Bryan electric hot water or steam boilers...

For commercial, institutional and industrial applications

Bryan BH Series Boiler Specifications

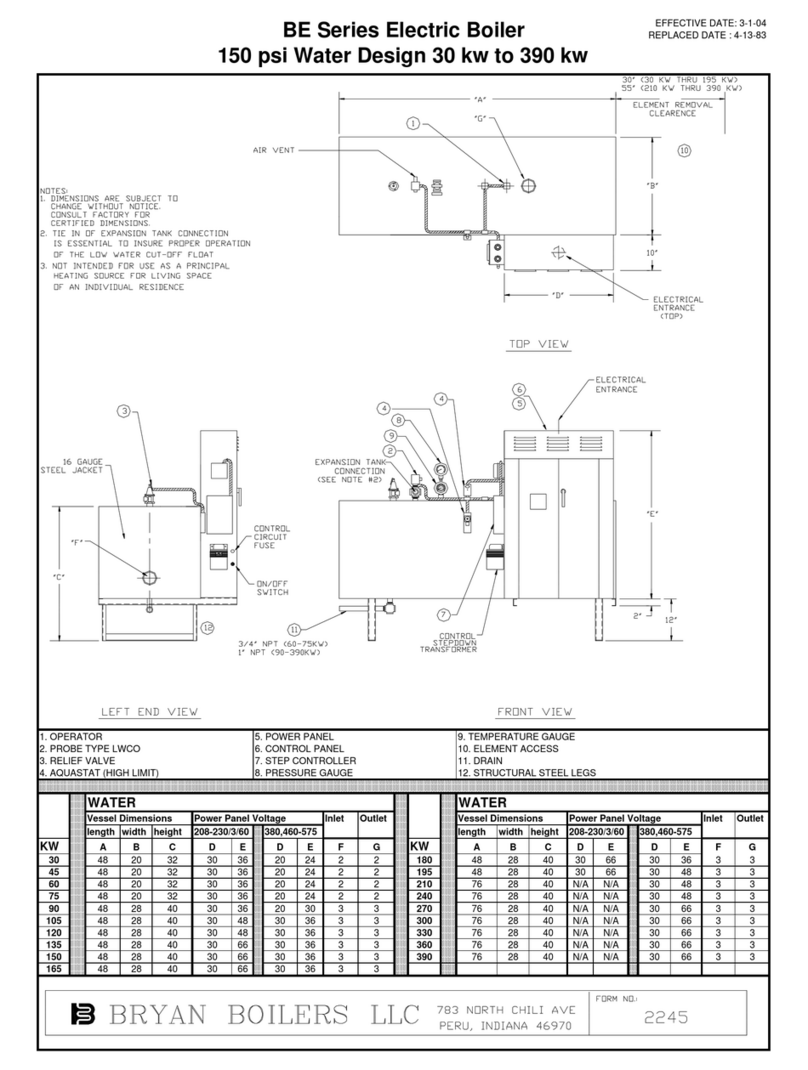

Model

Input KW MBH BHP lbs/hr (kg/hr) Water lbs (kg) Steam lbs (kg) Input KW MBH BHP lbs/hr (kg/hr) Water lbs (kg) Steam lbs (kg)

60BH 196 6 207 (93) 900 (408) 1,000 (454) 660BH 2,156 66 2,277 (1,033) 3,350 (1,520) 3,600 (1,633)

75BH 245 7.5 259 (117) 900 (408) 1,000 (454) 720BH 2,352 72 2,484 (1,127) 3,500 (1,588) 3,800 (1,724)

90BH 294 9 311 (141) 1,000 (454) 1,100 (499) 780BH 2,548 78 2,691 (1,221) 3,600 (1,633) 4,000 (1,814)

105BH 343 10.5 362 (164) 1,000 (454) 1,300 (590) 840BH 2,744 84 2,898 (1,315) 3,700 (1,678) 4,100 (1,860)

120BH 392 12 414 (187) 1,000 (454) 1,300 (590) 900BH 2,940 90 3,105 (1,408) 3,850 (1,746) 4,200 (1,905)

135BH 441 13.5 466 (211) 1,200 (544) 1,400 (635) 960BH 3,136 96 3,312 (1,502) 4,000 (1,814) 4,400 (1,996)

150BH 490 15 518 (234) 1,200 (544) 1,400 (635) 1020BH 3,332 102 3,519 (1,596) 4,500 (2,041) 5,000 (2,268)

165BH 539 16.5 569 (258) 1,300 (590) 1,500 (680) 1080BH 3,528 108 3,726 (1,690) 4,500 (2,041) 5,100 (2,313)

180BH 588 18 621 (281) 1,300 (590) 1,500 (680) 1140BH 3,724 114 3,933 (1,784) 5,000 (2,268) 5,500 (2,495)

195BH 637 19.5 673 (305) 1,400 (635) 1,700 (771) 1200BH 3,920 120 4,140 (1,878) 5,250 (2,381) 5,700 (2,586)

210BH 686 21 725 (328) 1,400 (635) 1,700 (771) 1260BH 4,116 126 4,347 (1,972) 5,500 (2,495) 6,000 (2,722)

225BH 735 22.5 776 (352) 1,500 (680) 1,800 (816) 1320BH 4,312 132 4,554 (2,066) 5,600 (2,540) 6,100 (2,767)

240BH 784 24 828 (375) 1,600 (726) 1,900 (862) 1380BH 4,508 138 4,761 (2,160) 5,700 (2,586) 6,300 (2,858)

270BH 882 27 932 (422) 1,600 (726) 2,000 (907) 1440BH 4,704 144 4,968 (2,253) 5,800 (2,361) 6,400 (2,903)

300BH 980 30 1,035 (469) 1,700 (771) 2,200 (998) 1530BH 4,999 153 5,279 (2,394) 6,000 (2,722) 6,600 (2,994)

330BH 1,078 33 1,139 (516) 1,800 (816) 2,300 (1,043) 1620BH 5,293 162 5,589 (2,535) 6,200 (2,812) 6,800 (3,084)

360BH 1,176 36 1,242 (563) 1,800 (816) 2,400 (1,089) 1710BH 5,587 171 5,900 (2,676) 6,400 (2,903) 7,000 (3,175)

390BH 1,274 39 1,346 (610) 2,000 (907) 2,500 (1,134) 1800BH 5,881 180 6,210 (2,817) 6,600 (2,994) 7,200 (3,266)

420BH 1,372 42 1,449 (657) 2,000 (907) 2,600 (1,179) 1920BH 6,273 192 6,624 (3,005) 6,800 (3,084) 7,400 (3,357)

450BH 1,470 45 1,553 (704) 2,100 (953) 2,700 (1,225) 2040BH 6,665 204 7,038 (3,192) 7,000 (3,175) 7,600 (3,447)

480BH 1,568 48 1,656 (751) 2,150 (975) 2,800 (1,270) 2160BH 7,057 216 7,452 (3,380) 7,200 (3,266) 7,800 (3,538)

510BH 1,666 51 1,760 (798) 2,500 (1,134) 2,900 (1,315) 2280BH 7,449 228 7,866 (3,568) 7,400 (3,357) 8,100 (3,764)

540BH 1,764 54 1,863 (845) 2,500 (1,134) 3,000 (1,361) 2400BH 7,841 240 8,280 (3,756) 7,600 (3,447) 8,300 (3,765)

600BH 1,960 60 2,070 (939) 3,000 (1,361) 3,500 (1,588)

NOTES: * Lbs. steam per hour from and at 212°F. ** Not intended for use as a principal heating source for living space of any individual residence.

Efficiency

Bryan Electric Boilers are nearly 95% efficient at all load levels.

Varying loads do not effect the efficiency since the resistive type

heating elements are immersed and designed to heat the water

directly. With a modulating step control only the elements that

are required to heat the water to the desired temperature/

pressure will be energized in order to encourage a balanced

load during operation.

Replaceable Hairpins

Each element hairpin is field replaceable with no welding,

soldering, or brazing required. Each hairpin, as standard for

all Bryan Electric Boilers, is Incoloy sheathed and industrial size

0.430ⴖdiameter. Elements are designed for 75 watts/sq. inch

for long life (optional 50 W/D available). Elements are individually

installed in a standard ANSI 150 lb. blind flange.

Steam Disengaging Area

Steam release area is near the middle of the horizontal vessel

for maximum steam disengaging area for dry steam and stable

water level.

Water Boiler Design

Vessel is designed for proper circulation around individual

elements to maximize heat transfer. High velocities, i.e. heat

pump applications, are handled with very little pressure drop

when using a horizontal tank for the pressure vessel. Supply

and return nozzle sizes can be made larger to accommodate

the flow requirements. Pressure drop is minimal through the

boiler and no dangers are involved with low flow conditions.

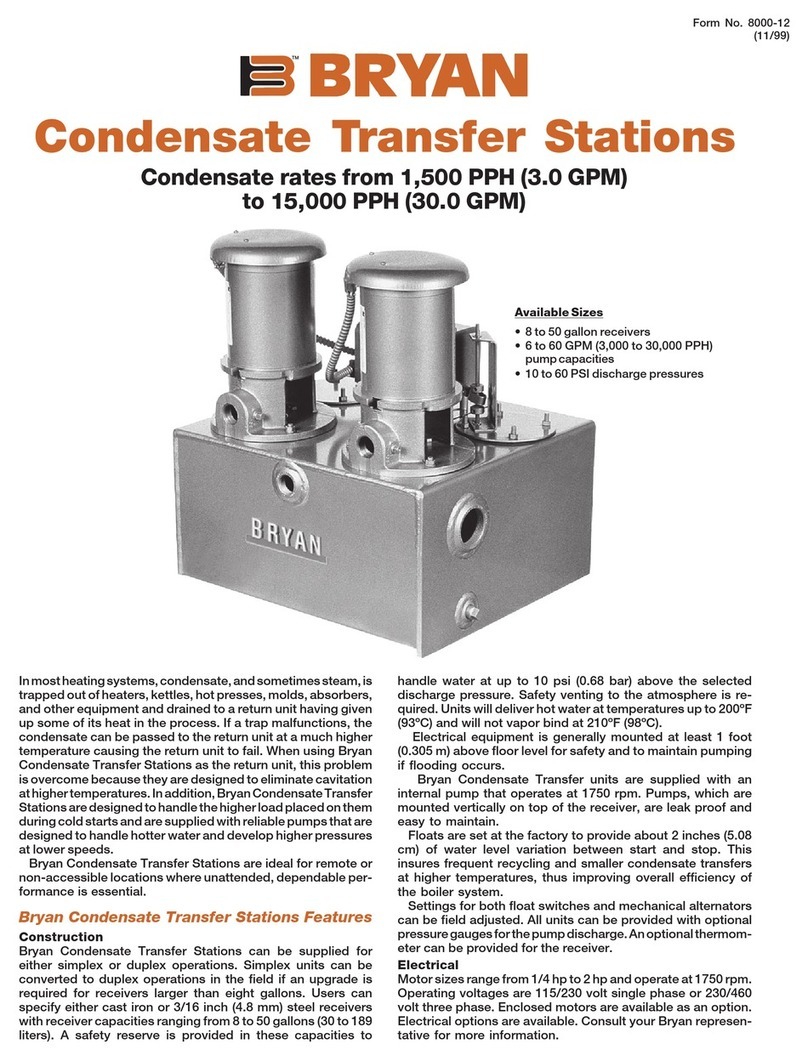

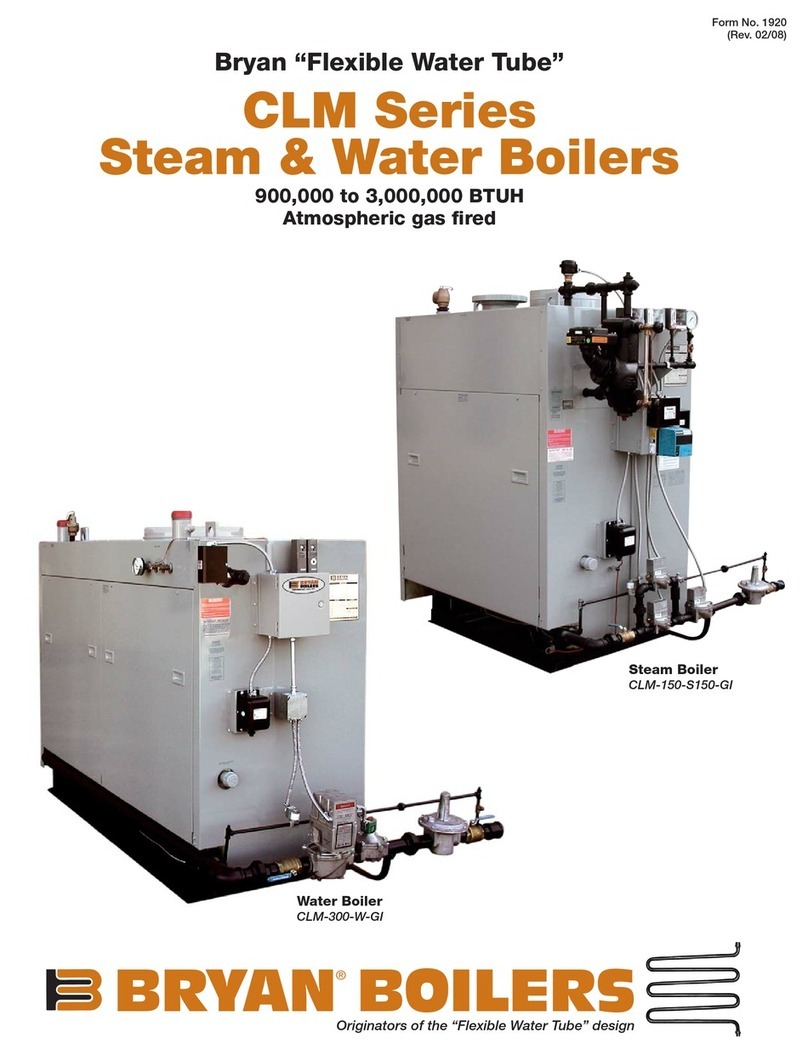

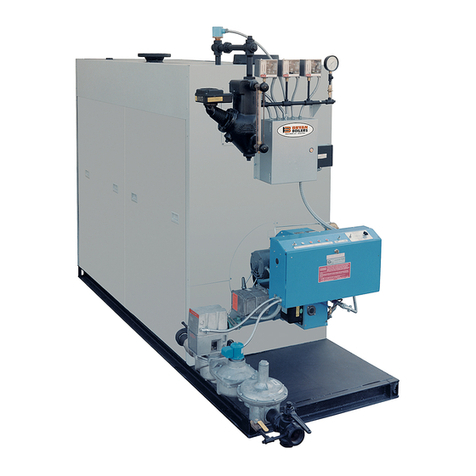

Bryan Series BH Electric hot water** or steam boilers are

compact, completely packaged and wired units with automatic

controls and featuring long life Incoloy sheathed elements.

Applications include hot water heating, steam heating, process

heating, and supplemental heat for heat pump type equipment.

All Bryan Boilers are built in accordance with the requirements

of the ASME boiler and pressure vessel code and are UL listed.

Water boilers are 150 psig MAWP and steam boilers either 15

psig or 150 psig. Higher pressures are available.

Electric Element Bundle

Each element

replaceable with

hand tools. Incoloy

sheathed, 75 watts/

sq. in.

Spacing disc

for support and

proper circulation

around individual

elements

Removable

threaded fittings

for ease of indi-

vidual element

replacement

150 lb. ANSI flange

Water boiler trim and controls Steam boiler trim and controls

Step

indicating

lights

Control panel

Lifting

lugs

ASME

relief

valve

Pressure and

temperature

gauges

(2) High

limit controls

Drain

Operating

control

Probe type low

water cutoff

control

Power

panel

Fused control

circuit

transformer

Blowdown

Fused control

circuit

transformer

Step

Indicating lights Control panel

Power

panel

Lifting

lugs

Standard Equipment Supplied:

HOT WATER DESIGN BOILERS:

Model “W” (150# ASME Design)

Temperature and pressure gauge, Operating

immersion aquastat, 2 high limit aquastats, Low

water cutoff, Relief valve, Metal jacket with 4ⴖ

fiberglass, 75 W/D Incoloy sheathed elements with

pressure connector power lugs. Separate power panel

and control panel, On/Off control switch, 120 volt

control transformer (fused), Magnetic contactors with

120 volt coil, Individual circuit Class JKS fusing, step

indicating lamps, First on/first off progressive step

controller, National Board Inspection and UL Label.

Power Circuit Design:

All Bryan BH Series boilers feature copper bus bar distri-

bution, wherein the fuse clip for each branch circuit and

the main power lugs are all bolted directly to a bus bar.

The bus bar can carry the full load current of the

boiler, withstanding the largest available fault

current from the entering power system. Use of

the bus bar protects all current-carrying parts

and prevents damage to the boiler.

Optional Equipment Available:

Power panel door electric interlock. Preheat

switch. Flow switch. Manual reset controls.

Manual blowdown valve. Automatic blowdown

with 24 hour time clock. Alarms. Indicating lights.

Larger connection for heat pump applications.

Other Designs Available:

1) BE – Economical Electric Boilers

(Form 3600)

2) WT – Indirect Hot Water Supply Heaters

(Form 4800)

Standard Equipment Supplied:

STEAM DESIGN BOILERS:

Model “S” (15# ASME Design)

Model “Q” (150# ASME Design)

Steam pressure gauge w/gauge clock, Operating

pressure control, 2 high limit pressure controls,

Combination low water cutoff and pump control,

Auxiliary low water cutoff, Relief valve, Water glass

set, Metal jacket with 4ⴖfiberglass, 75 W/D Incoloy

sheathed elements with pressure connector power

lugs. Separate power panel and control panel,

On/off control switch, 120 volt control transformer

(fused), Magnetic contactors with 120 volt coil,

Individual circuit Class JKS fusing, Step indicating

lamps, First on/ first off progressive step controller,

National Board Inspection and UL Label.

Standard Design Features

Nom. Output Steam Output* Approx. Shipping Weight Model Nom. Output Steam Output* Approx. Shipping Weight

ASME

relief

valve

Pressure

gauge

Probe type

low water

cutoff control

(2) high limit

controls

Operating

control

Water level

gauge glass

Low water

cutoff and

pump control

Heavy duty 11

gauge power

panel cabinet

Single point

electric

connection

Each branch

circuit is fused

individually using

copper bus bar

for power

distribution

Separate

control panel

for 120V

controls

4" channel base

Louvered panel cover for

proper cooling air circulation

Immersion heating

bundles broken down in

150 KW bundles or less

Hinged

access

door for

access

to vessel,

ASME and

elements

4" fiberglass

insulation

16 gauge jacketing all

around structural frame

(zinc-coated rust

resistant primer and

enamel finished)