4

BÜCHI Rotavapor R-187EL2 Safety

2.4 Improper use

Any use other than those already listed, and any application

that does not conform with the technical data is deemed to

be a case of mis-use. The customer shall bear sole

responsibility for any damage caused by such mis-use.

The following applications in particular are prohibited:

•Production and processing of substances which may lead

to spontaneous reactions, e.g. explosives

•Rotating the filled evaporation flask which is not immersed

in the water bath (risk of breakage)

•Drying of hard or brittle materials (e.g. stones, soil samples)

which can cause destruction of the evaporating flask

•Shock cooling of the evaporating flask

The Rotavapor is not designed to be operated with positive

pressure

2.5 General hazards

General hazards arise from:

•the hot water or oil bath (risk of scalding).

•polluted solvents which in the course of distillation may

form residues that lead to spontaneous reactions (e.g.

metal hydrides)

•solvents which can form peroxides (risk of explosion).

•solvents with low ignition, flash and/or explosion

temperatures.

•mixtures of unknown composition or with impurities.

•damaged glassware.

•combustible gases or solvent vapors which are not

permitted by the explosion proof safety standards.

•electrostatic charges during operation, e.g. when

decanting combustible solvents and when drying powders.

•coolant temperatures lower than the distillate´s freezing

point (will diminish the capability of the condenser coils to

cool the vapor, thus causing a build up of solvent vapor

and dangerous positive pressure).

2.6 Safety measures

Regional and local laws and regulations must be observed.

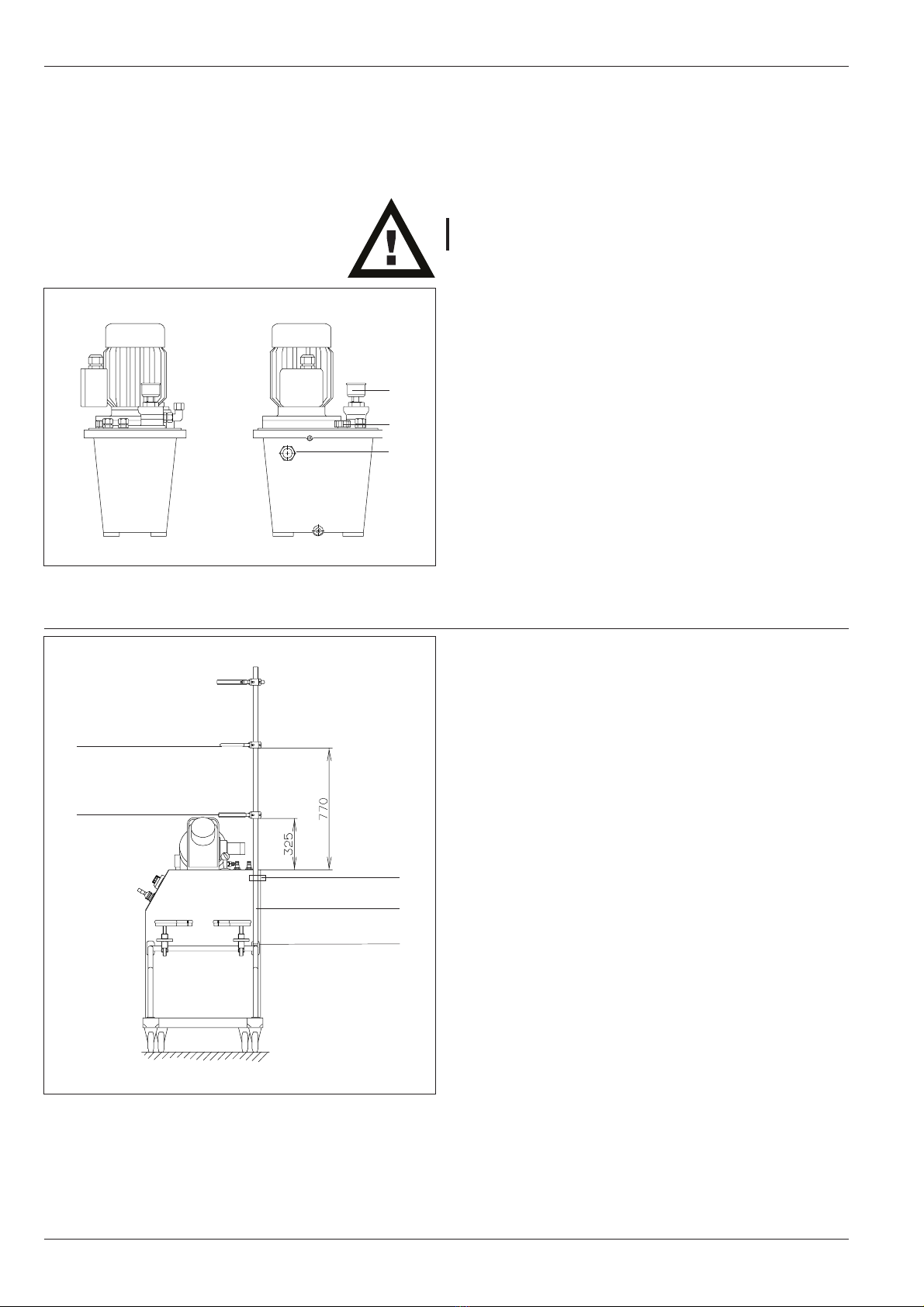

The unit is grounded internally in order to divert electrostatic

charges from the Rotavapor. There are also ways to divert

electrostatic charges from the glass couplings, by connecting

the couplings together with wires, which are also grounded.