Issue 04 14/10/2014 Pg 6 of 12

Cleaning,Maintenance

Repair

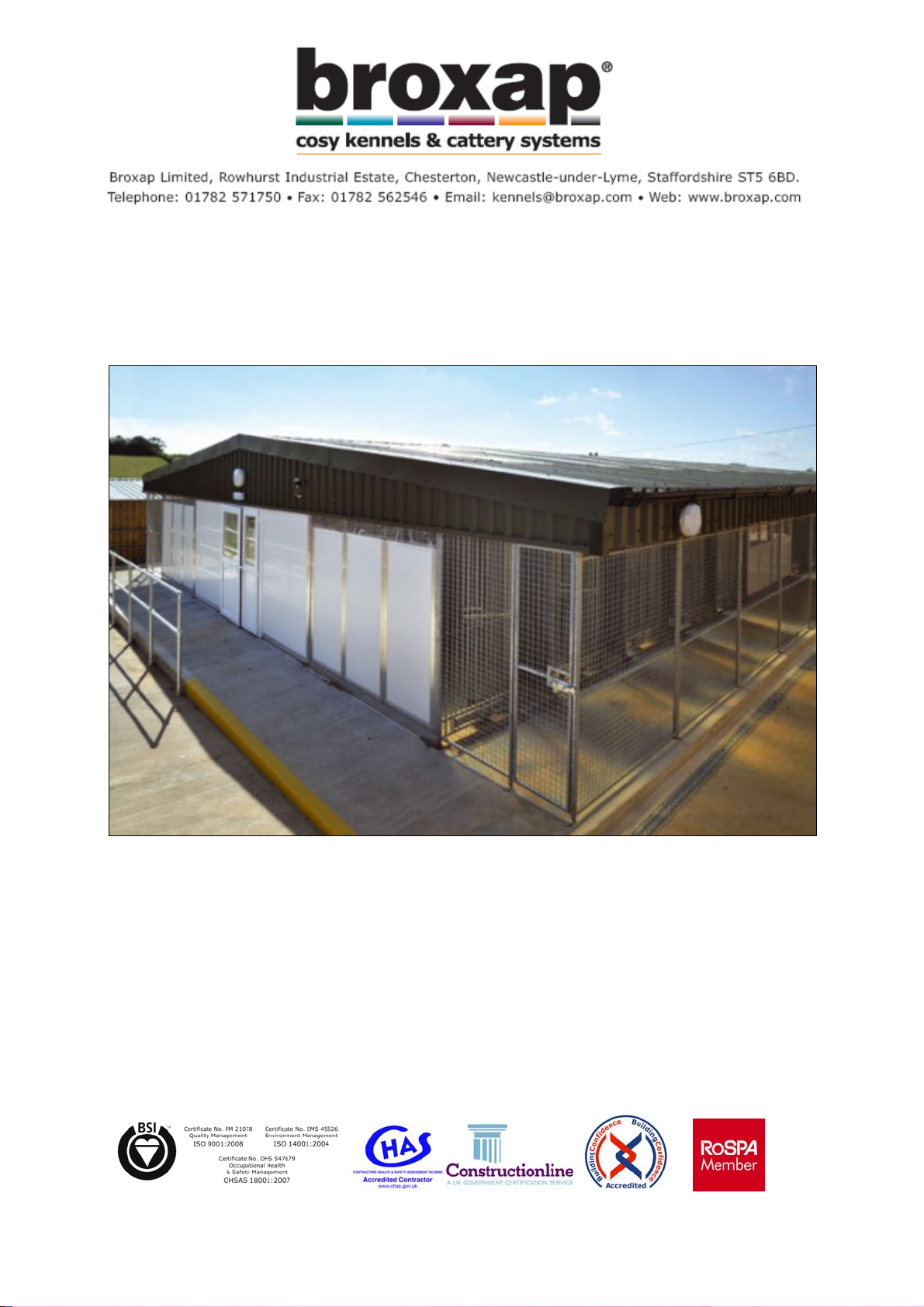

This section gives a generic overview of the inspection and cleaning regimes,

solutions, methods and techniques which will preserve the aesthetic finish of the

product.

Inspection & Cleaning

To maximise life expectancy the product should be visually inspected, on a regular

basis, for any signs of damage, breakdown of surface finish, reduction in

performance, build-up of salt, dirt or atmospheric residue, and loose fixings.

During these inspections, should any concerns be noted, then the Customer’s

attention is brought to the following pages whereby suitable maintenance and repair

methods are described for the various materials used.

In the event of serious damage to any main, or structural, component then Broxap

should be contacted immediately for detailed technical advice.

In addition to the visual inspection, the sleeping area panels will benefit from a clean

down being completed.

The required frequency of visual inspection and cleaning will be governed by the

usage:

In a harsh kennel environment, the cleaning frequency should be weekly, and

the inspection frequency should be monthly.

In a lower usage, or domestic, environment, the cleaning frequency may be

pushed out to monthly, with a 3 monthly inspection.

The clean down should be undertaken with a mild detergent in warm water. The

cleaning should be undertaken on all galvanized surfaces using a soft cloth or

sponge, at no time should any kind of abrasive be used.

Note – the above recommendations are over and above the normal expected daily

cleaning routines that are required to maintain the kennel cleanliness and hygiene.

This regime is in accordance with the jnown practices employed by the individual

kennel owner/manager. Broxap draw the users attention to the fact that all

cleaners and disinfectants must be compatible with the materials used for the

kennel. Broxap cannot be held responsible for any discolouration or

galvanizing oxidisation as a result of the cleaners used.

All cleaning and maintenance should be recorded, detailing the method of cleaning,

what products have been used, and what repair work has been undertaken.

In the case of a warranty claim against Broxap, this information will be requested.