Bandit

Copyright 8/07 PAGE 8

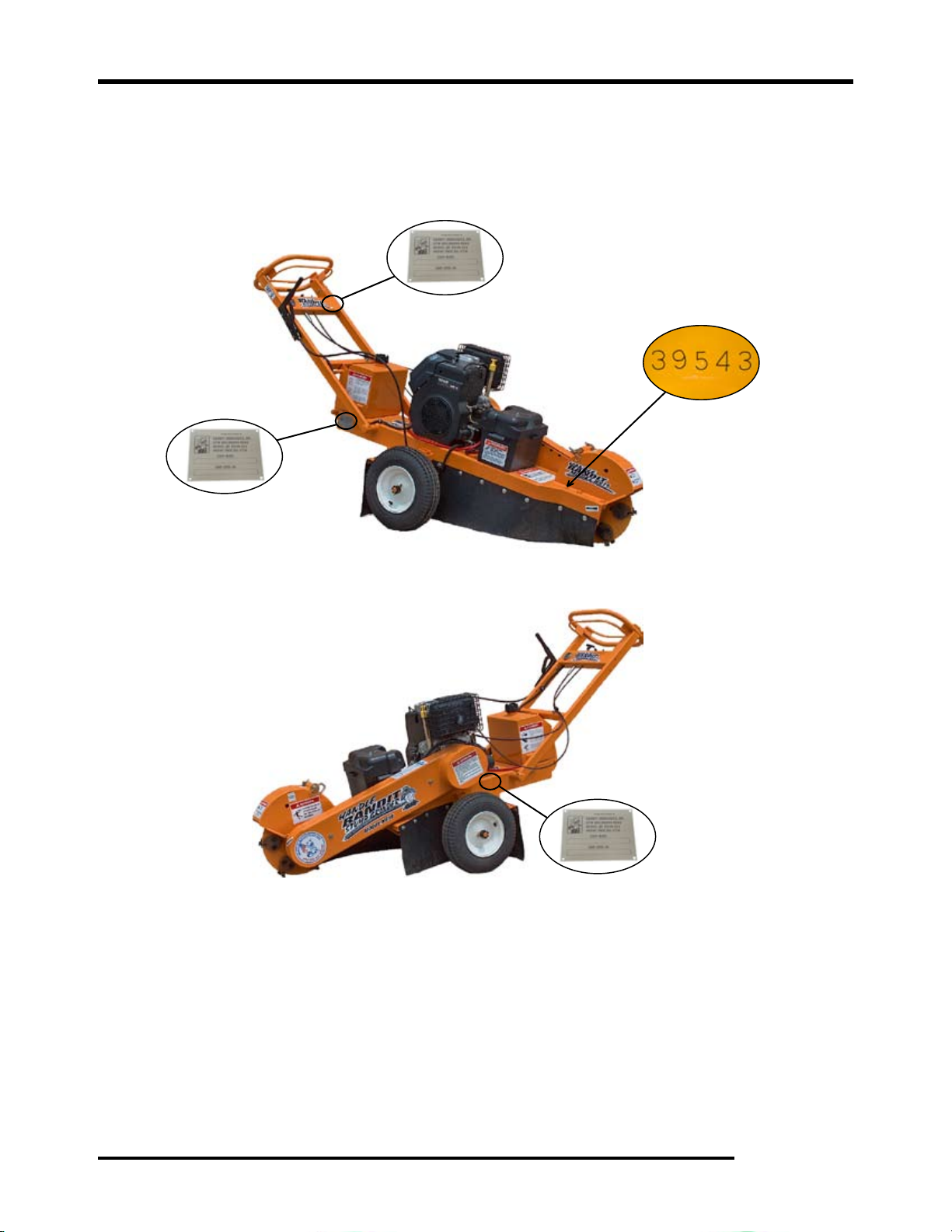

MODELS HB19/HB19SP/HB20SP

SAFETY PROCEDURES

Before attempting any type of maintenance

disengage clutch, turn off engine, wait for the cutter

wheel to come to a complete stop, install the cutter

wheel lock pin, disconnect battery, and make sure the

ignition key is in your possession.

ALWAYS install the lock pin into the cutter lock tube

before working on the grinder.

Simply slide the lock pin into the cutter wheel lock

tube. This is to insure that the cutter wheel cannot

be started while you are working on the grinder. If for

some reason the cutter wheel would start to turn, it

would simply hit the lock pin.

DO NOT operate this machine indoors! Exhaust

fumes can be fatal. Never refuel while the machine is

running. Never refuel in the shop or building. Always

refuel in a well ventilated area, away from sparks

or open ames, DO NOT SMOKE. Extinguish all

smoking materials. Wipe up all spilled fuel before

restarting the engine. Do not ll above 1/2” (12.7 mm)

from top of tank.

To obtain the most from your machine, for the least

amount of cost, it is a good practice to set up and follow

a scheduled preventative maintenance program. It will

eliminate many possible problems and down time.

It is very important after you have operated a new

machine for approximately an hour to shut down the

machine and recheck all nuts and bolts. It is normal

for nuts and bolts to loosen once on a new piece of

machinery. If you tighten them now, there is a good

possibility they won’t loosen again. Certain nuts and

bolts must be checked periodically such as cutter teeth

bolts, etc. for torque and t.

Most of the nuts used on the Bandit Grinder are

self locking. After a nut or bolt has been removed ve

times, it should be replaced to insure proper tightness.

This is especially critical on the cutter tooth bolts!

After the engine is started, let the grinder disc turn

at the lowest RPM’s possible. Listen for any type of

noise that is foreign. Any steel on steel noise is foreign.

If you hear a noise, stop the engine, nd the problem

and x it.

Never use jumper cables during freezing

temperatures. Haul the machine inside and allow

the battery time to warm up. If the machine must

be started outside, inspect the battery acid for ice

formation. Explosion will occur with a frozen battery.

Never use jumper cables in a conned or unventilated

area. Battery acid fumes are explosive. Never expose

an open ame or spark near the battery.

NEVER sit, stand, lay, climb or ride anywhere

on this machine while it is running, operating, or in

transit. You will be injured.

It is very important after you have operated a new

machine for approximately an hour to shut down the

machine and recheck all hydraulic ttings. Retighten

as needed.

DO NOT GO NEAR HYDRAULIC LEAKS! High

pressure oil easily punctures skin causing serious

injury, gangrene, or death. DO NOT use ngers

or skin to check for leaks. Lower load or relieve

hydraulic pressure before loosening ttings. Use a

piece of cardboard to nd leaks. Never use your bare

hands.

In cold weather situations let your hydraulic system

idle for approximately 15 minutes to allow the system

to warm up to operating temperature.

Do not go near or in-line with the debris eld of

the stump grinder while in operation. While grinding

stumps, the chips and portions of the stump y from

the cutterhead and can cause severe injury.

DO NOT operate this machine unless all hydraulic

control devices operate properly. They must function,

shift and position smoothly and accurately at all times.

Faulty controls can cause personal injury!

SAFETY PROCEDURES

WARNING

WARNING

DANGER

DANGER

DANGER

DANGER

WARNING

WARNING

Diesel engine exhaust and some of its

constituents are known to the State of

California to cause cancer, birth defects,

and other reproductive harm.