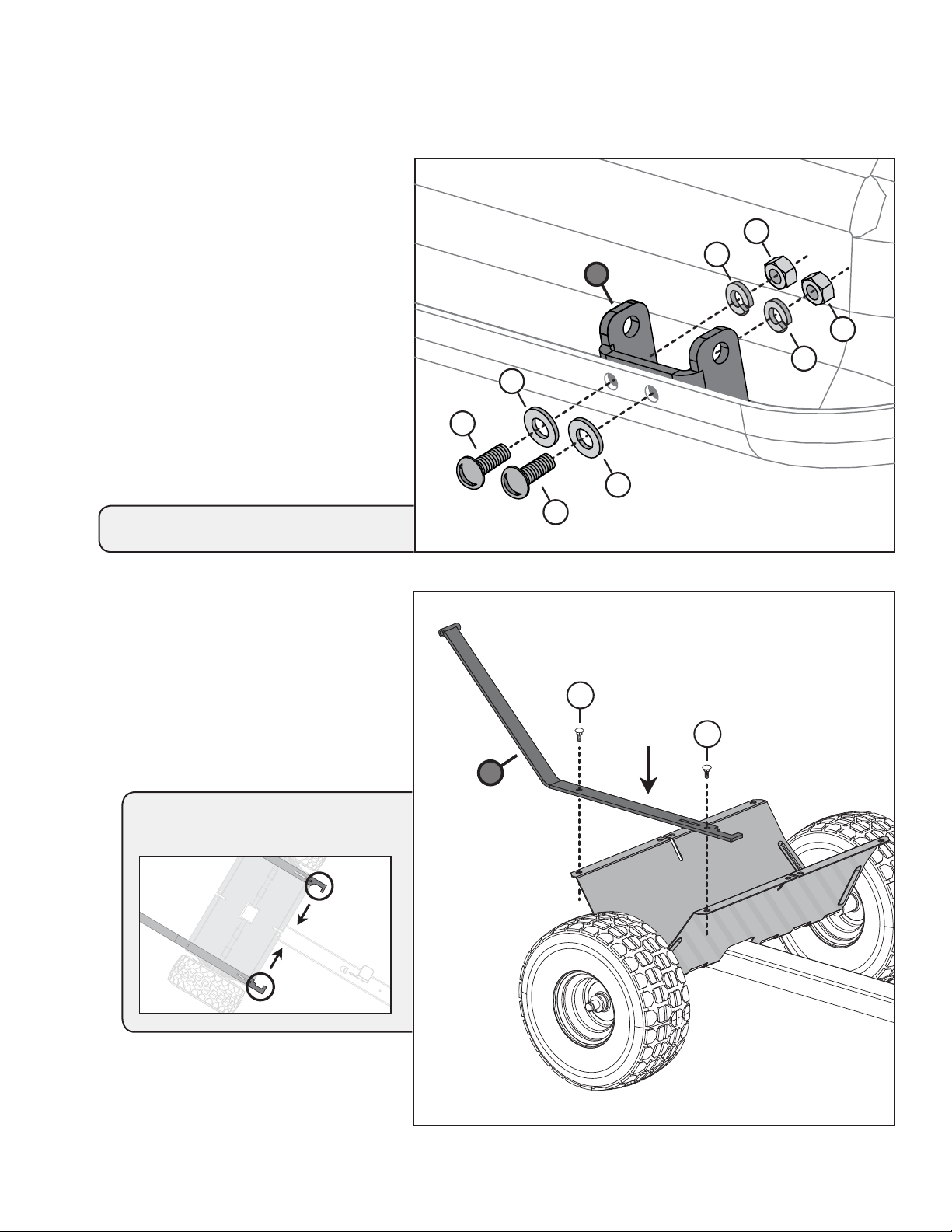

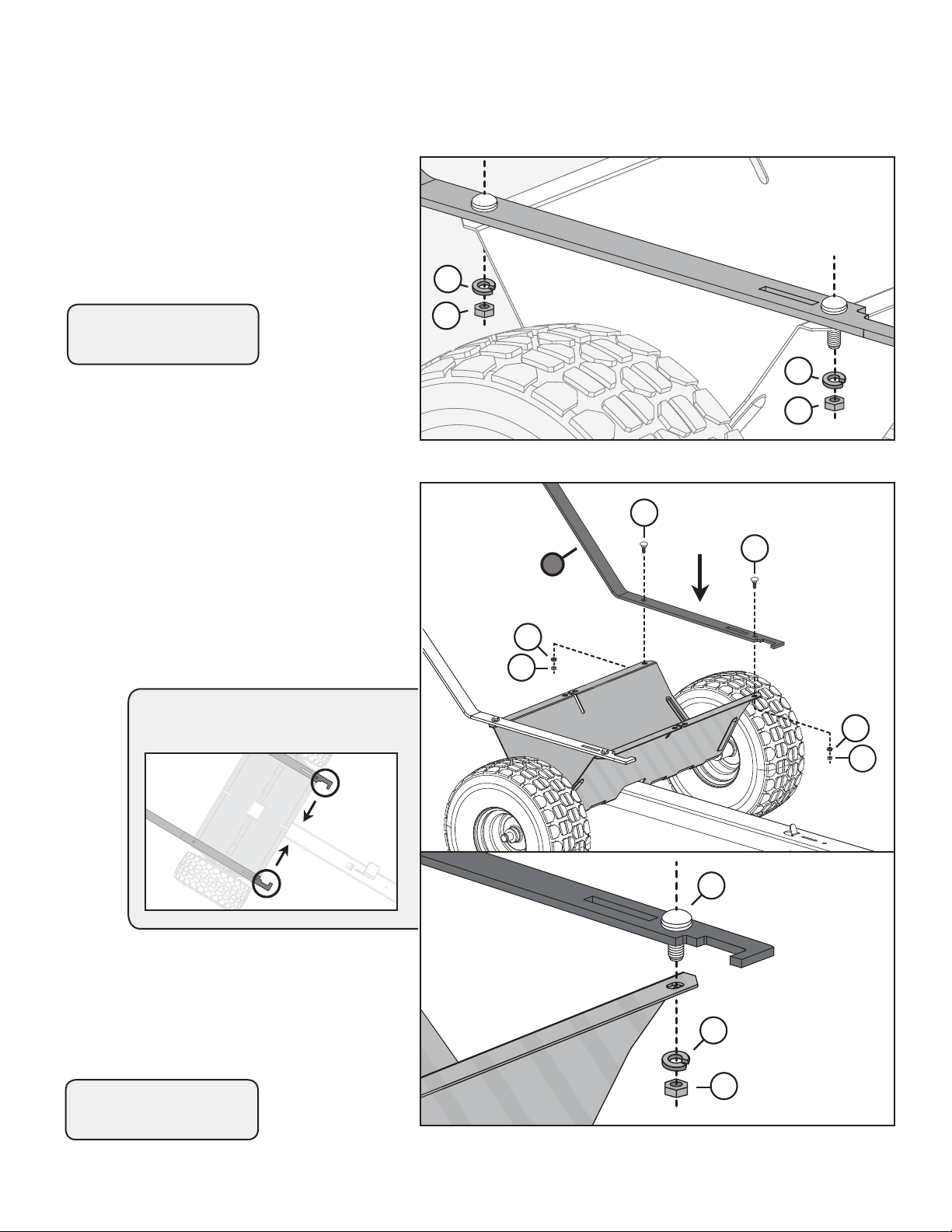

ASSEMBLY ............... 5 - 15

OPERATION ............. 16 - 17

WARRANTY .................18

RECORD PURCHASE INFORMATION

===========================================

Record your purchase information in the spaces provided below:

DATE OF

PURCHASE _________________________________________________

COMPANY NAME ____________________________________________

SERIAL NUMBER ____________________________________________

CO. PHONE ________________________________________________

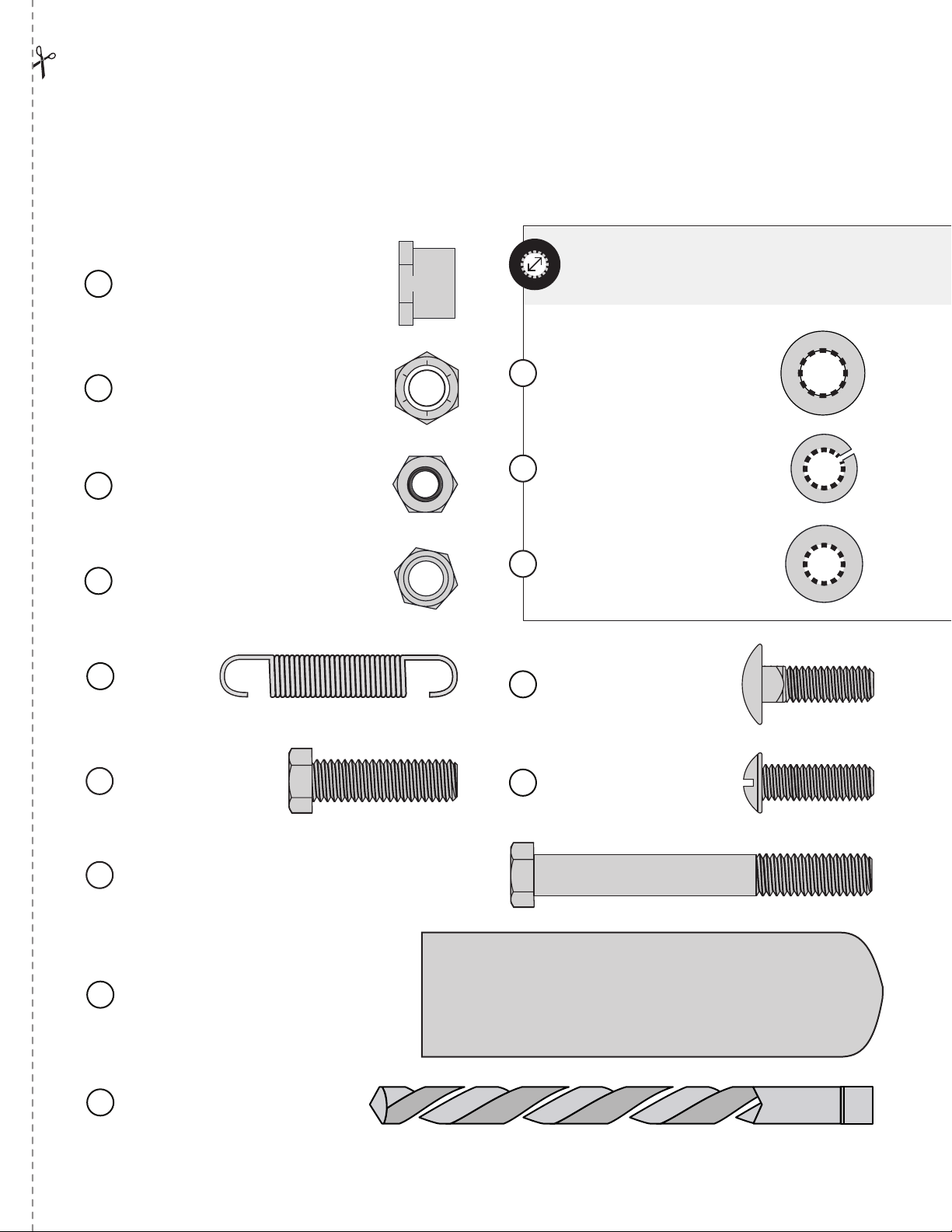

REQUIRED TOOLS

FOR ASSEMBLY

==========================

• 1/2” Wrench

• 9/16” Wrench & Ratchet

• Flathead Screwdriver

• Drill (5/16" Bit included with kit)

• Gloves