d06767.fm

27 July 2019 73-00-00

Initial Issue Page 2 of 13

Copyright - BRP-Rotax GmbH & Co KG. All rights reserved.

SB-912-073 / SB-914-055

SERVICE BULLETIN

NOTE: Carburetors with S/N higher than the range listed above, have already been inspected

during serial production and are equipped with the carburetor circlip part no. 945786.

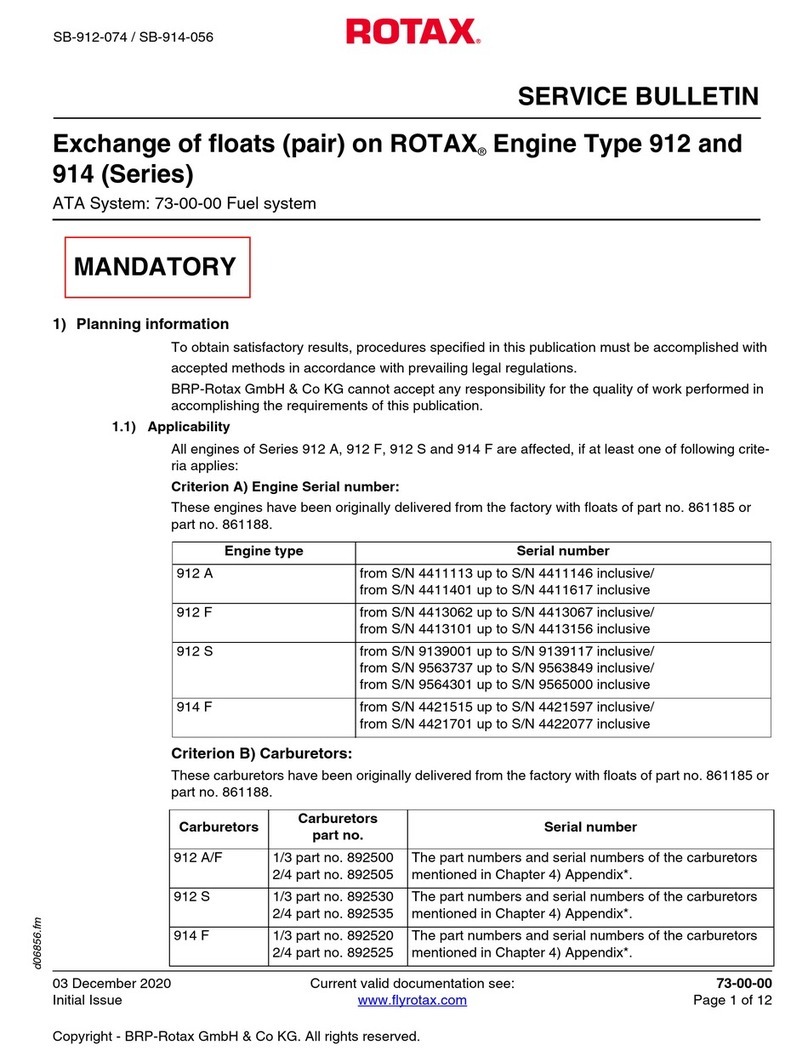

Criterion C) Spare parts:

Further all engines are affected which have been equipped with carburetors with part number and

serial number listedwithin Criterion B) above during engine repair, maintenance or general over-

haul or any other exchange action.

Further all engines are affected which have been equipped since January 01st 2015 with circlip

part no. 945785 asaspare part orprovided within aservice kit carburetor, maintenance kit

carburetor and overhaul kits during engine repair, maintenance or general overhaul or any other

exchange action.

1.2) Concurrent ASB/SB/SI and SL

None.

1.3) Reason

Due to deviations in the manufacturing process a partial fracture of the circlip may occur. This

fracture might lead to a crack/ total fracture of the circlip which in consequence may lead to a mal-

function of the carburetor. Possible effects might be rough engine running or an unusual engine

operating behavior.

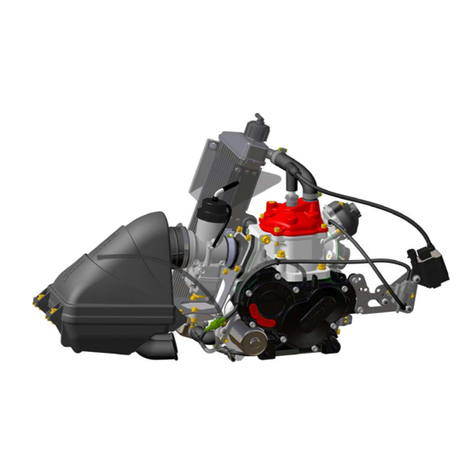

1.4) Subject

Replacement of circlip (carburetor) for ROTAX® engine type 912 and 914 (Series).

1.5) Compliance

- Immediately, on uninstalled engines / spare parts

- Within the next 25 hours of operation, but at the latest by July 31st 2020 the inspection and

mandatory exchange of the circlip must be conducted according to the following instructions in

Chapter 3

914 F 1/3 part no. 892520

2/4 part no. 892525

from S/N 143849 up to S/N 190436 inclusive /

from S/N 190438 up to S/N 190662 inclusive /

from S/N 190664 up to S/N 190864 inclusive /

from S/N 190866 up to S/N 190877 inclusive /

from S/N 190879 up to S/N 190885 inclusive /

from S/N 190887 up to S/N 190890 inclusive /

S/N 190897 / S/N 190903 / S/N 190906 / S/N 190908

from S/N 144003 up to S/N 185713 inclusive /

from S/N 185715 up to S/N 190359 inclusive /

from S/N 190361 up to S/N 190705 inclusive /

from S/N 190712 up to S/N 190740 inclusive /

from S/N 190742 up to S/N 190746 inclusive /

from S/N 190748 up to S/N 191408 inclusive /

from S/N 191418 up to S/N 191422 inclusive /

S/N 191424 / from S/N 191426 up to S/N 191427 inclusive /

S/N 191439 inclusive

mWARNUNG

mWARNING Non-compliance with these instructions could result in engine dam-

ages, personal injuries or death.