10.4 Setting the control box speed setting for the head ............................................. 25

11. Changing the function settings ...................................................................................... 26

11.1 Example for changing the memory switch setting .............................................. 26

11.2 Example for changing the parameter setting....................................................... 26

12. Adjustments ..................................................................................................................... 27

12.1 Synchronizer Model DB2-B737, B748, B774, B791............................................... 27

13. Troubleshooting guide .................................................................................................... 28

13.1 Error display and details ........................................................................................ 30

13.2 Control box troubleshooting guide ....................................................................... 31

13.3 Checking the machine solenoids........................................................................... 33

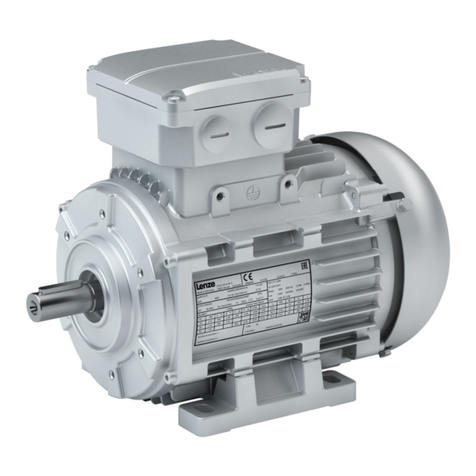

13.4 Checking the motor ................................................................................................ 33

14. VR1 & VR2 setting of treadle unit .................................................................................. 34

Technical Material

15. Explanation of each mode .............................................................................................. 36

15.1 Initialization mode .................................................................................................. 36

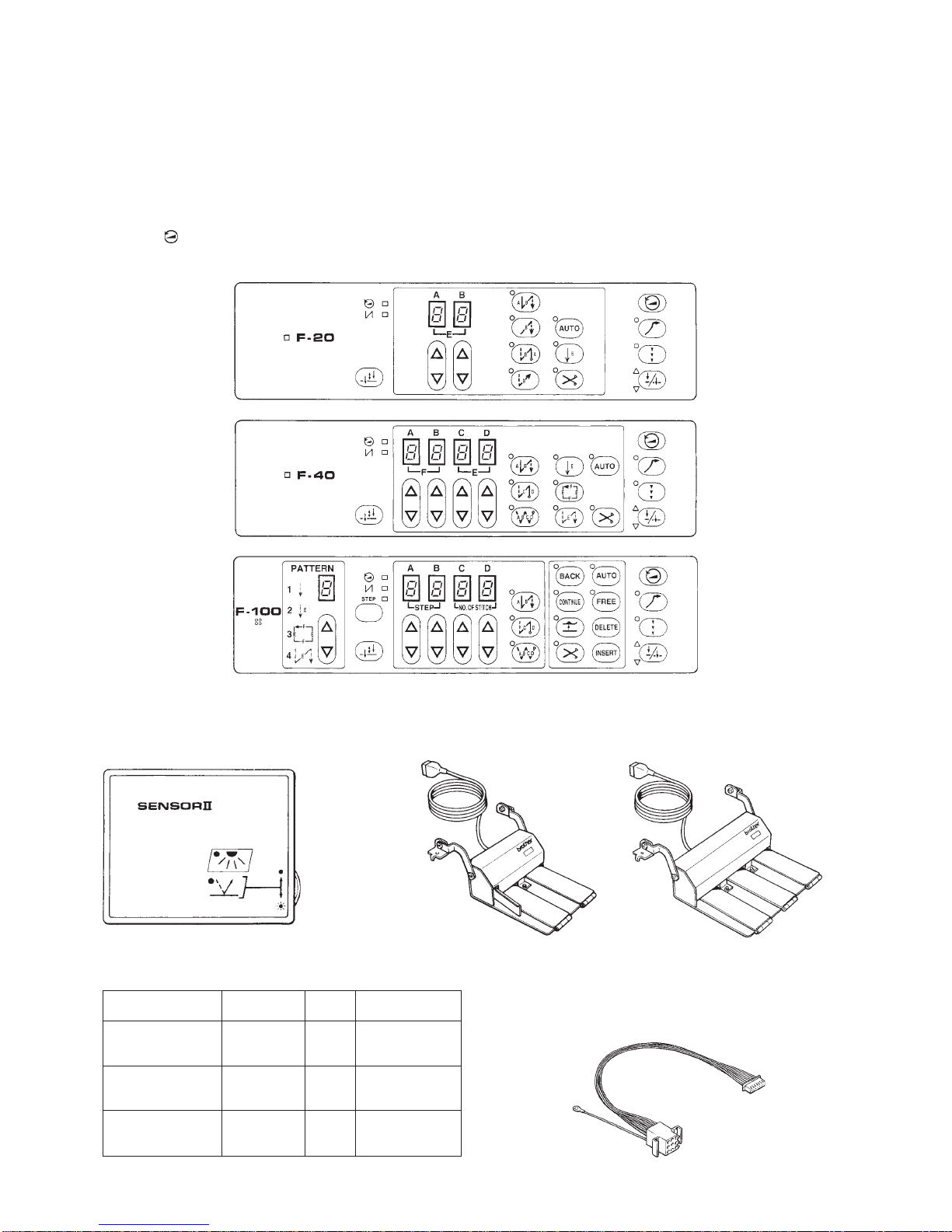

15.2 Head setting mode.................................................................................................. 37

15.3 Memory switch setting mode and parameter setting mode, etc........................ 38

15.4 Stitching speed setting mode ................................................................................ 40

16. Operational instructions ................................................................................................. 41

16.1 When the power SW is ON .................................................................................... 41

16.2 When the power SW is OFF ................................................................................... 41

16.3 Operation of the pedal............................................................................................ 41

16.4 While running.......................................................................................................... 41

17. Memory switch list .......................................................................................................... 42

18. Parameter list ................................................................................................................... 47

19. Panel display table........................................................................................................... 51

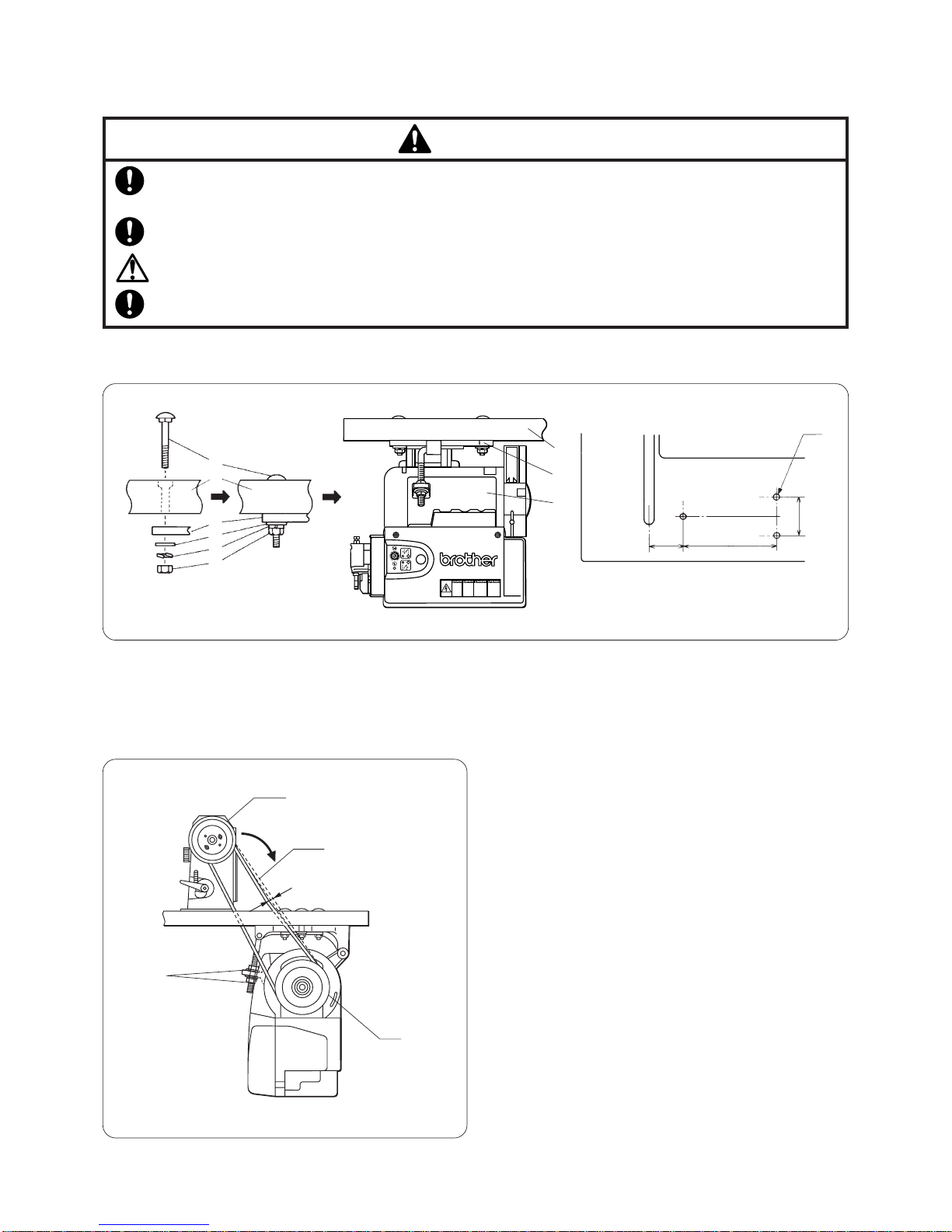

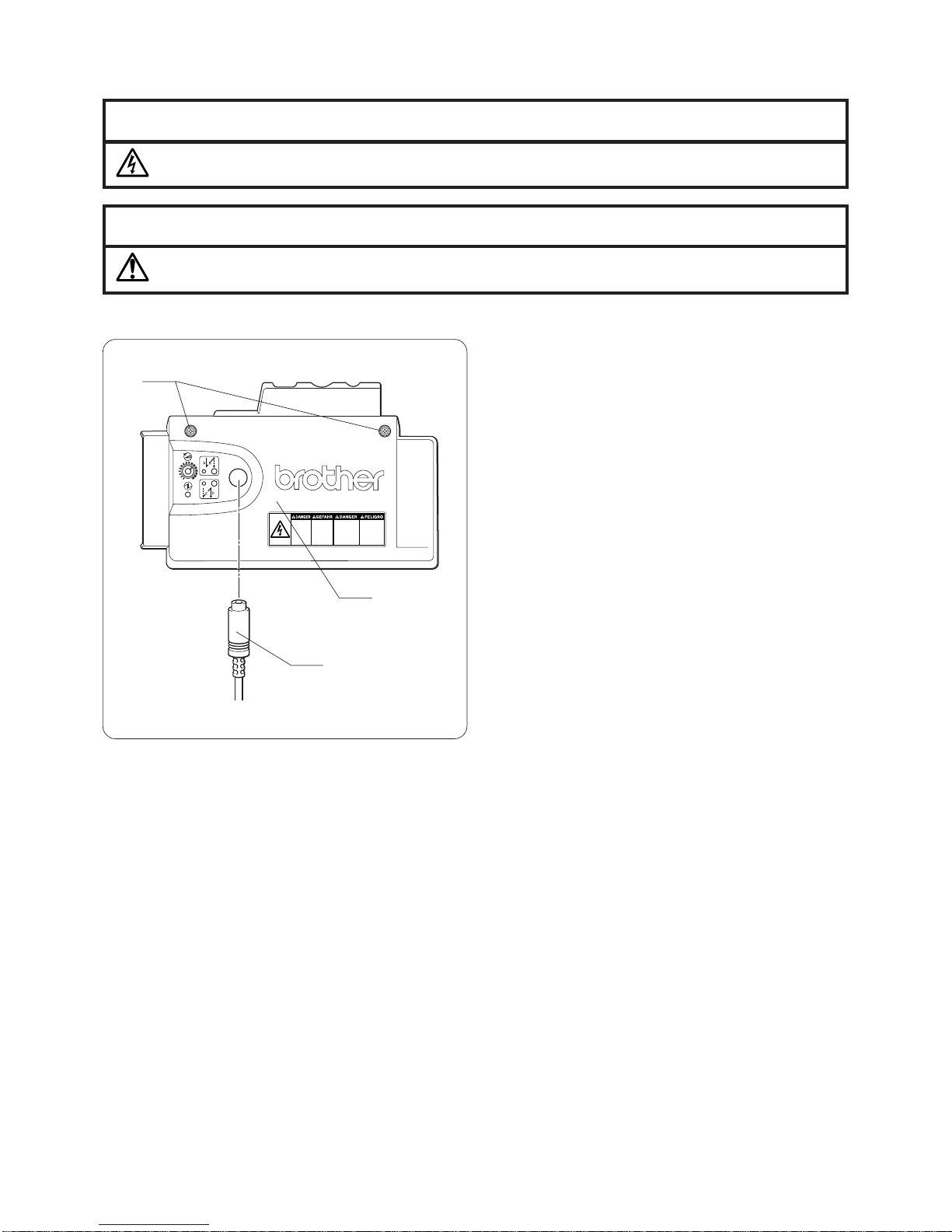

20. How to remove the control box ..................................................................................... 52

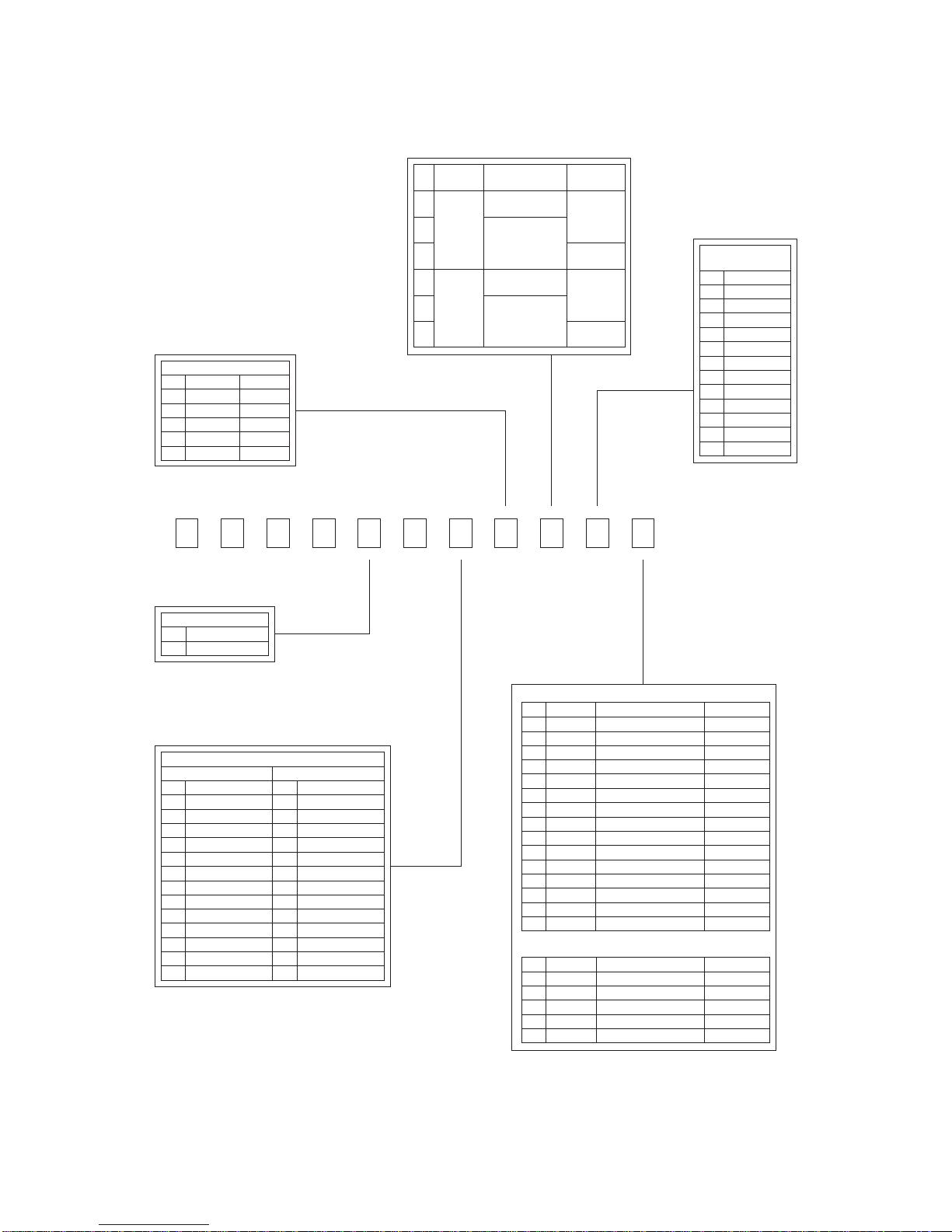

Control box block diagram ..................................................................................................... 53

Control PCB assembly diagram ............................................................................................. 54

Control PCB circuit diagram (1/3) (2/3) (3/3).......................................................................... 55

Power PCB assembly diagram (1-110/120) ........................................................................... 58

Power PCB circuit diagram (1-110/120) (1/2)......................................................................... 59

Power PCB assembly diagram (1-220/230-240) .................................................................... 60

Power PCB circuit diagram (1-220/230-240) (1/2).................................................................. 61

Power PCB assembly diagram (3-220) .................................................................................. 62

Power PCB circuit diagram (3-220) (1/2)................................................................................ 63

Power PCB assembly diagram (1-230(CE)) ........................................................................... 64

Power PCB circuit diagram (1-230(CE)) (1/2)......................................................................... 65

Power PCB circuit diagram (2/2) ............................................................................................ 66

Panel PCB assembly diagram ................................................................................................ 67

Panel PCB circuit diagram ...................................................................................................... 68

Treadle PCB assembly diagram, circuit diagram.................................................................. 69