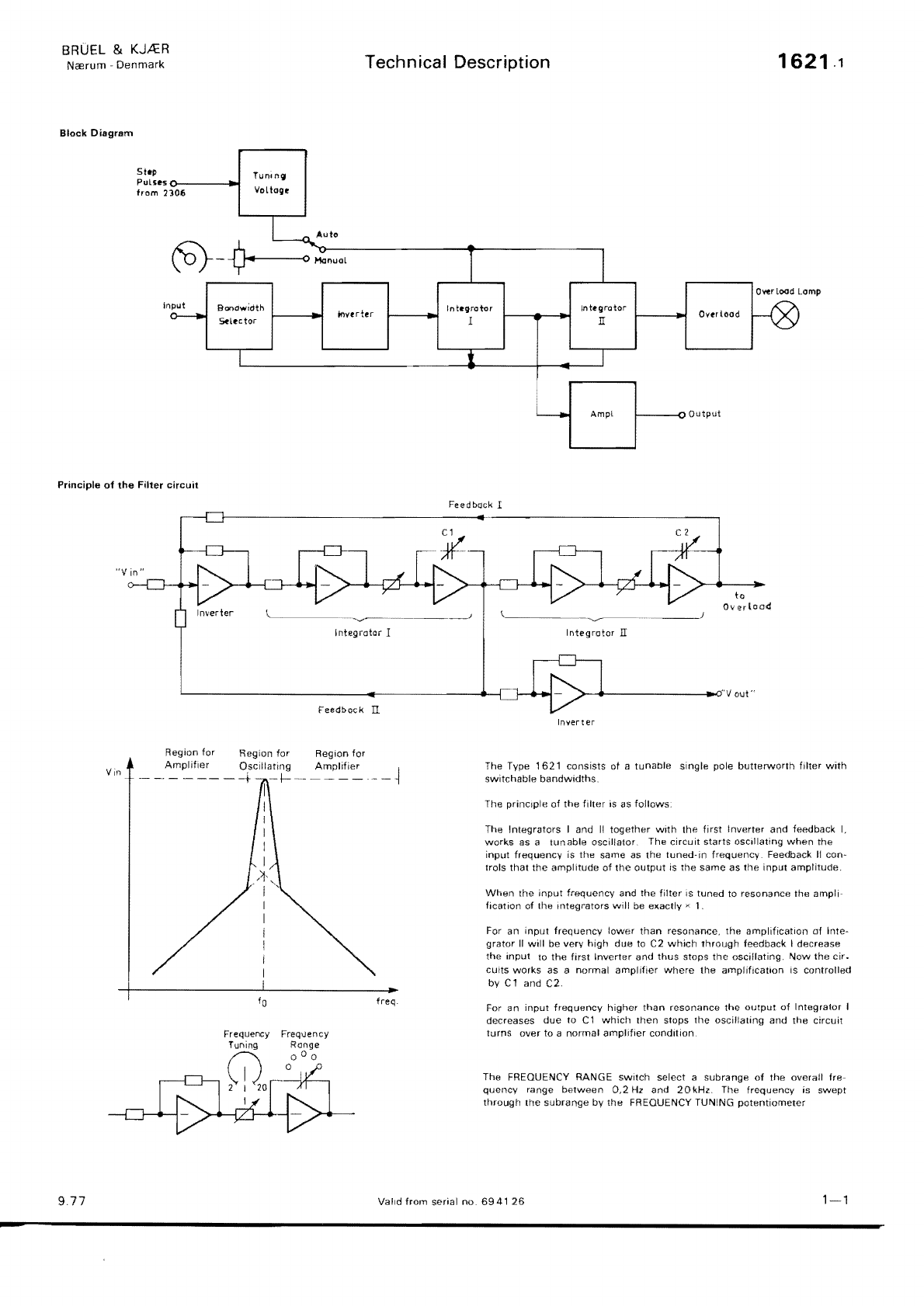

BRUEL & KJA:R

Ncerum

Denmark

Power

Supply

FilTER:

"linear"

INTERNAl BATIERY

Frequency

Tuning

Volta

ge

FILTER:

"Linear"

FREQUENCY TUNING

"r

SWEEP

CONTROl

"Manual"

DC-Off-set

Adjustment

FILTER

"23%"

FREQUENCY TUNING

"20"

SWEEP

CONTROl

"Manual"

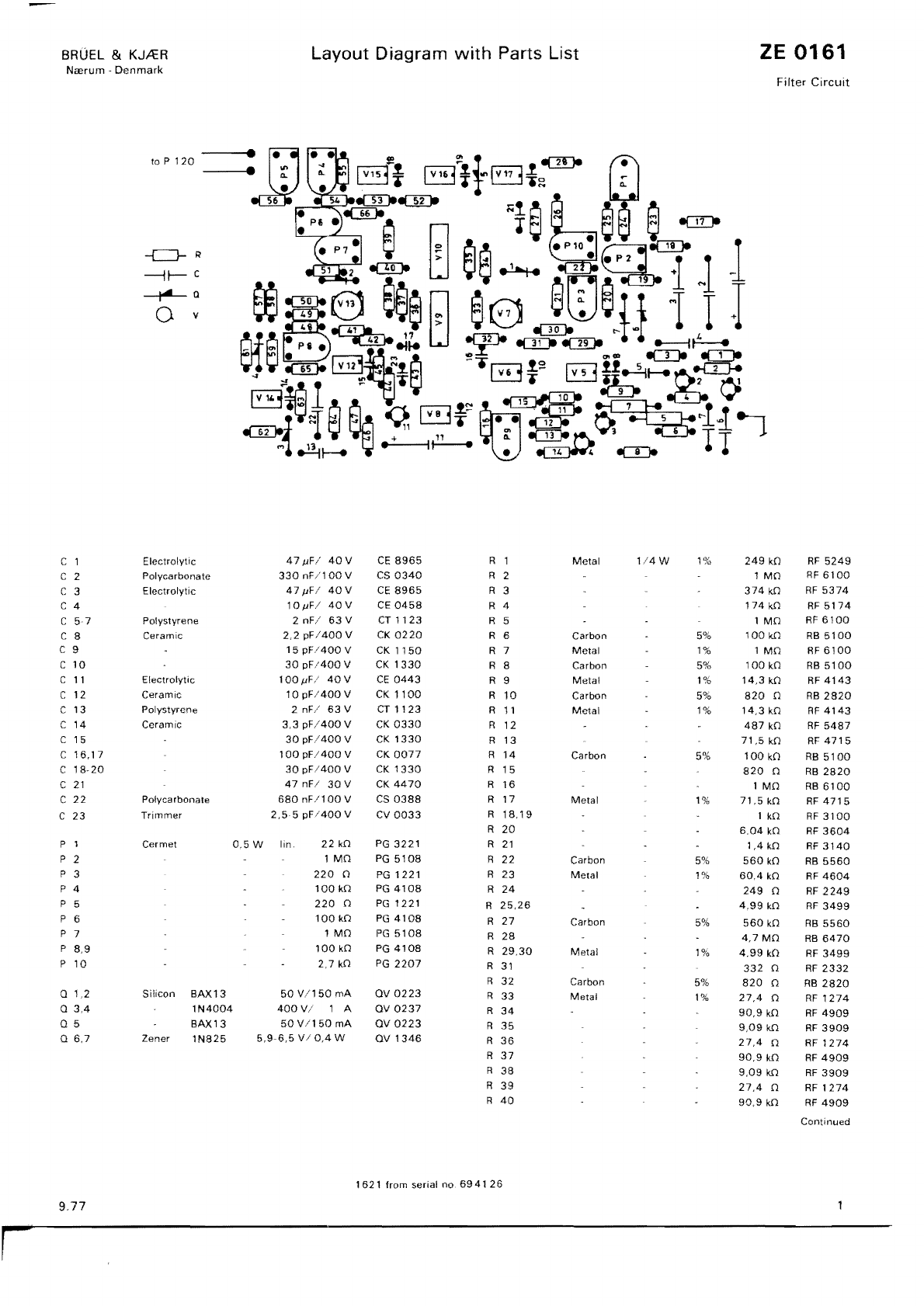

Adjustment Procedure

1621.2

Check the

following

voltages and adjust if necessary. +

12V

±0,3V

DC.

(P113)

+

lOV

±O,l

V DC.

(Pl11)

~10V

,,0,1

V DC.

(P112)

Remove

the

connection

between

P3 and

R26

on

lE

0161.

(Marked

'F'

on

the

P.

C board)

Adjust

the voltage on

the

slider

of

P3:

-1.20V

=

0,05

V

Reconnect P3 to

R26.

Check the voltage across

P120

FREQUENCY TUNING:

66

mV ± 2 mV

If necessary

adjust

P1O

Check if the voltages are

OV

0,2

mV

DC

between

ground

on

lE

0161

and

the

following

components (pin

2)

Component

V16 V15

V6

V12

If necessary ad]ust P4 P6 P9

P8

Amplitude

Controi

FilTER to

"Linear"

FREQUENCY RANGE

"2002K"

FREQUENCY TUNING:

"10"

MAX.

VOLTAGE:

"1

V"

SWEEP

CONTROl'

"Manual"

FILTER

to

..

3%"

FREQUENCY RANGE to

"2k-20k"

FilTER to

"Z3%"

Frequency

Control,

Manual

FilTER

"3%"

FREOUENCY RANGE

"ZO-200"

FREQUENCY TUNING

"2"

MAX.

VOLTAGE:

"1

V"

SWEEP CONTROL'

"Manual"

FREQUENCY TUNING to

"20"

FREQUENCY TUNING to

"2"

9.77

Check the voltage

between

pin 2 and 3 on

V17:

OV ±

0,2

mV.

If

necessary

ad]

ust P1.

Input

signal to

"Filter

Input";

1000

Hz

adjusted

for

1 V

deflection

on an electronic voltmeter

connected to

"Filter

Output"

Fine adJust FREQUENCY TUNING

for

maximum

output

voltage.

Deflection:

1 V ±

O,6dB.

If necessary adjust P

114.

(lG

0109)

C~ange

signal frequency to

10kHz

and check the

output

voltage

Deflection:l

V

0,6

dB.

If necessary

adjust

Pl15.

(ZG

0109)

For

the

positions

of

FREQUENCY RANGE

"0.2·Z",

"Z-20",

"ZO-200"

the tolerances are

±

O,6dB,

but

no adJustments.

Check as above.

Tolerance'

0,3

dB

0,6

dB

in"2

k

20

k"range

Input

signal:

20

Hz

0,01

Hz

• 1 V

Fine

adjust

FREQUENCY TUNING

for

maximum

output,

voltage

loosen

the

knob and

turn

the

pointer

to position 2.

Change signal frequency to

200

Hz

0,1

Hz

Adjust

P5

{ZE

0161)

for max.

output

voltage

Repeat

the

above adJustments

as

they

influence

e8ch

olhers

Check the frequency

for

the

other

positions

of

FREOUENCY

RAt'<GE.

Tolerance: ± 1%

In

the

rango"Zk-20k'

the frequency can be

adjusled

by

C

118.

(ZG

0109).

Valid from serial no.

6941Z6

-

2-1