Contents

4ID: 182463115

5.3.3 Mechanical interactions .................................................................................................... 28

5.3.3.1 Ground and building vibrations......................................................................................... 28

5.3.3.2 Impact noise ..................................................................................................................... 30

5.3.3.3 Acoustic ............................................................................................................................ 30

6 Planning details ............................................................................................................................... 31

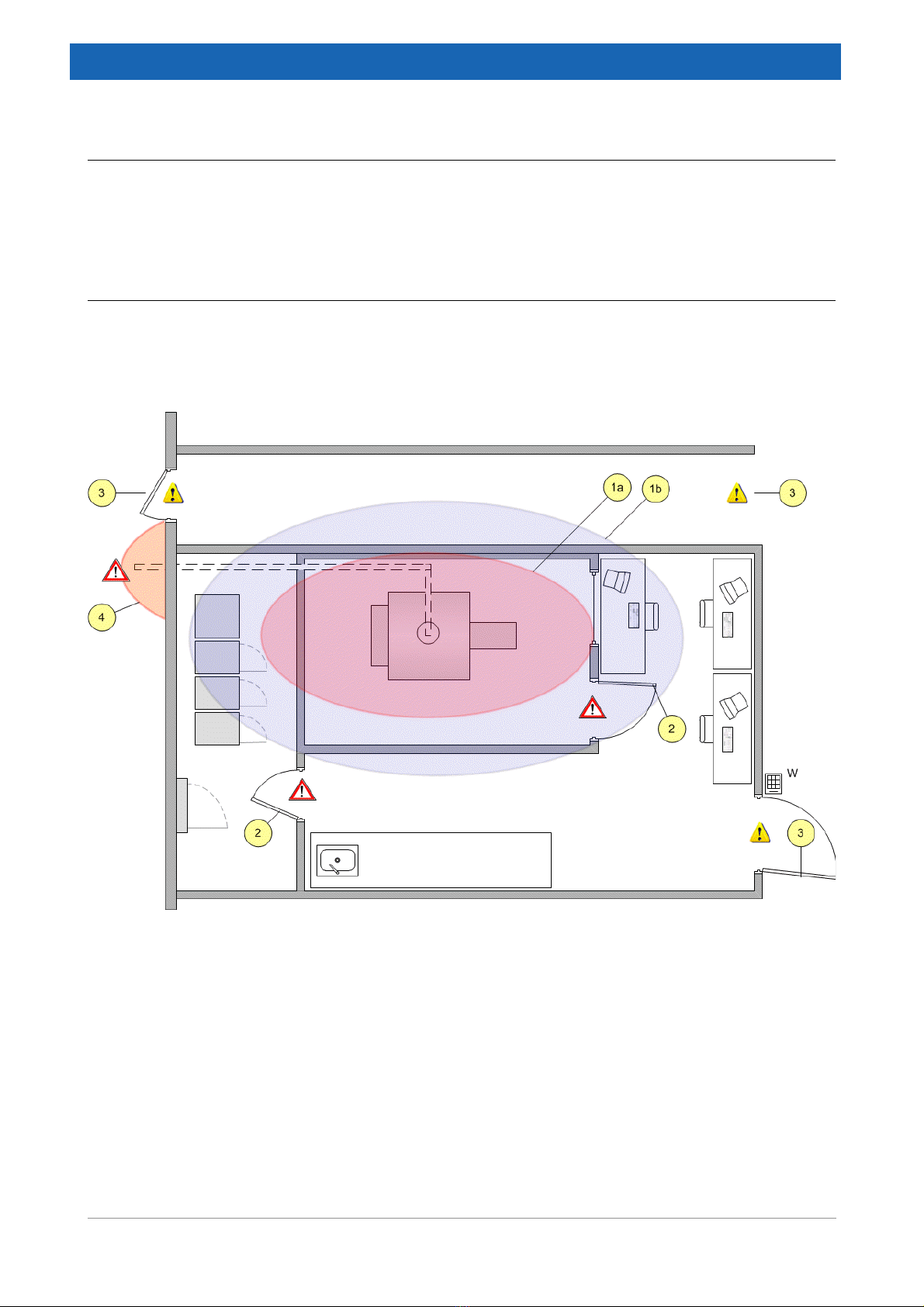

6.1 Measurements and room dimensions .............................................................................. 31

6.1.1 Overview........................................................................................................................... 31

6.1.2 Operating area.................................................................................................................. 32

6.1.3 Magnet area ..................................................................................................................... 32

6.1.4 Technical area .................................................................................................................. 34

6.2 HF shielded room ............................................................................................................. 35

6.2.1 Filter plates ....................................................................................................................... 36

6.2.1.1 Electronic filter plate ......................................................................................................... 40

6.2.1.2 Magnet filter plate ............................................................................................................. 40

6.2.1.3 Filter plate for anesthetic gas exhaust.............................................................................. 40

6.2.1.4 Filter plate for magnet exhaust system............................................................................. 41

6.2.1.5 MRI CryoProbe™ filter plate............................................................................................. 41

6.2.1.6 In-vivo filter plate .............................................................................................................. 41

6.2.1.7 Filter plate for Faraday cage ventilation ........................................................................... 41

6.3 Exhaust system ................................................................................................................ 42

6.3.1 Design criteria of the exhaust system............................................................................... 44

6.3.2 Calculating the exhaust system........................................................................................ 45

6.4 Floor construction ............................................................................................................. 46

6.4.1 Surface loads and weights ............................................................................................... 47

6.4.2 Magnet foundation............................................................................................................ 48

6.4.3 Electrostatic discharge ..................................................................................................... 50

6.4.4 Seismic safety standards.................................................................................................. 50

6.5 Electrical installations ....................................................................................................... 53

6.5.1 Overview........................................................................................................................... 53

6.5.2 Main connection ............................................................................................................... 54

6.5.3 Central potential compensation ........................................................................................ 56

6.5.4 Electrical connections in the magnet room....................................................................... 56

6.5.5 Electrical connections in the operating room.................................................................... 56

6.5.6 Connection and assembly of electrical distributor ............................................................ 57

6.6 Supervision signals........................................................................................................... 57

6.7 Cable lengths and routing................................................................................................. 58

6.7.1 Line lengths for the MRI CryoProbe ................................................................................. 62

6.8 Lighting system................................................................................................................. 63

6.9 Ventilation and air conditioning......................................................................................... 63

6.9.1 Overview........................................................................................................................... 63

6.9.2 Air conditioning systems................................................................................................... 64

6.9.3 Anesthetic gas extraction ................................................................................................. 65

6.10 Cold water supply ............................................................................................................. 66

6.10.1 Connections and installation............................................................................................. 67

6.11 Cryogen liquids................................................................................................................. 70

6.12 Compressed air and gas supply ....................................................................................... 70

6.12.1 MRI CryoProbe™ ............................................................................................................. 70

6.13 Laboratory furnishings ...................................................................................................... 71